No. Green homes are insulated well, tightly built, and well ventilated

Let’s take these issues one at a time. The “too tight” theory holds that houses need to breathe. Traditionalists can point to old houses and claim the only reason they’re still standing is because air leaks amount to natural ventilation that dries everything out and keeps the house healthy.

In reality, air leaks mean you’ve lost control of air movement. Air and moisture can be forced into wall and ceiling cavities where water vapor condenses and fosters the growth of mold. Warm air exiting the top of the house can draw in cold air to replace it, wasting heat and energy. In many ways, uncontrolled air movement wastes energy and increases the risk of long-term damage to building components.

Effective air and moisture barriers reduce those problems, but they come with a few caveats: Tight houses need mechanical ventilation to ensure a supply of fresh air to keep people healthy; and existing houses should not be tightened without assessing whether the existing combustion appliances have an adequate source of combustion makeup air.

As far as insulation goes, there may be a theoretical point of “too much,” but in most cases buildings have too little. At the very minimum, insulation should meet recommendations of the Department of Energy, but adding more is always a good thing. Properly insulated buildings are cheaper to heat and cool.

Where insulation is added can be as important to how much is added. Walls and roofs with an extra layer of rigid insulation outside the framing help cut energy losses due to thermal bridging. What’s more, some types of insulation are inherently more effective than others. But using too much should be the least of our worries.

More Info:

Green Building Encyclopedia:

Fine Homebuilding

Houses Need to Breathe. . . Right?

by Max Sherman

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

39 Comments

Mechanical ventilation is more than a caveat

Mechanical ventilation is more than a caveat...It is a "fact of life" for any modern home. We must incorporate healthy fresh air into all new and improved homes.

After we get over this "fact of life" then we can strive to make our homes AIRTIGHT and vapor permeable. The German Passiv Haus recognizes this. Our big problem is that we Americans just do not understand the significance of air tightness and healthy ventilation.

The affordable Arizona home that is featured on this site gets it right.

Natural Ventilation is within reach in some places

I am working in affordable green housing in Honolulu where we use natural ventilation as a very effective and renewable method of cooling and controlling humidity. Roof insulation and thermal barriers in the roof, and south, east and west walls are critical, as well as louvers, cross ventilation, and thermal chimneys.

I would disagree that mechanical ventialtion is a fact of life for any modern home. In fact, I would argue that it would be barbaric to ignore this natural condition and use mechanical ventilation, abusing the electrical grid.

Ventilation in Honolulu

Ah, yes — once again construction experts on the Mainland have forgotten that a few lucky Americans live in paradise. It's true: if you live in Honolulu, natural ventilation makes more sense than mechanical ventilation. You're lucky!

Look north

You don't have to go far to find expertise in building energy-efficient homes. Canada has been building them for 30 years. While many consider Canada's climate to be extreme, for the most part it is similar to the northern US states. Tight houses, whole-house heat recovery ventilation, setback thermostats, insulated foundations, low-E argon filled windows, ground source heat pumps - all common in Canada for over 20 years.

And to a large degree, a home that is easy to heat is also easy to cool, so with appropriate design changes, much of this technology can work in hot climates, too.

Too much insulation

Rather than too much insulation, I believe that insulation is governed by the law of diminishing returns....after a certain point, each dollar spent gives you less and less benefit. The question really comes down to how much are you (or the client if you are a contractor) willing to spend on insulation.

As far as making the building "too tight", lets just accept the fact that from this point forward, all homes will be tight and should be designed with mechanical ventalation in mind.

Thermal bridging

The last paragraph of this post about too much insulation contains, I believe, the key to insulating a high performance in the most effective way. Better than building 2x6 walls so you can get more insulation in the cavities would be to stick with the 2x4 walls and add foamboard to the outside. This provides a layer of continuous insulation that minimizes the effect of heat taking the path of least resistance--through the wood framing.

-- Allison A. Bailes III, PhD

Energy Vanguard

High Performance Homes: Knowledge + Service

[email protected]

vapor barrier and foam insulation or both

i have a wood siding and when to put stucco is putting vapor barrier an foam good ????

Can we find an energy-free way to ventilate homes?

I admit that I don't have a lot of experience with high-performance homes and I haven't installed or used any mechanical ventilation systems. My concern, though, is that we end up becoming fully dependent upon electricity to ventilate our houses. We had a bad ice storm in W. Mass. last winter and some people were without power for weeks. What happens if in the future we have a higher degree of blackouts and scarce/intermittent power? I like the thought of a house that is designed to be around in 100 years, hopefully more. Certainly a tight house is built to last, but do we know if extremely tight houses will make sense a century from now? Of course I agree that highly insulated, air-tight homes make sense now, and are the right way to build for our current needs. I just think that energy-dependent ventilation may have some drawbacks in the long term. Is there a possibility, perhaps through building design, etc., of an energy-free way to control ventilation in a house?

