As a small-volume builder who mostly does renovations, I have not built that many new houses in my career. But those I have built, have all been thoughtfully designed and constructed, with serious attention paid to energy-efficiency and resource conservation. Since we rarely build more than one new house per year, and often have a year or longer between new house starts, I have time to re-think my wall sections between each build. Despite that, I keep coming back to the method we’ve used since we built our first high-performance home, now over a decade ago—double-stud walls filled with dense-pack cellulose insulation, which is exactly what we did on the home shown here.

Modeled risks unproven in our builds

The ideal wood-framed wall assembly is debated constantly on GBA and elsewhere. I am well aware of the “cold sheathing” concern that comes up when double-stud walls are modeled in WUFI and other energy modeling software. I have previously described this as the Yeti of building science—it is much discussed, yet rarely seen.

We returned to our first double-stud wall house several years ago. The clients wanted to turn a window into a door leading out to a small balcony. Fortunately for our research purposes, the window was on a wall that was not only north-facing, but faced the water as well. If there was anywhere on the house where we should have seen moisture problems, it was here. Nevertheless, we saw zero signs of condensation on the sheathing.

On several more recent houses, we have buried Omnisense wireless monitors in the walls…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

46 Comments

This article is making an interesting case for double-stud walls.

When it comes to vapor barrier, recent literature on the topic and my personal experience make me think that vapor diffusion through walls is a negligible issue in most of the country. Rain water and air leakage (which can carry far more moisture) is what I worry about. A useful illustration on this is found in this Matt Risinger video. https://youtu.be/FXXgjvOJcYI?t=312

There is a minor typo toward the end: "We will often block off a bay every 8 inches to 10 inches" I think feet instead of inches is the proper word.

If someone could provide a rough number for quality dense-pack cellulose (cost per square foot of double wall or per cubic foot of cellulose installed) that would be greatly appreciated!

Vivian, 8 ft to 10 ft is correct. Each stud bay is open to the next one, so when you try to fill one bay it spills over into the adjacent bays. So every few studs you connect the inner stud and outer stud, typically with "netting," the air-permeable fabric that cellulose installers use.

Good catch Vivian.

I updated the text.

Thanks, Vivian. I think it's too hard to know if unit costs are relevant in different places. Even my different insulation subs have different prices. But I'd count on somewhere between $3-5/sf for 12" thick dense pack.

Dan,

Great article. I've been looking forward to it for ages. That house you built with Kaplan/ Thompson is one of my favorates. A couple of small questions I'd be interested in hearing your opinion on:

Is there a reason you mount your windows outboard of the cavity strapping? Builders here in the PNW were split about 50/50 when rain-screens first came out, but all mount the windows first now. It makes head-flashing back to the sheathing easier.

How important do you think the moisture buffering of the cellulose is? Would you be comfortable doing similar walls with batts?

Hey Malcolm, I can chime in on some of this...

We don’t always bring the windows out flush to the plane of the cladding but on this house it was the look the client/architect were after so that’s the direction we went. This avoids the need of extension jambs one both sides of the window but does add a bit more work for properly integrating the flashing layers. Stay tuned to GBA and FHB for an upcoming article on the methods we used on this particular project.

As far as using batts in a double stud assembly- I’m cautious of that approach. I think the reason that moisture profile modeling of double stud walls misses the mark is that it doesn’t take into account the 3D hygric buffet capacity of cellulose. No other readily available insulation can mimic this phenomenon of absorption and redistribution. Blown in wood fiber will likely perform the same when it becomes more available here in the US.

If you’re going to use a batt type insulation then mineral wool would be my choice but you need to pay extra attention to it having no voids at the sheathing interface as well as an inboard vapor retarder like Siga Majrex.

What Ben said. And I actually wrote a piece about that house a decade ago - https://www.jlconline.com/how-to/insulation/building-a-tight-house_o

Thank you Ben and Dan.

Dan and Ben,

One more related question: If the double walls are isolated - say the inner-one is sheathed on the outside as an air-barrier/vapour retarder - do you think some combination of using batts and cellulose would then make sense? Sorry if this is sort of leading things into the weeds a bit.

To extend this question, what are thoughts about blown-in high density fiberglass with "smart" air barrier/vapor retarder? There are some portions of the country (e.g. northeastern Oregon) where dense pack cellulose is not available, but blown-in fiberglass is.

