Image Credit: American Chemistry Council

Should spray polyurethane foam be installed in an occupied house? Hundreds of spray foam contractors around the country are happy to answer “Yes!” In almost all cases, these jobs end successfully: the spray foam improves the home’s thermal performance and the homeowner is happy.

However, a small number of these jobs go seriously awry. Although each story varies somewhat, reports of bad spray foam jobs have many recurring themes. In most cases, the foam installer made an error: either the foam was installed too thickly or the chemicals were not heated to the correct temperature before they were sprayed. In most cases, the insulation contractor failed to ventilate the job site with a fan during or after the installation. In some cases, areas of foam remained gummy or damp. The biggest common complaint, however, is a bad odor, usually described as a fish-like odor, that lasts for months and is almost impossible to get rid of.

Even do-it-yourself two-component spray-foam kits occasionally produce smelly foam, according to a report by Larry Burks and Jill Burks of Cambridge, N.Y.

Spray foam manufacturers concede that some foam jobs result in smelly foam. I asked Mac Sheldon, Western region manager for Demilec foam, how many spray foam jobs result in odor complaints. “When we looked at the numbers, it appears to be less than one tenth of one percent,” he told me. “While that is not acceptable, we’re working diligently to try and get a handle on the root cause.”

Some manufacturers have responded promptly to odor complaints, and done everything necessary to satisfy the homeowners. Other manufacturers have reportedly brushed off questions from homeowners and referred complaints to the contractor who installed the foam. Finally, some manufacturers have acquired a reputation for doing everything they can to avoid responsibility…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

43 Comments

Contractor-manufacturer responsibilities

Some manufacturers seem to be pretty quick on handing off responsibility for the incorrect installation to the contractor. However has ANY manufacturer refused to sell their product to an installer who has shown a history of not following the guidelines for installation? Contractors do not decide “I’ll take shortcuts on this one job only”. There will be a pattern of bad installs. I assume (a bad word I know) that contractors sign a waiver absolving the manufacturer of liability. However if the manufacturer continues to supply “bad” contractors it shows they DO NOT care about the consumers, just their bottom line.

Spray Foam Now

I love the smell of Spray Foam in the morning.

It's kinda like that new car smell

Only Better

Nathan Spriegel comment

Good point. In our case BASF did not seem to care at all. They told me they only sold the raw materials. That is contrary to their web site.

It is my opinion that their MSDS sheet is completely false. It should discuss reaction byproducts that are formed and what they are and their toxicity.

The only thing that will resolve these issues is a class action lawsuit.

Great and timely post Martin

I've always heard that for every positive reference from a satisfied customer you get seven negative referrals from dis-satisfied customers. The Spray foam industry would do well to pay attention to this adage and invest marketing dollars in better training and customer satisfaction.

Applicator training is the key to good spray foam applications and the best thing the industry can do is get a strong training and certification program in place. Cold weather, excessive humidity, bad spray practices and overheated or cold drums are the factors most associated with off-ratio and unsatisfactory foam applications. These are all things the installers have control over.

Termite poison installers are subject to spot inspections and audits. Foam applicators could take a lesson here and institute a third party audit, testing and certification program that would help address these issues.

Better education is needed for the home owners and folks working on homes w/ spray foam in process. I tell my people to stay out of the site until three days after foam has cured except for short QC inspections. Most of the foams have halogenated flame retardants that can be released as dust when the foam is trimmed and disposed of. These have been linked w/ birth defects and loss of fertility, so minimizing shaving and hiring well trained crews is imperative.

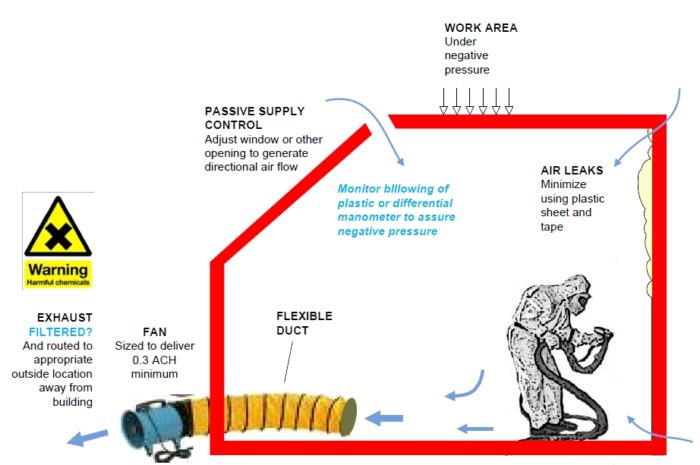

The illustration at the top of this article is great! I don't think I have ever seen all of the best practices included in this drawing implemented on a job site.

Response to Michael Chandler

Michael,

If Demilec is accurate in its assessment that only 1/10 of 1% of spray foam jobs result in odor complaints, then it would appear possible for spray foam manufacturers to invest some of their profits from the 99.9% of jobs that are smooth and profitable to help resolve complaints lodged by 0.1% of their customers.

