Blowing cellulose into rafter bays:

A question from a Portand, Maine, homeowner kicks off a discussion about whether dense-packed cellulose insulation can be used successfully in an unvented roof assembly.Dean Manoogian has a Cape Cod style house in Portland, Maine, and is puzzling over the best way to retrofit the roof with rigid foam insulation.

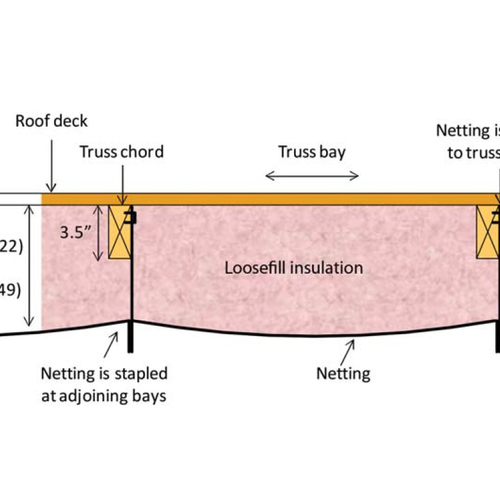

Working with both an insulation company and a roofing contractor, Manoogian has come up with a plan: apply 2-in. rigid foam on the interior of the dormered roof and then fill the rafter bays with dense-packed cellulose.

“My question,” he writes in this Q&A post at GreenBuildingAdvisor, “is the air/moisture permeability against the roof sheathing/rafters.”

The roof has been built without ridge, soffit or gable vents. To protect the sheathing and rafters from moist air, mold, and possible decay, Manoogian proposes covering the underside of the roof sheathing and rafters with a peel-and-stick membrane before adding the foam and cellulose.

The rigid foam would be capped with 5/8-in. gypsum wallboard to meet fire codes.

Is Manoogian on the right track, or courting a problem? That’s the focus of this week’s Q&A Spotlight.

Not the most elegant solution

The plan has already won the city’s approval, but to GBA senior editor Martin Holladay, it has its drawbacks.

“No,” Holladay writes, “you can’t solve the problem by adhering Ice & Water Shield to the underside of your roof sheathing and your rafters, for several reasons: the materials would be expensive, the work would be awkward, it’s impossible to do a perfect job, and you would be creating a vapor-barrier sandwich with roof sheathing in the middle — a disastrous approach if you ever get a roof leak.”

There are only two reliable ways of keeping water vapor away from the roof assembly, says Holladay. One way is to spray closed-cell polyurethane foam on the…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

18 Comments

Flash and batt?

Peter and Martin,

It would be very difficult to seal this roof assembly with Peel and Stick. Would a Flash and Batt application work here?

The text says Bill Hulstrunk suggests using EPS, XPS or Polyiso as a permeable rigid board insulation. My understanding from Martin's previous GBA blogs is that EPS is semi permeable, but XPS and Polyiso have low permeability.

Reponse to Jim

Jim,

Yes, flash-and-batt could work here, as long as the closed-cell spray foam was thick enough. That's why I wrote, "There are only two reliable ways of keeping water vapor away from the roof assembly. ... One way is to spray closed-cell polyurethane foam on the underside of the roof sheathing..."

Open cell on underside instead of closed cell?

But will the closed cell foam on the underside of the roof deck not also create sandwich of impermeability?

Please advise...I am installing 4" of poly iso over top of ice and water shield on the roof deck (then outside strapping/venting and another layer of osb under the metal roof).

On the inside I was considering any option that was vapor open (so not to create the impermeable sandwich)....for this reason (and my concern of cellulose settling) I was leaning toward open cell foam between the rafters, rather than the closed cell spray foam.

Flash & Batt

Dean,

A cold roof in NE. is best all around .If your going to the trouble of applying rigid foam to the underside of the roof sheathing then you might as well create a ventilation channel by ripping 1x3 strapping in half ,apply these to the sides of the rafters and then nail the foam to these. Seal the edges with foam spray and then drill 3" or 4" vents into the soffit for for ventilation. Have the roofing contractor cut in a ridge vent and be done with it.

Vent-skin radiant barrier assembly alternative

I would agree that closed cell applied to the underside is reliable for as long as the roof is. I have seen the disastrous potential of internal moisture condensing on the underside of a cold roof deck, and I wouldn't want my cellulose anywhere nearby.

An alternate I would propose is a vent-skin assembly as follows:

3/4" plywood roof deck on 2x10 @ 16" O.C. w/ 1.5" vented air space created using furring strips and Astro-foil faced bubble wrap stapled to the underside of them. The radiant barrier heat is in this way vented from the soffit to the ridge. On the underside of the foil faced vapor barrier we will then apply the closed cell. I've done this successfully with techshield, plastic air baffles continuous, and 5.5" of open cell. It was simple and affordable - and allows you to see if there's a water problem at the bottom of each joist space outside the house (where you generally want the water to be). Comments please from all those much smarter than I.

Response to Matt Berges

Matt,

Either option -- cellulose or open-cell spray foam-- will work fine in your case.

a vapor intelligent membrane

at interior side of cellulose - by Pro Clima - could do the trick.

No need to risk making sheathing a mud sandwich. Foam can be eliminated too.

The intelligence keeps the vapor out in winter and allows assembly to dry to interior in summer.

Full disclosure: we represent Pro Clima in America...a little googling can find us.

spay foam + high density cellulose + XPS?

