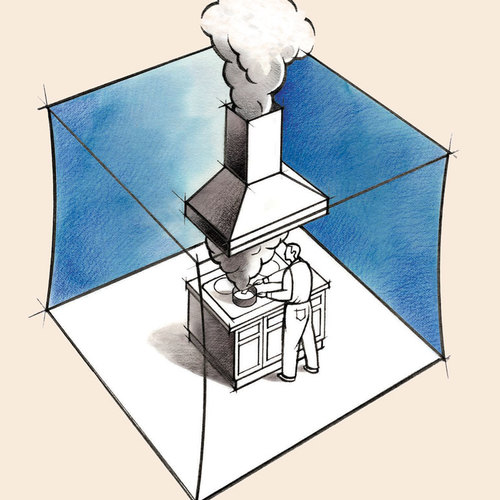

Roger is building a two-story, 3500-square-foot house that will have an energy-recovery ventilator (ERV) and a kitchen range hood. His question is about how this ventilation system will affect the range hood, and vice versa.

“Should one try to install a range hood exhaust with 400 cfm [cubic feet per minute] or less?” he asks in a recent Q&A post. “Would it be OK to install a 600 cfm unit in a home that has an ERV unit? If so, are there any special things to do differently when considering a makeup air strategy for a home that has an ERV with dedicated duct lines?”

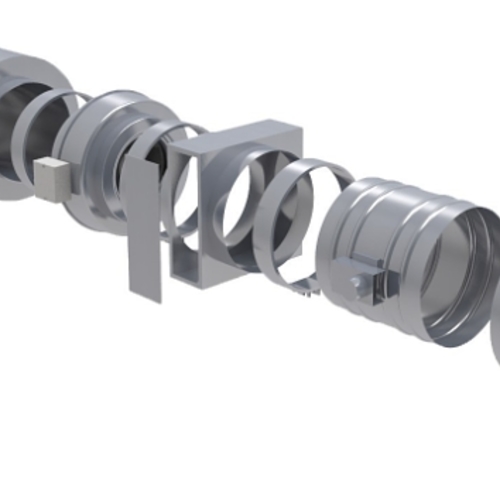

An ERV supplies continuous fresh air throughout the house with its own ducts and it exhausts indoor air at the same rate, for balanced ventilation. Range hoods provide relatively powerful spot ventilation when needed, but do not replace that air; they are an exhaust-only appliance. The topic for this Q&A Spotlight is whether those two systems can work together to maintain not only fresh air, but also to balance pressurization of the house.

ERVs and makeup air?

Nicolas Bertrand wonders whether the ERV could be installed in such a way that it provided makeup air for the range hood. “Do they have a function where they could run as an inlet only for the house and have the exhausts blocked?” he asks. “This way the hood could do the exhaust work and the ERV supply some of the required air. I know a dedicated return-air supply is normally required for a tight house, and sometimes with an inline heater if it is cold outside, but maybe there is a way to rig the ERV to take its place.”

Probably not, replies Malcolm Taylor. He knows of no ERV that can run in an…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

33 Comments

Not sure how old the table is in exhibit 1 but 1,000 CFM@50Pa is a high leakage rate for most new homes being built in my area. (Majority are under 2500 square feet and closer to 700 CFM@50Pa.) I try to steer my customers away from woodstoves and gas ranges. Make-up air is a problem in my climate, around 100 hours per year with temps below -20°F. Last heated make-up air system I worked with required a dedicated 100 amp electric service to handle the heating of the make-up air. Homeowner decided to go with an unheated system. Haven't heard how that's working out.

Visa-versa? Vice versa.

Vice versa, for sure, and that was my mistake. I intended to circle back and check it when I was working through this, but never did. Fixed now. Thanks...

Hi Everyone. I'm glad this is being addressed, if only to provide a definitive answer "no" to the oft-asked question "can the ERV provide adequate make up air for my range hood."

ERVs are sized to provide acceptable indoor air quality. The continuous mechanical ventilation rate of most homes is substantially below the flow most range hoods. Ignoring temporarily the hotly debated controversy about ASHRAE 62.2 infiltration credits, the worst-case scenario for a 2,000sf, 3-bedroom house is:

(2,000cfm)(.03cfm/sf) + (7.5cfm)(BR + 1) = 90cfm.

In Nicholas Bertrand's cook's kitchen, even the low end of the range exhaust (600cfm) is nearly SEVEN times the ERV flow rate. Simply put, the fans in an ERV sized for 90cfm will never be able to provide that much air. And if they could, the duct system would have to be sized accordingly, and only for the times when the range hood is in use. Thus the ducts would be grossly oversized for the majority of the time.