I would add to Malcolm's question, wondering about Rockwool batts in particular. I used them on my house and found them straightforward to install. A good option if you don't have access to, or confidence in, a local dense-pack cellulose installer, so maybe Rockwool batts are a good option for double stud walls?

Dan,

It seems common for thick straw bale walls to have splayed window openings to allow more light into the room and to reduce glare. With your 12 inch thick double stud walls, does the deep angular window opening reduce natural lighting in any noticeable way?

I'd appreciate a photo of a finished window from the interior of a double stud wall, if anyone would be so kind as to post.

Thanks,

Aaron

I don't think it's a significant issue. Here are some pix from various projects.

The 12 inch thick window opening does not seem as overwhelming as I had imagined it might, even for this lone hung window. This window in particular and the thickness of jamb and sill have a similar look you'd find in old adobe homes here in the SW. Very nice, thanks for sharing.

2

3

Aaron,

Some pictures Martin posted of alternatives in a similar discussion:

https://www.greenbuildingadvisor.com/question/framing-splayed-window-openings-with-double-frame-walls

I find that, perhaps counter-intuitively, they somehow make the windows feel smaller.

4

Great Article Dan..do you use any type of vapor control layer on the inside of the double stud wall, and what is your typical WRB on the exterior?

Hey Tim - no, nothing on the inside but drywall. I tend toward vapor-open these days.

And we like the self-adhering WRB's - SIGA Majvest, Blueskin, etc. With rain screen.

Dan,

How easy are the self-adhered WRBs to install?

Pretty easy. Ben and crew try to do it on the ground and strap the walls for siding, so you skip the staple step.

Dan,

Thank you very much for the article. I am a little late to the discussion, but I was hoping that you might be able to address a question that I had. How crazy do you go with the drywall as an interior air barrier? Are you sealing all of your electrical boxes? Are you taping the drywall to the slab? Or is it not quite as serious as I am thinking and more so just standard practice?

Thank you for these details in the article and the comments on how this assembly is performing in the field. Maybe Dan or someone else can answer my question. Where are you connecting the 2x pieces you use to connect the two walls? Does it connect the bottom plates or the studs? I'm looking at a similar wall assembly and slab foundation for my house build.

We are also curious about what most builders do for sliding doors on this isolated slab situation where the foam is not covered by the interior wall. Do you cut a seat in the stem wall and the foam and cover with something? Looking for ideas on what works well and looks good.

Thanks,

Brad Walker

Hey Brad - it doesn't really matter where you nail. I think stud is easier than plate, but I can't think of any reason why it matters.

And there are various things you can do at doors - thin the perimeter insulation in those areas, recess it and put some other material in there, or hold to the interior and do extension jambs to the exterior.

Dan couldn't agree more about false concerns for "cold sheathing". I have never run into any of the problems that people are so concerned about. It just doesn't show up even taking apart poorly constructed osb clad buildings years later.

Anyway can you explain why you prefer plywood vs zip sheathing?

It's not a huge preference, but one nice thing about plywood (or solid wood) over OSB is that, when it gets wet, it's permeability increases. Also the baseline perm rating of plywood is higher than zip.

But we've built several houses with Zip (including the first one, mentioned in the article) with no apparent problems.

