Air-to-water heat pumps generate a lot of buzz, but is anyone installing them? When we purchased our hydronics-based home in 2015, I was intrigued by the prospect of replacing the propane boiler with an air-to-water heat pump (AWHP). But no one was doing it and the equipment options were limited: the Daikin Altherma had been pulled from the market, the Sanden was being tested at a few homes in the Pacific Northwest, and I didn’t know of any other market-ready options.

Four years on, we finally took the plunge and are now two-thirds of the way through our first winter with our AWHP. I’ve learned a lot. Given how few stories are circulating about this technology, I figured I’d share ours. Before I dive in, I’ll note that many feel the industry and contractor base isn’t there yet. So, is it? I now think the answer is “yes” or at least “pretty much.”

Project goals

During our first year in the house, we had a carbon monoxide scare that evacuated us from our home in the middle of the night. It was a leak issue easily fixed by a boiler service, but reinforced our desire to wean the house from propane completely: not only would it improve health and safety, we’d never again have to deal with propane supply contracts, winter fuel deliveries, and volatile unregulated fuel prices (currently, propane costs are low, but hovered in the $4/gallon range in recent years). Given the relatively clean generation portfolio of our electrical utility, transitioning from fossil fuel combustion to electric could also help us be better climate citizens.

We could have just installed minisplits—it certainly would have been easier, as I’ll get to—but we liked our radiant slab and wanted to reuse at least some of our hydronic infrastructure, and we didn’t want minisplits heads and linesets scattered around the interior and exterior of the house.

In sum, we wanted to eliminate fossil fuel combustion in the home, improve health and safety, use existing hydronic infrastructure, be pinned to more stable energy prices, and run our home with lower greenhouse gas impacts. There were other benefits realized along the way, but I’ll get to those later.

Fixing Distribution

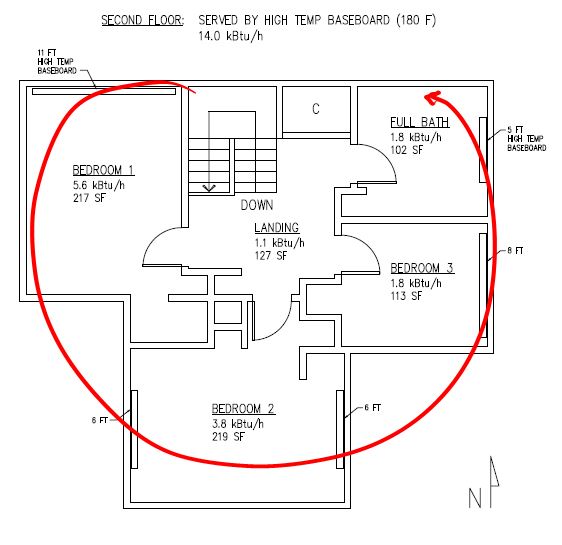

Our slab-on-grade home has radiant heating tubing embedded in the slab for the main level. The second-floor zone consisted of baseboard radiators installed in series (a single loop) serving four rooms. To evaluate the system, it was critical to not only figure out the home’s heating design load, but to calculate room-by-room loads. I used REM/Rate to get an estimate of the heating design load, and then an Excel-based UA calculator for a deeper dive and to look at the room loads.

On doing this, I found that the existing system was 30% undersized in one upstairs room—the master bedroom, which was not a surprise given our comfort experience. And that’s with 180°F supply-side water from a boiler. Now, substituting in 120°F supply water—which is a reasonable upper temperature limit for an air-to-water or ground-source heat pump—the existing emitter was about 4x undersized. The other rooms upstairs would be 3x to 4x undersized with the lower temperature supply.

This part is frustrating: If the second floor of my house had been plumbed in parallel home runs (dedicated supply and return from the mechanical room to each upstairs room), upgrading heat emitters could have been relatively straightforward. But in series, it’s was pretty much impossible to get adequate heat to the second, third, and fourth rooms in the loop after starting with 120°F water and dropping degrees every time the water hits another emitter.

The right way to do this was to get home runs to each room, but that meant ripping open a combination of floors, walls, and ceilings. This was a major barrier that we only justified (eventually, and not without major reservations) after committing to install an ERV and its duct work at the same time as the heating system work. And while we were busy ripping things apart, we decided to gut renovate the only full bathroom in the house. Scope creep? Absolutely. But these other factors were ultimately what helped justify moving forward with the project rather than just installing a gaggle of minisplits, dropping the idea of balanced ventilation, and calling it a day.

Onward. The new distribution system had to be properly designed. In 2016, I took a John Siegenthaler course on AWHPs and got some decent foundational knowledge on designing low water temperature distribution systems. People who work with ground-source heat pumps already know the options: radiant walls/ceilings/floors, high output baseboard, fan coil units, fan-assisted panel radiators, and just plain panel radiators.

I ultimately settled with panel radiators. They’re ubiquitous in other parts of the world, are mechanically very simple, don’t require power, and they’re relatively inexpensive. My room loads for upstairs varied from 1800 btu/h to 5600 btu/h. The final design included two large three-plate panel radiators (for the two larger bedrooms), two smaller two-plate panel radiators (for the bathroom and third bedroom), and a tiny two-plate radiator for a loft space.

It’s worth noting that someone accustomed to boiler installs would consider them grossly oversized. But for 120°F supply, a factor of about 0.28 has to be multiplied by the manufacturer listed output (at 180°F supply)—though they are perfectly capable of putting out useful heat at lower temperatures, most manufacturers don’t publish the output that low and you have to dig into technical literature to find it. Note that the large size of the radiators wasn’t a problem; hundreds of sizes are available, which allowed me to get creative in matching panel radiators to the unique space and window configurations of each room. And interestingly, selecting larger sizes didn’t come at a significant price premium.

Selecting the AWHP

At my home’s outdoor heating design temperature (-6°F) and an indoor temperature of 68°F, REM/Rate gave a design heating load of 31.1 kbtu/h. My own UA spreadsheet yields 32.3 kbtu/h.

Currently, I’m aware of five residential-sized air-to-water products available in the US: Aermec, Arctic, Chiltrix, Nordic, and SpacePak. All use R-410a refrigerant. Sanden makes an air-to-water heat pump with CO2 as its refrigerant, which was very appealing from a global warming impact perspective, but currently only markets a system for supplying domestic hot water (DHW); a modulating space heating version is being tested in the Pacific Northwest but is not available for sale.

I liked certain features of a split system, which narrowed things down to one manufacturer, Nordic. Though not familiar with installs using that equipment, I was comforted that they were a North American manufacturer (New Brunswick, Canada) with a product built around their long-established ground source heat pump line. Advantages of their system vs. a mono-bloc design were that it keeps most sensitive electronics and moving parts indoors, doesn’t require pan heat, crankcase heat, or constant circulation, and avoids the need for glycol, as only refrigerant passes through the building envelope. There are advantages to the mono-bloc design as well, which I’ll cover later.

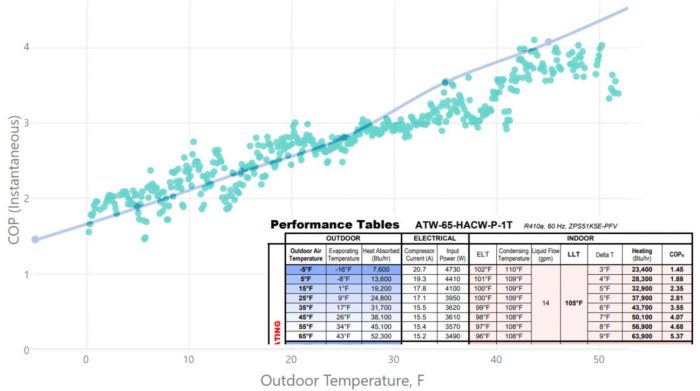

All of Nordic’s units operate down to -6°F, though at low temperatures (5°F and lower, from my understanding) it will only heat water to 105°F. Right-sizing was important to me and I settled on the ATW-65 model; at 5°F, its capacity matches almost exactly my heating load calculation at that temperature.

