EDITOR’S NOTE: This post is part of the Expert Exchange series, an editorially directed and expert-driven platform for information and discussion around leading-edge building science principles and projects. The fourth quarter topic—made possible with support from our sponsor*, Rockwool—is “Choosing Products and Materials for a Green Home.” The series will culminate with a webinar panel discussion among contributing experts on Dec. 7 at 6pm ET. Click to register.

When my family decided to build our dream home in 2021, I knew the process would be challenging. Working in the design-build industry, I understood related supply chain complications, labor shortages, and price hikes would be part of the picture. I was prepared for potential delays or possibly having to change design decisions for budget reasons, which thankfully didn’t happen, but I wasn’t prepared for the challenges that came with choosing materials. I review sustainable and healthy materials on my projects all the time, so how hard could it be to select products for my own home? (Harder than I would have thought.)

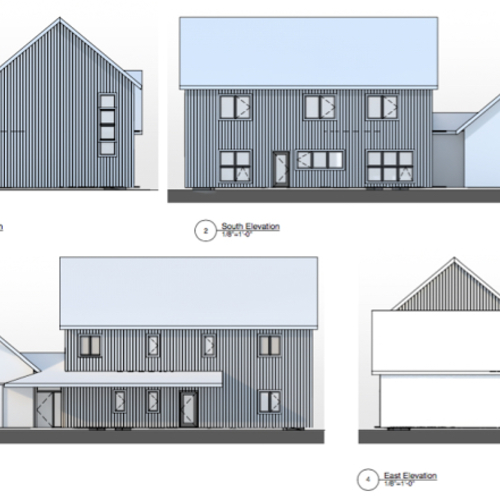

We knew from the start we wanted a high-performance home. We found a great architect who understood our goals for creating customized spaces for our family of five, plus our pets. Conceptual design or pre-planning is the first opportunity to give considered thought to selecting materials and minimizing their associated impacts. The size of the house, the roof line, and orientation on the site all influence materials.

Our house—located on 155 acres of Maine land—is considered small by typical standards for our size family. We don’t have lavishly large bathrooms or walk-in closets because we don’t need those things (does anyone?). Our road to building a high-performance and sustainable home started with our choice to live more simply, with a smaller footprint and fewer things. These decisions automatically reduced our carbon footprint and the resources needed to build.

One of our primary goals was to source products as locally as possible. This took precedence over any potential green building certification that we considered. The building enclosure assemblies didn’t change because of that objective; for example, we have double-stud walls, but the studs are sourced from local Maine mills. In fact, all framing lumber was sourced or manufactured locally, including the pine shiplap sheathing. We have the largest hemlock beams on our porch that I’ve ever seen, also from Maine. Other locally sourced materials include custom-made bathroom vanities from a maker less than five miles away, who selectively harvests wood from his own lot (and replants). Putting local manufacturers and makers first not only contributes to lowering a project’s embodied carbon, but also supports our local economy and community.

Perhaps predictably, not all of our local-first efforts worked out as planned. At the start, I spent a significant amount of time looking for a local cabinetmaker who I could work with to reduce the VOCs in the adhesives and coatings typically used. I finally found one but there were some major labor issues the month before we were to place our order; the eight-week lead time became 20 weeks, which we couldn’t absorb. We had to pivot and select a line from a major manufacturer. Cabinetry is always a challenge for projects prioritizing low-VOC emissions and material transparency. At a minimum, I suggest looking for the KCMA (Kitchen Cabinet Manufacturer’s Association) Environmental Stewardship Program seal. It’s not perfect but it’s a start toward more transparency and accountability in an industry that uses a lot of natural resources and chemicals.

As we worked with our contractor beyond those major materials, I relied on my professional experience to make things easy for him. I made a list of common adhesives, sealants, paint, drywall, and insulation manufacturers that meet the VOC emissions criteria, and asked him to prioritize products that also had material certifications such as the Declare Label, Cradle to Cradle Certification, or Health Product Declaration. Taking this approach made things simpler for our contractor when procuring interior finishes. Creating a list like this takes a bit of time but is worth the effort on the front end, if this is an important priority. We used online resources including Spot, EcoMedes, and SCS Global to develop the list and vet future selections, such as flooring and some furniture, fixtures, and mechanical equipment. These tools are free and easy to use to verify environmental and health impacts of thousands of products.

Our house is still under construction with a targeted completion date of December 2022. Stay tuned for a follow-up post, which will include specific product selection information and their environmental impacts.

*Sponsors are not offered the opportunity to review articles before publication or to edit our authors’ words.

_______________________________________________________________________

Laci Hoskins, LEED AP ID+C, WELL AP, Fitwel, is founder of NovoSustainability, a consultancy firm specializing in certification management.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

0 Comments

Log in or create an account to post a comment.

Sign up Log in