Image Credit: Environmental Protection Agency

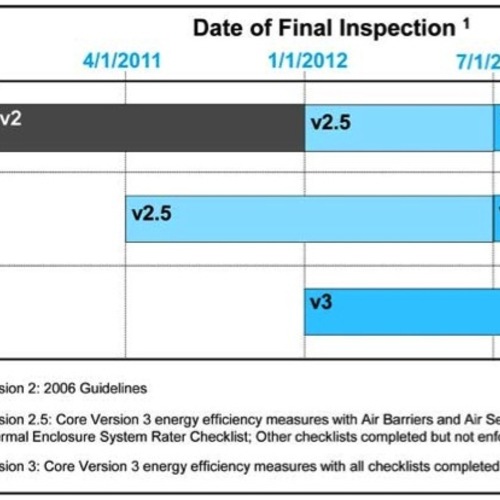

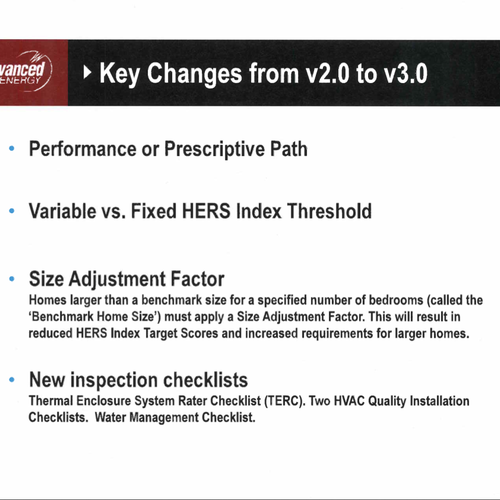

The Energy Star Homes program has been in trouble since 2012, when the Environmental Protection Agency rolled out a new version (Version 3) of the program’s requirements. Many builders found the Version 3 requirements so onerous that they dropped out of the Energy Star program. The number of new homes that have been certified under the Energy Star program has fallen 36% in recent years — from 130,305 in 2011 to 83,897 in 2015.

Complaints about Version 3 focused on the new requirements for the design and installation of heating, cooling, and ventilation systems. In a recent article in Home Energy magazine, Dean Gamble, the technical manager for the Energy Star Homes program, ruminated on these HVAC requirements. “The new design requirements were certainly expansive,” Gamble wrote. “By and large, though, they simply mirrored what was already required by code. That is to say, they were not the ‘best practices’ known to the industry. Quite to the contrary, they represented the bare minimum required by law. So, why were so many designers encountering difficulties? The primary answer was that this was the first time that any national program had enforced HVAC design requirements in a systematic way. While these requirements were written into code, jurisdictions rarely tasked inspectors with enforcing them. On top of that, Home Energy Raters had never been asked to review designs as part of their scope.”

Reflecting on the participation drop-off, Gamble wrote, “Despite the best of intentions, Version 3 nearly ground the Energy Star New Homes program to a halt.”

Residential HVAC contractors aren’t paying attention to details

The Energy Star Homes program faced a dilemma. Program designers knew that HVAC installers are, on average, doing a terrible job — as energy experts have noted for years, most residential HVAC systems are oversized,…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

14 Comments

Thinking out loud...

The biggest reason must houses have substandard HVAC systems designed and installed is because Builders allow it so, and Homeowner rather trust a “Professional” than educating themselves in the biggest purchase they make their lifetime, although is changing. All Builders have the control on who works on their houses, and I hardly ever see a Builder DEMANDING of their subs to things as they should, or even code, mostly because of ignorance and/or greed.

Second, IMO it was a mistake when ICC allowed HERS Raters and Verifiers to perform the work of Building Official. I understand not all municipalities have the resources to train all their Building Officials, but that really was passing the buck to someone else, and as you point out, RESNET has been inadequate about proper training, not only on HVAC systems, but on other house systems and Building Science.