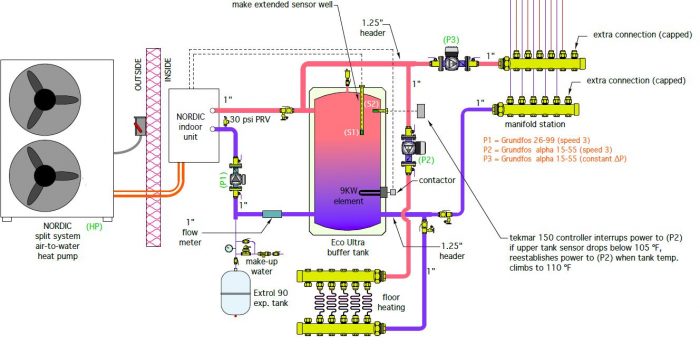

Their heat pump is designed to integrate with a EcoUltra buffer tank (50 or 70 gallon options) with an electric coil to provide backup in case the heat pump is out of commission, can’t meet the set point, or the temperature drops below the operation limit. I chose the 70-gallon version and an appropriately sized coil. For what it’s worth, published heat pump performance suffers a lot at 5°F and below; the reality is we’ll mostly burn wood when it’s that cold out.

System design

Early iterations of my design (a couple years ago) were based on a mono-bloc heat pump and circulating 30% glycol through the whole system. As mentioned above, I liked the split system in part for the reason that I could avoid having to think about antifreeze and its maintenance.

Some other decisions we made:

- Cooling: we opted against it; I didn’t want to deal with condensate lines and neither my wife nor I like A/C

- Domestic hot water: after considering various viable ways to integrate it (the Nordic has built-in provision for DHW preheat), I decided to keep DHW independent

- Piping: we decided on 3-pipe design for its direct-to-load pathway with less mixing in the buffer tank

My credo was simplicity, simplicity, simplicity, which also influenced decisions to leave cooling and DHW out of the picture. The result, I think, is mechanically elegant and repeatable. Many thanks to John Siegenthaler, who was a great thought partner and did the system schematic, and Nathan Mascolino of Efficiency Vermont, who is an incredibly knowledgeable advisor. (Disclosure: I work with Nathan at Efficiency Vermont.)

Installation

Phase I of the project occurred in April-June 2018, when I selectively tore up the house interior to put in the new distribution system for the heating and ventilation systems (and redid the master bath). It was painful and took longer than we hoped. Is anyone surprised?

I used PERT (polyethylene raised temperature) tubing rather than PEX (cross-linked polyethylene). This stuff will only ever see temperatures up to 120°F and PERT can handle 180°F, so there was no need for PEX. There are advantages to both materials, but I liked that PERT is more easily recyclable and the cost difference was not significant.

After routing the distribution from the mechanical room and into the office (losing two small storage nooks), the distribution went up a level to serve the master bedroom. These two rooms both had to be padded out 1 1/2 inches to make room for the tubing to avoid a structural beam. A portion of the distribution then went up another level into a loft space and crossed into an unconditioned flat attic (covered with R-30 of air sealed insulation), before dropping down an interior wall and into the floors of three more rooms. This was all very inconvenient, but worked out well in the end and no one who sees the home would ever know.

The project paused for nearly a year at this point. We left the boiler in place to serve the downstairs through the 2018-19 winter. We burned wood to keep the upstairs warm enough. We sleep on the cool side, so this was acceptable for one winter (and one winter only).

Phase II occurred April-June 2019. The boiler and indirect tank were extracted, our propane tank was disconnected and dug out of the front yard, and we put in a heat pump water heater to have continuity in DWH. The air-to-water heat pump installation then took place.

I was fortunate to work with a quality-focused and conscientious HVAC contractor Bill Chidsey of Solar Harvester throughout. We worked together to put in piers below the frost line for the outdoor unit and prep the indoors. He was diligent with his handling of ACR tubing (cut, ream, min. 15% silver, dry nitrogen purge, vacuum), which is critical in order to avoid refrigerant contamination, minimize future leaks, etc. This is where a mono-bloc system would shine—you avoid refrigerant lines altogether and the necessary precautions including great care taken to minimize risk of flexing and damaging joints in the long term.

Timewise, I was under pressure to get the job done (my wife was pregnant with twins), so it took some active management to coordinate the sequencing of heating, ventilation, and electrical work that had to take place. But it all worked out. I got the Zehnder ventilation system in and commissioned. Bill’s copper work in the mechanical room was impeccable and we put in a new manifold for the ground floor that would allow me to balance the highly variable ground floor slab loop lengths. An identical one was used for upstairs as well; these are compatible with zone valves if needed/wanted in the future, and each has an extra connection—for example, to facilitate installation of a small emitter if it’s determined in the future that the heat pump water heater over-cools the mechanical room.

Commissioning went pretty smoothly, though an error in Nordic’s instructions on the buffer tank setup cost a fair bit of time to troubleshoot (hopefully the manual has been updated by now). When we needed to contact their technical support, they were responsive.

Operation

The system is working well. Operation is straightforward: all the heat pump does is heat water whenever the buffer tank falls below a delta-T on the setpoint. The downstairs zone is controlled by a programmable thermostat—we chose EcoBee largely for its online portal that allows downloading of temperature and relative humidity data. A call for heat activates the single Grundfos smart circulator pump (set to constant flow) for the radiant slab loops.

The upstairs zone is also controlled by a programmable thermostat located in the mechanical room, but I’m not using it in a conventional way. I began the winter with it set to 80°F at night (when we want heat upstairs) and 50°F during the day (when we don’t need it)–basically functioning like an on-off switch on a timer. Each of the five panel radiators has a thermostatic radiator valve (TRV), and we have them dialed in to the temperatures we want: two of them are set to stay in the 50s, two keep rooms at 60°F, and the room where we all sleep is set to 68°F. This will of course change as our family grows and we start using more rooms. The TRVs are pretty slick (for more on how they work, this is a good primer). This zone is served by a single Grundfos smart circulator pump (set to constant delta-P) that adapts flow based on what the panel radiators are calling for. It’s a nice way to minimize both control complexity (i.e. things that can go wrong) and circulator electricity.

The Nordic has integral outdoor reset, which allows you to reduce buffer tank setpoint with warmer outdoor temperatures/lower building load in order to maximize COP.

One of the things I like about the design is how it minimizes extra electrical loads. As I mentioned earlier, the design of this heat pump means no constant circulation, no pan heater, no crankcase heater—items that could potentially chew up hundreds of watts 24/7. The circulator pump for the downstairs zone draws about 15W or 40W, depending on which constant speed setting I’m using (still playing with this). The upstairs circulator pump electricity use varies from about 15W-35W.

Performance

The system has a monitoring system installed: current transformers on circuits, a high accuracy turbine flowmeter on the heat pump-buffer tank loop, and some temperature sensors both integral to the heat pump and on the distribution.

The system is operating at a COP of about 3.0 at 30°F. At higher temperatures it approaches 4.0 while it dips below 2.0 when temperatures hit the single digits. My seasonal COP from November to mid-January is 2.49, which includes defrost energy.

My results closely align with the manufacturer specs and is higher than published data I’ve seen (so far) on other residential air-to-water systems. We’ve had temperatures drop below zero and it’s performing well. In fact, I’ve found that our distribution system works just fine thus far with 105°F supply water, which indicates that my heat load calculations (sized emitters assuming 120°F supply) were likely on the conservative side.

Later, I’ll process data from the entire winter and will look at total cost of this winter’s heat (new system vs. old system at current propane price), greenhouse gas impacts using 2018-19 ISO New England fuel mix data (new system vs. old system), and other items. I presented some of this—along with an overview of the project economics and several dozen photos—at the Better Buildings by Design conference in Burlington, VT in early February 2020 and will be doing a similar presentation at Building Energy Boston in late March.