Since they aren't doing a very good job at resolving these complaints, one might conclude that either:

(a) the percentage of jobs with smelly foam is higher than Demilec reports, or

(b) the spray foam industry is taking a short-sighted approach to business when they decide to fight these claims rather than settle.

Three Men and a Truck

I admit that I have only witnessed a handful of sprayfoam applications. My experience may not be typical.

There is usually One Guy who is "the cook" and the other 2 or 3 guys are doing the prep work.

The cook fires up the machine and fusses with the equipment.

The equipment seems to be tempermental....just when they think they are ready to spray...something goes wrong and the cook has to fiddle with the dials or give something a kick. Wrap some more duct tape around the hose and curse a little.

I can't be sure...but I don't think these guys are highly paid. The cook is the guy who wears the "full gear".... the other guys may or may not be wearing a blue paper mask.

As a witness...I was warned not to get too close .. but was allowed to view without any gear or a mask.

The cook sprays a little on the wall ...curses and goes back to the truck for a while. Eventually the cook is either satisfied (or frustrated) and the work progresses.

THE BLUE HAZE

Ok, I did something VERY,VERY stupid on my personal home....

I knew there were some tricky spots in my attic just behind the HVAC equipment.... I wanted to make sure this area was carefully air-sealed...so I crawled under the Air Handler with the cook and supervised....

I think he was trying to tell me that I was getting too close...but I ignored the warning.

Later the guys asked me if I was experiencing "The Blue Haze" (and I was) I knew what they were talking about...everything looked fuzzy and had a blue halo around it. They told me it happened to them often and it may last for a day or so....and it did.

I know...I was stupid....But it makes me think "this can't be good" for these guys that do it every day

Prevention or resolution

My experience with spray foam is that once a job goes off-ratio or the tanks are too hot and the foam is coming out with huge air pockets in it etc. it's really hard to go back and fix it. it's just really critical to get it right the first time. going back and pulling out bad foam just isn't a good solution. So good preparation and good equipment are critical.

I was touring a neighborhood of whole house gut rehabs with a real estate sales woman and a bunch of green building geeks and they were actively spraying in the crawl as we were walking around above them No safety precautions, no sign of a blower as shown in the illustration. Some of these foams have halogenated flame retardants in the B-side component that have been conclusively linked to birth defects and loss of fertility. I'm old enough that fertility isn't an issue. but there were plenty of people of child bearing age in that group who definitely should not have been in an active spray foam site.

A comment from Mason Knowles

[Mason Knowles sent me this comment by e-mail and asked me to post it here.]

I was wanting to put into perspective the odor issue. Considering that Roger Morrison and I are the only independent consultants in the country that specialize in sprayfoam applications, it is my opinion that I am aware of 30 to 50% of the odor issue claims made in the last 3 years.

To put some numbers to the issue:

There are approximately 3,500 to 5,000 sprayfoam insulation contractors currently spraying foam in the US. If each contractor sprays 25 houses a year, that would range from 87,500 to 125,000 houses a year. Times 3 years equals 262,500 to 375,000 houses.

I have been contacted about odor issues a dozen times in the past 3 years from homeowners or building owners. I also have worked with a half a dozen suppliers (and their insurance companies) on odor issues during the same time. Roger has been involved in a slightly fewer number of cases. Based on our experiences, I estimate that there are between 30 to 50 odor issue claims in the last 3 years. The large majority of the claims occurred from projects installed from 2007 to 2009. I see fewer claims of foam installed in 2010 or 2011.

Take also into consideration that of the projects I have personally inspected, 20% of the projects do not have odor issues from the foam. Rather it is other sources or the inhabitants have an extremely sensitive nose. For example, I have been in houses with 8-10 persons (including lawyers for the plaintiff) and no one except the owner can smell anything out of the ordinary.

It is difficult for a supplier to "sweep" problems under the rug in an industry as small as this. So, it is my estimate that most of these odor issues are fairly well documented.

So, I think the claim by one of the folks you interviewed that the odor issue problem represents 1 tenth or 1% of the sprayfoam applications is accurate. Actually the number of odor issues involving foam would conservatively be 2 one hundredths of 1% or 0.0002. Pretty low numbers.

Plus, the number of odor problems has been greatly reduced since the industry began instituting specific quality control training as part of their basic fundamental instructions to contractors.

Another item not mentioned in your article, foam that exhibits strong odors will have poor cell structure or discoloration in the foam that can be observed by quality control sampling during the project or quality assurance inspection after the project.

Mason Knowles

Mason Knowles Consulting

Customer service problems

Mason,

Thanks for the additional information.

If your estimates of the prevalence of odor problems is accurate, it only makes the failure of spray-foam manufacturers to settle these cases all the more mysterious. I just can't understand why some manufacturers are so reluctant to help these homeowners -- even (apparently) brushing off customers who call the manufacturers directly, asking for help.