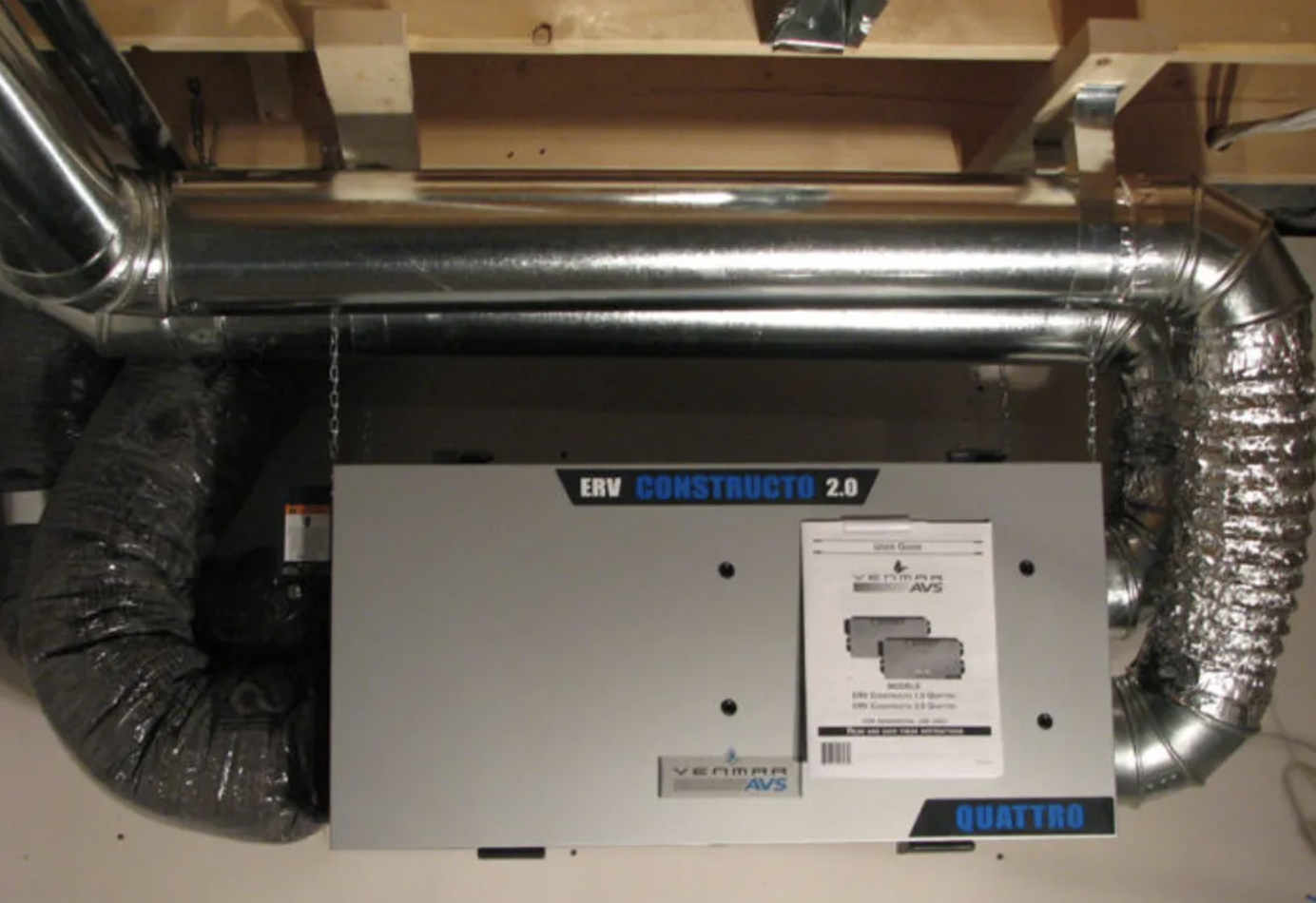

FMI - here's a video that ProTradeCraft shot last year with Ben and the rest of the crew on double wall. https://www.youtube.com/watch?v=b6xOWrmUvls

I'm curious about the interior ceiling construction. You state that you install OSB as an air barrier. Is this necessary? Wouldn't air sealing the drywall provide similar performance?

What do you install below the ceiling OSB? Are you installing strapping and then drywall to create a service cavity for electrical wiring?

Thanks.

Jim

Hey Jim - yes, we strap down. 2 perpendicular layers of strapping.

We do it to create a robust assembly that is difficult to damage and can be tested before drywall. We’ve done membranes but they’re easily damaged in that location.

Just caught version 2 of this article in fine home building. Love to see incorporation of these comments :)

I wondered why a double base plate? And inner walls have a single top plate to raise them. That’s neat but why not a double vase plate in outer wall and then drop the height using a single inside. Then you could overlap top plates as usual for inner walls? Is it because you have the ceiling joists in place so no need for overlapping top plates to secure the inner walls?

The sill plate on the exterior wall gives us the additional height for our ceiling service cavity so we can still use standard length pre cut studs and drywall.

Ah, perfect. It's like you've thought about this!

Hello Dan -

I am really interested in building, especially energy efficient, healthy, mold free building. I have a question about the doubel stud wall set up in a unique situation. We are a year and a half out from building a house (and we are actually hoping to assigned to Portland), and I really enjoy learning this stuff, partly so I can be a well informed client.

