Image Credit: Image #1: Louisiana-Pacific Corp.

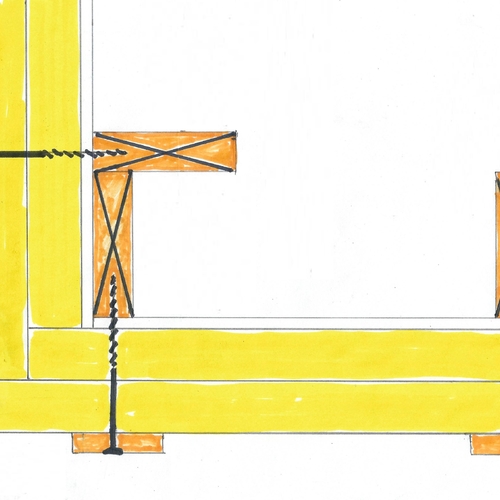

William Costello is building a new house in southwest Virginia that will be framed with 2x6s and will include up to 2 inches of exterior rigid foam insulation. He plans on installing 3/4-inch thick plywood furring strips on top of the exterior foam, and then will side the house with LP SmartSide lap siding designed specifically for houses with 24-inch on-center framing.

It all sounded straightforward enough until Costello took a close look at the installation instructions from LP Building Products.

“I discovered that LP’s installation instructions specify 1.5-inch by 3.5-inch furring strips for foam greater than 1 inch in thickness,” Costello explains in a Q&A post. “So I guess that would basically mean a 2×4 stud for every 2×6 stud in the wall. This is more material and expense than we had bargained for, and perhaps also more increase in wall thickness than we want for window installation.”

He double-checked with LP to make sure that’s what would be required to maintain his warranty, and indeed that’s the requirement. There’s a chance he could keep the thinner furring strips if he used fasteners for the siding that were long enough to bite into the 2×6 framing, a rep told him, but he’d need written approval. That would leave him with buying more expensive fasteners, so the option isn’t necessarily very appealing.

Costello sees several options: install the siding according to LP specs; install it his way and hopes he never has to make a warranty claim; use 1 inch of polyiso insulation instead of the 1 1/2-inch to 2-inch EPS and forget the vented rainscreen; or use extra long fasteners for the siding.

What’s his best option?

Next time, plan ahead

Costello’s dilemma is a good example of why better planning is important, replies GBA…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

15 Comments

Helpful?

I wonder if the engineers at LP ever spend any time on sites or in a lumberyard. Try going to the contractor sales desk and asking the specific gravity of the wood they stock. Installation guides that rely on that sort of requirement are why builders seem so resistant to changing the way they do things.

Specific Gravity of Solid Sawn Lumber or panel products

We're also dealing with this issue in our office. It isn't easy to find southern pine here in northern MN. We found documentation, linked here, that lists the specific gravity of many hard and soft woods, though they make no mention of moisture content.

http://www.wood.tcaup.umich.edu/exercises/SpecGrav.pdf

https://www.cecalc.com/WoodDesign/Graphics/SpecificGravityValues.pdf

I did find some documentation of the specific gravity of plywood and OSB. Seems to me one could specify plywood or OSB strips with a specific gravity matching LP's requirement. We recently specified 3/4" southern pine plywood cut into 3 1/2" strips@ 16" O.C., with siding fastened with rink shank nails, for our furring on a project with LP SmartSide.

Here's the documentation on specific gravity of plywood and OSB:

https://www.apawood.org/Data/Sites/1/documents/technicalresearch/paper-2006-wcte-nail-withdrawal-and-pull-through.pdf

Rachel

I can't understand why they didn't just say: these are the three commonly available materials that builders typically use as furring, and these are the thicknesses we need them to be.

I wonder what the specific gravity is on Mars?

What a bizarre chart in the

What a bizarre chart in the second attachment.

For siding at 11psf @ 16" o.c. it considers a No. 10 screw @ 1" penetration as equivalent to a 1/4" lag screw with 1.5" penetration.

This all smacks of information that was assembled without any particular science behind it. "We guessed at a bunch of stuff and put a table together". Seems like these should be plots or lookup tables instead of one catch-all table.

Peter Yost's Recommendation

I am curious about the recommendation made by GBA technical director Peter Yost when he says: "far better to attach furring to framing, then cladding to furring". Wouldn't this method create a lot of thermal breaks in the insulation layer applied to the exterior wall?

For example, if you were using a layer of 1.5" thick Roxul Comfortboards over your exterior wall sheathing then I'm assuming that you would also need 1.5" thick furring strips attached directly through the sheathing to each wall stud in order to attach the cladding. The Roxul panels would have to sit in between the furring strips. This method might make attaching the cladding easier but it seems to defeat the purpose of having a continuous exterior insulation layer.

