Image Credit: Image #1: Martin Holladay

Many GBA readers have built homes with 4 inches or 6 inches of rigid foam on the exterior side of their walls. Typically, these walls include vertical 1×4 furring strips, 16 inches or 24 inches on center, on the exterior side of the rigid foam. The furring strips perform at least three functions: they hold the foam in place, they create a rainscreen gap, and they provide something for the siding to be fastened to.

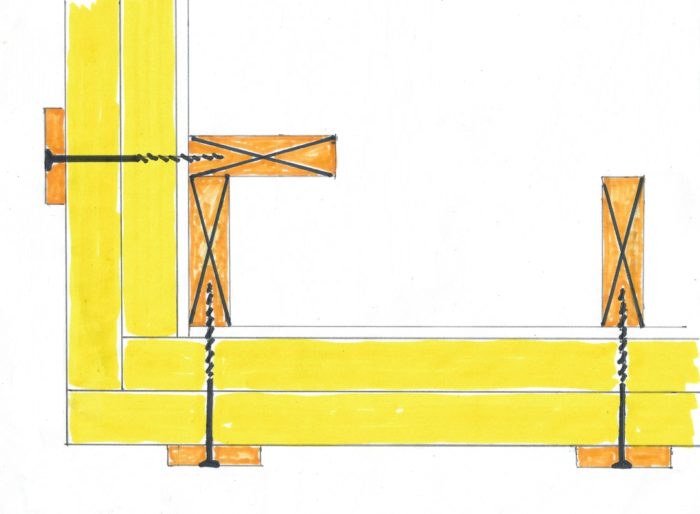

If you look at the illustration at right, you’ll realize that there is no easy way to install a 1×4 furring strip at the exterior corner of a wall with thick rigid foam. Sure, you can attach a furring strip to the stud nearest the corner — but the rigid foam extends further, beyond the last furring strip.

When it’s time to install vertical corner board trim, you realize that there isn’t anything at the corners to nail to. Oops.

OSB or plywood to the rescue

The solution is to plan ahead by installing wide strips of 3/4-inch-thick material (usually OSB or plywood).

If your house has 4 inches of exterior rigid foam, then these strips should be 6 or 7 inches wide; if you have 6 inches of exterior rigid foam, these strips should be 8 or 9 inches wide. It’s also possible to use a 1×8 or a 1×10 board instead of OSB or plywood for this purpose.

One of these strips (or a wide board) is screwed through the foam to the last stud on the wall, so that the strip extends all the way to the exterior corner. After the first one is installed, the corresponding strip on the intersecting wall is installed to overlap the first, and the two strips are fastened together at the corner with staples,…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

6 Comments

Integrated corner post with rain screen.

I am currently building a home with thick foam and using fern strips as a rainscreen/nailer. My father pre-assembled the corner posts on saw horses using 1"X 6" trim boards screwed together to form a typical corner post. Then he nailed the corner to a 3/4" nailer before attaching it to the wall. The nailer which could be any width to suit your foam thickness, was cheated out from the inside corner of the post which left a vent space on the outside corner of the foam. The corner assembly was screwed through the nailer to the framing studs in the corner. Siding was also nailed to this same nailer where it met the corner post. Of course I only am installing a measly 3" of foam to my exterior, but I can assure you it is a pain in the butt, Ah yes the crazy things we will go through to say I have super insulated walls, do you?

Response to Dillon Vautrin

Dillon,

Thanks for sharing your method.

Picture

This is an undershot before I slipped in some cobra vent. I never took a picture before it was put on the wall but this might help explain what we did. You can see the corner posts with the air space and where eventually the corner and freeze board are overlaid on the furring strip. And yes I could have painted the back side of my trim boards, but I didn't, and yes my LP smart boards warranty is void because I do not have 2"X furring strips. Call me lazy, cheap and half hazard.

Picture

Try again

How does someone meet code when using 6 inches of foam and furring strips? My inspector has informed me that i must get an engineer involved because his chart only going to 4 inchs of foam.

Thanks in advance for any guidance

Hi user-7527443 (it would be great to get your real name).

You can check out this article: Fastening Furring Strips to a Foam-Sheathed Wall, but it is only going to agree with your inspector. I think it is pretty common that you'll need an engineer's stamp when using exterior foam over 4 inches; at least, I've heard this before. And, if that's what your building official said, then, well, meeting code is getting an engineer to spec your fasteners and details.

Log in or become a member to post a comment.

Sign up Log in