For those exclusively tuned into payback, note that installing one of these is probably a big leap for an existing home, even with the generous $1000/ton rebate from (and currently still provided by) local efficiency utility, Efficiency Vermont. For new construction, I don’t think the case is hard to make. In most existing buildings, retrofitting the distribution system is a major hurdle; most of my pain (and expense) could have been eliminated had the original contractor put in home runs to the upstairs rooms.

In my opinion, anyone putting in a hydronic distribution system designed for 180°F is doing customers a huge disservice in terms of future retrofit-ability. Even if putting in a fossil fuel system today, consider:

- Install a home run to each emitter (or a supply and return loop with zone valves at the take offs)

- Size the heat emitters (radiators, baseboard, etc.) for 120°F or lower water delivery, and

- Mix down to deliver 120°F to the distribution (not strictly necessary, but a John Siegenthaler recommendation).

If you do nothing else, just do 1. Numbers 2 and 3 aren’t difficult with a bit of guidance.

Closing thoughts

Beyond dollars, cents, and COP, I’ll close with some thoughts on how this project has impacted our home. Simple payback be damned, this was a huge win for us. Why?

- We no longer have comfort issues in our home; in fact, we have highly tunable individual room control that simply works. It’s an amazing upgrade. People are surprised that we can get high quality heat with nothing more than 105°F water from the heat pump.

- We have no fossil fuels in our home—and thus a significant health and safety/risk improvement, which was very important to our family.

- We paired this installation with a high-efficiency (balanced) fresh air ventilation system—measurements of indoor air quality before and after is a whole different topic (but has had a big impact that I’ve quantified with data).

- Our first-floor slab heat is now balanced.

- Removing the boiler, removing the exhaust-only ventilation system, opening up and tightening the mechanical room, and filling all the passive air inlets in the home reduced our ACH50 to 2.1 (a 10-15% improvement).

- The heat pump water heater works symbiotically with the heating system, scavenging waste heat from the mechanical room slab, heat pump indoor unit, pumps, and buffer tank.

- Our mechanical room has become a nice cool/dry zone where we now hang laundry (which we have a lot of, in cloth diapering our twins).

How do you put a price on all of that? Simple payback is the wrong measure.

I was fortunate to be supported by great professionals, including an HVAC contractor who did a lot of learning on his own time rather than charging the customer for it. There are things I’d do slightly differently knowing what I do now (system and buffer tank size), and I’m also excited for 3-4 new air-to-water heat pumps scheduled to hit the market later in 2020 that have some intriguing features.

In the meantime, I’ll sign off with my favorite photos from the project.

Brian Just is a mechanical engineer who manages a team of energy consultants at Efficiency Vermont. Photos and illustrations courtesy of the author.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

96 Comments

Thank you for this article. Not a lof of real user experiences on this heat pump so I'm glad to see it's a great system.

I'll be building a new house next year north of Quebec city and this is exactly the system I'm planning to use. Since it's a new construction, I'll probably opt for radiant ceilings instead of radiators. The cost is about the same as installing a two zones minisplit here if I install all the radiant ceilings myself. And with minisplits since I'm in zone 7a, I would still need backup heating while this in built in the Nordic heat pump system.

I'm wondering how a passive house retrofit would compare in terms of payback and complexity. The same question would obviously apply to new construction. I'm also looking forward to your air quality review data.

Here's a quick snapshot. Typical nighttime CO2 spikes anytime bedroom door closed, in 1800 ppm range, recovering down to 600-ish during daytime (left side). Post retrofit, sails along at 800 ppm at night, gets down to nearly atmospheric levels during (unoccupied) daytime.

brian, this is very interesting and important for all of us who are creating very tight buildings now. we are installing an ERV. it would be fun to monitor CO2. what monitoring instrumentation did you use?

thanks again for all this great info.

Hi Sandy,

I used a TSI meter that was fairly pricey, but it was part of a larger research project (here's a short article on that work: https://www.nxtbook.com/naylor/ENEB/ENEB0217/index.php#/p/30). But CO2 can be measured reasonably accurately by devices in the $100-300 range. A colleague of mine has a fleet of "Air Visual Pros" that are lent out to contractors and customers in the state of Vermont and she's had good luck with them.

Whatever you purchase, if the device has a feature called "ABC" for Automatic Background Calibration, I recommend turning that off if possible. The way some devices to this is they take the lowest reading in the past 24 hours and call that atmospheric (~400ppm). If it's in a room that doesn't drop below 800 or 1000 ppm during the day because it's not well ventilated, I don't trust the ABC feature to maintain good accuracy.

Good luck! In addition to being an interesting exercise, it can help you dial in flows based on actual room usage (by adjusting registers and/or flow at the ERV) if you're so inclined.

Thank you for detailing your experience, Brian. I, too, am in New England (CT) and have been considering an ATWHP.

My home is a 1950's ranch with easy(ish) access to all rooms from the basement. If this were your layout and you were planning to install only radiant panels with TRVs, would you have gone with one of the monobloc units? Did you prefer one?

By the way, at some point in my HVAC journey I spoke to someone at Efficiency Vermont and he was incredibly helpful, even when I told him I didn't live in the state! Thanks to you and your team.

In a recent presentation, I suggested a decision tree for existing homes - see attached. Your home seems to fit the bill as a reasonable candidate. My personal decision to use a split system was not dependent on emitter type. If you only have radiators with TRVs, you could go either way. There are relatively few field studies at this point, so there's not a clear winner...

Just my $0.02; for those predisposed to cool(er) homes in the summer, a hydronic system works equally well to heat & cool. Tekmar 406 will control the delivery of cool water temps ABOVE the dew point and you can also temper incoming ERV air too.

See also, Jaga low temp convectors - heating & cooling baseboard, trench, panel, low wall. All units have small computer-sized internal fans, drip pans, and condensate lines. Huge selection of these and other heat only hydronic emitters. Manufacturer’s rep is O’leary, in Norwood, MA outside of Boston. Brian Loder handles the account.

FYI Sanden CO2 HPWHs have been used in DHW+space heating applications successfully for years. They did undergo testing (successfully) and now we're seeing dozens of systems operational.

Sanden HPWHs can deliver 175f water with no capacity loss to +5F and operation to -17F and beyond. Their output is relatively small, at 4.5KW, however, multiple units can be utilized for heat loads beyond 10kbtus/hr (leaving 6k for DHW).

Great stuff, Brian. If there are any engineers or contractors in the San Francisco Bay area who are confident or adventurous enough to retrofit a residential A2WHP in the 2-4 ton range, by all means speak up. FWIW I'm in Brian Just's "new emitters" category on his decision tree. Of course the same would be true w/a minisplit or multisplit. Those might be my destiny partly because still not enough A2W talent available.

Comment: Like Brian I don't need a/c either but if condensate drains are in place some mini splits and some A2WHPs do dehumidification, which I believe can be of benefit in marine climate zones, mine being 3C. I wonder if engineers specify controls for dehumidification mode with compressors that are not specifically rated for that mode (I could be wrong but it seems the Nordic and some other A2WHPs are not rated for it).

Sounds like a nice way to waste money. System you replaced was from 2015. I know the way things are looking with fossil fuels and give incentives to replace with electric. Wish I had the money to throw away like that.

Frank,

Your insult-sentence fragment-insult sandwich is not very helpful.

While the project may not be financially feasible for everyone, Brian's detailed article does demonstrate that air to water space heating is possible- even in a cold climate in today's market. As such, the article may become an important reference piece for others looking to build this type of system.

Hear, hear. Whether or not I would have gone this particular route, I'm incredibly grateful to Brian for both forging this path and giving such a helpful write-up of it.

The boiler I replaced was 19 years old - it was never stated that the system replaced was from 2015. I agree that had it been that new, it would have been wasteful.

Thanks for the post!

I’m curious: how would designs change if you did want cooling ?

I am exploring a similar retrofit to my 1930s era Tudor.

It seems I really need to work on lowering the loads before I can get a system like this to work.

I also want cooling though. Any thoughts ?