“[Deleted]”

Increase In Wall Thickness

I did this to our house when we replaced the siding a few years ago. We put 2 X 4 furring studs laid flat over the foam and attached to the wall studs with 1.5 inch foam between the furring studs, rain screen over everything, and finally the LP siding. This only increases the wall thickness 3/4 inch vs the furring strips William Costello was planning to use and would only require increasing the interior window sill by 3/4 inch.

Scott

I think what Peter meant was it is easier to nail the cladding to furring, rather than right through the exterior insulation to the framing behind. At what thickness of exterior insulation this becomes true for is an open question which comes up here quite often.

I don't think he was advocating applying the furring directly to the sheathing, but rather on top of the exterior insulation, so there would only be the nominal thermal bridges of the fasteners.

What about SIP's? Is there

What about SIP's? Is there siding you can put on them and follow the manufacturers directions?

Response to Dangrs 1

Dangers,

Of course there are many types of siding that can be installed on SIPs. SIP homes are built every day, and every single SIP home has siding.

If you have any doubts about a particular type of siding, contact (a) the SIP manufacturer and (b) the siding manufacturer to verify that the products will work.

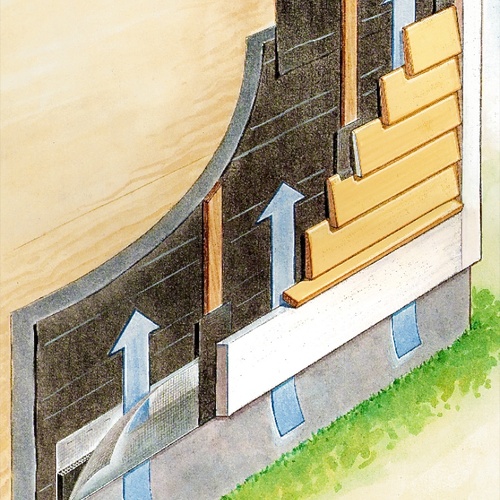

Most SIPs have OSB facings, and OSB is subject to rot if it stays wet for a long enough time. That's why most experts emphasize the importance of including a rainscreen gap between SIP walls and siding. For more information, see All About Rainscreens.

Response to Scott Wilson (Comment #5)

Scott,

Thanks for your comments. Malcolm Taylor's response (Comment #7) was correct. I have edited Peter Yost's advice to remove any ambiguity.

Still Not Clear

Even though Peter Yost’s comments have been edited it’s still not clear what he is concerned about. In his initial observation he states: “I find attaching cladding through just about any thickness of rigid insulation unnecessarily difficult”.

To me this implies that he is referring to people having to nail the cladding through the furring strip, then through the rigid insulation layer, the sheathing layer and on into the studs. That would require a nail between 4-6” (depending on the thickness of the rigid insulation).

His solution seems to be that people should be focusing on first anchoring the furring strip through the rigid insulation and sheathing into the stud with one nail and then using a much shorter nail or screw to attach the cladding to the furring strip.

If that is his intent then the issue becomes one of “what length and type of nail should be used for each part of the process” and perhaps that could be discussed.

Scott

What Peter is saying is that not using furring, and instead just trying to secure the cladding though the exterior insulation into the studs underneath is "unnecessarily difficult".

The discussion of how to secure furring through exterior insulation has been the subject of a lot of threads here - and a previous blog.

https://www.greenbuildingadvisor.com/blogs/dept/musings/fastening-furring-strips-foam-sheathed-wall

Response to Scott Wilson (Comment #11) and Malcolm Taylor

Once again, Malcolm has it right. And once again, I have edited one of Peter Yost's sentences in an attempt to remove any possible ambiguity.

LP siding with Fern Strips over insulation.

Well call me half hazard. Last year I installed LP lap, smart trim, shingles, and the 4X8 sheets of LP with batts all over 3" of continous XPS foam using fern strips. Of course I did this all knowing my warranty would be void. I did use larger diameter ring shanked nails than specified to fasten the siding to the fern strips. A year later I have not noticed any problems with the siding. In fact on my garage which has only an 1/8" thick rainscreen and is nailed directly to stud through the sheathing (which is allowed by the warranty) has a few siding and trim seams that open up in the summer and close in the winter On my home which is much larger I have only one seam opening. I am curious what LP would say the mode of failure would be due to using furring strips. Is it panel movement due to moisture content that will loosen the nails over time? I used a dark paint which should promote a lower moisture content and maybe this is preventing expansion of the panels. Who knows maybe all the siding will fall off my home in twenty years. Probably not though. Most warranties are written to cover the lowest denominator. So while it allows smaller nails, it won't allow the thinner substrate to nail to. Most commonly LP is nailed over a sheathing and can be stud nailed so it makes sense that they will write their warranty to reflect how they expect their product will most commonly be used. Not many people are installing LP over thick continuous layers of foam, so why spend much time specifying your product to do that.

Log in or become a member to post a comment.

Sign up Log in