So, even if one installs a range hood rated for less than 400cfm (to avoid the requirement for makeup air) there will either be some serious depressurization or all the various penetrations in the home INCLUDING the ERV will allow infiltration when the hood is activated.

In a home I designed recently, the blower door test resulted in 0.4 ACH50 (191cfm). Of course the ERV exterior grilles were taped off. I chose a 350cfm range hood (to avoid the hassle of makeup air and the energy penalty of tempering it). It stands to reason that when the hood is activated, every possible penetration will contribute some make-up air...INCLUDING the ducts for ERV intake and exhaust. And guess what? Nobody has died, nobody notices any comfort issues, and there was no noticeable increase in the electric bill.

John Rockwell

Zehnder America

Scott:

thanks for mentioning our best practice guidance document for ROCIS.org.

For a quick overview, your readers may also be interested in the 2018 NAPHN conference presentation at Downloadable PDFs at http://rocis.org/kitchen-range-hoods. It addresses make up air, low E airtight homes, electric stoves, and recent research on ERVs and cooking emissions.

Tom Phillips

Rather than a separate heating unit for external makeup air during winter-time operation, it seems like you might be able to use the outer insulating jacket of an appropriately-sized double-walled exhaust duct to heat-exchange the incoming makeup air supply with the outgoing exhaust air from the range hood.

I was trying to figure out if this exact setup would work for a current build but couldn't get around the damper aspect. Those double walled pipes are used for closed systems like gas fireplaces where you're not worried about having to close them off to stop cold air from coming in when the fireplace isn't running. In that setup the cold air just blows through the firebox and back outside. For a range hood it'd be dumping cold air into the house all the time unless you could damper both the intake and exhaust.

For the dryer issue, a ventless heat pump dryer could be an option. But the obvious time penalty exists if moving from propane.

Afternoon all. I've been attempting to obtain a definitive answer to this exact question since 1993 when I had a 2200 sq ft bungalow built in southern Ontario near Trenton. The house was an R2000 build with 2x6 wall studs,6"wall insulation and about 12" of blown cellulose in the ceilling. The air transfer was tested when the construction was complete and the Independant tester advised that my home was the second tightest home he'd tested. The heating system was and is Hydronic Forced Air with a High Performance NG water heater (Polaris 95+% efficiency) intake and exhaust to the exterior of the structure. The house has a NG Clothes Dryer which uses inside air and vents out, NG fireplace that draws air from outside and also exhausts to the exterior of the house. I have replaced the HRV a few years ago which runs through the winter 20 minutes plus when ever the furnace kicks in. I have had an unducted range hood for years and we are in the middle of a Kitchen Reno and are about to purchase a range hood and complete said reno. What kind of power do I need? by you article I'd say about 800 Cuft exhaust, and makeup air. One suggestion was to dump makeup air over the stove, however midwinter I fear everyone would feel the cold that would accumilate 2 to 3 feet off the floor of the kitchen/familyroom. It would likely drive anyone out of the room within minutes. Adding another electrical element to heat the incomming cold air would likely be expensive to operate. ( Just paid $199 equal payment to this months electric bill.) I don't know what to do.

Signed, Scratching my head in Ontario (the hair is just about gone on top and I'm working on the sides)

The "greenest" option would be to get an induction stove and use a smaller range hood. But if you already have a stove that might not be a good option.

Otherwise I think there is no good answer. What we need is a HRV specifically designed and listed to be used with a range hood. Compared to a regular HRV, it would need to offer higher flow rates (800 CFM or more), and it would need to be able to handle some grease. I don't think anything like that exists right now.

PS: Got an engineer wound up when I told him that I was going to directly pipe the range hood into the HRV collection pipe in the kitchen. It was an interesting conversation as I made like I didn't understand his consern

I investigated several of the above suggested alternatives and found them both overly complicated and expensive. In my 1750 sq ft sip panel house with ERV(200cfm max) and 600 cfm max range hood I did the following with excellent results over the last 3+ years.

Induction cook top

600 cfm range hood with baffle type grease trap

NO make up air

No make up air heater (we live in heating dominated climate)

No range hood exhaust roof penetration

The way my system works is the hood traps grease particles then vents the exhaust into adjacent mechanical room through a large activated charcoal filter box to capture odors. There is an 8” dia. ERV exhaust duct above.