If I wanted cooling, I would have installed condensate lines to all of the panel radiator locations and then put in fan coil units. This would have added a lot of headache given the circuitous routes followed and the fact that I would have then needed power at those locations too -- not easy in some of the rooms. But I've seen it done elsewhere (gut retrofit project with easier access to wall cavities).

Most manufacturers and Siegenthaler's hydronics textbooks provide schematics to show how the system design would be tweaked to add in cooling.

Because I’m old enough to remember the screwing lots of people got the last time the electric companies got lots of people to do all electric houses, I’m going to hedge my hydronic HVACDHW bets in my new build ICF house. ATWHP, probably a Daikin or Space-Pak mono bloc unit with the extra condenser to make DHW connected to a good electric water heater capable off being driven by a future SV array. Duel use emitters for both heating and cooling distribution. Concrete basement slab and above the floor wood radiant heating on the main floor. HP backed up by a propane fired condensing boiler with a good rep and long warranty. Prices of both propane and electricity will continue to be manipulated and a big freeze could render the HP about as useful as a dead engine block for a while. The system is also redundant as to heating and DHW against simple equipment failure with or without a power failure or debilitating storm. A small standby propane generator backs up the power supplies of both redundant hydronic systems. The short warrantys on most of this equipment concrns me. Only the Daikin ATWP has a straight 10-yr. parts and labor want if bought from a certified installer. I think Space-Pak is 10/5. You want to buy these thing from a certified installer who is factory-trained and stocks some parts. These things are complicated enough that they are going to fail sometime. Condensing boilers make tremendously caustic acid in their condensing combustion chambers. They are essentially self-destructve. So this stuff is all environmentally responsible and may even save you some money for a while. But I think at least for now, you better get the longest warranty you can find and build in as much redundancy as you can afford and build your solar toward being off grid. If you have wood on your land and want to further separate yourself from the grid short to midterm, get a super—efficient gasifying wood hydronic boiler. No splitting. All you need is a chain saw to cut it to length. If it fits, it will burn all the way to fine ash. Extremely efficient. Way more than one way to come at all of this.

If you were not around or don’t remember the rest of the all-electric house story, it goes like this. All or most of the public utility electric companies paid incentives to homeowners to retrofit electric appliances and electric resistance heating and offered extremely low RH rates. This was in the 60’s, before the first oil crisis, the subsequent oil crises, deregulation, heat pumps, or even central air. After enough electric customers tore out their gas and oil furnaces and boilers to become dependent on the utilities, the RH rates started to go up and then disappeared. Then the utilities had insufficient generating capacity because of all the new customers they had enticed to use the absolutely most expensive heating method on the face of the planet, Naturally, they had to have massive rate increases to afford to build new generating capacity. Buyer beware.

Thanks for the detailed article. I've been watching the ATWHP space for a couple years and hoping to dispense with the gas boiler and water heater when we finish the basement. That would eliminate site fossil energy, in line with one of your motivations. While my 1930s house was almost certainly designed for 180º water, the radiators are pretty big. And the addition of Insulation and air sealing means a design day can be satisfied with 130º water... so in the ballpark for a heat pump.

PS: You are brave to have two babies in cloth diapers simultaneously. I recognize those liners!

Thank you for the writeup! What was the installed cost of this system? I’m wondering if electric radiant + PV panels may make more financial sense, especially as it’s easier to DIY.

Brian,

First off, great article. I appreciate the analytical approach and attention to detail. I’m looking forward to updates as you gather data.

Side note, my stress level rose when I saw the wall of tubes image, then you said you were expecting twins, then you said cloth diapers with twins! You are a brave/strong man. I have twin 3-year olds and couldn’t imagine adding in the effort of reusable diapers at that stage.

I like the design of the Nordic with the compressor on the interior, but does that cause noise issues?

Nordic sells an isolation pad that goes under the indoor unit and an noise dampening jacket that gets factory installed inside the indoor unit. I wouldn't consider buying without both.

I insulated the interior-facing walls of the mechanical room when redoing that room. But yes, we still hear it. Not loud, but it's there. We also noticed the boiler, for what it's worth.

Ideally, I think in a slab on grade house I'd decouple the mechanical room slab. It's probably an easier sell in a basement for homes that have one.

Thanks.

Brian,

Great article and I love Siegenthaler's work. Using constant pressure and TRVs are a great way to do a home run system. I used quite a few of john's ideas when designing our heating system with a wood boiler. I find the TRVs are fairly responsive and they make for a much cleaner mechanical room without all those zone valves, pumps, and power requirements for them. Like your system, we mix some of our return water back into the distribution supply in order to provide water temps based on our outdoor reset. The reset ratio is set pretty low. Lower than originally anticipated; at 0C we are delivering about 100F water which corresponds to about body temperature and it keeps the house quite comfortable. Once again, great article. Integrating hydronics and heat pumps is a great way to do retrofits on existing systems.

Air source heat pumps are a no brainer for buildings with a tight envelopes. Especially those who already have solar pv installed. I always recommend integrating multiple heat sources for "staging". That way, only one unit will operate and create a minimal btu output when the heating demand for the home is low, and multiple systems working together will create the maximum btu output when the outdoor temperature drops really low and the home has a higher demand. Having a great buffer tank makes all the difference in a system as well. Check out Solar assisted Heat Pumps. They are new to the U.S. market, from England, but use only a 600w compressor to pump refrigerant through a coil inside a hot water storage tank and then outside to a black refrigerant panel which absorbs heat and sunlight to assist in heating the water before returning to the compressor. I've used them on multiple applications from radiant heating, domestic water heating, pool heating, and they are the best buffer tank I know of. They have a stainless steel coil to integrate solar thermal, or boiler backup as well. They have a backup electric element for additional btu output if needed, and a 25 year warranty.

Brian - Thank you for the great article. I am looking at installing a similar system in a new build for my own house. I was a bit frustrated trying to incorporate radiant heat in my new house because I figured I would need to use a natural gas boiler until I came across the air to water heat pumps. It looks like this technology is a great alternative to mini-splits for people that want radiant heat.

Another thought and a couple comments:

Do you have historical propane consumption data to compare with your load calcs out of curiosity? I had a Man J done with Wrightsoft and it, too, was pretty conservative (perhaps 30% over on our coldest days, which were below the design temp). That's compared to duty cycle data from our Ecobee thermostat and compared to the gas bill for reasonableness.

"For those exclusively tuned into payback, note that installing one of these is probably a big leap for an existing home, even with the generous $1000/ton rebate from (and currently still provided by) local efficiency utility, Efficiency Vermont."

I was quoted $10k by two contractors to replace my 1980s cast iron boiler with a lower-end mod-con boiler without DHW, buffer tank or distribution plumbing. I haven't yet sought ATWHP quotes, though I'm guessing/hoping they'll be in the ballpark. Is that folly?! I'm in the D.C. area and there aren't significant incentives, at least in Maryland.

"In most existing buildings, retrofitting the distribution system is a major hurdle; most of my pain (and expense) could have been eliminated had the original contractor put in home runs to the upstairs rooms."

It really depends. I have access to all radiator plumbing (two pipe) in my 1930s colonial from the basement, except for two upstairs bathrooms that share pipes. Removing the iron pipes below the basement joists and re-piping with home runs to a manifold is straightforward. (Boiler replacement is intended to coincide with finishing the basement.) The radiators were sized well, though a couple bedrooms overheat a bit and will be getting TRVs.

To give you an idea, my quote for the 2 tons ATW was 10 750 CAD$ just for the unit itself.

Buffer tank is 700$, pump 300$, controls 250$ and assembling all the components on a board is 500$. After that, you only need someone to install the unit and connect the refrigerant lines.

Brian,

What a fantastic write up!