Heat is stored in objects not air

having grown up in northern US climate in a house that was very tightly built (30 years ago) and before heat saving air exchangers, my parents would open up the home and vent it out (windows and doors in a cross ventilation pattern) to whatever conditions were outside during the winter for 10-20 minutes right after lunch. Sure it would cool the air temp 20-30 degrees for that time but never to freezing, and the temp would be restored to previous temps within a 30 min with a very nice fresh dry air feel and no condensation/mold problems. There are still low tech common sense approaches to tight house air renewal problems!!

Windows are not affected by power outages

Unless the heat source in your home is a wood stove, power outages will cause problems. Tightly built super insulated houses hold the heat longer in power outages, and therefore are more robust. They're also better at keeping cool during power outages in heat waves.

If ventilation becomes a problem in a power outage, open the windows. Just because the house is built tight, doesn't mean it's hermetically sealed.

I dare you tell me what the thermodynamic term "diffusion" means

I am tired of bad advice from your editorial staff. The reason why old houses are still standing is not because of air leaks, but because moisture is allowed to move out of the exterior walls that make up the structure. Moisture is actually "diffused" out as long as the structural materials do not trap it inside. This is what we mean when we say a "structure needs to breathe" to prevent mold. This is why we must not build "too tight"

Air leaks, however, is a different problem. Leaks can be controlled (prevented) by improving building codes and specifications; that simple.

Diffusion

Dear Anonymous,

You have dared me to tell you what the thermodynamic term diffusion means. I'll do my best.

Water vapor diffusion is the process whereby water vapor is absorbed by a material and moves through the material. The direction of the drive is from the region with a higher concentration of water vapor to the region with a lower concentration of water vapor. In other words, water vapor will diffuse through a permeable material; this vapor drive happens when one side of the material is damper than the other.

The permeance of materials is physical property that varies with the material. Vapor diffusion occurs readily through permeable materials like unpainted gypsum drywall, but very slowly through impermeable materials like 6-mil poly or aluminum foil.

I agree that it is an oversimplification to say that "old houses are still standing is because of air leaks." For an old house to be still standing, the three most important things it needs are (1) a solid foundation, (2) a sound, waterproof roof, and (3) adequate structural integrity.

In an old, uninsulated, heated building, air leaks do, indeed, help keep the wall framing and wall sheathing dry. The escape of warm interior air through the wall assembly carries away moisture and bakes the wood dry. This is a fact, but it is not the best way to keep your walls dry.

The statement that "a structure needs to breathe" is meaningless. Breathing is performed by mammals and birds, among other animals. The chief purpose of breathing is to oxygenate the blood. Structures lack blood and have no requirement for oxygen (although a structure's occupants do need oxygen).

Every building that requires conditioned air (heated or air conditioned air) should be built as tight as possible. If a builder fails to do this, uncontrolled air leakage can damage the structure of the building. The classic example occurs when leaky walls allow warm, humid interior air into the framing cavity, where the moisture in the air can condense on the back side of the wall sheathing.

I disagree that "leaks can be controlled (prevented) by improving building codes and specifications; that simple." I wish it were that simple! Sadly, most building codes in the U.S. are not enforced. As a result, code requirements for preventing air leakage are widely ignored.

Vapor diffusion

To Martin Holliday,

I was interested in your discussion of "diffusion." I think what you describe as diffusion is actually osmossis. The word simi permeable membrane is never mentioned in a discussion of diffusion.

An example of diffusion is easily shown by putting a drop of food coloring or ink in a fish tank of water. Watch it spread throughout the tank. No other explanation need be given. This, of course, is a diffusion of a liquid to a liquid which but the process would be the same as gas to gas or gas to liquid.

Osmossis, on the other hand is the tendency of of a solvent to pass through a simipermeable membrane, as the wall of a living cell into a solution of higher concentration, so as to equalize concentrations on both sides of athe membrane. "Webster" This can be illustrated by seperating the two liquids by a simipermeable membrane. The liquid with the higher concentration will actually draw from the other side and rise to a higher level.

More on diffusion

Anonymous,

Building scientists and physicists use the term "water vapor diffusion" to refer to the mechanism I described. For a more in-depth analysis of diffusion, see Building Science for Building Enclosures by Straube and Burnett or Water in Buildings by William Rose.

See also Vapor Diffusion Retarders and Air Barriers:

"Water vapor moves in and out of a building basically in three ways: with air currents, by diffusion through materials, and by heat transfer. ... While it was once believed that only coatings with low perm ratings constituted the only effective VDR [vapor diffusion retarder], it is now believed that any paint or coating is effective at restricting most water vapor diffusion in milder climates."

http://www.utahenergy.org/PDF/Vapor%20Diffusion%20Retarders%20and%20Air%20Barriers.pdf

Osmosis versus Diffusion

There is actually no osmosis going on in this example. Osmosis is a special type of diffusion whereby a solvent is transferred across a semi-permiable membrance by a driving force which is a difference in solute concentration on either side of the membrane. The solvent will keep moving until the solute conncentrations on the two sides are balanced

Diffusion is a simple movement of particles from an area of high concentration to low concentration.