When I cook (I do a lot of aisian cooking IE: stir frying ) I ramp up the ERV and use the range hood at a flow rate that will capture vapors. I do not have odor, vapor or negative pressure problems. This approach requires a high quality grease baffle hood run at conservative flow rates and a cheap fabricated filter box and that is it. I clean my ERV filters(MIRV 13) about every 8 weeks and have not observed any grease buildup in the media whatsoever. The system is Inexpensive and effective.

I find the building science data very interesting and useful but the proposed solutions in this case have many down side that are not addressed like complexity, expense, reduced air tightness and energy efficiency. I welcome any comments or questions, Cheers

“[Deleted]”

That's an interesting solution. I wonder if conceptually it's any different than having a filter on the HRV return, and either having that return over the range, or directly ducting the hood into the return? In all three cases the system relies on the filter to keep the HRV clean.

A second question would be: Isn't it really just the efficiency of the filter you made that distinguishes any of those solutions from just using a recirculating range hood?

Could you give some details about where to buy or how to make the charcoal filter box? And how often do you have to replace it?

I appreciate the various concerns stated and agree that an ERV is not the path for hood make-up air. I also agree about not using a hood larger than what is really needed.

I think Mike Turns' info about a 10 sq. in. engineered opening not being enough is somewhat misleading. Doing the math, that's less than a 4" diameter intake (2^2 x Pi = 12.6 sq. in.).

I like the simplicity of a motorized damper that is wired to the hood fan switch and introduces the make-up air at or near the cook surface. If the intake, motorized damper is an 8" round duct (4^2 x Pi = 50.3 sq. in.), my guess is the extreme negative pressure danger isn't going to happen with a reasonably sized hood.

I live in the south and so acknowledge that our houses aren't super tight and people rarely freeze to death; I think the engineered opening is viable for us and probably is my preferred approach.

Best, -mike barcik (special greetings to Mike, Peter and Laura!)

Regarding Malcolm Taylor’s comment: Yes I agree it is conceptually the same but functionally different in that the exhaust through the activated charcoal filter is only in the same room as the ERV exhaust and not piped into the system so the opportunity exists for plenty of mixing with ambient air to occur before it is evacuated. I should also not that the activated charcoal filter is large 24” X 24” so more area than could be inserted into a pipe run. Please note the filtration is two stage, first the vaporized oil is removed and then the odors. It is basically a modified recirculating range hood strategy so no pressure imbalances and no damage to the ERV filter media and in my case less expensive than any of the other suggested solutions.

One thing that still strikes me though is that unbalance between the CFM of the range-hood and the HRV return. For short periods of use it probably performs as y0u have described. But if the range-hood is on for a while it is pressurizing the mechanical room, so the air in it isn't really ambient air, but rather is entirely supplied by the fan, and the majority of the filtered air in the mechanical room must circulate back into the house. If that is so, I wonder if it makes much difference where the mixing occurs? If you could fit a filter into the cabinet above the range-hood, maybe it would be possible to do all the same things within the kitchen.

Malcolm,

Hmm, you are maki g me think about this but here goes:

There is no pressure imbalance created by this re-circulation strategy. The overall building envelope is pressure balanced by the ERV. The range hood is taking a portion of that air and moving it from one area to another (the spaces are adjacent and communicating as in no separating door so no opportunity to over pressurize the mechanical room which is quire large and should actually be called the mechanical/laundry/storage room. The air in the mechanical room does not recirculate back into the house because it has a oversized(8”) ERV exhaust duct. You could fit a filter into a cabinet above the range hood as you suggested but then you might as well just get a manufactured recirculating fan. The downsides are the units I looked at had very limited filtration capacity except for one with very expensive activated carbon canisters. I think the important considerations if you go that route is make sure you have oil vapor baffling in the hood (like restraint fans use) and an ER V exhaust in the same room as the fan discharge.

By the way we cook and bake A LOT and do not have any odor or excess humidity problems in an very tight air sealed house.

I don't want to nit-pick at what is an interesting and obviously effective solution (and by the way - nice kitchen!), but I still think your system works because of the quality of the filtration you have made. An average ERV, whatever the size of the exhaust duct, moves somewhere in the range of 100 - 200 CFM of air. Your hood is exhausting 650 CFM, so the balance must be recirculating out of your mechanical room into the rest of the house.