Great write-up and comments! I need to pull together data and do a write-up on my commercial and residential installs with Arctic HP (14 installs) and Chiltrix HP systems (3 installs). I have an Arctic HP/EcoUltra buffer tank radiant/DHW system on my house in Montana and have been very impressed with it even though this winter has not gotten much below zero F. Once I install an induction range I will be fully net zero - offsetting all electrical usage with solar PV. One thing I like with the A2W heat pumps is the service-ability. Unlike an A2A mini-split it would be very easy (!!!) to access and replace any electronics or integral components, and I much prefer having hydronic lines running to emitters (either radiant or low-temp hydronic emitters) instead of refrigerant lines. Although I have not run any COP measurements I can say that I have observed the Arctic units have output water temps of 120 to 125F at 2F outdoor temperature and that daily kWh usage on my small 20A HP at home is below what my calculations based on NG use in previous winters predicted. One other factor on the Arctic models is that there 3 output sizes (and a bigger 4th soon). This has allowed us to tackle bigger homes and higher commercial DHW loads (the commercial applications have been water heating only). Pls feel free to PM with questions.

I don't think GBA has a message feature, though I think I found your LinkedIn profile and will send you a message that way. Thanks.

Jeremy. You can track me down via my (outdated) Liquid Solar website. Happy to discuss

Brian

Great article. I am designing a system now similar to ours for my house as a retrofit (switching from gas furnace to radiant. Gyp over pour). At the end you mentioned several A2W HPs coming out in 2020. Can you advise of these. So I can look out for them. Curious if daikin is one of these.

Hi Colby, no Daikin that I'm aware of. Check out: SpacePak (new monobloc, new split), Taco (based on EU Dimplex), Enertech (based on EU Nibe), and Stiebel Eltron.

I am in the middle of installing an Arctic Heat setup for hydronic floor heating/cooling and hot water heater prep. Warmboard/Pex installed and pressure tested to manifold. Supply chain issues held the project up for 6 months but I finally have my 70G 18KW Alt-Source tank, 55G chiller tank and 060ZA/BE Arctic Heat Pump.

Budget is completely blown and I am very much looking to install it myself. I think I can do it - electrical is easy but the equipment order and placement, extra equipment needed (expansion tank, piping etc) are lost on me.

The Arctic manual is missing those pieces. Do you know how one could go about getting that information? It would be a very expensive mistake if I screwed up the installation.

The 120F supply temp has immediate payback even starting out with a gas boiler as that will operate a modulating-condensing boiler in the 95% efficiency range. Once it goes above about 140F, the condensing stops and it becomes a regular boiler at about 80% efficiency. The ability to switch to a heat pump system in the future becomes an added bonus.

Brian,

Thank you for your article. The information is very useful as we start construction on our home in coastal Alaska. Utilizing John Siegenthaler’s book we have determined a combination of low temperature emitters and slab heat would be best for us, so your design looks very applicable. Hopefully you might answer a couple questions as we make final decisions.

Could you explain why you chose not to incorporate the Nordic desuperheater function to preheat your DHW? It seems the DHW and heating system would still work independently.

Was your choice of ventilation system made primarily on the space you had available for duct work?

I am looking forward to seeing the performance report from your first winter.

Hi Mark, good questions! Here you go:

- I like the independence and simplicity of keeping DHW completely separate. Adding another tank and more piping (see schematic from Nordic manual below) was something I wasn't interested in for the 6 months of the year I'd utilize it. But this could certainly be something you do.

- My choice of ventilation system was based on heat exchanger performance, filtration, controllability, and space. (1) The Zehnder cores have incredible SRE and I was happy to pay a modest premium (which ended up being a minor fraction of installed cost) to have warmer air delivered on cold days. (2) It's a shame that so many HRVs and ERVs don't have the capability for MERV 13 or better filtration. I wouldn't touch a ventilation unit that doesn't allow this. (3) Rather than a single or a couple fixed speeds, the ERV I chose has great controls that can be dialed in to provide exactly what you want, where you want it. (4) It would have been impossible to get ductwork where I needed it, so the tubing was what made this retrofit possible in the first place.

A few notes from winter #1:

- I set up the ERV to supply 15% more than it returns. This helped the woodstove run better, on days when we used it. Last winter I did a long-term radon test (when our home was still exhaust only). Between the balanced ventilation and the fact that we're slightly pressurizing, I look forward to comparing results with the second long-term (6-month) test that I'm currently taking.

- ERV chugs along consuming 28-30W, about double that when we boost during cooking. I like that the ERV we chose doesn't resort to recirculation as its defrost strategy. I.e. we're always getting fresh air. Its onboard resistance heating element really only kicks in below 15F (it used about 50 kWh during the whole winter).

- We continue to love the room by room controls. We're at the portion of the year when we always stopped using the boiler, but we're leaving the nursery at 68F and still do some slab heat. It works great, and the AWHP doesn't run very often and has high COP in the shoulder season.

Fantastic article Brian! Just about as eloquent as one could get. For anyone interested in a potential game changer in the air to water heat pump space, keep an ear out in Q4 2020/Q1 2021, Taco has partnered with zee Germans (Dimplex) to bring in the Dimplex outdoor unit variable speed compressor technology to North America starting with a soft launch in Canada. May or may not disrupt the whole game and inspire Daikin/Mitsubishi/Fujitsu to get their act together a little more quickly. See vids and links below. The games begin!

https://www.facebook.com/watch/?v=636600260459312

http://www.dimplex.de/fileadmin/dimplex/downloads/produktschrift_syst/en/795-37800_MP-1-1058-EN_Sys_M_Broschuere_web_ds.pdf

We are at the beginning of a beta installation of the Taco System M unit. This is in a gut retrofit 1880's brick townhouse in NYC. Our mechanical plan has radiant floors (Warmboard), a single ducted zoned Aermec fan coil and the Taco system M unit powering both and providing DHW. I will do a writeup on the forum here at some point once its all up and running as I received so much inspiration from the contributors to this site.

Itai K, how did the Taco System M installation go? thanks for your post.

Just revisiting this on the coldest day of the Winter so far. The installation went great thanks to an excellent plumbing and HVAC contractor Chester Birchwood from NY Solar. The unit is excellent, we have achieved COP consistently over 3.5 and over 4.5 at times. Our distribution system using radiant in the winter and a single fancoil in the summer works great. Currently at 16 degrees outdoor, the heating circuit is supplying 90 degree water and the room temps (we are microzoned to individual rooms) are ranging between 69 and 74 degrees depending on occupant preference. The System M unit was initially supposed to supply HVACDHW for just the upper duplex but after some calculations we decided to also plumb in the one bedroom garden level apartment instead of a separate Mitsubishi unit and instant hot water heater. We added 2 Jaga fan assisted trench heaters to the manifold which perform amazingly well with the low temperature water supply (we don't provide a higher temperature than the radiant floor!). We can easily maintain comfort levels in the low 70's year round in the apartment and even with 6 people in the house we are yet to run out of 85 gallon of heat pump produced DHW and use the backup immersion heater.

Needless to say this is assisted by the deep energy retrofit. The house was gutted and r-30 dense pack cellulose added to front and rear walls and r-40 to the roof using the Pro Clima Intello vapor barrier and air sealing system, Triple pane Kolbe windows either casement or tilt and turn. The ERV units are 2 Broan AI units which run at 75% efficiency and with the Merv 13 filter upgrade are allowing us to average 650 ppm co2 across the day occupied and balance the humidity quite well in the summer, pm2.5 is also normally around 1 or 2 which in NYC is amazing.

All in all am close to 100% happy with the System M A2W system, they are perfect for well built modern houses. I might not recommend them for anything else though as I could see a power struggle on a cold or hot day because of how DHW takes priority over HVAC. Our house cruises through that because of the low heat loss and heat gain.

