Image Credit: Unless otherwise noted, all photos are by Energy Vanguard

A while back I wrote about the incompatibility of putting an atmospheric combustion furnace in a sealed attic. Most often the attic is sealed by installing spray foam insulation at the roofline, thus bringing the attic inside the building enclosure and turning it into conditioned space (directly or indirectly). The good news is that some installers understand this problem and seek to address it. The bad news is what a few of them do.

Combustion air retrofits

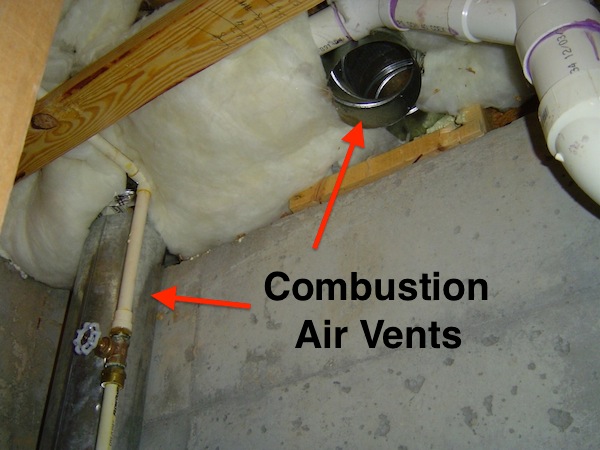

The photo at right is a case in point. The furnace was up in the attic before the spray foam was installed. The homeowner hired a spray foam contractor to improve the building enclosure but the budget didn’t include enough money to change out the furnace at the same time.

I don’t know if the combustion air retrofit you see above was done by the spray foam installer or the HVAC contractor, but in either case, this one’s almost certainly not going to work. Here are the main problems:

- Inadequate duct size. They used a 4-inch flex duct that you usually see on bath fans (which have their own problems), and it ran at least 20 feet to the place where it exited the attic. This would not meet the code requirement for combustion air inlets, as you’ll see below.

- Poor duct installation. The duct wasn’t pulled tight, further reducing the air flow through the duct.

- Tape over furnace louvers. The louver area is designed to allow the proper amount of combustion air to enter the furnace. By covering some of them with tape, the installer of this retrofit may be guaranteeing the opposite of what they were aiming for: less combustion air, not more.

And that air might even move toward the furnace instead of away from it. Of course, there’s no guarantee of that. As my friend David Richardson likes to say, combustion air doesn’t care which way we show the arrows pointing on our diagram. Air flows from areas of higher pressure to areas of lower pressure. Under some circumstances, air might flow out through that inlet rather than in.

The need for air

Now let’s go a little further. Let’s look at what building codes say is the right way to do it.

The image at left shows the burners in a particular type of furnace. When you pull the cover off of this furnace, you could stick your fingers right there in the flames. (I said you could do it. I certainly don’t recommend it, though.)

What that means is that the flames are open to the air inside the furnace cabinet. Since we know combustion is the chemical reaction of a fuel (natural gas in this case) with oxygen, there’s got to be a supply of air to keep it going. The air in the furnace cabinet itself would be exhausted quickly, so more air has got to come in somewhere, right?

That’s why the furnace in the image at left has louvers in the cover. It allows air from the surrounding space to be pulled in for combustion. This is what we call the standard efficiency furnace. If you buy a new furnace these days and want to get the cheapest one you can, this is probably what it’ll look like.

Some older homes, though, have a type of furnace that isn’t made anymore: the natural draft furnace. The photo at left shows what they look like. Notice that there are two places where this furnace pulls in air, and these guys pull in a lot of air. They’re also easier to backdraft, but that’s not our focus here.

Where does the air come from?

So if you’ve got any type of atmospheric combustion appliance, you need to make sure it gets air for combustion. The two options are:

- Indoor air

- Outdoor air

Let’s take a look at them separately.

Using indoor air for combustion

If you’re going to use indoor air, there’s got to be enough of it inside the house. Two building codes that address this issue are the National Fire Protection Association Standard 54 (NFPA-54) and the International Residential Code (IRC).