We would like to build a well insulated cabin (one floor with a partial loft) that has an interior wall of exposed 2x4 framing with tongue and groove planks on the OUTSIDE side of it. This will serve as the wall we see - we do not want to use products with chemicals like drywall, and I like the natural look of the framing being exposed (except that I think it is creating more work!).

These tongue and groove planks could serve as the "interior vapor retarder" barrier you mentioned in your article. If we were to build using a double stud method, I assume the exterior weight bearing stud wall would need to be 2x6, and spaced 6 inches away from the back of the tongue and groove planks to create the 12 inch total gap. Then you fill this 12 inch space completely with cellulose (though we were thinking real sheeps wool (not the same as rockwool)). Then on the outside of this 2x6 stud wall you would apply the sheathing (we prefer hardwood, as the moisture vulnerability and chemical offgassing of OSB and plywood concerns me, but I bet that is expensive!), and then the rainscreen, then siding. Is this correct?

Or, would we need to build THREE stud walls out of 2 x 4 - the first being the exterior weight bearing, the next being the interior-middle, which is placed with a 5 inch gap from the exterior weight bearing wall (to total 12 inches), and then the third being the inner most interior wall which is the wall we see from the inside with the tongue and groove planks on its outside side?

I've included a link below to a visual of what I mean with these exposed stud walls, and I know they insulated this old cabin from the outside, but they dont describe how they did so.

https://www.dwell.com/article/burch-cottage-lead-studios-9e7ccf52

Thankyou and I really appreciate your time in reviewing my question!

I'm not Dan, but here are my thoughts on that proposal. Some challenges you have are air sealing, fire safety, and where to put utilities like electrical wiring.

One option for wiring is to run conduit in the exposed framing, and run the wire through the conduit. If you are OK with the expense and aesthetics of that great; otherwise, you'll need to think about what you want to do instead.

On fire safety, normally, the drywall protects the structure from fire. If you have your structure exposed, you lose that protection. I'm not sure how you can address that problem.

And on air sealing, you'd normally want something continuous for air sealing behind the tongue and groove boards. I'm not sure what would satisfy your chemical-free criteria. If you just wanted to avoid drywall, you could consider MgO board. You could consider simple plywood with safe glues in them. Would cardboard, like ram board, be acceptable? You'll still need some kind of tape or sealant at the seams.

Thankyou Charlie, this all makes sense! Yes, we were thinking of exposed conduit, which can look quite nice if quality materials are chosen. And I will continue my search for non toxic materials. With the increasing awareness of indoor air quality, I think the market will offer more options in the years to come!

Emily,

I'm not Dan either (hopefully he sees your post and will comment).

The two challenges you have are:

- Sequencing of construction - which will be a lot more complex than the more conventional double walls Dan builds because of the t&g on the exterior face of the inside walls.

- The need to incorporate an effective air-barrier if you don't want to use sheet goods like drywall or plywood.

That said, it's an interesting idea. Figure those out and you will end up with a very nice cabin - albeit one what takes a lot more work to build and finish.

Thankyou so much for your response Malcom, it is encouraging to know this is possible!

Emily - for better or worse, I am Dan. Much as I may try to deny it.

We are currently finishing up a complex job that’s a mixture of reno and new construction.

The reno part is an unfinished camp (maine talk for summer cabin). Clients also wanted to leave the old framing and t&g sheathing visible. The best approach was the modified Larsen truss - in this case, using i-joists to bring the wall out to our desired thickness.

I think that’s your best bet too. If you’ve only got a roof to support, 2x4 will probably be ok for the studs. An architect or engineers can easily tell you.

You can run all your wiring in the i-joists and poke thru for outlets.

Same for roof - sheathing, then I-joists. Depending on your roofing, you may need to sheathe with plywood on top.

The t&g is useless as a barrier for anything other than your head or a raccoon. You’ll need some kind of membrane as an air barrier, and the best place to put it, I think, is right over the t&g, before the I-joist. You’ll probably want to use air tight electrical boxes, but it’s probably not a big deal if you don’t. Then a WRB at the exterior.

If you really want to do double stud, i guess you could do it the same as in the article but install the t&g on the backside of the wall while it’s still laying down. But it seems like a huge pain the ass - you’d need to do all the wiring first and poke thru as you go.

Hello Dan, and thankyou so much for taking the time to respond! Your answer was super helpful, and I've also watched the webinar you and Ben gave in double stud walls.