GREAT article Brian. completely relevant for my oil to AWHP retrofit project near Portland ME. i'm a wind energy engineer/researcher/CEO coming from Boulder CO that had no intention of heating with oil so our house purchase was predicated in making the conversion. i wanted a wood shop and my wife wanted a indoor endless pool and we both wanted radiant heat in these additions plus the main floor and A/C on the top floor, mostly for dehumidification. hydronics offered all these options. the house we ended up with is much bigger than we planned on but it has great southern exposure, location, real estate needed for additions so we gulped and bought it. in the end we were able to re-insulate the entire house with spray foam (we found extensive rot in the sheathing... in a 20 year old house!!!) and add new Alpen Windows (R-9 fixed and R-6.8 casements) throughout. that completely changed the heat load profile. we are using Arctic AWHPs because of their low temp performance. i want to track performance so i'm interested in how you extracted the the performance data that you published. is that data available from the Nordic controller?

another detail, we added 23 kW of PV in December. we have been producing WAY more energy than we can use till the heat pumps going in this summer. we will have banked enough energy to keep us net positive for quite a while.

thanks again for the great article. i hope to hear more as you (and i) go through our first winter on heat pumps!

Nice work on re-insulating. Nordic's indoor unit provides the water temperatures necessary for the calculation, but for your system you will need to get some temperatures so you know the water delta-T across the heat pump plus flow rate. Some meters do this in an integrated fashion, such as the Onicon BTU meter. And separately, you'd want to meter electricity usage of the circuit. Good luck with the system!

whats your heating zone Brian? Great article 100% of my clients in upstate NY want warm floors, this seems to be the only solution for that.

Hi Tim, Zone 6 over here.

In the system schematic, cold water returning from the radiators is forced to travel across the bottom of the tank. Why? At the top (hot water), this isn't the case. I ask because the heat pump is most efficient with the coldest possible input water - ie, direct from a T from the radiators, without any mixing with warmer tank water.

Jon, it's a good point. A 2-pipe design would allow return water to go directly to the heat pump. On the other hand, the way it is plumbed can potentially stabilize heat pump operation / reduce cycling. Efficiency-wise, I think any difference between the two is probably lost in the noise.

It would be interesting to see numbers. Siggy seems to agree that two pipe (vs 3 or 4 pipe) buffer tanks are best.

https://www.pmmag.com/articles/100544-the-finer-points-of-applying-a-2-pipe-buffer-tank

An addition to the list of manufacturers of air-to-water: Enertech Advantage. Variable speed, units from 2.5 to 5 tons. Looks like good stuff, made by the same company that makes Hydron Module and Geocomfort water-source heat pumps.

As of early January these Enertech units are not available but they look interesting. I have tried to find out what contractor pricing will be through their wh0lesaler but no info was available.

Todd

Check out the Gree Versati III Air to Water system. Very similar to Daikin Altherma but easier to set up programming wise.

https://www.gree.ca/collections/air-to-water

Very interesting story. I'm in a somewhat similar situation, wanting to retrofit my house, built in 2014, with an AWHP system. The good things about my house are that it already has in-floor radiant hydronic heat, with home-run piping to the mechanical room - 8 zones in all. It is currently heated by a 20kW electric boiler. The water temperature is usually in the 140°F range. We recently added 14kW of solar panels. I avoided an AWHP system because of the mechanical complexity and noise of a refrigeration system. Is it worth thinking about adding an AWHP system, and using the electric boiler as a backup?

I live in Essex Co, NY., (150mi S of Montreal).

Absolutely a good candidate for this! My suggestion would be to start by gathering data on your system to understand the parameters better:

1. Add an electric power monitoring system, such as Iotawatt, to log the electricity use of your boiler. Then you can correlate that data with the heating degree day weather records to very precisely find the heat requirement.

2. Experiment with the water temperature, setting it lower and finding how low you can go before it can't keep up.

You could just wing it by getting a system that might be undersized and relying on your electric boiler for when it can't keep up, but since you have the opportunity to find out exactly what you need with just a few weeks of monitoring, it seems like it's worth making an informed decision.

Thanks for your suggestion. A simpler way to get the heating requirement is to turn off one or two of the four heaters in the boiler (separate breakers for each) and see what the water temperature at various outdoor temperatures is. One incentive for me to do this is that I have no backup power in the event of a long power outage and a 20kW or 30kW generator is quite expensive. Haven't had any power outages over a minute to date; keeping my fingers crossed!

Check out the Gree Versati III system similar to Daikin Altherma but much easier controller set up. We have been selling these in Western Canada, Washington State and New Mexico for the past 4 years.

https://www.gree.ca/collections/air-to-water

Where in New Mexico are the installations and can you give me the name of the local installer?

This is a perfect candidate. If you don't want noise indoors, get a monobloc and use a glycol mix. With proper controls, current electric boiler is a nice backup without you adding a lot of new cost. Have someone run a heat load calc on your house or do as Charlie suggests and find actual data. This will help with sizing.

I have two air to water heat pumps, one in my home and one at my cottage. The cottage unit is suppling radiant floor heating as well as radiant cooling using Klimabelt for the emitters. I have enough capacity that so that this summer I will be adding a fan coil out to my insulated shop via a trench I will dig. The system works fantastically well and my heating bill for the entire 2000 sq ft bungalow in January was $223, my neighbor with 3 Mitsubishi heat pumps spent $334 for the month. Mind you while I leave my heat on all week I am only there on weekends and he lives full time. The comfort is second to none. Jim

Sounds great. Is there an AWHP on the near horizon which can work with standard baseboard so it can act as a simple plug and play replacement for an oil or gas boiler???

My heat pump hot water heater does a good job producing 120 degree water, but it is in a heated place and doesn't need to continually replace radiated heat...A plug and play unit that maybe produces 140 degree temps???

The Aermec ANK045 will produce 140F water but when the temperature really drops it will not so it will only work in warmer zones, the Aermec NRK will do it but it is a 3 phase unit. Jim

Nick - here is a bit of "light" reading on air to water supply temperatures and radiator efficiencies. https://core.ac.uk/download/pdf/4955636.pdf

Bottom line is that R-410A as a refrigerant is limited by physics to generate any more than 55C water at 8C (47F) outdoor air temperatures. As putdoor temp drops so does the capacity of the air to water unit to maintain its set point temp, or the supply water temp drops accordingly as well. The other limiting factor may be the surface area of your existing radiators which were designed to produce some many BTUs based on 160F or 180F incoming water temperature. There are new generation heat emitters that are designed for lower water temperatures to get the same number of BTUs out.

We are using fan coil units with our Chiltrix CX34, because we need heat and cooling, in Maryland. It looks like your are using 1/2" or 3/4" tubing. We used 1" pex. We have the DHW on the same system, a 3 way valve makes the switch. All home runs for the Pex.

Hi Brian, I'm looking at replacing our NG boiler/radiator in our 1920 tudor in Baltimore with probably more than one Chiltrix with FCUs so we can get heat and AC. How is the Chiltrix working for you in this climate? It sounds like you replumbed to incorporate the home runs, that sounds like a daunting task for a retrofit. How did it go for you? Thanks

It’s 2021, and in 2017 or earlier we tested for a year, on a Seattle passive house with an Sanden 80 gallon tank for in floor heat…Couple of burps, but no major issues?

Tandem was never meant to heat a home, but it works… far far healthier then refrigerant, it uses co2 and is an Air-to-Water heat pump and works down to -20!

Hi Brian, thanks for the article. I'm way out of my league among this crowd, with almost no technical knowledge of heating systems, but I was still able to glean a little from your piece. I'm preparing to renovate my historic, poorly insulated home in the Boston area and the project will almost certainly include an update of the heating system. Like you, I'd prefer to keep a hydronic heating system, and I dream of getting rid of the gas-fired boiler at some point. It may not be possible this go-around, but I want to at least make sure I'm not making investments in heating infrastructure that will make a conversion to an electric system more difficult in the future. But the bottom line is that I lack the knowledge, time, and confidence to make these decisions myself. Do you happen to know of any good consultants, plumbers, or other technicians in the Boston area that might be able to provide me with an informed perspective on my options? I would greatly appreciate any guidance.

Thanks very much,

Alex

Hopping to see an update on your experience. Your article prompted me to consider replacing my twenty year old cast aluminum condensing boiler with the newly available Enertech "Advantage" air-to-water heat pump which is possibly the only thing available to me here in the St. Louis MO area. I have an existing in-slab and underfloor radiant heating distribution system.