Water cannot move in and out of a building by heat transfer. Heat is energy, water vapour is mass. The transport mechanisms are completely different.

Foam Insulation vs Permeable Structural Materials

Perhaps the ultimate insulator with “breathing” properties is wool. “breathing” is a classical term indicating that wool, while keeping your heat inside your body, it does not trap moisture inside it. In the same manner, a good insulated structure with “breathing” properties will limit heat transfer and will not restrict vapor diffusion from taking place. I assume the above analogy is clear.

Now, if we are building new construction, how can we insure reliability against structural defects resulting from mold? We obviously have two options. The first is to use permeable materials facing the exterior, including insulation materials. This option proved itself for decades. The second option is to use a closed structure whereby moisture cannot penetrate inside it from any direction. This one is good in theory but defunct in practice.

Unfortunately, all the current advice works against what we are trying to achieve which is to prevent moisture entrapment inside the structure. Take a look at the illustration above in this article. People actually believe that spray foam will keep moisture out of a structural wall. I would like Mr. Holladay to explain how? Do we have historical data that backs up this claim? Or, are we facing another fad that will be exposed in time and paid for by whom else other than the home owner?

Permeable versus impermeable materials

Anonymous,

It would still be nice to have a name so I know whom I'm corresponding with.

You asked me to explain how the foam in the illustration reduces the chance of moisture problems. Here's how: closed-cell spray foam is an insulator as well as a vapor retarder. When sprayed on a rim joist, the spray foam creates a thermal barrier between the warm, moist interior air and the cold rim joist. That raises the temperature of the surface facing the interior and removes a potential condensing surface. It also creates an air barrier that seals cracks and prevents warm, moist interior air from reaching the joist. If the spray foam were not there, moisture would condense on the joist, leading to mold and rot.

I'm an agnostic when it comes to the permeability of building materials. I don't believe "all building materials should be vapor impermeable," nor that "all building materials should be vapor permeable." (The latter principle would be hard to follow, in any case, unless one wanted a house without glass.)

Simply put, a builder should understand vapor flows and air flows, and should build wall assemblies and ceiling assemblies that are able to handle expected environmental factors. Ideally, the assemblies should never get wet. However, if they do get wet, they should be able to dry out.

While these principles are simply stated, they can be tricky to implement. Fortunately, building scientists have developed building assemblies that work well in a variety of climates.

Too much insulation

I'm not entirely convinced that the statement "you can never have too much insulation" is unequivocal.

I did some energy analysis on passive solar houses a couple of years ago and realised that given a constant glazing area, there is some point at which there is no advantage in adding insulation to the walls - the relatively poor insulation value of the fenestration totally dominates the heat loss. This loss through the windows could be mitigated by thermal shutters, but in the case of passive solar the use of shutters (assuming they are only closed at night to prevent heat loss) assumes that the solar gain during daylight hours is much higher than the loss over the same period.

Now a passive solar house may typically have more glazing area than a conventional house, but this just means that the point of diminishing returns in terms of adding wall insulation is achieved later in a conventional heated home than in a passive solar home.

Not debating the point that adding insulation to conventional homes is a good thing, just pointing out that there is some point at which there is little benefit to do so.

I'm getting confused

I still don't know whether I am corresponding with one Anonymous or several Anonymice; names, please!

I'm confused by the multiple negatives in your last opening statement: "I'm not entirely convinced that the statement "you can never have too much insulation" is unequivocal." Okay, someone made that statement -- but who? Are you trying to paraphrase the sentence in the original article, which states, "As far as insulation goes, there may be a theoretical point of 'too much,' but in most cases buildings have too little"? Sounds like you are setting up a straw man to knock down. It's a bad paraphrase.

Okay, you proposed a statement -- source unknown. Then your imply that another person -- who? -- called the statement "unequivocal." Who was that?

Finally, you tell us that you aren't convinced of the truth of the statement made by that the unnamed commenter on the paraphrased statement. Okay. I guess.

For the record: Yes, it is possible for a building to have too much insulation.

Vapor diffusion explained

I asked Bill Rose to explain diffusion briefly for me, here's what he said:

Diffusion is a very slow method of wetting or drying. Wind whistling through leaky stud cavities is much quicker.

Bill is a professor of architecture at University of Illinois at Urbana-Champaign. He has a fantastic book called [Water in Buildings: An Architects Guide to managing Moisture and Mold](http://www.amazon.com/Water-Buildings-Architects-Guide-Moisture/dp/0471468509). It's well worth the read and deserves a spot on any shelter nerd's Christmas list.

