Whether you’re thinking of getting a heat pump or you already have one, knowing these heat pump basics can help you get the right heat pump and operate it properly. The Inflation Reduction Act (IRA) here in the U.S. has made some nice incentives available to help homeowners switch to heat pumps. I’ve covered a bunch of heat pump basics below, but this is just a start. Click the links here to go deeper.

One limitation in this article is that I’m covering only air-coupled heat pumps with forced-air distribution systems, sometimes called air-to-air heat pumps. Now, let’s get started.

What a heat pump does

Let’s begin with the most basic of the heat pump basics. How does a heat pump get the heat it delivers to your home? It’s simply moving it. A refrigerator, which is a type of heat pump, moves heat from inside the box to outside. An air conditioner moves heat from indoors to outdoors.

A heat pump does the same thing an air conditioner does when the house needs cooling. But when it’s cold outdoors and the house needs heating, it moves heat from outdoors to indoors. Yes, this really works.

3 types to choose from

This past summer I wrote about the three basic types of heat pumps. (These types also apply to air conditioners, furnaces, and boilers.)

- The most common is fixed capacity. It’s either on or off. It’s either moving all the heat it can, or it’s not moving any heat at all.

- The second is multi-stage. It can operate at two or more heating capacities, which helps with comfort, noise, and power use because it more closely matches the capacity to the load.

- And then there’s variable capacity. It can change the heating capacity smoothly from 100 percent down to some bottom end, which could be as low as 20 percent. Mini-split heat pumps are in this category.

Heat pumps come in all three types. In our HVAC design projects, we do mostly variable-capacity or multi-stage equipment because of the load-matching advantages.

Here’s another one of the heat pump basics, and it’s super important. All heat pumps going into new homes should be sized according to a Manual J load calculation and then the Manual S equipment selection protocol. In existing homes, the best way to determine how much heating and cooling you need is to monitor equipment runtime and capacity. For example, if you have a 60,000 BTU/hour furnace and it runs only 30 minutes per hour at design conditions, you really need only about 30,000 BTU/hour of capacity.

Sizing a heat pump can be tricky, though. Since this piece of equipment does both heating and cooling, you have to account for both sides. Manual S says you should size for the cooling load and then make up for any lack of heating capacity with auxiliary heat (covered below).

The problem with sizing for heating shows up in homes with significant cooling loads and high outdoor humidity. If you size for heating and end up with a heat pump that’s oversized for cooling, indoor humidity levels can be too high. If you have supplemental dehumidification, you can manage the humidity, but at a higher cost. It’s best to size appropriately for cooling in mixed-humid and hot-humid climates.

And then there’s the issue of variable-capacity systems. Some people think you can’t oversize them because they can ramp down and run at lower capacity. That is wrong.

Outdoor air temperature and heating capacity

With air-coupled heat pumps, the heating capacity drops as the temperature drops. Usually, the capacity drops below the load at a temperature higher than the design temperature. That point where the capacity and load are equal is called the balance point temperature. (This is a thermal balance point. We can also define an economic balance point for dual fuel heat pumps, which is where the cost to run the electric heat pump equals the cost to heat with the other fuel.)

For example, if your balance point is at 32 °F (0 °C) and your design temperature is 14 °F (-10 °C), the heat pump can’t provide enough heat for the house when the temperature is still well above the design temperature. That means one of two things:

- If the heat pump is all you have for heating, the indoor temperature will drop below your thermostat setpoint.

- If you want to keep the house at your indoor design temperature—normally 70 °F (21 °C)—you’ll need a source of supplemental heat.

Auxiliary heat

Usually the supplemental heat is supplied by an auxiliary heat system integrated into the heat pump. Often it’s an electric resistance (strip heat) element that comes on when the thermostat calls for extra heating. So one job of the auxiliary heat is to make up for that difference between capacity and load when the outdoor temperature drops below the balance point.

The other job of the auxiliary heat is to provide emergency heat. That’s for when some part of the heat pump is out of commission but the blower can still move air through the system. It should not be confused with the need for supplemental heat. (See next section.) I’ve written an article on auxiliary heat, which will help you understand this topic better.