Hi Brian great writeup! What's the follow up to the tease line: "There are things I’d do slightly differently knowing what I do now (system and buffer tank size)"? I'm sizing my own system and debating whether to: 1. size larger to cover more heating hours, and accept some cycling during shoulder and cooling seasons (even with buffer tank), or 2. size for a -13C (8.6 F) balance point (in Zone 6, -22 C (-7.6F) 1% design temp) and accept ~240 hours of electric boiler auxiliary heat with fewer hours DHW preheat.

Robin, I think the answer depends a lot on what equipment you are looking at and how much modulation it is capable of. Also might depend on how well insulated your house is, not just for how low the head load is, but also how well it can ride through a cold night or a cold day below the balance point. And finally, it depends on your level of certainty about the load. An option might be to heat with electric only for a month to find out with more certainly what your load is.

A big buffer tank might be valuable in the future if consumers can get reimbursed for offering flexibility in timing of electric consumption. Tanks big enough for that are expensive but might become cheaper if that option become popular. So maybe leave room for one?

A 1000 gallon, non-pressurized plastic water tank is around $1000. Combined with a heat pump for heating, there is the potential for lower electricity cost and better COP.

Charlie,

The three caveats are:

- Make sure your tank is rated for heated water.

- Check that it is allowed by the local authorities where you are (ours don't allow them without engineered seismic hold-downs).

- Run it by your insurer.

Thanks Charlie, your input is much appreciated. The Hydro Solar house brand AWHP units are capable of modulating compressors down to 46%, and pumps down to 60%, for an effective minimum 27% (but only at a greater delta T EWT/LWT than it may ever see). A 4-ton unit would virtually eliminate the need for an auxiliary electric boiler (a 4.5 kW element in the buffer tank would be fine), narrowing the first cost differential , but potentially leading to cycling above ~20 F, where a smaller unit would modulate and run almost continuously (but without much extra capacity for DHW).

The interior equipment is going in basement, so a buffer tank large enough for what you describe would be a physical challenge, even though it's a great suggestion for a new build. I'd have to excavate below the slab (and probably underpin some column footings), even if I could get the tank down there. :) I was only intending on ~ 50 gallons to smooth things out a little for zoning (1 AHU/floor * 3 floors) and to cover defrost cycles.

Your comment about certainty of loads is on the mark. My own UA calcs, and timing of overnight gas furnace cycles last winter (admittedly before some further insulation and air sealing took place) suggest significantly higher heating loads than my Carrier HAP calc. At the very least, I am very confident about the upper end of the load. If I could wait, your advice above and in comment 46 to empirically determine loads is without doubt the best method.

I can appreciate Brian's position of separating DHW heating in a heating-dominated climate installation. It can skew your equipment sizing, and for the cost of a preheat tank and motorized 3-way valve, you're halfway to a dedicated Sanden CO2 package (materials only), if you can actually get one...

For the interest of those in similar situations, I'm appending some balance point analysis of bin hours (average of 2015-2020 historical) vs loads vs AWHP output for a 2-storey detached home + basement, ~900 ft2 footprint, R-18 (effective) walls, U-0.28 fenestration, and R-60+ attic in CZ6.

Robin, it sounds like this is an existing home? If so, you can use this to size your system:

https://www.greenbuildingadvisor.com/article/out-with-the-old-in-with-the-new

My comment about a huge buffer thank was more of an aside than a recommendation.

I don't think the compressor and pump turndown ratios multiply like that. I think it's more like with the compressor running at 50%, you want the water flow at 50% to avoid wasting pumping energy, but you still get 50% of the heat, not 25%.

I also would like to hear how the Taco installation went as I have only heard of one other installation. I have a n air to water with radiant floors and radiant ceiling cooling and it is perfect, electric buffer tank provide backup very rarely.

Thanks SO much for this article and for the amazing commentary from experts. As an interested non-expert, I'm left echoing somebody else's question above: Is there an A2W solution that allows us to leave our radiators in place, when those are made for the fossil fuel systems of the last century? This is a 100 year old house. I've done some efficiency retrofitting (air sealing, new windows, caulking, blown in cellulose in attic), but it's far from efficient by the standards of this crowd. The radiators at present keep the house warm, but I'm not sure if they would at much lower temperatures. So one question is if it ever makes sense to do an A2W system that then feeds into the boiler as well as taking care of the DHW needs, plus perhaps chilling the radiators in the hot season? The alternate is the plug and play replacement for the gas boiler, and whether than can be a realistic solution. I live in DC, and pretty well all the contractors and sellers seem to be Canadian! Many thanks to all!

Cooling with existing radiators would most likely cause big condensation issues. As for heating on single phase units the best we can do is 140F thus far commercially (3 phase) we can now reach 149F. If the windows have been changed and insulation upgraded 140 F Might work but a heat loss calculation would be the way to check. Option two is to use an air source heat pump on the days that 140F or 131F will keep you warm and have the heat pump turn the boiler on when it cannot keep up. At the same time the heat pump would go into standby mode until the out door ambient rises above the setpoint. At my cottage my heat pump is operated this way, I run the heat pump to 0F and bring on the backup below that. Jim

Thank you! I had not thought about condensation with the existing radiators. I have a spacepak cooling system in place anyhow, so that's efficient enough, I suppose. Mostly I like the idea of chilling the house with radiant. Heat is much more of a cost and also the main consumer of gas in my house.

OK, will turn my attention to the heat loss calculation.

On your Option two, what kind of air source heat pump are you thinking of? One of the ones discussed here, or some other technology? Thanks!

I represent a certain manufacturer in North America so i am a little biased. Pick a unit that has a track record in North America and you should be fine. There are many units that come and go under different names is the issue. Even Spacepak has a new heatpump that they are promoting, relatively new but looks ok. Jim

Got it! Many thanks for the wisdom.

Hi Brian, great article and comment string, and still very relevant. I'd like to elaborate on your comment re: an advantage of Nordic (versus mono-bloc) is no pan or crankcase heater or constant circulation. This implies, perhaps unintentionally, that these are inherent disadvantage of the mono-bloc design, which is not the case.

I'll explain the purpose of the heaters for those unfamiliar with the details. First, the crankcase heater... Liquid refrigerant naturally migrates to the coldest point in the circuit between cycles. At the end of a heating cycle, the evaporator is the coldest point (i.e., outdoor coil in split system). In cold weather, the compressor sump can get colder than the coil, drawing refrigerant into the sump. This reduces the effectiveness of the oil. Adding heat to the compressor housing ensures this won't happen. The pan heater prevents ice buildup in the bottom of the outdoor cabinet that could damage the coil. This ice is primarily the result of defrost water that refreezes in the pan.

All cold climate heat pumps must address these issues one way or another. In general, split systems are more susceptible to liquid refrigerant migration than mono-blocs. The Nordic split ATWHP avoids this problem altogether by locating the compressor indoors. And according to a technical rep at Nordic, it doesn't need a pan heater because the evaporator coil is sloped and raised up on legs with no bottom pan. The forthcoming Stiebel Eltron ATWHP avoids the need for pan heat by the proximity of the refrigerant tubing just above the pan that feeds the evaporator coil. Warm refrigerant entering the bottom of the coil warms the pan. This also increases subcooling. A small heating element is available for the condensate drain tube as required in very cold climates.

One way to avoid the need for pan heat was suggested by Mike Miller of Taco: route the pan drain into the ground beneath the frost line so the condensate can drain into the soil.

Moreover, your claim that "these items.. could potentially chew up hundreds of watts 24/7" overstates the penalty. Crankcase and pan heaters typically consume in the 10's of watts each, at least the ones I've tested, and they don't operate 24/7. There's usually a temperature or demand based controller to minimize standby losses. The Chiltrix mono-bloc operates its circulator at very low speed (and power draw) during off-cycles to ensure it recognizes a load and to prevent loop water from freezing.

I think manufacturers could do a better job disclosing these parasitic power requirements, but the onus is on the designer to sort sort it all out. Just to clarify, I'm in no way trying to trash Nordic's ATWHP. In fact, I think it's a great design, but as you said, each type of ATWHP has its pros and cons.