Great Discussion, but inconclusive and not "simple"

I have been designing residential projects for over 40 years and I appreciate the information in the article and the helpful discussions. Many of the discussions posted use the word "simple" or "simply." and, frankly, I do not think this is a "simple" topic. In fact, much of what is being suggested today in the form of "tight" construction is totally opposite of what was considered standard 5 years ago. For example, installing foam insulation (also a vapor barrier) on the exterior side of a wall was considered a way to trap moisture inside the wall (between a vapor barrier on the inside of the wall and a vapor barrier on the outside of the wall). Most vapor barriers (the vapor barrier on batt insulation) was always on the inside surface of the wall. So, which is it? Vapor barrier on the inside or vapor barrier on the outside? (I have also wondered about how much of a vapor barrier was created by plywood or OSB wall sheathing, supposedly permeable.) I practice architecture in a region where we experience hot humid weather in the Summer and frequent below freezing temperatures in the Winter so we face the water vapor issue all year long, but from opposite directions. Sometimes the water vapor is inside and sometimes the water vapor is outside. I am not in the habit of adopting the latest "fad" in construction practice because I have seen too many products and techniques fail over the long haul. We should be building structures to last decades or even hundreds of years so I am more interested in "proven" techniques. Having said that, I am also aware of the urgent need to conserve energy so we may not be able to wait for "proof of concept" which might take 20 years or more.

I must admit, I am reluctant to specify foam insulation on the exterior side of a wall and I am reluctant to completely seal up the exterior side of a wall except for House Wrap (permeable, in theory). I have installed foam insulation on the interior side of frame walls and I consider this a better solution. This reduces thermal bridging from the studs without creating an exterior vapor barrier. Unfortunately, this does not prevent thermal bridging at band or rim boards.

On another similar note, what about air space above sloping ceiling/roof insulation? Should the framing cavity be completely filled or should there be an air space between the insulation and the roof sheathing? Depending on the type of insulation, the climate, and the version of code in effect at the time of construction, there are major conflicts between various factions as to what is the proper technique. The typical homeowner must be a little distressed and/or annoyed by the lack of standards regarding proper installation of insulation and vapor barriers, and so am I.

I hope this topic will be dealt with in greater detail in future articles with a consistent message. This is a complicated issue and one which building science along with practical job-site experience plays a major role in clarifying. It may very well be that there is no one solution, but rather a certifiable "assembly," much like fire rated "assemblies," which will consist of specific components tested in specific climates with measurable vapor flows and demonstrated points within the assembly where water condenses at various temperature and humidity conditions.

Your last sentence nailed it

Samuel,

Your statement at the end of your post is tentative, but it is in fact entirely accurate: "It may very well be that there is no one solution, but rather a certifiable 'assembly,' much like fire rated 'assemblies,' which will consist of specific components tested in specific climates with measurable vapor flows and demonstrated points within the assembly where water condenses at various temperature and humidity conditions."

Bingo!

The best discussion of these issues can be found at a valuable Web site hosted by the Building Science Corporation.

Joe Lstiburek has written a series of books that include wall and ceiling assemblies that work in a variety of climates. Check out this page for links to articles describing "designs that work."

It is simple, simply remove complexity

When you build a conventional modern home, HVAC can be very complex. Low tech building has always been the solution.

Quote: "Mechanical ventilation is more than a caveat...It is a "fact of life" for any modern home. We must incorporate healthy fresh air into all new and improved homes.

After we get over this "fact of life" then we can strive to make our homes AIRTIGHT and vapor permeable."

Statements like this are the problem...wrong building paradigm.

Recycle content and insulation

Has anyone used foam backed vinyl siding as a way to reduce thermal bridging? I understand that CertainTeed has launched a foam backed vinyl siding with 60% recycle content. Do you still need house wrap if you use this product?

Welcome to the 20th Century

I was surprised to see that American designers/builders are still having this discussion on the verge of 2010, especially in a "Green" building forum.

Any building that aspires to be Green must first and foremost be energy-efficient and "Minimise energy consumed for space heating/cooling" will be at the top the EE strategy list.

To accomplish that, the building must be super-insulated and when one super-insulates, air-tight construction is a fact of life. A knowledge of building science basics will confirm that the later is not debatable.

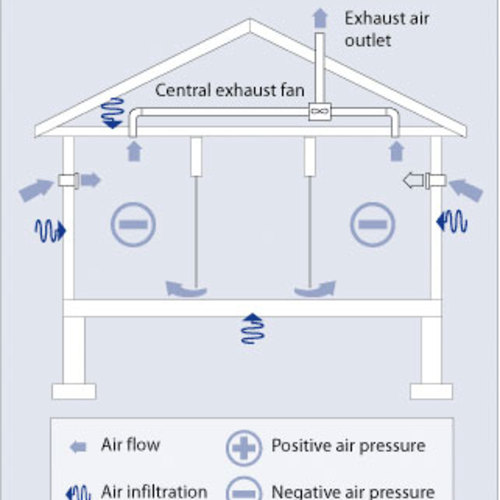

Mechanical ventilation is not a "must" as has been stated by some here. There are exhaust-only/passive-inlet ventilation strategies that can be successfully implemented in < 6500 HDD/yr climates.