For a retrofit situation with 2x6 rafters in zone 5, I've considered using 3 1/4" closed cell spray foam on the underside of the deck, plus high density cellulose to fill the remainder of the rafter bay, plus 2" XPS on the underside of the rafters. Is the XPS permeable enough to work in this situation? Since the air barrier is provided by the closed cell, is is necessary to seal the seams on the XPS? If you did seal the XPS on the interior to create an air barrier here, could you use less than 3 1/4" of closed cell spray on the under side of the roof sheathing?

Put the foam boardinsulation where it belongs . . .

. . . on top of the roof deck. No condensation, no peel-and stick wrapped around rafters, no ventilation issues, no muss, no fuss, and--to quote from a Monte Python skit that some may remember--"No Kangeroos!!!"

unvented cellulose

Advanced Energy did a mockup of a roof several years ago that include 1/2" OSB, tarpaper and shingles. They got it wet and then turned on sunlamps to simulate the sun. The idea was to see if the sun would drive moisture through the roof assembly. In 4 seconds the humidity was coming through. .You have to worry about moisture also coming through the roof assembly. John Tooley as of 2 years ago was recommending closed cell foam only. An impermeable roofing membrane under the shingles might work. Use Membrane on the inside. 2" XPS has a perm rating of less than 1. Be careful of doing a vapor barrier sandwich. You must know the perm rating of what you are using.

Capes in Maine

This is a very pertinent question...I wish I could post a photo of my Portland neighborhood. About 50 Capes with no eaves or soffits and no possibility of retrofitting ventilation. This leads to folks doing things like punching holes into the kneewall spaces through the gables.

I often see folks use flash and batt or dense packed cellulose and, like Dan Kolbert said, without issues.

Response to Ed Voytovich

I agree completely: "Put the foam board insulation where it belongs . . . on top of the roof deck."

keep it simple

I had the same issue last year with venting vs non venting a cathedral ceiling using dense pack cellulose insulation . In the end I opted for the time tested solution of ridge & soffit vents with baffles between the rafters. With all the back and forth opinions on whether I could or couldnt insulate with or without ventilation I choose the to vent and not worry about condensation issues down the road...

Rigid Foam Right Under the Deck.

As long as the R-value of the foam, given its gradual decrease over time, is high enough to break the temperature differential between the interior and exterior, eliminating the potential of dew point, the rigid foam can be fit tight inside the joist bays and sealed into place with expanding foam. (There is a good explanation of thicknesses needed in "Why Flash And Batt Makes Sense", by Michael Maines, Fine Homebuilding 217.) If the roof is already installed, and the rigid is already bought, this is the most cost effective way of managing the hot roof. Cellulose can still be installed under the rigid foam, and then your ceiling of choice under that. Otherwise, I'd agree with Ed Voytovich, put the rigid on the exterior of the building, further increasing the foams effectiveness by eliminating the thermal bridging caused by the joists.

We've done a couple of crawl spaces with the first method, and it has increased the comfort level in the rooms above tremendously. I'll be including pictures and a write up on our blog soon. http://www.redhousecustombuilding.com Obviously, there is a lot more heat and humidity at the top of the house, but this is all the more reason to think about putting the proper R-value on the exterior of the roof sheathing.

Sealing the rigid

I strongly second Peter Yost's recommendation of being painstakingly thorough in air sealing the rigid foam before densepacking. Although the densepacked cellulose is almost air tight, it is still very vapor permeable and moisture could see a cold roof deck via gaps. Remember the SIPS roof fiasco in Juneau?

interior Vapor barrier required

For dense pack cellulose to be used successfully in an unvented roof, an interior side (warm side in wettest season)vapor barrier must be used IMHO.

Unvented roofs & the Code

The 2009 IRC (section R806.4) makes explicit the requirement for impermeable insulation (eg rigid foam board or closed cell spray) above permeable insulation (eg blown cellulose or fiberglass). The R-value of the impermeable layer depends on climate. R25 is required for climate zone 6 in Maine. So, for an UNVENTED roof, either rigid board on the outside to keep the sheathing warm, or closed cell on the inside to keep the sheathing cold but inaccessible to warm interior air. Then fill your remaining cavity with cellulose.

For a recent retrofit, we obtained a lot of 3" poly-iso board for no cost, and installed it between the rafter bays, sealing all gaps with expandable foam. A labor-intensive approach, but OK for DIYers.

Alternately, for a VENTED roof, you can skip the foam. Cross strap the ceiling for added insulation and use cellulose - a friendlier product for the environment. The effort to 'retro- vent' the top of the rafters shouldn't be too bad, through the soffit or frieze board.

Retrofit roof with cellulose insulation

What insulation details would you recommend for an existing 2x8 roof with 4yr old roofing and plaster finished interior. The existing paperbacked fiberglass was not installed correctly leaving the space cold and drafty. The house is a cape with a shed dormer roof with Front pitch 6/12 and shed pitch 2-1/2 /12. There are continuous soffit vents.

The insulation installer is recommending opening the soffits and ridge. Pull out the fiberglass and install R-20 dense-pack cellulose by National Fiber for the rafter bays at the cathedral and R-40 for the attic floor. How can one be certain that the cavities are full and are there moisture concerns?

Thank you

Glenn Berger

Log in or become a member to post a comment.

Sign up Log in