My spray foam contractor at a

My spray foam contractor at a trade show discussed the smell of foam with me last year or so. He and I both like open cell icynene. But as to smell, he handed me chunks of foam and the closed cell foam definitely was giving off chemicals enough that one whiff close to your nose was enough. The water blown open cell had absolutely no smell. And the three homes I have had open cell installed in have no smell and are performing well as insulation and air barrier.

IMO, make sure you hire the best, their best crew sprays using their best equipment during favorable weather conditions.

Mason Knowles thank you for sharing first hand information that so many of us desire.

I too second Martin in that the industry must insure their work and quickly remedy spray foam situations that prove to be less than satisfactory.

Ensuring foam is applied in the proper conditions?

I'm wondering how highly trained foam applicators control for all conditions required for safe and effective foam installation. For example, one foam installer told me that the way to fix my crawl space is to just open up the floor and spray the dirt with several inches of foam. Alternatively, they would go down there and spray under the floor planking. In either case, I doubt the temperature ever reaches the recommended install temperature of 70-80 degrees F in my crawlspace, particularly on the surface of the dirt!. But so many crawlspaces are foamed--and I doubt any of them are warmer than 70 C (in the northeast at least). Does the temp spec apply to only the bottles of chemicals themselves, or does the envrionment and surface need to be at the recommended temp? If so, do they use a space heater? That seems to come with its own dangers. Can they still ventilate properly if they're trying to control the temp? Was this investigated in the fires that accured recently in MA--where at least in one case spray it is suspected that the foam was installed in crawl space too thickly in one application? And what about the added expense of having an installer come out 2-3 x over a period of weeks to apply the recommended max 2 inches of foam at a time and allow for the recommended 2-4 day curing and unoccupied period per coat? Seems not very cost effective or convenient for either the installers or customers.

Response to Steven O'Neil

Steven,

Spray foam chemicals are heated in the truck or trailer before the chemicals are sent to the spray wand. Depending on the temperature of the surface being sprayed, different temperatures may be required for the chemicals leaving the wand. These details are covered in training.

It isn't necessary to wait 2 to 4 days for foam curing after a 2-inch lift is sprayed before spraying a second lift. Once the initial heat of the exothermic reaction has dissipated -- often in an hour or less -- another layer of foam can be sprayed over the first layer.

Free foam education courses

My name is robert and I'm the northeast sales manager for a large foam manufacturer. You can reach me at 860-933-7076. Our company offers AIA as well as educational spray foam presentations at no charge. If after reading all of the articles you're unclear or uncertain on any aspect of spray foam please feel free to contact me.

ComfortFoam

I had my basement walls sprayed with BASF's ComfortFoam. The contractor then sprayed a fire-retardant over the ComfortFoam, per code in Maine. The basement has stunk ever since (about two years now). I will admit that the smell is not as strong as it was right after the work was completed.

Fortunately, little of the smell migrates into the living area, but I hate going down there to work on anything.

I've always wondered whether the smell is coming from the ComfortFoam or the fire retardant. Has anyone heard of smell problems with fire retardants?

Nice Job Green Building Advisor

Green Building Advisor did an excellent job with this article. I've been following its development from afar for a while. I know this is not a report that developed over night, but rather months. I think your conclusions validate what many of us thought from the beginning when these complaints first began to surface. But you clarified the issue and substantiated your conclusions with a lot of research and interviews. I hope that anyone who is considering spray foam will happen upon this article FIRST. Not that I think foam is a bad thing -- I have it in my own home and have had no problems. But these are serious chemicals and people need to realize their are contractors out there who wield them like gunman without proper training or a license.

Response to Trish Holder

Trish,

Thanks for the feedback. Like you, I think spray foam insulation has its uses. But the stories I heard from homeowners with odor problems were a wake-up call.

The bottom line is: know the credentials of your contractor, and weigh the risks of failure against the benefits you hope to achieve.

smelly foam

This from a contractor with 20+ yrs residential experience who is a lousy typist.

SPFA had a convention in February 2011 in Reno where the spraypolyurethanefoam.org website was introduced and contractors were made aware of the need for site ventilation. we were also told EPA is investigating spray foam in general. EPA, NIOSH,and NHTSA are 'encouraging' the foam industry to change their SOP's.

To be fair, the manufactuers have very little control over contractors. This is one of the few industries where the 'manufacturer' is not the supplier, the end manufacturer is the contractor. Foam 'manufacturers' make hardner (MDI) and Resins, or polyols. they do not make foam. Contractors make foam. That is why manufacturers don't want to claim the problems of foam.

But, is that ethical?

What about this, if I want to send a crewman to get trained to be the 'cook' as one of your posters refers to them, I have to pay for the training, pay for a trip to the manufacturer's site, pay for the employees wages, travel, and lodging, and lose production for about a week. Then that employee can work for any competing contractor. Frankly, if the manufacturers are so worried about proper applications, they should at least offer the trainings for free.