For Americans who are just now familiarising themselves with these concepts, I would highly recommend the free publications that are provided by Canadian govt. orgs like Canada Mortgage & Housing Corp (CMHC), the Institute for Research in Construction (IRC) at the National Research Council of Canada (NRC) and the Office of Energy Efficiency (OEE) at Natural Resources Canada (NRCan), all of which are on the WWWeb.

Specifically, have a look at the R-2000 performance standard (in use since the 1980's) to which thousands of homes have been built and the more recent EQ performance standard which is similar to the PassivHaus standard. The techniques & strategies developed by these programs will provide invaluable info for novices and pros alike.

I am typing this as I sit in an almost three decades-old house built to exceed the R-2000 standard when it first came out. The weather report claimed that the temperatures today would be in the vicinity of minus thirty Celsius. This old house has not required any auxiliary heating since late last night and will not again until late tonight, if at all. And the air's fine thank-you very much.

Great Contractor Interview Question

When interviewing home builders for projects in areas lacking experienced builders, I've always used the "too tight" excuse as red flag. Especially if builder is not willing to learn from / discuss this widespread misinformation. Wholeheartedly agree with electricity caveat. However, believe we have moved far beyond the era when occupants (in USA) are willing to do much more than move a thermostat, yet we should still be striving to reduce electric ventilation.

I often state that the invention of A/C and the automobile have made the biggest contribution to the dumbing down of the design profession (self-included). Professionals only have ourselves to blame for dumbing down of occupants. The good news is re-connecting buildings to environment generally creates a more healthy place.

Its a tricky balance - thank God using our brains is fun!

A misunderstanding

Anonymous,

One of your statements reflects a misunderstanding.

You wrote, "Mechanical ventilation is not a 'must' as has been stated by some here. There are exhaust-only/passive-inlet ventilation strategies that can be successfully implemented."

But an exhaust-only strategy is a type of mechanical ventilation. Mechanical ventilation refers to a system of moving air with electric fans. The three major types of mechanical ventilation systems are exhaust-only systems, supply-only systems, and balanced systems.

Houses without mechanical ventilation systems must open a window or door to introduce fresh air.

Here's a page with more information:

https://www.greenbuildingadvisor.com/green-basics/ventilation

YES- They Can Be TOO Tight

The answer to the question "Can a house be too tight?" is "Yes!". A more accurate answer is "It Depends!". For the sake of simplicity let's stick with homes that are designed to be mechanically heated. The main reason It Depends has to do with the building science concept of viewing the "Building as a System". Looking at the home in this way one must consider the construction of the wall and roof assemblies and their inherent air leakage qualities along with other factors such as the strategy for ventilation, as well as the combustion mechanisms of the heating, hot water and other carbon burning equipment in the home.

Existing Home Extensive Air-Sealing and Improved insulation- It Depends:

When tightening existing homes built with conventional stick frame construction, and insulated with either fiberglass or cellulose, you'll need to evaluate the type of draft systems the mechanical systems employ. If these are Atmospherically Drafted (also referred to as Natural Drafted) it means that they draw air from the room they are located in to assist in exhausting their combustion gasses.

Tightening the envelope of the home too much when these types of systems are in place creates the potential for back-drafting these systems and bringing dangerous carbon monoxide into the home.

Extensive insulation and air sealing work on these older homes reduces the envelope air leakages which have been contributing air necessary to support these naturally drafted mechanical systems. The same envelope air leakage has also been supporting the ventilation/exhausting systems (bath fans, range-hoods, dryers etc) by replacing the air they are exhausting from the home. Can you see where this is going? The elimination of air leakage through the building envelope now puts the mechanical systems in competition with the ventilation/exhaust systems. The air necessary for the ventilation/exhaust systems must be replaced by air drawn in from the outside. Being denied the air leakage that had been occurring through the envelope, the next best source for this replacement air is to draw it down the chimneys of the homes mechanical combustion systems. And as these mechanical systems are Atmospherically Drafted systems, they have unrestricted openings to the outside air supply making it easy for this to occur. This is where the potential to back-draft the mechanical systems happens and can draw deadly carbon monoxide into the home.

Without the proper approach to air sealing and tightening the homes envelope and the identification of the mechanical systems the scenario I describe above will poison and possibly kill the occupants of the home. Each year there are over 20,000 poisonings and between 250 - 500 deaths related to carbon monoxide. A percentage of these are attributed to the scenario above.

When doing the type of work mentioned above it is best to have a qualified professional with specific training in this field to evaluate and test your home to avoid this situation. This is something we do on all the homes we air seal prior to the work and post improvements and use the protocols developed by BPI the Building Performance Institute. It is not worth taking the risk. While some that do this type of work may say they have not seen the issues I describe above, the reality is that unless they are testing for this situation they don't really know. And while their clients may not have died, they may well be getting some amount of poisoning related to carbon monoxide without knowing it.