Third, most industry associations, from builders to trades, develop programs that are designed for those members interested in learning and doing things right, which are the minority; however, since the industry is accustomed to cheap bids, most Builders and trades are used to doing what they can get away with.

HVAC is by far the hardest task.

"Framers work from good plans and execute the plans well. Framing failures are very rare.

Electricians and plumbers are also doing excellent work. Residential electrical system design and residential plumbing system design are both excellent, and these systems are installed well.

So what’s wrong with residential HVAC work? Why are contractors doing such a lousy job?

The failures can be partly blamed on equipment manufacturers, since manufacturers are doing a terrible job of training contractors.

The failures can be partly blamed on regulators, since regulators are doing a terrible job of certifying contractors.

And the failures can be partly blamed on code officials, since code officials are doing a terrible job of enforcing existing codes.

While residential HVAC contractors do a poor job with heating and cooling systems, they do an even worse job with ventilation systems."

Not to criticize too much, but I think a solid paragraph in there explaining the difficulty of HVAC work would be justified. Framers, electricians, and plumbers have a far, far, far easier task to accomplish than the HVAC subcontractor. When something is framed improperly it is clear as day to see and relatively easy to correct before proceeding. An electrical load calculation is not 'easy' per se, but it involves far fewer variables than an HVAC design. Plumbers know they just need to get water in and that water flows downhill.

HVAC contractors face a problem of almost mind-boggling complexity. There are multiple different systems with all their nuances, and annoyingly complex load calculations are fraught with the dangers of plug-and-chug garbage in and garbage out. Energy modeling and utility usage predictions are dubious at best. Also, when installed, it may not be immediately obvious that the HVAC system does not work or how a failure may occur. Framers, electricians, and plumbers have immediate and obvious feedback that is visually apparent when something is incorrect. HVAC installers may perform best practices but some unknown influence caused by them or somebody else will result in mold, failure, or lack of performance down the road.

These reasons are the primary reasons why it is so hard, not because of a collective failure of manufacturers, designers, code officials, inspectors, subcontractors.

Response to Gavin Farrell

Gavin,

Thanks for your comments. You are partly right.

But there are lots of trades that are complicated. In most trades, the incompetents are weeded out by stricter certification requirements.

Electricians can easily burn down a house, but we make sure that electricians are licensed.

Plumbing system design can also be quite complicated. But most states don't allow incompetents to stay in business.

Have you ever noticed that plumbing pipes on new homes don't leak, but that most duct systems do? It's not because sealing duct seams is technically challenging. One trade cares -- the other doesn't.

I could marshal lots of evidence to buttress my claims. To take one of my points -- my reference to code officials: How many residential jobs get an electrical inspection? Far, far more than ever get a meaningful HVAC inspection.

Response Response

By the way Martin, I owe my respect to the difficulty of the HVAC task over the years primarily by reading your articles :)

Response to Gavin Farrell

Gavin,

I'm not sure if that's a compliment or not. I usually strive to make complicated tasks seem simpler, rather than striving to make simple tasks seem more complicated.

But I'll take it as a compliment. Thanks.

There are relative risks behind those facts. @ Martin, # 3

"To take one of my points -- my reference to code officials: How many residential jobs get an electrical inspection? Far, far more than ever get a meaningful HVAC inspection."

Improperly installed electrical work can kill you pretty quickly. While that's also arguably true for HVAC systems, it's a harder to screw up the HVAC install so that it's a lethal hazard, yet quite easy to screw up wiring that badly.

Plumbing systems that leak are an immediate and obvious hazard, but drain venting errors getting by the inspectors abound. Again- if it's not fatal or immediately damaging, it doesn't get as much attention.

From an efficiency & comfort point of view, the more efficient the building envelope, the less the HVAC details matter. Amending the Energy Star standard to disallow ducts & air handlers being located outside of conditioned space would make them matter even less, and inspecting to verify compliance would be pretty easy.