Training, weather it be building science, foam applicator, or BPI tech is always very expensive, and I don't think it should be if the trainer is selling product.

On the subject of pay rates for foam applicators. they are usually paid pretty well becasue they are key personnell.

On the subject of Personal Protective Equipment (PPE) for applicators and helpers, I spend several hunderd dollars per week on PPE, yet I still find crew personell on foam jobs without PPE. The OSHA people say 'terminate them or you will be fined'. I have been looking for a new applicator so I can start another rig for over a year now. I have lost a couple good candidates to our random drug testing policy. I cannot aford to terminate everyone. You can lead a horse to water, but you cannot force him to drink. Lately I have been telling guys 'if you do not respect yourself well enough to wear the PPE, how can I trust you with more responsibility and pay you more money?' They are catching on SLOWLY.

On fishy foam, you have nailed the reasons in this article already, and removal and replacement is ALWAYS expensive. suck it up, or do it right the first time.

You did miss a couple things though:

The intumescent paints can give off odors that people find irritating (one component that lasts a long time is isopropyl alcohol, which responds well to ventialtion and heat)

when Mason said the probelms were more prevalent prior to 2007, he didn't elaborate. In 2004 the EPA decided to get hard core on SPF to stop depeting ozone. that forced all producers to change formulations. Between 2005 and 2007 there was a lot of adjusting going on in formulations and installation guidance was not stable. Stability came in early 2007, and smelly foam became more rare around then too, coincidence?

If you want a good job you need a good contractor. good contractors don't work cheap. stop looking for the low bid guy.

This is harder than you think because there really aren't viable certifications to ask for. SPFA has one, but it costs several lost hours of production and several hunderd dollars PER Employee to get them, it also requires three inspections of jobs in process, which means flying an inspector (Mason Knowles or Roger Morrison are the only ones) to your site for the inspection. I know both of them and I like both of them, but they both live in the southeast and I am in the northeast. So, what do you think it will cost to get one or the other of them to come to NY and look at a job? I cannot get the builders to leave buildings open long enough to get three ready simultaneously, so multiply the inspection fee by three, and add travel and lodging for the inspector each time, then multiply that by the num ber of applicators. Like i said, training is expensive.

The other applicator certification is Air Barrier Association of America, which is even more expensive and involves Bonding the company.

Good contrators are not cheap. Stop looking for the low bid guy and expecting the high bid job.

Foam suppliers want to sell product and will not hesitate to sell product to anyone with the bucks. this kills the good contractors because when they invest the time and money into creating a good market invariabley they attract competition and the suppliers will sell the competition anything they need.

Anyone looking into becoming a foam contractor should look at these hidden costs more than the equipment costs, most don't, which is why you see newbies selling at discounts of 20 to 30% at times.

if your deal seems too good to be true, walk away. if you get two experienced contractors with bids within 5% of each other and a third guy at 15% lower, the third guy is probably not your friend.

Response to Pat Dundon

Pat,

An excellent post -- thanks for all your details. You've provided a lot of food for thought.

Here's one of your most important points: "Foam suppliers want to sell product and will not hesitate to sell product to anyone with the bucks. This kills the good contractors because when they invest the time and money into creating a good market, invariably they attract competition and the suppliers will sell the competition anything they need."

The foam suppliers -- the group I have been calling the manufacturers -- are at risk of killing the entire industry unless they alter their current practice of selling chemicals to anyone who shows up.

Martin, Robert Quesnette, Pat

Martin, Robert Quesnette, Pat Dundon, this thread is fantastic and exactly the kind of information all of us really desire in regard to spray foam. Contractors, architects, clients, customers, we all desire some real behind the scenes information, discussion, thoughts and opinions.

Robert Quesnette and Pat Dundon, help us out here at GBA by sticking around the spray foam discussions. Martin, maybe GBA should ask these gents to participate in future GBA white papers.

see my post above

I must step in and say this is an unfair statement being made that all manufacturers will sell to anyone and charge for education. In my last post I listed my name and phone number and offered FREE educational courses. As far a sales are concerned at the end of the day it's a salesman job to sell chemical ...that being said, my company always runs a demographic on the territory were a new applicatior is looking to come on in order to be certain we're not over saturating a given market. I cant speak for all manufacturers only for my company and territory. Once again my phone number is 860-970-3515, please contact me directly if you have any further questions regarding our free education.

This is excellent information!

I am a public health official who receives complaints about smelly spray foam installations. As there are no regulations, I am generally at a loss for what to recommend. When I suggest that the underlying cause is usually misapplication, the contractor always denies that could even be a possibility. I am interested in developing a sampling and analysis protocol which can be used to demonstrate the presence or absence of indoor air contamination from spray foam installations. Is this something that you have some background information on?

Response to Todd Crawford

Todd,

I don't have an answer to your question. Of course, IAQ consultants are able to test air samples for VOCs, formaldehyde, and a variety of chemicals. But smell is subjective, and I don't know of any tests that can confirm that spray foam is the source of a dead-fish smell.