Both say the same thing about using indoor air for combustion. The space that the atmospheric combustion air can draw from has to have at least 50 cubic feet of volume for each 1,000 BTU/hour of appliance capacity.

Let’s say you bring the attic inside the building enclosure by putting spray foam insulation at the roofline (the case with the two furnaces in my previous article on this topic). Now, let’s put some numbers to it. (Yes, we’re going to do math, but it’s just simple arithmetic. I know some of you were hoping for partial differential equations, but you’ll just have to console yourself today by memorizing some more digits of Pi, I guess.)

If the attic has a floor area of 800 square feet and an average height of 4 feet, for example, the volume would be 3,200 cubic feet. Divide that number by 50 to find the maximum capacity appliance you could put in the attic, and you get 64,000 BTU/hr.

That would be a medium-sized furnace. But you could put only one in this attic. Put two of them up there, and the codes say you don’t have enough air for them. And an 80,000 BTU/hr or 100,000 BTU/hr furnace, neither of which is uncommon in homes, would be right out.

One way to get more volume of indoor air for your atmospheric combustion appliances would be to connect the space they’re in to other spaces in the home. You could put a couple of grilles in the wall separating a mechanical room from the conditioned space, for example. The codes specify how you should do that and how big the openings have to be.

Another way to get more air is to count infiltration. Again, check the codes if you’re planning to do that.

Using outdoor air for combustion

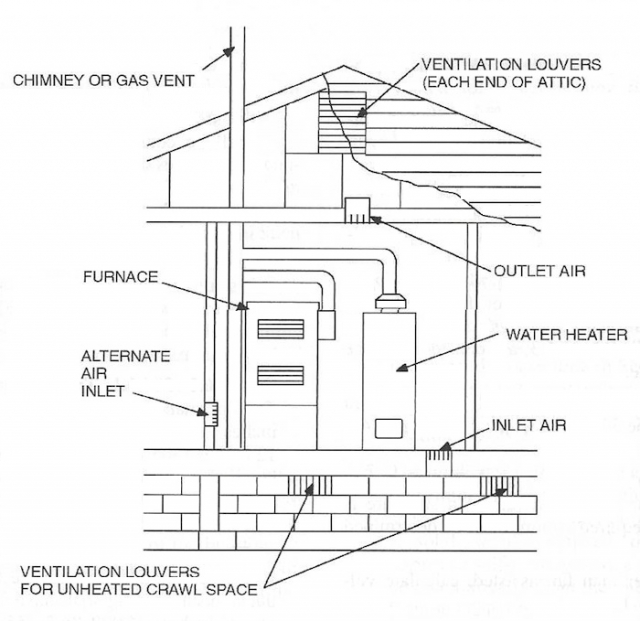

The other way to provide air for your combustion appliances is to bring it in from outdoors. The standard way to do this is with “high-low vents.” The image at left shows an example. Two ducts are open to this mechanical room in a basement. One of them terminates near the ceiling, the other near the floor.

Another method specified in the code is to use a single opening. The image at left shows a basement mechanical room attempting to satisfy the code requirement this way.

With both the high-low vents and single opening methods, the building codes specify the amount of vent area required. As with calculating volume when you use indoor air, the vent area required is based on the total capacity of the combustion appliances.

Here are the rules for the two-permanent-openings method:

- 1 square inch per 4,000 BTU/hr – vertical ducts

- 1 square inch per 2,000 BTU/hr – horizontal ducts

When using the one-permanent-opening method, you need:

- 1 square inch per 3,000 BTU/hr – vertical or horizontal duct

How many code violations do you see?

Now go back and look at the two photos I opened the article with (at the top of the page). Both use the one-permanent-opening method and would require 1 square inch for each 3,000 BTU/hr of capacity. The first one is a 4-inch-diameter duct, so the area would be about 12.6 square inches. Code would allow it for a maximum capacity of about 37,700 BTU/hr. In other words, it’s probably too small because there aren’t many furnaces that small.

There’s still the issue of the tape covering the louvers, of course. And there’s another code violation as well. Combustion air vents are supposed to have a minimum clearance of 6 inches from the front of the combustion appliance.