Probably the biggest impediment to others copying your set-up is that the overwhelming majority of homeowners simply don't do any routine maintenance. If they can't regularly replace the filters on their furnace, ERV, water-purification, etc., what are the chances they will keep that range hood filter clean? You belong to that rarified group of people who maintain things. Hardly anyone I know does.

Malcomb,

Yes I am afraid I am a bit obsessive about maintenance. My mini split head filter looks a mess after about 5 weeks and the (UltimateAir) ERV MIRV 13 filter light goes on about every 6-8 weeks. The grease baffles in the range hood get put in the dishwasher about every 10 weeks and the activated charcoal hood discharge filter gets changed about every 6 months. My old 1922 house was drafty, and uncomfortable but still required oil tank fills, furnace air and oil filter changes and burner service. The furnace also needed “vacuuming” out of the heat exchanger and flue cleaning on occasion. The conventional range hood needed cleaning as well. Guess there is no free lunches in the land of entropy.

Well I haven't had time to catch up any articles on GBA lately, but imagine my surprise today reading this one that actually had my name in it! I actually logged on to see if there had been updates to the previous posts made about this hood/ERV situation, so I am glad it morphed into its own article.

I have actually contracted with Allison Bailes of Energy Vanguard to do a full mechanical calculation and plan for my new home. There will be a manual J calc, then manual D (duct design) and then a recommendation of the correct equipment. I have also added in the design of the ERV system and ductwork. The only option I didn't go for was for hood & make-up air calcs. I may add that on after, depending on what type of results they come up with.

"differentpath" - I like the idea of your system, and apparently it is working fine. I considered doing something along those lines and simply venting to my basement's storage or mechanical room. My wife likes to cook foods with lots of spices and things that smell great (Indian food, stir-fry), but nobody wants to walk into their bedroom 3 hours after dinner and be stuck with the smell of it lingering around. Perhaps that charcoal filter, combined with the grease traps, is enough to take care of things. If that was the case, then maybe I should further pursue this option. The idea of a a damper with a several-thousand watt electric inline heater just kills me, but I know from experience with our current hood/house situation, a properly-functioning hood vent is priceless, especially if you are making fried chicken.

While I know this isn't a new problem, it is becoming more well-known and discussed. There never seems to be a one-size-fits-all solution, but I would think that somewhere, some company would have developed something by now. I had previously thought of the idea of a system that heats the incoming air using the outgoing air, but I have yet to see one on the market.

Oh well, due to CoViD-19, my SIP walls and roof panels are literally on the Insulspan production floor in Michigan, which was closed down the week they were to be completed. So, I am in a holding pattern awaiting all of my parts and pieces to get the house together.

Cheers,

Nick

I know this is a slightly older article, but it is so close to answering my question I had to post.

Why not pair a more powerful ERV such as a commercial one capable of 600 or 900+ cfm and simply have the exhaust go out the ERV and the make-up air come back in the ERV one-to-one. I'm in NC, so we aren't looking to heat make-up air very often but this would do that for the northerners. As long as your range hood or downdraft unit was filtering the grease prior to the ERV, it seems this would be a reasonable scenario. Also, as in my case, the ERV would be in the crawl, so you would only hear the sound of the air being pulled into the downdraft unit rather than the blower in the hood itself or a cabinet.

Other than the potential additional maintenance of the ERV filters, is there any reason this would be a terrible idea? For my specific application, I was imagining putting dampers on the ERV and when the hood switches on, we can control the ERV up to 900 cfm. Then dampers from the baths would set the ERV to 75-150 cfm when the bath switch is on. The return air would be dumped into the HVAC plenum to be filtered and conditioned before entering the home to provide makeup air. We have a Trane XV20i, so it is almost always running at least on low, which would allow the makeup air to get at least somewhat conditioned on the way back in.

I welcome your thoughts! This is my first question, so I appreciate any grace in posting on an older article.

Obvious drawback is the cost of a 900cfm HRV or ERV. I doubt you'd ever recoup enough energy in a residential application to pay that off. The control system you'd need is also far from trivial, what with servos to control multiple dampers and to send to commands to the ERV to change fan power.

How many new house heating systems have the extra 45,000 btu/hr needed when running a 600 CFM exhaust fan? Or an extra ton for cooling + a huge amount of dehumidification? Think carefully about the airflow path to reduce this issue.

START BY READING BEST PRACTICE GUIDE & SLIDES AT ROCIS.ORG RANGE HOOD SITE (2019 UPDATE), http://rocis.org/kitchen-range-hoods

re: “Should one try to install a range hood exhaust with 400 cfm [cubic feet per minute] or less?” he asks in a recent Q&A post.