Running all the design math on an HVAC system is more complicated and time consuming than running the load calculations, which is why contractors take rule-of-thumb shortcuts, and inspectors remain clueless. In CA under Title 24 duct leakage is required to be tested & documented, and refrigerant levels of central air & heat pumps checked which is reasonable. But doing a rigorous design review on the entire system would be cumbersome, even if the inspectors had the core competency. It's not too much to ask to run blower door & duct blaster testing on new houses, which would be enough to catch the most egregious faults. But flow testing each register against the design and the pressure differentials in each bedroom would be time consuming- it's no surprise if contractors aren't signing up for Energy Star in droves.

Oversizing ducted heating & cooling systems has remarkably little negative impact on energy use, and is rampant. But it does have comfort consequences. Right-sizing ducted air mechanicals are always the right thing to do, but since it barely moves the needle on energy use, it's a bit outside of the core mission of Energy Star.

Response to Dana Dorsett

Dana,

You wrote, "Improperly installed electrical work can kill you pretty quickly. ... Plumbing systems that leak are an immediate and obvious hazard. ... Again- if it's not fatal or immediately damaging, it doesn't get as much attention."

You're absolutely right, of course. There are historical reasons for this focus. Building codes arose from lobbying efforts by the insurance industry, and building inspectors have always focused on fire hazards and life safety concerns.

When energy codes were developed in the 1990s, building inspectors found themselves in over their heads, without the knowledge needed to enforce the new energy regulations. So many energy code requirements have never been enforced.

Maybe it's too complicated?

Electrical work on a house may become just as fraught with problems as HVAC if we heed the call of Smart House advocates and load it up with complex electronic controls, and appliances that are part of the Internet of Things.

Itching to remove the simplicity of plumbing, manufacturers now sell faucets that work off sensors and need batteries to function.

Perhaps the problems in part stem from the designs of the HVAC systems we are installing? Maybe it would be worth a small energy penalty to avoid some of the complexity?

Response to Malcolm Taylor and Dana Dorsett

Dana wrote, "the more efficient the building envelope, the less the HVAC details matter."

Malcolm wrote, "Maybe it's too complicated? ... Perhaps the problems in part stem from the designs of the HVAC systems we are installing? Maybe it would be worth a small energy penalty to avoid some of the complexity?"

You are both right, which is why the GBA site has always urged readers (a) to invest in a building envelope that is more airtight and that has higher R-values than miniminum code requirements, and (b) to specify simple heating and cooling equipment (like ductless minisplits) that doesn't need a complicated distribution system that is designed by the contractor and site-built.

The Energy Star Homes program still permits contractors to install ducts in unconditioned vented attics. If the Energy Star Program insisted that all HVAC equipment and distribution systems be inside the home's thermal envelope, then some of the problems that the program needs to pay close attention to (with lots of paperwork documenting compliance) would go away.

Response to Malcolm Taylor and Dana Dorsett

In my view, many of the negative (apologetic comments) stem from the perception that the HVAC problem is simply too complicated. I believe if the problem is broken down into its component parts and each part is tackled (engineering-wise) a separate but related problem. HVAC designs can be dramatically improved. At a minimum, we should that the HVAC contractors designing systems do so where the ducts don't leak and the air distribution is balanced. When I did this to my house on the east coast. I fundamentally changed the comfort levels throughout the house -- temperatures on each of the 3 floors now do not differ by more than one or two degrees from that set on the thermostat. Further, the flow of conditioned air into each room radically increased without any increase in the cost of operating the system, and the system is balanced. In fact, by taking these basic steps, I have been able to save about 30% on my heating and cooling bills. BTW, the cost of all of this was approximately $1,600 for a 2,800 sq ft house built in the 1950s. Frankly, from my experience, I'd love to have the time to take a crack at designing a system for a new house. Of course if I were to do so, I would demand that I oversee each and every aspect of the installation of the system. I understand the import of folks on this site spreading their design wings. But while we wait for the new modernized HVAC community to catch up to code and design us our sophisticated systems, etc., we can take care of a bunch of basic changes that will dramatically improve our comfort levels and save us money in the process..