Great article. I am trying to learn about the practicality of replacing our propane boiler in floor heating system with an ATWHP system. House was built in 1995, ground floor is 2,000 sq ft, in floor hydronic with a 105.000 BTU boiler. Second floor is about 1000 sq ft and is heated by in wall electrical resistance type heaters. Our house is near Seattle (Whidbey Island). My question is who can I go to to get an evaluation of a conversion to an ATWHP system?

Hi Brian, I may be able to help with that [email protected]

I see this thread heated up again (no pun intended). I recently saw an article regarding a new heat pump that was developed by the Dutch heat pump company Feenstra in partnership with a Swedish utility called Vattenfall>According to the article this unit can produce high output temperatures of 60-80C using a C02 compressor and a fairly large buffer tank...... The article said that the roll out of the system is coming soon but otherwise was cryptic...Obviously if this works as advertised this would be the plug and play game changer for those who have existing hydronic delivery systems based on 160-180F water. Has anyone seen any more information about this system?

Thanks Brian.

I don’t think I saw it in the comments but after a full winter we’re you able to gather the comparison data with your previous propane boiler?

Thanks!

Steve

I’m on Vancouver Island. Have to replace my heat pump system as the compressor went in my Payne exterior unit. I think we pushed it too hard to get the need temperature to heat my floors. Local contractors want a fortune to fix. I am looking at the Spacepak 5 ton split. I am also looking at Arctic 5 ton mono block (but only 1 or 2 year warranty ) I think I like the Spacepak since no glycol (currently quite expensive). I need 115f to 120f (we tried pushing Payne to 112 :-( . Anyway, anyone have concerns with Spacepak?

I need to make a decision about what heating system to go with in our home in Moretown, VT that we are currently building and would appreciate recommendation and/or pros and cons of the three systems we are looking at. Our house is one story on a slab about 1400 square feet. If you need any more information about house please let me know. Here are the 3 systems:

1)air to air heat pump (4 heads)

electric radiant heating (wire under tile) in Kitchen, mud room and bathrooms

this is the cheapest way to go and the one our builder is recommending

We also will have a 45 BTU wood burning stove -hearthstone

This system not including wood burning stove will cost us around 25,000

2) air to air heat pump (4 heads)

propane boiler for radiant floors and hot water

We also will have 45 BTU wood burning stove- hearthstone

this system will cost us around $40,000 not incuding wood burning stove

3) air to water heat pump for radiant floors and hot water

fan coils for AC

We also will have 45 BTU wood burning stove- hearthstone

this system will cost us around $50,000 not including wood stove.

Solar Panels are not in our budget for this year but do hope/plan to add solar down the road.

Looking forrward to your feedback

Glenn

@Glenn, $40k-$50k for heating a 1400 ft2 house is crazy, IMO. Even $25k sounds high (although admittedly I don't know your market). You could probably save some money on option 1 if you can find a way to install a ducted system (cold-climate heat pump), thus avoiding all those heads, and the need for expensive electric floor heat in rooms without a head.

For domestic hot water, propane may not save much if anything compared to a conventional electric water heater. Here's the math: divide average $/gal for propane by 0.916, then divide by water heater efficiency as a decimal to get the price per therm (100,000 BTU's). To get the equivalent $/therm for an electric heater, multiply price per kWh (excluding all fixed charges) by 29.3, then divide by electric water heater efficiency (typically 0.93). For example, if propane averages $3.50/gal and electric rate is $0.14/kWh, a 90% sealed combustion water heater would cost about $4.25/therm to operate, while a standard water heater would cost about $4.41/therm. When relative costs are close like that, electric wins due to the significantly lower first cost, no storage tank fees, and especially eliminating an in-home combustion appliance.

As an aside... a little extra heat in the bathroom is nice, but I've always thought radiant floor heat is the wrong way to go for secondary heat in a bathroom. Here's why: radiant floors, especially when combined with mass, require more energy to charge the flywheel, so to speak. That's great for continuously heated living space, but most people are in and out of the bathroom before a radiant floor has time to produce much heat in the room. Sure, you can use a timer to turn on the floor heat an hour ahead, but a small electric baseboard or toekick convection heater works instantly and thus will use less energy overall, as it only needs to operate when you need the extra heat. For example, after a shower. I can't count the number of people I've talked out of a radiant floor in the master bath ;-)

David Butler

Optimal Building Systems

I agree about cost - we are in our 70s and are looking to balance both comfort and cost. We have already invested in the pipes for radiant heating but that has only cost us 1500 so we and are builder are looking for less costly heating systems. If we go with an air to air heat pump system and woodburning stove for the colder days and power outages - our main concern would be comfort due to the cold floors - what about ways of better insulating the floors in the living areas especially - living room bedrooms etc. . I found this website that addresses that option: https://www.rockwool.com/north-america/products-and-applications/floor-insulation/ Look forward to your response

Glenn,

As David said, a floor with adequate sub-slab insulation should track the air temperature of the house pretty closely. It will still be a hard, unyielding surface which will feel cold on your feet. I've lived with slab floors for over 25 years I like them, but wouldn't characterize them comfortable. If that is important to you, you will need supplemental heat in the slab.

The dilemma is that that amount of heat necessary to make the floors comfortable is large enough that it would become your main source, and the proposed heat pumps would become largely redundant.

@Glen, you can install either Rockwool, EPS or XPS Styrofoam under a slab. Keep in mind that sub-slab delta-T will be much lower than walls & ceilings so the R-value (for an unheated slab) quickly hits diminishing returns. Anyway, the edges are where the action is at.

Your floors obviously won't be as warm as with a heated slab, but if your house is tight and well insulated, the floor temp required to maintain setpoint won't feel warm to the touch anyway (otherwise your home would overheat).

BTW, I'm surprised you're going with slab-on-grade in that climate zone. If you haven't already broken ground, you might consider excavating for a heated crawl space and put the air handler & ducts under the floors. Given the frost line in your climate zone, the footings will be deep enough for plenty of overhead clearance, unless builder plans to go with 'frost-protected' shallow foundation. In that case, dropping the footings for a crawl would be a bit more expensive.

David Butler

We already have foundation. I forgot to mention we are planning on having tile over the slab in kitchen, mudroom and bathrooms and floating engineered woods floors in rest of house. Sounds like our only option at this point is to go with air to air heat pumps and wood burning stove and cover floors with rugs or spend alot more money for either the propane radiant heating and/ or even more expensive air to water heat pump with fan coils for AC. I appreciate everyone's detailed comments.

@Glen wrote:

>...or spend alot more money for... radiant heating...

As I said, even if you went with radiant floors, the entering water temperature wouldn't be high enough to make the floors feel warm to the touch. Typical floor temps in tight homes built (and verified) to current energy codes are in the upper 70's. Said differently, the more efficient we make the building enclosure, the less sense radiant floors make (and radiant heat in general).

Socks and/or slippers have worked well for me over the years :-)

You'll get more comfort benefit by spending an extra few grand on upgraded glazing and advanced air sealing (blower door verified!).

David Butler

"Solar Panels are not in our budget for this year but do hope/plan to add solar down the road."

What level of insulation and air-sealing are you planning? How much is installed solar per watt in your area?

PVWatts shows 12 kW of PV will generate about 15,000 kWh/yr in your town. For a 1400 SF house, that's an available energy use intensity of about 115 kWh/m2. Does that amount of 'free' electricity let you meet heating and cooling needs using a system with lower upfront HVAC costs, assuming a well-insulated, tight house?

Hey Brian, thanks for the thorough article. I'm curious, does a below freezing vapor line temperature pose condensation/freeze risk on the indoor portion of the piping? Working in commercial HVAC/refrigeration, it's typical to see fairly well insulated suction lines forming ice in lower ambient conditions. I assume you used a high wall thickness closed cell foam to insulate the piping?

Log in or create an account to post a comment.

Sign up Log in