Perhaps another GBA reader will be able to respond.

smelly foam

In NY any business can ask (once every 6 years) for the NY Dept of Labor, Div of Safety & Health to come out and do an OSHA type inspection of your business practice for free. it is encouraged to find and mediate hazards owners may not realize are there. if the inspector sees someting massively wrong, he can call an OSHA guy and get the owner fined, but if they see stuff that can be easily fixed (and is), they just point it out and make no record of it. if you have this done, OSHA cannot inspect you for 6 months.

I have had it done twice since 1993. both times I asked for an Industrial Hygenist to come out and do air sampling for MDI. Back in 1990's I was the guy on the gun and the guy in the truck. The first time we were using open cell foam, the second time we were using closed cell foam. both times, the hygenist had my sprayer wear a pump that trapped particulates and vapors in some sort of canister, and had another crew guy wear a similar apparatus in the back of the truck. The samples were sent out for anaysis. OSHA has an 8 hr PEL of something like 5 ppB (billion) for MDI, and we were under that limit on all tests.

The Hygenist told me, and I have verified, that MDI is a material that is colorless, odorless, and tasteless, but people do react to it over time. it works similarly to an allergy. eventually, MDI at levels that cannot be measured do affect people with sensitivity to MDI, and you get sensitized by repeated exposure. so, the Hygenist said wear appropraite PPE at all times.

Happily, MDI is not a very common chemical in our world unles you are installing urethane products. However, urethane products include items like polyurethane caulk (availabe at your local hardware store), urethane glues (like Gorilla Glue), single component foams (Great Stuff & similar products), and urethane paint (your car us coated in it (even that Prius)) all have some level of MDI in them.

what changed this year is the polyol, and the materials other than MDI that get released during the curing process are now being studied. No one has good data from long term study of these materials. the feeling is, and I ssume it is at least tacitly accepted by EPA and NIOSH, that these products are probably not very dangerous. However, the current guidance is to have unprotected people leave the premisis during the spray process and for 24 hours after we finish.

Even EPA & NIOSH agree that after the curing process has completed there is no offgassing. in a home show environment, foam samples are pawed, crushed, cut, broken, etc. so there are constantly new pores being opened, and you will get smells, but that is not a valid test process for stuff contained inside a building cavity.

Suppliers put out materials and directions for applicators to use and follow. if they are followed properly, things go very well. if someone tries to cheat somehow things can go terribly wrong. If someone does something wqrong just becasue they don't know what they don't know, things can go wrong too. there are lots of ways to do something wrong when you install any chemical process, and only one way to get it right. With foam, if you get way wrong, you usually don't get foam, and it shows quickly. usually is not always though.

there is nothing anyone can do to make this perfect, but you can do a lot better by using someone experienced, and that begins with someone ethical to a point of admitting when something is not going well and stopping to figure out what it is and how to fix it. SPFA is doing that with the support of several dozen suppliers and EPA, NIOSH & NHTSA. Watch SprayPolyurethaneFoam.org for reporting on their progress.

Update & Request

I'm still suffering from exposure to whatever is coming out of the foam in my attic. I just returned from a week of vacation in Colorado and within 24 hours my family and I were again experiencing severe congestion, lung irritation, and dizziness. I even called my local HVAC guy and a different foam installer, both of whom have spent time in my attic recently and they both reported similar symptoms.

Does anyone know a good lawyer who can help negotiate? Or a contractor in the DFW area that can help remove the bad foam?

In the meantime, I'm working to publicize this as much as possible, hoping that awareness will ultimately bring a solution.

Info for Brian Hanks

Martin Holladay has my contact info, please contact him.

Foam

If Mac Sheldon of Demilec thinks removing Spray Foam is not an answer to foam problems than why does Demilec remove it? They say they don't remove the foam, but they certainly have.

Important information about polyurethane spray foam insulation

If you are thinking about using polyurethane spray foam to insulate your home, please read the following information at the links provided below. What you are venturing into is bringing a chemical manufacturing process into your home that uses highly toxic chemicals, that as folks in this article can attest, can go badly wrong. Please be well informed first, before making a decision.

http://epa.gov/dfe/pubs/projects/spf/health_concerns_associated_with_chemicals_in_spray_polyurethane_foam_products.html

http://www.sprayfoamsafety.com/federal-agencies-spray-foam-safety-activities.html

What is going on in some homes with SPF?

Lately there is a lot of speculation that spray foam insulation is not as inert as once thought and in fact, SPF may continue to off gas for many years. The EPA has also voiced their concern about the need for further research on the short and long term safety of SPF in residential use.

We are in contact with 30 other families in the USA and Canada who may be suffering from symptoms related to their SPF home (NOTE: schools and offices are using it too).

Some families have moved out of their homes. Other families have removed roof decks and/or walls of SPF in hopes of reducing the chemicals and symptoms experienced in the home. Some families have no choice other than to remain in their home and rely on mechanical ventilation/filtration to help ease the chemical burden and symptoms, but find little relief.