New Home Construction - It Depends:

To simplify this scenario, lets assume that all new homes are installing sealed-combustion heating and hot water systems (as should be) so there is no concern for the issues I mention above with the mechanical systems. And while I did not address the issue above of the ventilation required for the occupants, I will here. So using the same consideration as above, the "House as a System" applied to new construction. Can the new house be too tight - It Depends. What It Depends on is the method of controlled air exchange in relation to the type of construction method/materials chosen for the building envelope, are they compatible? The two most popular and air-exchange choices are the Exhaust Only strategy (which is an incorrect description of what actually occurs) and Balanced Ventilation (such as an HRV or ERV). Of the 300+ homes I've tested over the past five years, of every type of construction, from stick frame, SIP's, ICF, Double Wall, Larsen Truss and Straw Bale, here is what I have found. For the Exhaust Only strategy to work, there must be enough leakage in the building envelope (or passive vents) to replace the air being exhausted with fresh incoming air from the outside. So truly this method is NOT Exhaust Only. And balanced ventilation systems such as HRV (ERV) systems, while my preferred method of mechanical ventilation need to be designed and tested to ensure they are balanced and moving the air as expected.

In most conventional stick build homes, even making a decent effort at air sealing, insulated with either fiberglass or cellulose, you'll almost always find enough leakage in the envelope for the Exhaust Only strategy to work.

For stick frame homes using either the, Flash-and-Bat method (air sealing with a layer of spray foam and cavities filled with either fiberglass or cellulose insulation), or rigid foam applied to exterior, taped with good attention to air sealing and either fiberglass or cellulose cavity insulation, it's a 50/50 bet as to if there will be enough envelope leakage for the Exhaust Only strategy to work.. With any of these methods of envelope construction, I would hedge my bet and either plan to provide some additional passive vents in the envelope at well placed locations, or just go with an HRV (ERV). For me, if I were going to use a mechanical method for air exchange, I'd just go for the HRV for the added benefit of heat recovery.

For stick frame with spray foam walls and ceilings, Double Walls with good air sealing, Larsen Truss with dense packed cellulose, SIPs and especially full ICFs with spray foamed ceilings, the HRV (ERV) or similar balanced ventilation is the way to go.

House as a system

Jay,

Thanks for your comments. You're right, of course, that any air-sealing contractor must be familiar with house-as-a-system thinking.

But I disagree with your conclusion that a house can be too tight. No, a house can't be too tight. But it is essential for any air-sealing contractor to follow all of the necessary steps when tightening a house. These steps routinely include:

1. A combustion safety evaluation. In some cases, existing appliances may need ducted combustion air. In other cases, existing atmospherically drafted appliances may need to be replaced with sealed-combustion appliances.

2. A properly commissioned mechanical ventilation system. As you point out, a contractor has not completed installing a ventilation system until it has been commissioned — that is, tested.

These two steps are necessary, routine steps for air-sealing contractors.

In conclusion: no, a house can't be too tight. But contractors need to understand house-as-a-system thinking, and contractors can't skip the above steps.

Questions Concerning Construction Method for a New House

I have just read all postings in this section titled "Can Houses be 'Too Insulated' or 'Too Tight'." I learned a lot from information posted, and it made me think more about the construction method I am planning to use for construction of the house I plan to build.

My desire is to build a super insulated, very air tight house, so it will be very energy efficient to heat and cool. My wife and I are senior citizens, so the house design is one story (no stairs to climb).

We live in the state of Virginia, on the east coast near the cities of Norfolk and Virginia Beach. During the coldest days of winter, temperature in this area drops down to around 20 degrees F. During summer, the temperature can rise to 95 degrees F. and it is very HUMID during the months of June, July, and August.

I am planning to use Structural Insulated Panels (SIPs) to build the house. The entire envelope of the house (walls, floor, and ceiling) would be built using SIPs. The SIP panels are 6.4 inches thick and are made using a polyurethane foam center sandwiched between two sheets of 7/16 inch OSB. The polyurethane foam center is 5.5 inches thick. The SIP supplier claims the insulating value is R 40. For the floor, SIP panel sections will be made in 4x8 foot sections. The top side will be 3/4 inch plywood (in place of the 7/16 inch OSB) so hardwood flooring can be nailed to it. Ground water in this part of Virginia, is only about four feet below the surface of the earth so no houses are built with an in-ground basement. Higher priced houses here are built up on cinder block piers so there is a three foot crawl space under the house. SIPs used for the floor will be attached to, and lay on top of, traditional wood floor joists installed 16 inches on center. SIPs used for exterior walls will be installed beside (next to the outside edge of) the floor SIPs. In other words, wall SIP panels will stand directly on a sole plate which is attached to the top of the floor joists.

SIPs for the ceiling will be installed as follows. Simpson Strong Tie metal brackets will be used to support ceiling joists (attic floor joists). The metal brackets will be attach to the top of the SIP wall panels and extend down the inside of the SIP wall panel to hold attic floor joists. The top edge of attic floor joists will be level with the top edge of wall SIP panels. Ceiling SIP panels will lay on top of attic floor joists and extend over the top of wall SIP panels to achieve a complete house insulation envelope using SIP panels. The void area inside and between attic floor joists will be filled with blown in cellulose insulation after wiring and plumbing is roughed in.

