ABOUT ADVANCED FRAMING

Less lumber means more insulation

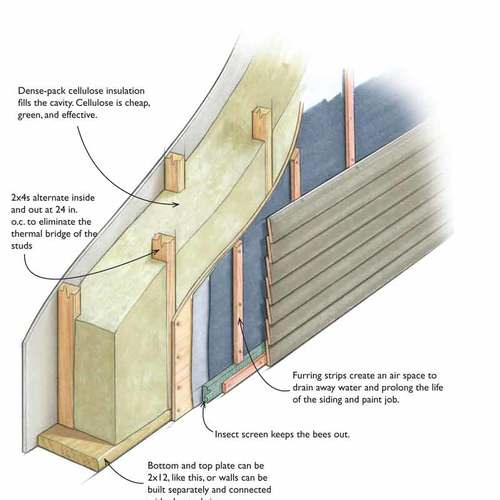

The whole point of advanced framing, also known as optimum value engineering (OVE), is to frame a house so that it meets its structural requirements without wasting material. A welcome corollary is that the same house will have more room for insulation inside the walls and will therefore be more energy efficient than a conventionally framed house. Minor downsides, for example, attaching trim in areas with less structural lumber, and wider spacing of siding fasteners, are easily overcome.

Load paths must line up

The main principle of advanced framing is to eliminate unnecessary lumber. For example, double top plates can be eliminated as long as each joist and rafter is lined up with a stud and partition walls are tied into intersecting walls with steel strapping.

Lining up framing materials in this way may require the designer to draw up a framing plan for each wall and floor.

Use more engineered wood

OSB, finger-jointed studs, laminated veneer lumber, and I-joists are all examples of reliable building products that can replace conventional plywood and large-dimension sawn lumber. Pressure on old-growth forests is reduced, waste is reduced, and better performance often results.

Omit needless wood

Using two studs instead of four in outside corners saves a lot of lumber. Instead of using the same header size over all openings, engineer each header for the load it will actually carry. Headers in non-bearing walls can be eliminated entirely.

Consider insulating sheathing

Building scientists recommend replacing OSB or plywood sheathing with rigid foam insulation. This reduces the transfer of heat and cold through wood framing, a phenomenon known as thermal bridging. Diagonal bracing and shear panels can provide racking strength.

FURTHER READING The Pros and Cons of Advanced Framing BuildingScience.com: Using Wood…

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

2 Comments

EXTERIOR WALLS ABOVE GROUND

COULD YOU EXPLAIN THE USE OF RIGID FOAM BOARD IN PLACE OF OSB AND THE DIAGONAL BRACING SHEAR PANELS YOU REFER TO ABOVE USE FOR RACKING STRENGTH. DOES ONE THEN APPLY A TYVIK BARRIER OVER THE FOAM BOARD?

THANK YOU,

RICHARD BOWER

Response to Richard Bower

Richard,

Here is a link to an article that explains what you need to know about bracing foam-sheathed walls: Four Options for Shear Bracing Foam-Sheathed Walls.

Here is a link to an article that answers you question about whether Tyvek goes over the foam: Where Does the Housewrap Go?

Log in or become a member to post a comment.

Sign up Log in