After nearly a year of research, ventilation, lots of lab testing (chamber and air samples), and expert opinions, our family has begun tedious process of removing our SPF (roof deck and wall cavities). The removal is being performed by a local remediation company (the company has removed SPF in homes prior because of mold and moisture issues.

A detailed protocol created by our Certified Industrial Hygienist (other credentials include CSE, CIEC, CEICC, CIAQP, CIAQC) whom has experience (20+ yrs.) with isocyanates (Side A of the two part foam) is being followed to ensure safe removal (dust created from breaking the foam is a respiratory and dermal hazard).

We are hopeful that removal of the SPF along with soda blasting will remove and neutralize the chemicals associated with the application of the SPF. We will do more testing after remediation is complete to ensure a safe environment prior to resuming to build

According to the EPA the SPF should be cured (inert) and safe for re-entry 23-72 hrs after install. According to SPF companies, there should be no odor or off gassing after it is cured.

Our home experienced something much different; a chemical smell has lingered and when we entered the home we experienced respiratory issues, headache, flu aches, muscle aches, throat, eye irritation and chest pain. On warm days, the smell and symptoms were more severe. Some visitors experienced the same symptoms while others do not. There is a varying degree of threshold levels, but almost everyone, after prolonged periods complain of eye, throat irritation.

A lot of lab work has been completed by a well known leader in product testing. Our chamber and air tests show a long list of chemicals that at even low levels, chronic exposure to most of the captured chemicals in our home will undoubtedly cause health issues after little or prolonged exposure. Frighteningly, our chemical profile from both the chamber and air testing mimics most of the other homes experiencing the same complaints with the SPF.

Is this all a coincidence that the same chemicals are found in homes with spray foam and the owners are experiencing the same symptoms?

Today we are much more sensitive to things that contain isocyanates and flame retardants. Renting a car, walking into REI, IKEA, and HomeDepot can cause eye irritation, burning throat and chest congestion. Even running on a refinished track or wearing a wetsuit can evoke our symptoms.

Other SPF homeowners have had severe reactions and illness thought to be associated with the chemicals from the SPF. Children of some of these SPF homes develop a chronic cough and asthma like breathing. Chronic low grade fever and autoimmune responses have also been observed. Muscle aches and mental confusion and chest pain are other symptoms and can be seen during exposure and/or develop after being in an SPF home for long periods.

Our SPF manufacturer/supplier is very aware of our complaints and concerns (and the complaints of the other homeowners), but the company continues to deny any sort of problem with their product.

The contractor who installed the foam (in18 degree weather, with zero ventilation during install [two weeks], and allowed us and others to be in the home during installation) denies anything is wrong. Needless to say, like most of the other homeowners, we are left on our own to handle this because the science is not yet 'there'.

Do you have SPF insulation somewhere in your home (attic, wall cavities, crawl space)? Do you experience asthma like symptoms, chronic cough, headache, throat or eye irritation, nausea, skin rash, muscle aches, flu-ish, any new autoimmune issues since moving into or installing SPF?

If so, do your symptoms decrease when away from the home OR during times of lower temperatures?

Another issue has been seen in older SPF in homes. Have you had SPF insulation for 1-8 years and recently notice a new chemical odor or the above symptoms? A family we know has removed SPF from their home after 6 yrs. because in June 2011 it started to smell and the family had to move out because of their related symptoms. Test results indicate the foam is decomposing and releasing the same chemicals that we have in our relatively newly sprayed home.

I hope our situation is a random, but if it is not and other homeowners with SPF are experiencing similar symptoms, it is important that information is being gathered and awareness is spread.

contact email for Spray Foam problems

It is unfortunate, but the number of families with spray foam issues is getting very long, we would like to hear from you if you have problems with your SPF. Please contact us at

[email protected]

Updates?

Martin,

My family is having health problems related to Demilec that was installed March 2011. We moved in the house in January 2012 and our symptoms have been getting worse as the Texas temperatures rise. Do you have any updates? I would like to find out what Brian Hanks was able to do to remedy his situation (or if anyone else has found anything that works). It would also be helpful to find out what they've tried that has not worked. We've already contacted Demilec. Robert Naini came out and took samples. The official word back was that the samples all smelled like they were supposed to and that it must be the paint in the attic -- of course, there's no paint in the attic. In fact, we tried to be very careful with all of our choices as we were building to protect our indoor air quality (NAUF building materials, no carpet, etc.). Our builder used Demilec Sealection 500 without our knowledge and against our wishes because they wanted to.

Christine, contact me. We

Christine, contact me. We have been thru the same song and dance with Robert Nanai and Demilec.

We are in Austin.

[email protected]

Blog: http://www.sprayfoamdangers.com

Smelly foam

I have foam installed in my basement and the installer is brushing me off. Does anyone know you remediation servers available to remove the product. My marriage depends on it. I am in the Midwest (Oh) region. Airing the basement out does nothing. I am at a total loss. Can anyone help me please.