Response to User-6810620 (Arch Shero)

Arch Shero (a.k.a. User-6810620),

Of course we can all agree that duct systems shouldn't leak, and air flow should be "balanced" (by which you mean, I assume, that the system should be commissioned, adjusting the air flow as needed so that the air flow to each room matches the design air flow).

If you performed this work at your own house, bravo. Doing this work should be a routine part of installing any forced-air system. It should be -- but usually isn't.

It's also no particular surprise that a tight duct system saves energy compared to a leaky duct system.

GBA has been hammering home the importance of these steps for many years. I'm glad that you agree that these steps are essential.

Response to Martin Holladay

Martin, my name is Arch Shero and I live in Virginia. Thank you for your additional, but probably oft repeated thoughts. I have significant respect for your writings, finding them loaded with helpful technical information. I know you stress the importance of sealing ducts and balancing air flow into the rooms. I wish in the case of my old home, the original HVAC system was thoughtfully designed. Instead, I suspect, a builder in 1954 simply threw something together and called it enough. I was the eventual victim of this poor effort, as you can well imagine.

The purpose of my comment was not to try to grasp my 15 minutes in the sun, but to remind your readers -- as you do on a regular basis -- that fixes come in different sizes and that there are things each of us can do to greatly improve our HVAC system's performance without spending a ton of money. When I first started with the fixes, the changes seemed small from an engineering perspective, but the results were absolutely huge. I will always remember the HVAC system sales people and technicians telling me that I needed two splits to fix my problem, for a price of around $10,000. In the end, as I intimated above, I was able to fix my system's performance by aero sealing the ductwork (plus a some mechanical sealing with aluminized foil tape) and changing the location of a return from the first to the second floor -- all for around $1,600. BTW the aero sealing was the most expensive part -- $1,200.

I know you and several others who provide comments on this site know infinitely more than I do about designing HVC systems and all the important factors that need to be considered. I offered my comments only because I'd like to encourage people to take some intermediate steps to improving their comfort levels in their homes as a first step toward changing the way the HVAC community does things. So, let's retro-fit our old homes, as well as work with the HVAC community to design and BUILD more responsibly!

It's the HVAC people... (at least in my area - Seattle)

It's not the Energy Star 3.0 requirements - from what I've seen in my area it's the HVAC bidders and installers that really don't care.

Three years ago, my 90+ efficiency NG furnace was coming up for a replacement. So I contacted SIX local HVAC installers for three of the major name furnaces... and asked for quotes to:

1 Replace furnace with 98% high efficiency furnace, fully modulating gas AND fan speed adjustable by electronics as heating needs dictated. The prior furnace was 90,000 BTU, I had done the manual S and Manual J... figured with all the changes we had done and were doing that a 30,000 BTU furnace was more appropriate - thus I wanted a modulating furnace that could drop down to below 30,000 and up to about 80,000BTU.

2. Six" high capacity filter to be installed at same time.

3. I wanted work to include - and be priced for - replacing the incoming plenum to change from using the studs in the wall as the plenum to using sheet metal. Not a major task.

4. I wanted the furnace to be mounted 2.75" above the current concrete floor - and I had a template 3/4 plywood outline and 2" (250#/sqft foam) prebuilt. That just needed to be laid in place before the started measuring the new duct work and re-installing the furnace.

5. I wanted turning vanes installed in the duct work at the point where the duct needed to make a 90 turn into the furnace (all the manufacturers install instructions say using turning vanes). In other word I wanted the furnace installed per the manufacturers recommendations.

6. I would haul away the prior HVAC equipment including furnace (I wanted to tear down the prior NG and do some forensics on it).

7. I wanted their best thermostat that allowed the full functional use of the furnace - and if possible - access to the settings by computer such that I could capture and log what it claimed it as the set points.

8. I wanted permits pulled and vendor to be contact for inspection. We would be onsite.

9. And I had cash in hand - I made it known that I would choose based on what I thought was the best fit, not the lowest cost. And I reiterated that the ducting related changes were expected to increase costs and I was willing to pay for that. Essentially I wanted to correct the poorly designed return ducting at the time this new furnace would be installed.

