According to Jesper Kruse, founder of Maine Passive House, when air sealing a conventionally framed house is an afterthought, it is nearly impossible to get a decent ACH50 number. He believes that’s when builders rely too heavily on spray foam. He thinks getting Passive House–level airtightness isn’t difficult if you practice sound building techniques. His company has developed a few methods they use regularly to improve airtightness, minimize thermal bridging, and super insulate a building envelope.

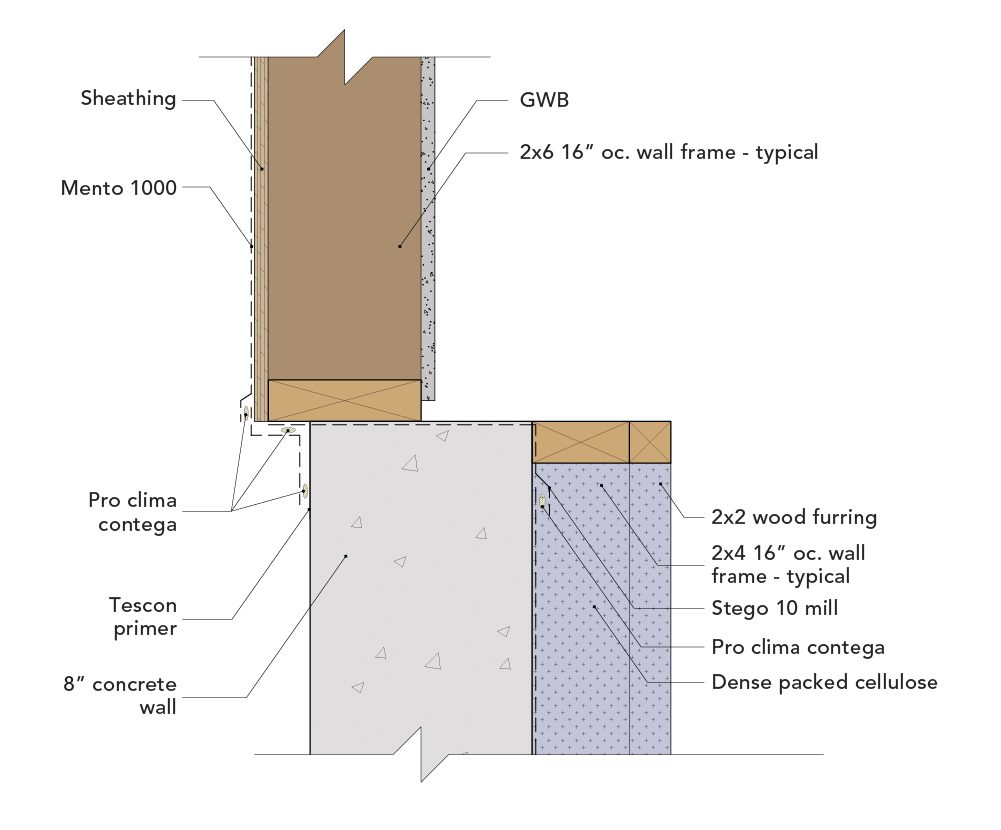

2×6 wall framing meets frost wall

This detail was developed in response to significant air leakage at the foundation, where exterior wall framing meets frost wall; they used it for the first time on a recent project and have found it to be exceptionally effective.

Previously, they had been relying on the 15 mil Stego wrap installed to the inside of the foundation wall to act as the air barrier at the joint between the main floor framing and the frost wall. But they found it was difficult to protect the membrane during the building process and winter weather conditions. With this new method, they have created a redundancy with the Mento 1000. It is an exterior air barrier as well as the WRB on this assembly; it comes down from the floor framing and is draped over the frost wall; the sill plate is then installed, and the Mento is taped to the Stego vapor retarder and to the primed concrete frost wall. “It eliminates our reliance on the Stego as the primary air barrier,” lead carpenter and project manager Anna Heath explains. Before framing the wall assembly, they add 2 in. to 8 in. of rigid foam where the main wall cantilevers out over…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

One Comment

Very interesting strategies. Overall, I really like cellulose. So the attic space above the 36" of cellulose is unvented? Only the space above the roofing membrane is vented, right under the roof panels?

Log in or become a member to post a comment.

Sign up Log in