The furnace in the second photo comes closer to meeting code. If it’s a 6-inch duct, it would have an area of 28 square inches and meet the requirement for an 84,800 BTU/hr furnace. If it’s an 8-inch duct, it could meet the requirement for about 150,000 BTU/hr in total capacity. It still doesn’t meet the 6-inch clearance requirement, though.

But will it work?

Whether any of the methods above will work is debatable and depends on what criteria you use to gauge acceptability. Here are a few pitfalls:

- Using indoor air still means using outdoor air. Each cubic foot (or cubic meter) of indoor air that gets pulled into a combustion appliance will leave the house with the exhaust gases. When that happens, another cubic foot gets pulled in from leaks through the building enclosure.

- Air doesn’t always follow the arrows we draw on diagrams. You can put all the vents you want into a mechanical room, but whether air moves in the direction we’d like it to depends on the which way the pressure difference pushes it. Wind, stack effect, and other mechanical systems could cause air to flow the “wrong way.”

- Bringing combustion air in from outdoors can waste energy and lead to comfort problems. We know the old saw about how “a house needs to breathe” is a myth. Houses need to be able to dry out and they need good indoor air quality. They don’t need extra leaks. It’s the people who need to breathe.

- Occupants sometimes seal them up because they don’t understand why there’s a hole in their house. It happens, just like they sometimes caulk the weep holes in a brick wall.

As I’ve said before, it’s time to put atmospheric combustion appliances on the pile of obsolete technologies. Let them take their rightful place as relics of a bygone era, along with steam engines, typewriters, and slide rules.

Allison Bailes of Decatur, Georgia, is a speaker, writer, energy consultant, RESNET-certified trainer, and the author of the Energy Vanguard Blog. Check out his in-depth course, Mastering Building Science at Heatspring Learning Institute, and follow him on Twitter at @EnergyVanguard.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

3 Comments

Confused

"Bringing combustion air in from outdoors can waste energy and lead to comfort problems." I'm a little confused about this comment. Or perhaps I'm reading this out of context. Isn't this only true if the outdoor air displaces indoor living space air before it reaches the unsealed combustion site? If the outdoor air goes directly to a sealed combustion site without displacing living space air that seems ideal to me.

EDIT: I guess the key is how you define the sealed space and how you define the living space. For instance, in your example of a sealed attic with insulation beneath the roof how you define the attic ceiling boundary is important. If that boundary is totally air sealed the you must bring in air from an attic vent to outside air for the open burner. But in this case the cold air from outside will cool off the attic and negate the whole idea of having a conditioned space attic. If you vent to the living space below then you depend on air leaks to the living space and then have the same problem, only more so.

However it seems helpful to not define the problem using the attic as the sealed combustion space. In the end you have to localize the sealing to the burner combustion area and always have remote ducting for both exhaust and inlet air if the fire is anywhere within the house. So your conclusion is perfect.

Consistancy

If a foolish consistency is the hobgoblin of small minds I guess I have to plead guilty, at least in part. It seems to me that there is no good way to seal a gas range and so one would have the same problems discussed here. Just smaller. Actually, I've seen people comment that their house CO^2 measurements go up when using a gas oven or range so it may be that the combined effect of cool (or hot) displacement air along with combustion byproducts is not a good thing in an otherwise healthy house.

Something to consider although a lot of people will just hate having to take this idea seriously. It will be interesting to see if eventually gas ranges also become a relic of the past. I would guess "yes", though perhaps not in my lifetime.

atmospheric furnaces - just say no

For both air quality (NOx) and energy efficiency reasons, they're not allowed in Switzerland any more. Germany mandates replacing furnaces that are over 30 years old.

A concentric exhaust system (intake air on the outside, exhaust on the inside) takes care of the venting, and improves efficiency by preheating the combustion air with waste heat from the exhaust.

Another regulation here mandates a system temperature of no higher than 50 C to allow future upgrades to heat pumps, and keep the furnace in the more efficient condensing mode.

Log in or create an account to post a comment.

Sign up Log in