Response to Barry Webber

Barry,

Contact the foam manufacturer. Some are responsible. You may also need to contact a lawyer. Document everything in writing. Good luck.

Responsible Foam Manufacturers

Mr. Holladay, Please share who these responsible foam manufacturers are? From all the jaded consumers I have spoken to, only one has stepped up to help the consumer on their dime. This chemical manufacturer did not do this without first having the consumer waive their right to file suit. This same chemical provider is now hiding and denying the reasons certain hazardous chemicals are showing up in the spray foam lab tests. The testing is being handled by a licensed environmental engineer hired by the consumer. This experience has not been easy for this family however, it is at least getting somewhere which is unlike many in this circumstance.

Health Issues Related to Spray Foam Insulation

The largest part of all Spray Polyurethane Foam discussions is ignored. "HEALTH."

People are constantly asking for help and no one will touch the topic. There are a few who understand this is a real issue and there are those who dismiss the issues.

Do any of you readers understand the health ramnifications of using spray foam insulation?

Do you understand what these products will do to you, your family and others you recommend it to? Well, I do and it's not pretty. Try keywording some of your own health questions. You may be shocked to find there are very, very few answers. That is unless you know where to look. Here's a couple links for you:

http://blogs.cdc.gov/niosh-science-blog/2012/03/sprayfoam/ and http://www.epa.gov/dfe/pubs/projects/spf/epa_niosh_osha_spfa_confernce_p...

All to often builders and industry experts make a claim to fame when something new is introduced to make our lives safer and more economical without doing the research first. I will be the first to admit, I did this to. However, I did do the research on spray foam insulation and came up with nothing but the positives of spray foam (aka SPF). The real issue with these SPF products (open and closed cell) is any keyword you use online dating back to 1997 to current is industry promoted.

HGTV and many other DIY channels are promoting Spray Polyurethane Foam Insulation without publishing any research on the health implications. Holmes on Holmes appears to be in the room as the guys are spraying the foam. Bob Villa and Norm of This Old House promote these products now and in years past. As a matter of fact, my SPF applicator was the same company which recently sprayed a home for This Old House in a Rhode Island home. This company is one of the largest in the northeast and sprayed my home with off-ratio foam. (ie; closed and open cell name brand foams)

What would you say if I told you part A-side of SPF was modified Formaldehyde changed chemically to make (MDI) methylene diphenylene diisocyanate. Well, it is! This is the A-side of all SPF manufacturers foam insulation. Many have Formaldehyde in the B-side as well. In CT Formaldehyde containing spray foam is legal as long as it is Urethane or Styrene foam and not (UFFI).

See: CGS Sec. 29-277. Urea-formaldehyde insulation: Definition; prohibition concerning use; penalty. (a) Urea-formaldehyde (UF) foamed-in-place insulation, also referred to as formaldehyde-based insulation, means any cellular plastic thermal material which contains as a component chemical formaldehyde, formaldehyde polymers, formaldehyde derivatives and any other chemical from which formaldehyde can be released, but does not mean urethane foam insulation or styrene foam insulation.

(b) Urea-formaldehyde foamed-in-place insulation shall not be installed in any building or structure on or after June 1, 1981.

(c) Any person who violates any provision of this section shall be fined not more than five hundred dollars for the first offense and for each subsequent offense shall be fined not more than one thousand dollars.

(P.A. 81-250, S. 1-4.)

Are you aware that if you are in a home when these products are installed without respiratory protection the chemicals can cause permanent lung damage and death?

"Persons developing sensitivity to isocyanates may have dangerous systemic reactions to extremely small exposures, including respiratory failure. MDI should not be heated or sprayed except with strict engineering controls and personal protective equipment."

See: http://www.thefullwiki.org/Methylene_diphenyl_diisocyanate

Are you aware that the medical community is studying humans who have these products installed within their homes? Are you aware the medical community is studying the men who apply these products? Dr. Redlich of Yale University is the most known doctor researching the effects of SPF and humans.

Are you aware our own government is just recently taking notice and most recently are studying the health implications of these products.

Do you think the government is studying these products just because they want to help us. No!

People are complaining and are injured. ie; health and property damage. Many believe SPF is the next Chinese Drywall and the next (UFFI) Urea-Formaldehyde Foam Insulation which is banned in many states.

I know first hand because my contractor contaminated my house with 3 different spray foams and they all failed.

My reason for posting is to help you. Every SPF company I have spoken to will not tell the truth and/or are afraid to. Reality is this... you complain, you are ISOLATED.

Ask your State Department of Public Health and or Building Officials for information relating to health and SPF. Do not feel shocked when you learn as I did they do not know how to handle issues relating to spray foam insulation.

Please do your homework first guy's. There is a lot more to building than energy conservation. There is responsible building to.