Heat pumps in cold climates

A revolution has occurred in heat pump technology since these things first came out decades ago. There’s a class of heat pumps that can provide a lot more heat when the temperature drops than their old-school forebears. My ducted mini-split heat pump, for example, keeps its full capacity (the amount of heat provided at 47 °F/8 °C) all the way down to 5 °F (-15 °C). Since then, the manufacturer has made further improvements so that it keeps full capacity down to -5 °F (-20 °C).

Where do you find these cold-climate heat pumps? The good folks at the Northeast Energy Efficiency Partnerships (NEEP) have you covered. Just go to the NEEP cold-climate heat pump page and download the product list and specifications.

But don’t feel like you can’t use them in warmer climates. I’m in Atlanta and going with the cold-climate version of my heat pump has allowed me to install it without auxiliary heat. And it worked well in our arctic blast last winter.

Using the thermostat correctly

Two things here. First, ignore the advice from some well-meaning people who don’t understand heat pumps. Please do NOT set your thermostat to emergency heat just because it gets cold outdoors. That turns off the heat pump and uses the auxiliary heat only. Aside from it being a much more expensive heat, it’s unnecessary. The auxiliary heat will kick in and supplement the heat pump when necessary. Your heat pump is generally 2 to 3 times more efficient than the electric resistance heat.

Second, be very conservative with setbacks. Heat pumps are slower than furnaces. If you turn the thermostat way back when you’re away or when you go to bed at night, it takes longer for it to catch up and bring the house back up to temperature. A big difference between the indoor temperature and the thermostat setpoint as you try to reheat the place might also cause the auxiliary heat to come on, costing you more money.

In short, keep the thermostat in “Heat” mode, and keep your setbacks close to the normal setback.

Heat pump air temperature and flow rate

Here’s one of the heat pump basics that people often miss. A significant difference between heat pumps and furnaces is the temperature of the heated air. A furnace will give you air that’s heated to 125 °F (52 °C) or higher. A heat pump heats the air to somewhere in the range of 90 °F (32 °C) to 110 °F (43 °C).

That’s a good thing! It means you don’t get blasted with short bursts of really hot air. A heat pump will provide its heat to the living space with longer run times or higher airflow rates or both. The result will be that the space heats more evenly, and you probably won’t notice when it’s on or off.

For new construction, it’s easy to do a proper duct design to make everything work properly. With existing homes converting from a furnace to a heat pump, things are a bit trickier. If the furnace and ducts were sized correctly—practically impossible, but stick with me here—replacing it with a heat pump would mean the ducts are too small. Because of the lower temperature air, you’d need bigger ducts to get the same heating capacity.

The good news, though, is that furnaces are rarely sized correctly. The bad news is that neither are ducts. So you might still have a duct size problem when converting. It’s possible some duct improvements will make it doable. Usually, though, the best thing to do is replace the ducts with a properly designed system.

Ducted versus ductless distribution

Ductless units are appealing because there are so many problems with duct systems in the real world. But eliminating ducts doesn’t eliminate all problems. You still need to get the heated or cool air where it needs to go. And by going all ductless, you’re substituting moving heat via air with moving heat via refrigerant. That means more refrigerant in the system, more possibility of leaks, and more refrigerant that can escape to the atmosphere.

Here’s my quick take on this issue. What we generally do in our duct designs for someone who wants ductless units is to use them in connected common areas only and put ducted systems in bedrooms. Putting a single ductless unit in each bedroom isn’t a good idea because the smallest ductless unit usually has far more capacity than a bedroom needs.

Ductless has its place, but I like well-designed ducted systems for most areas.

Energy efficiency ratings

The efficiency of a heat pump is defined by the amount of heat moved divided by the amount of energy it takes to move that heat. Every heat pump manufacturer in the US has to have their equipment tested by an independent lab to get the official efficiency ratings.

Yes, ratings…plural. Since heat pumps both heat and cool, there’s an efficiency rating for each.

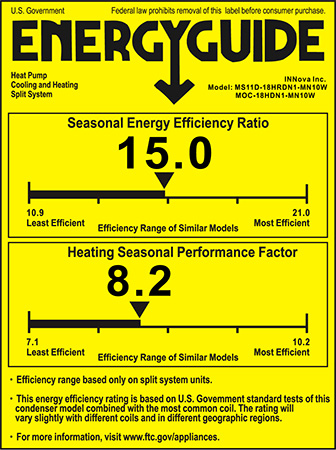

- SEER – the efficiency rating for cooling by a heat pump (or air conditioner). It stands for Seasonal Energy Efficiency Ratio, so it’s based on the efficiency over a whole cooling season.