10. I started the process in September (after the cooling season and before the heating season was going hot and heavy).

So the results:

A) I had one contractor never return my calls or emails.

B) I had one contractor said they were too busy with new installs and existing customers. Strange in that that year and the next they had constantly been advertising on the radio about their 24hr policy (after quote they could install a new furnace in 24 hours).

C) I had two with quotes that didn't address any of the items on the list - instead they quoted 90% efficiency 120,000 BTU based on the outside dimensions and age of the house. Ugh!

D) I had one quote which said they'd do the duct work - but they insisted on quoting a non-modulating furnace... and they wanted to install a 90,000BTU replacement.

E) I had one quote that responded earlier with proposal for hardware - but then started to walk away because they figured they would the the highest bidder. I had to talk with sales person quite a while and remind him that I wanted the best fit not the lowest cost. Please finish the bid.

This process took nearly six weeks - amazing - trying to schedule people in to look at the house - see what the plans were and read my specs - something that should have been fairly quickly - but there always seemed to be a scheduling conflict and a few no shows that took multiple calls before people came out.

My selection:

I choose the last contractor with the higher price - it was a contractor that was honest about the estimates, they priced out the costs for the added work I was doing - while they didn't think I needed turning vanes - they added them in.

Scheduling then became a problem - we were now into October - and that old NG furnace condensate pan outlet had started to rot through (leaking water onto floor and into hallway). I patched the condensate outlet pipe and tried to move the new furnace install forward... but by that time we'd started to have a cold spell and everyone that had furnace failures was calling for emergency replacements. I had a working solution to my problem - so I asked them to schedule me as soon as possible normal flow... that ended up being first week in December (remember this started in late September). High demand for furnaces nation wide meant three weeks for furnace delivery since I wanted high end instead of generically stocked furnace.

Then a couple of days before the install - I got a call and the installer that was scheduled to do the work was in an accident and they had to reschedule me once again -- another week away......

The work was eventually done the fixed the return duct and set the ducting and furnace up on the insulated assembly. The turning vanes installed the new fully lighted (not just using studs) return duct was complete - and the furnace was installed and running.

It was now December - and it was a cold December/January... the furnace spent most of its time running at about 30,000 BTU's. Previously the furnace was noisy - with most of the noise coming from the return duct and the air turbulence. It's quite now... and the rooms at the far ends of the duct runs - they are comfortable - those oversized furnaces meant that the house never really had good air mixing - the temps didn't have a chance to even out before furnace would kick off because the ducts closer to the thermostat overwhelmed and drove the temps.

If we'd put in one of those UPSIZED 120,000 BTU furnaces - we'd be burning through gas, complaining about the noise and thinking the house had problems. Those were specified by HVAC sales staff that I could only describe as untrained.

The problems I saw were for existing construction that just involved fixing return duct and installing new furnace. But it was real apparent that the HVAC people simply size a house by the sqft and recommend furnace based on the stock or discounts that they get from the manufacturer.

A builder should (especially one with an architect and mechanical person on staff) should be able to provide the Manual S, J, and D for the house... my guess is that many of the HVAC installing companies simply don't want to be bothered with the extra work when there is all this other "EASY" money available to them for people who don't know better and push for better.

If we want the Energy Star 3.0 installations to go better - we should be pushing for retrofit installs to be checked for size and train the HVAC businesses that helping customers fix ducting is good business for them... not a pain to avoid. If installers become comfortable doing the right thing on existing construction - they will also find it easier to do the right thing on new construction - instead of trying to sneak minimal sub code projects through....

Response to Dennis Heidner

Dennis,

Thanks for sharing your story, which echoes many reports we receive regularly here at GBA.

As I said in my article, no trade on a typical residential job site -- not framers, not plumbers, not electricians -- is as deeply troubled as the HVAC trade. I don't see a solution on the horizon, unfortunately.

Log in or become a member to post a comment.

Sign up Log in