All joints where SIP panels connect together will be sealed and caulked to achieve as tight a house as possible. SIP panels connect together using a tongue and groove design.

The house will be all electric. It will be heated and cooled using a geothermal heat pump. A geothermal heat pump has the capability to preheat hot water, so this feature will be used. Heating hot water to final temperature will be via a tankless electric hot water heater. There will NOT be a traditional fireplace with a flue. NO gas stove or any appliance that uses natural or propane gas will be used.

Exhaust openings to vent bathroom smells and kitchen cooking odors to the outside will be exhausted using a separate Energy Recovery Ventilator (ERV) system. The ERV system will be self contained using its own duct system and NOT connected to house heating / cooling ducts. Incoming fresh air will be ducted through the ERV to heat or cool the incoming air (depending on season of year). The conditioned fresh air will then be distributed to bedrooms and living areas. The only other wall opening I can think of will be for the electric clothes dryer. All plumbing and electrical wall / floor penetrations will be sealed to maintain air tight integrity. Total square footage of the house will be about 3,100 sq. ft. Most rooms have a ceiling height of eight feet, but some are nine feet, and the great room has a vaulted ceiling. Total inside the house cubic feet of air space will need to be calculated so the ERV system selected will achieve the recommended amount of house air changes per hour; which I think should be about 0.5. Breathing excellent quality fresh air is one of the ten natural laws of good health, so we certainly want plenty of fresh air supplied to the master bedroom where we will sleep eight hours a day.

I desire to increase the R value of exterior SIP walls by adding additional insulation as follows. To add insulation to the exterior side of SIP wall panels, I plan to attach 3/4 inch foam board panels. These foam panels are made by R Max company and are called R-Matte Plus 3. They can be purchased at Home Depot. They are made using Poly Iso foam and have aluminum foil attached to both sides. One side is layered with reflective aluminum foil; the other side is layered with white colored aluminum foil. Exterior siding of the house will be brick, so the R-Matte Plus 3 panels will be installed with the reflective aluminum foil facing out toward the brick. A brick veneer exterior wall is built using a one inch air space between the house exterior wall and the brick. This air space provides additional insulation value when next to a reflective aluminum foil surface. During summer, when hot radiant energy from the sun heats up the brick walls, the reflective aluminum foil will radiate the heat away. The manufacturer claims a 3/4 inch thick panel of R-Matte Plus 3 has an R value of 5.0. Additional information about R-Matte Plus 3 is available at the company web site: http://www.rmaxinc.com

Now to describe how insulation will be added to the interior side of the SIP wall. 3/4 thick R-Matte Plus 3 panels will also be attached to the inside surface. All seams where R-Matte Plus 3 panels butt together will be covered over with reflective aluminum tape to maintain air tight integrity and keep a uniform reflective surface. Inside R-Matte Plus 3 panels installed on the interior side will have the reflective aluminum foil facing in toward the living space of the house. This will reflect radiant energy back into the house during the heating season. For this to work, I am told there needs to be an air space between the aluminum foil surface and the sheetrock. Therefore, I plan to attach 1x3 furring strips every four feet so sheetrock can be screwed to the furring strips. This will achieve a 3/4 inch air space between the aluminum foil surface and the sheetrock. All seams where R-Matte Plus 3 panels butt together will be covered with reflective aluminum tape to maintain a sealed vapor barrier. Before any sheetrock is installed, 6 mil thick black polyvinyl plastic sheets will be tightly secured over wall furring strips, and across the under side of SIP ceiling panels. This is a vapor barrier, so all seams will be sealed. Before hardwood flooring is installed on top of floor SIPs, 6 mil thick black polyvinyl plastic sheets will be tightly secured over SIP floor panels and sealed at the bottom edge of all walls. 15 pound black felt paper will be laid over top the black polyvinyl, then 3/4 inch hardwood floor strips will be installed.

It will definitely cost more to build the super insulated air tight house described above than a standard 2x4 stud wall house, so I'm hoping you have read this far and will have some answers to my questions. My worst nightmare is to spend extra money building the house described above, live in it ten years, and then discover I have a moisture and mold problem.

I have been concerned about excess water vapor generated inside the house from cooking and taking showers. In thermodynamics we learn that heat always flows from the hot side of an insulated wall to the cold side. I assume water vapor also travels from the side that contains the most moisture to the side of least moisture. Since the house will have a ERV system continuously operating with its own intake and exhaust ducts, then excess moisture should be carried outside through ERV exhaust ducts. If the house turns out to be so well insulated the ground source heat pump does not run much during summer, then a dehumidifier may need to be installed to maintain Relative Humidity at 50 percent. The house design does have a fair amount of window area, so windows used have an R value of 10.