We were envisioning exposed wiring in conduit, which would make it a simple operation, and we don't mind that look (a shame it is actually more expensive, despite being a simpler approach!). I imagine this would also help decrease likelihood of vapor migration.

And yes, exactly - I was thinking we would line the third stud wall (the inner most) with the wood planks, then lining with a barrier before raising it.

However, I also believe in functionality and practicality, and do not believe in doing things that are a huge pain in the ass (and potentially use materials in excess) just for aesthetics sake. So we shall see where we end up when the time comes!

As I learn, my appreciation for building science and the professionals that contribute to the field (whether scientist or carpenter) continues to grow. I've got lots of grit, but am completely lacking in hands-on experience - so personally feel confident I am ill-equipped to build a safe and healthy home on my own. However, I love that the building community supports learning, and hope my efforts will contribute to intelligent and productive conversation someday with our future builders!

Thanks again for your response and wishing you a peaceful winter!

Good luck. Debating wall sections is every energy nerd’s favorite hobby.

Getting interested in building science is a good way to never sleep well again.

And building 3 walls is, frankly, insane.

I agree, insane indeed!

But I suppose much of what we do, as the collective homeowner community, is insane. A modified larsen truss that (I think?) uses 2 x 10s or 2 x 12s that are more likely to come from old growth trees. Building a house with more square footage than any human/human family would reasonably need. Building a house in that dream location that requires more use of fossil fuel guzzling machinery. Using products that are easier or cheaper despite being toxic to human health. Using products that are easier or cheaper despite production contributing to pollution. Using products that are prettier and fancier but deplete our natural resources. And, building three walls because we like how it looks.

So, as much as I hate this saying - I suppose we have to pick our poison?

I have a (possibly unrealistic) vision of building a house out of primarily non toxic materials, which includes replacing as much of the synthetic stuff as possible with other products. This means endeavoring to exchange the drywall for sustainably grown hardwood. Not only is it just energetically nicer, it would also be better for our health (hardwood is less toxic than OSB, plywood, glass faced gypsum etc, and is less likely to mold than some of those products as well). This means I have to figure out how to build wooden interior walls (that aren't of the cheesy-paneled-accent-wall variety).

Being surrounded by beauty is also important for our health and because we also want to build a small house (not tiny, just not more space than a human/human family would reasonably need), we have to get creative about how to build in charm and character so it doesnt just look and feel like a dumb box to us, and so the builder that takes on our project actually gets some sense of fullfilment out of creating it.

We also want to build a house that is well insulated, dry, and energy efficient. And so this may require a bit more work, if we also want it to be a creatively small house.

I know building codes will demand the installation of potentially toxic products to some degree, and for good reason. All-wood houses still got moldy back in the day if they weren't properly insulated, and proper insulation will have to include some chemical laden products. These all-wood houses also most certainly caught on fire easier. So, I am grateful for our modern inventions, as I dont like toxic mold or a burnt down house as much as I dont like toxic chemicals. And I know even "non toxic", "sustainable" products are guilty in some way (even sheep wool insulation, which is what we would prefer, contributes to pollution (sheep do fart, right?).

So we, as the collective, do our best to pick the least poisonous option, to ourselves, the planet, and our beloved builder who holds our dreams in his/her hands, much to his dismay :)

My desire for a creative, charming home is my poison, and it is how I will contribute in some way to the collective insanity. But my desire for a non toxic home is most certainly not insane. We worry alot about the health of our planet (and we should) but "green" to me means we also worry about the health of humans, since healthy humans are more likely to be sane, and sane humans are what keep this world from becoming intolerably unhealthy (and intolerably insane). I hope to counterbalance my contribution to our collective insanity by building an energy efficient, small home using sustainably sourced non toxic materials that will make it more likely that any who enter have a better chance of individual sanity.

Hoping you sleep well tonight Dan!

Emily,

I sympathize with what to me are sensible and reasonable ambitions. Unfortunately like much else, the green building community is a bit polarized, and I have been involved with two projects where the owners desire to reject modern building techniques (rather than just highly manufactured materials) resulted in poorly performing and uncomfortable houses. I'd suggest picking your battles, and making sure the building enclosure will work well, even if it means a few minor concessions.

One of the beauties of Larsen trusses is they’re often built from scraps that otherwise would be tossed. Definitely not solid lumber. I’m sure there’s stuff on GBA

Here’s a shot.

Log in or become a member to post a comment.

Sign up Log in