I'll be the first to tell you, these products do not belong around people or children with Asthma!! If you still want to specify or use these products, call the manufacturer and verify your applicators credentials first. Do not trust the salesman! Call the manufacturers corporate office for credential verification. Make sure you get "EVERYTHING IN WRITING" from the manufacturer and the installer. Do not believe the verbal claim's because when you have a failure (odor, shrinking, cracking, etc.) and you do not take the proper steps, this will easily become the most expensive insulation you ever gambled on. One last piece of mind for you.....your homeowners policy will not cover you for any SPF failures. You better verify your contractor is insured for a minimum $1M policy plus an umbrella policy endorsement for at least $5M. General Liabilty Coverage will not protect you from a bad job. Make sure your contractor carries Contractors Pollution Liability Insurance. This will help you if and when things go bad. Also make absolutely sure they carry Workman's Compensation Insurance or you could be on the hook if their employee gets hurt in your home. Do not be afraid to ask to be named as an additional insured. The future is only going to bring numerous lawsuits as more and more people have these products installed in their homes and complaints surface. Builders, Architects, Designers and Applicators are not immune from the claims.

I hope my experience helps you all. If you are like my family and have experienced smelly foam, health problems and off-ratio foam, feel free to call me 860-460-5434 and I will share with you my findings. I have spent hundreds of hours researching these products to find the answers for my family since my SPF application company and the chemical manufacturer refussed to take responsibility for their actions. I do not work for the industry and I do not have a financial interest in this. What I do have is failed Spray Foam Insulation and I'm not happy about what this industry has forced me to do to get answers.

Response to Slawek Rafacz

Slawek,

The only advice I can give you is the usual: Take notes. Document everything. Talk to the manufacturer and the installer. And talk to a lawyer. Good luck.

Sprayfoam nightmare

got basement sprayed. Wasnt done right. Got removed and resprayed and still smells. What to do?

Smelly Foam

We had our one car attached garage ceiling sprayed a couple weeks ago. I knew there should be no smell a couple days after the application so when I noticed it smelled like rotting fish I got to googling and found this website. I had the installer come back out within a week after they sprayed it. He claimed he didn't smell anything but he did contact the chemical company they use: BASF and a rep came out to inspect it within a couple days. He determined the installer sprayed his passes too thick and before the first pass cooled down enough. We demanded the installer company remove it all and return our money. They complied thank goodness. They had 2 men for 3 full days tearing the foam out. No respirators in a 250 sq. foot confined garage?? It reeked like ammonia when they were tearing it out. It'd been a few days since they removed it and it still smells. The smell has been reduced I'd say by half it's potency but it's definitely still there. Thank goodness this happened to our garage and not inside our home! Although plans to turn the garage into a shop are on hold until we can figure out how to remove the remaining smell. Has anyone tried sand blasting wood that held the foam?

Smelly SPF Remediation

I'm dealing with this problem in my entire house. Per the EPA website there are no known methods of remediation with studies or trials to verify the effectiveness.

Has all the foam been removed by the installer? This includes wire brushing the roof sheathing and truss system. Are there pockets of foam in corners? A 100% removal is not possible since the foam expands into cracks and spaces between the lumber. Make sure they remove it all before proceeding with any other treatment.

It has been suggested to me to try soda or dry ice blasting. It's softer than sanding blasting. As my engineer tells me, no amount of wood can be removed during any type of blasting. Its likely the odors and chemicals have penetrated the wood. Before spending $$$ on blasting, remove some lumber from the garage, only if it can be replaced to code. Take your samples to a blaster. After treatment place an untreated piece of lumber in a plastic bag and a treated piece in a different plastic bag. Place them in the sun and do your own smell test. Remember you will not be able to remove all of the foam in the garage with blasting.

Sealing will be another method suggested. It comes with it's own set of VOC problems. A sealer against the roof sheathing will contract and expand daily in the summer and eventually crack, besides as with any paint the surface has to be clean.

It's unfortunate that the SPF industry isn't proactive on conducting remediation studies.

It's been a number of years since this was written and a few since the last comments. Is this still an issue in the industry, still a concern when applying foam to an occupied house?

Great series of posts. As a homeowner finishing a basement, I’m getting quotes from local installers and asking for references. That said, as with previous post from 2019, has anything changed regarding toxicity/odor with catalysts? Now, I’m rethinking this option.

Is there a green chemistry certified product?

Wayne,

I don't think that the situation has changed much since this article was written. The vast majority of spray foam jobs are trouble-free installations, but the ones that are problematic are an enormous headache.

Thanks Martin;

I’m blown away by the stories of installers not ventilating at all during the spraying. Though, I can see the problem of poorly trained installers in areas of rapid growth.

I’m using the “trust but verify” mode on this, ask for references (from similar jobs), ask how they ventilate while spraying, ask about training, the SPECIFIC material they use, and anything else I think of.

If they balk, that’s an indicator.

Good news is, VT’s a small place, so word gets around re: shoddy work.

- Wayne.

Log in or become a member to post a comment.

Sign up Log in