Can poly be used under rigid foam?

Although many builders have abandoned the use of polyethylene vapor retarders in wall assemblies, a GBA reader wonders whether poly can be an effective air barrier when used beneath a layer of rigid foam insulation.Polyethylene sheeting has had its ups and downs as a preferred building material over the last 20 years.

At one time, it was routinely used in wall assemblies as a vapor barrier. As building scientists learned more about air and moisture movement through walls and ceilings, however, they began to advise builders that an interior vapor retarder is better than an interior vapor barrier, and the perceived usefulness of poly plummeted.

In most climates, air movement, not vapor diffusion, came to be recognized as a bigger threat to buildings. Air barriers, which can be vapor-permeable, became a more important priority. Builders also realized that because of its very low permeability, polyethylene had the potential of trapping moisture inside walls.

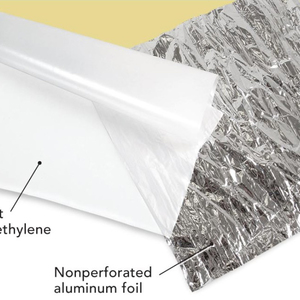

Even though poly has gradually lost its luster, a GBA reader nicknamed Minneapolis Disaster wonders whether it could have a place in an outbuilding he’s putting up. In a a Q&A post at GreenBuildingAdvisor, Minneapolis lays out plans for incorporating a 6-mil poly air barrier in both the walls and ceiling of his planned building. In the exterior walls, the poly will be sandwiched between the exterior plywood sheathing and 5 1/2 in. of layered and taped polyisocyanurate foam insulation. In the ceiling, Minneapolis plans on adding poly between two thick layers of polyiso.

He’s encouraged by the practices of Alaska builder Thorsten Chlupp, who has successfully used poly in cold-climate buildings. In addition, the poly is available in 12-ft. wide rolls, which will make it easier to lap and seal than 10-ft. wide housewrap. “I’ve come to the conclusion that for the small building that’s underway in my yard, I’ll see good air-sealing results from 6-mil poly, adhered at edges and openings, around the walls and another layer lapped over, across the ceiling,” Minneapolis writes.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

4 Comments

Dry to the cold side

I am all for the use of polyethelene in exterior walls in cold, dry climates, right under the drywall on the warm side. It works, is easy to seal and greatly improves ach50. As for poly farther out (nearer exterior) in the wall assembly, I would follow the 1/3, 2/3 rule, with 2/3 of the R-value on the cold side of the poly. This is how some superinsulation retrofits have been done in Canada, wrap the existing wall exterior with 6 mil poly, then build a Larsen Truss from the top of the footing to the soffit and fill with Roxul.

Benefit of the interior insulation

Mpls Dis' building is an outbuilding but if it had mechanical cooling I like Doug's suggestion of having roughly a third of the insulation inside the vapor barrier in this climate.

Having grown up in Minnesota I know summers can be hot and humid for stretches; people like to run their AC and dehumidifiers, sometimes for weeks on end (like my parents). It isn't Miami but installing some insulation inside the poly would reduce the possibility of condensation on the outside of the poly in the summer. In the case of the walls it adds R-value compared to leaving the stud bays empty.

Perhaps one could argue condensation in the exterior wall rigid insulation isn't a problem but why tempt an issue? And in the ceiling/roof assembly any condensation certainly could present a potential problem (leaks, wet framing). Therefore the 1/3 - 2/3 approach seems like the safest approach given this assembly in cases like a typical home with cooling.

Stud bay insulation.

Thanks to Holladay for the clarity brought to the issue of stud bay insulation in a REMOTE wall assembly, even though his message is troubling for me. He said "The fluffy insulation just makes your plywood sheathing colder. Empty stud bays are better from a building science perspective.”

The REMOTE manual discusses the issue of percentage of insulation inside and outside the structural sheathing plane at length however for all their efforts the issue remained mysterious. I've just designed a house in NH (zone 6) with 2x6 stud walls and (2) layers of 1.5 -inch Polyiso exterior of the sheathing and Tyvek. I intended to insulate the 2x6 walls with dense pack cellulose which will bring me to roughly a 1/2 ratio with nearly equal amounts of insulation split inside and outside. The design temp for this region in Winter is 10 degrees (cold but not quite Alaskan cold) and my math tells me just 1 -inch of nearly any rigid insulation should prevent dew point temps being reached at the inside of the structural sheathing. The question of insulation ratio certainly must be temperate zone related and needs more delineation for those using REMOTE insulation wall assemblies. It's not to late for me to increase the exterior insulation but obviously with a 2x6 stud bay insulating just part of it seems impractical and leaving the entire bay empty would sacrifice too much insulation performance. I'm left to ponder and to worry.

Response to Harry Seidel

Harry,

Relax; your wall is fine. Here is the article with the relevant information to reassure you: Calculating the Minimum Thickness of Rigid Foam Sheathing.

PERSIST walls were developed in the 1960s by several researchers and were popularized by Chris Makepeace of Edmonton, Alberta. You are not building a PERSIST wall; you are building a conventional 2x6 wall with exterior foam sheathing.

PERSIST walls depend on a peel-and-stick membrane adhered to the exterior side of the wall and roof sheathing. This impermeable membrane is at once the home's air barrier, vapor barrier, and water-resistant barrier. Because this barrier is unforgiving to moisture accumulation, it's important that the peel-and-stick layer and the wall sheathing stay warm. That's why you really don't want any insulation between your stud bays for a PERSIST house, in my opinion. If you are building a PERSIST house and you want more insulation, just make your foam thicker.

The CCHRC researchers in Alaska tweaked PERSIST and started calling it REMOTE. At this point, the definitions are getting a little hazy, and I'm not sure exactly where to draw the line between an Alaskan REMOTE house and an ordinary 2x6 house with exterior foam insulation. That question is probably best directed to our Alaskan friends. I'm not sure, in fact, whether the REMOTE acronym is useful -- I'll just leave it at that.

Log in or become a member to post a comment.

Sign up Log in