-- YES. But make sure it has size, shape, and location for good Capture Efficiency (HVI should be listing CE ratings within a year, I hope, and mfrs might give you "recommendations" based on their CE testing.

See the Supplement on Caveats & Cautions Supplement with details on make up air: mechanical dampers, multiple supplies, measure P drop.

Even if less that 400 cfm, you may still cause depressurzation and subsequent radon, VOC or moisture problems. Note that 100-200 cfm could depressurize a very tight home (see chart in slide with extended lines to low ach).

“Would it be OK to install a 600 cfm unit in a home that has an ERV unit? If so, are there any special things to do differently when considering a makeup air strategy for a home that has an ERV with dedicated duct lines?”

Sounds like overkill unless it is a commercial grade stove with fire safety requirements.

One option: Use an induction stove instead to reduce both pollutant emissions from stove and burner waste heat. Many professional cooks use these stoves now.

An ERV by pass connected to range hood exhaust might work to keep grease out of HRV.

Just heard part of a webinar on Chinese MFam Passive Houe projects doing this, because high emission frying etc. is very common in China. They also provide makeup air.

Don't know how well it actually works or if they have good field data yet.

More info & contact at Passive House Accelerator Happy Hour, 7/22/20, to be posted at https://passivehouseaccelerator.com/global-happy-hour.

Posted on YouTube channel: https://www.youtube.com/watch?v=MJGN3C2KX8s

In any case, it would be great to get particle count data and pressure data to see how well your final system design works. ERVs in Colorado passive house study did not help remove particles (and probably gases) very well.

They've been saying those CE numbers will be published for the past 4 years and it never happens... I wish it would hurry up and get done. In the meantime I'm tempted to put in a $200 hood and replace it later.

BTW, Broan and probably other mfrs have an online MakeUp air calculator

and equipment selection too.

Why not? Arguments against include:

1. Depending on how often it's used, it would be hard to get enough energy savings to make it worthwhile.

2. Grease filtering is hard. Likely, it will stay in the air until the air is cooled through the ERV core, and thus clog the ERV core. That's hard to clean. An HRV core might be eaiser to clean, but still quite difficult.

3. Dending on the climate the season, you might not want the moisture from the exhaust that an

ERV would be helping retain. Or maybe you would.

I'm building a net-zero home in Portland OR. It'll have an HRV with a boost mode. I'm struggling to decide on a Vent-a-Hood ARS recirculating, ductless range hood over 30" induction range on the wall vs a traditional outside vented hood. The Vent-a-Hood has a sophisticated centrifugal grease trap along with charcoal and smoke filters. Any experience out there? Suggestions.

Take a look at the Renewaire SL series ERV. It has a boost mode that you could interlock with a pressure switch at the hood and you can adjust the airflows to be unbalanced, thus providing some MUA. Its a very small unit so I doubt you will get more than 80 cfm or so however. Ventilation and the required MUA is a compromise between price and convenience (passive damper, interlocked, electric resistance MUA, or open a window). If your going to want a kitchen hood to have a chance removing grease, more CFM is better, but your going to pay a price for that. I would definitely not bring kitchen exhaust through and ERV/HRV. Variable speed hoods are great but harder to interlock with MUA electrically. As someone mentioned, if you want X cfm to leave the house, the same X cfm must enter one way or another.

One solution I have been considering for house in planning is to have a motorized damper on the HRV unit exhaust outlet which would interlock to kitchen hood. When hood exhaust is on the HRV would activate and the damper would open blowing the HRV exhaust into the conditioned attic area. The HRV unit would then be unbalanced, just supplying tempered outside air into the space, with the HRV exhaust remaining inside conditioned space. Dumping the HRV exhaust into conditioned attic (within the air barrier envelope) would add heating or cooling load to indoors, but should not be a comfort issue as this air would just diffuse back into the conditioned space by way of leakage through interior finishes. The HRV unlikely to fully balance out the kitchen hood (less CFM of HRV versus hood fan) but would certainly help.

I would advise against any ideas of running hood exhaust through an ERV unit however. Grease laden air should go direct to outdoors.

A general comment on kitchen hoods: Much less CFM required if range and hood are against a wall, or even better yet in a corner of kitchen. Range tops mounted out on an island are subject to air drafts from all directions and need higher CFM and capture velocities to work properly. And of course the lower the hood is to the range top the better (24" is about as low as I would go).

Log in or become a member to post a comment.

Sign up Log in