- HSPF – the efficiency rating for heating by a heat pump. It stands for Heating Season Performance Factor and is likewise rated for a whole season of heating.

Both ratings are on a scale of higher numbers for more efficient equipment. As of 2023, the minimum SEER is 14 in northern states and 15 in the warmer southern states. The HSPF just rose from 8.2 to 8.8. The yellow EnergyGuide label will show the efficiency ratings.

The skinny

That’s quite of lot of heat pump basics, and I’ve really just scratched the surface with each of them. If you want a heat pump in your home, it’s important to understand how it differs from other heating systems. It’s also important to know its strengths and weaknesses. This article should have given you a good foundation in the basics. You can go much deeper by following the links spread throughout the article.

If you have questions, criticisms, or experiences to share, please put them in the comments below.

________________________________________________________________________

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to Energy Vanguard’s weekly newsletter and follow him on LinkedIn. Images courtesy of author, except where noted.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

8 Comments

Thanks for another interesting article. One area that wasn't covered was "What's the correct fan speed for a ducted unit?" Is it better to opt for a continuously-running fan at the lowest speed setting or to pick a mid-point or highest fan speed? My LG system allows low, medium, or high fan speeds.

You want the lowest fan speed that meets your load.

The most sophisticated systems vary the fan speed to match the load. It requires a smart thermostat. The most efficient operating mode is if the compressor is able to run continuously, that requires that the air handler also run continuously, which requires that the fan speed be matched to the load.

Thanks for the details. I wonder if my LG RED system (with PREMTBVC2 thermostat) has the "vary fan speed to match the load" capability. In a case where I have to pick one of three speeds how do I calculate / make the determination that the fan speed matches the load? (Energy Vanguard designed the HVAC system so I have the Manual J/S data on hand.)

Bill, can you help me understand the relatively new vapor injected technology. IE “Hyper Heat”

Many HPs are sold as cold climate HPs and do pretty well without vapor injection. The numbers for the vapor injected units look very impressive.

Questions

Is the indoor temp delta higher with a vapor injected compressor?

Vapor injection seems magical in that people only talk about its advantages. Are there any down sides and what would they be?

How cold does one’s climate need to be to make a return on investing in the higher cost equipment?

Walta

Walta --

Think of the refrigeration cycle: gas is compressed, the compressed gas is then cooled to around ambient temperature, which gives off heat. The compressed gas is then allowed to expand, which causes it to absorb heat (or "give off cooling"). It warms to ambient, and then it's compressed again and the cycle repeats.

With vapor injection, not all of the compressed gas is allowed to expand, some of it is fed back into the compressor. This allows the compressor to produce a higher volume of compressed gas, which means more heat is available. When the outdoor temperature is lower, the gas flowing into the compressor is colder. Colder gas is effectively already somewhat compressed compared to warmer gas, so compressing it the same amount yields less heat. Vapor injection compensates for that.

Vapor injection is less efficient, so it's only switched on when needed. If you look at the performance charts for this unit: https://ashp.neep.org/#!/product/34584/7/25000/95/7500/0///0 , it's like there are two separate lines, one for when vapor injection is off and one where it's on -- one line between 47F and 17F, and a different line between 5F and -13F.

Note also that while the capacity at 17F and 5F is the same -- 37K BTU/hr -- at 17F the COP is 2.17 and at 5F the COP is 1.91.

Walta-

Local climate aside, I've seen that some energy companies have rebates that only cold climate equipment qualifies for, which can significantly change the math for the extra equipment cost investment (without even factoring in any differences in equipment efficiency, etc.). May end up saving money by purchasing cold climate equipment in those areas, depending on rebate amount.

DC I agree with most every you said except.

“fed back into the compressor. This allows the compressor to produce a higher volume of compressed gas”

I think this statement is backward. By reinjecting you are reducing the volume of refrigerant flowing away from the compressor but that smaller flow is at a higher pressure and temperature.

I think the vapor injection increases the compression ratio increasing the differential pressure the lower lows and higher highs.

Walta

I'll accept that as a friendly amendment.

Log in or create an account to post a comment.

Sign up Log in