In winter, more water vapor will be inside the house trying to flow to dryer air outside. In summer, more water vapor (high outdoor humidity in this geographic area) will be outside trying to flow inside. On the interior side, there is the 6 mil thick black polyvinyl plastic vapor barrier and 3/4 inch behind that is a second aluminum foil vapor barrier. The exterior side has an aluminum foil vapor barrier. I don't know much about the permeability of these materials, but I do know water vapor flows through materials at a specified (tested rate) and is measured in perms.

I am concerned that after living in this house for 10 to 15 years, it will be determined the house walls are trapping moisture and it has a mold problem. A big mold problem inside exterior walls means your house is worthless.

Thanks for reading this far. All comments, suggestions, and advice will be appreciated.

Inslating 100 year old house

Just heard of your website from recent edition of "Fine Homebuilding". Our home is over 100 years old..all wood construction..on pier and beam foundation. We have insulated the attic, under the floor boards and blown cellulose into the walls via interior plug holes. All interior walls are stacked plank with stretched muslin/wallpaper. As we redo the walls, would it be a bad thing to apply ridgid foam sheets on the interior side before finishing with drywall or paneling?

No

Anonymous,

No, it would not be a bad thing.

2/4 or 2/6 walls

I plan to build soon , are 2/6 walls the way to go.

Anonymous

Anonymous,

2/6 and 2/4 are fractions. I think you probably mean 2x6 and 2x4, which are framing-lumber designations.

It's possible to build a very well insulated wall out of either 2x4s or 2x6s; the studs are only one component of the wall assembly. It's also possible to build a very poorly insulated wall out of either 2x4s or 2x6s.

Where do you live?

Stop reading/writing books, build something or shut up!

ASHREA requires .35 ACH. Period. If you want to trust your health to a moving fan motor, please do, it will probably reduce the amount of idiots on the planet. Did you read somewhere in a good book about home energy? Gonna show me a link to a great Dr. Scientist Know All. Do you build dozens of homes a year? Then set the keyboard aside and shut up! You don't know what you are talking about, that simple. If every house in this country were super tight, with mechanical ventilation, how many of the houses in this country would be getting .35ACH or better? Exactly, you all have boners for home energy efficiency, please put health number two on your home, cause energy is #1. LOL Single source of fresh air going through a fan motor bound to fail with no warning.......hmmm......... Wish some people I knew had super tight homes with mechanical fresh air........I could put a big chunk of poo in their air intake and they would have no idea why their house smelled like crap. Get it yet? Super tight homes are only for the super ignorant builders. I really don't give a rats ass about energy, in comparison to getting fresh air to my daughters room.

Weird smell, could it be the house isn't ventilated properly?

Hi, I just read your article. We built a new house three years ago and used a builder that wanted to be green. He assured us that our house was super tight with great insulation. However whenever we open our windows and doors we get a weird smell in the house a mix between a gas smell and a sewer smell. I've had the gas company come out and check all the lines, I've had a plumber come out and he couldn't find anything. I'm wondering if the house could not be ventilated properly. Has anyone ever heard of this? I'm not even sure who I would call to get this problem fixed. I'd love some advice. Every year when it warms up and we want to be outdoors I'm reminded of the problem and just want to get it taken care of. Thanks in advance for any suggestions.

Response to Issue Slade

Issue Slade,

I urge you to post your question on our Q&A page. That way your question will be viewed by more GBA readers, and you are more likely to get a useful response. Here is the link: https://www.greenbuildingadvisor.com/qa

Just to get you thinking: One possible reason for your odor is that (a) Your house is normally pressurized by the operation of your HVAC or ventilation system, and (b) opening the windows changes the pressure dynamics in a way that allows you to smell an odor that is usually disguised by the pressurization, and (c) you have a funky smell in your wall or ceiling (perhaps a dead animal) that is hard to smell unless the pressurization ceases. But I'm guessing.

drying

The reason that "traditionalists" talk about "breathing" a lot (even if it is a kind of misnomer) is only because of new construction practices which can inhibit an old home's ability to *dry out.* You prove nothing and make no point by saying buildings don't need to breathe or can't be too tight - it misses the point. The point is that a lot of older structures do not have air and moisture barriers. Old structures DO need to be as tight as possible in the places where it matters (the interior envelope and certain areas of the exterior envelope), but not in the areas where there is drying needed. I do agree with you that "traditionalists" can re-examine air-leakiness purportedly helping indoor air-quality. As you know, letting in dirty air through leaks in a crawlspace is making matters worse. Ventilation has to be very specific, whether in an old or new structure.

Response to Nicholas Bogosian

Nicholas,

Old buildings rot, of course, and so do new buildings. The ones that don't rot have good details; the ones that rot have bad details.

Here at GBA, we encourage builders to study good details that avoid moisture problems in floors, walls, and roofs.

It's perfectly possible to build a very tight house that avoids moisture problems by incorporating good details. Our detail library is full of information to help builders.

These details have nothing to do with breathing. What builders need to understand are the potential sources of moisture -- both exterior moisture and interior moisture -- and how to handle these moisture sources so they don't hurt the building.

Log in or create an account to post a comment.

Sign up Log in