Image Credit: BuildingGreen, Inc.

If there’s one thing that we can predict with certainty about fuel costs, it’s that they fluctuate a lot. That wasn’t always the case. The price of electricity, natural gas, propane, and heating oil were remarkably stable for decades — up until the 1970s.

Since then, prices of most fuels have gyrated wildly, driven by political unrest in some parts of the world, periods of greater or lower demand driven by periods of strong economic growth or contraction, resource limitations (real or perceived), and the situation in China and other parts of this increasingly connected world.

With regulated energy sources (particularly electricity), there is often less volatility, because regulators have to approve changes in pricing.

What does this mean for you as you compare one heating option to another or try to figure out whether to buy a pellet stove this winter? How does oil compare with propane or electricity as a heating source? Those sound like simple enough questions, but it’s actually fairly complicated.

How many BTUs per gallon?

For starters, different fuels are sold in different units. Heating oil, kerosene, and propane are sold by the gallon; natural gas by the hundred cubic foot (ccf) or therm (defined as 100,000 Btus); firewood by the cord; wood pellets and coal by the ton; and electricity by the kilowatt-hour (kWh).

Second, different fuels have different energy densities. According to The Engineering Toolbox (a great source of facts related to energy), a gallon of propane contains 91,330 Btus, while a gallon a #2 heating oil contains 139,600 Btus. Pellets contain 16.5 million Btus per ton, and natural gas contains 950 to 1,150 Btu per cubic foot.

Equipment efficiency matters

Third, the amount of useful heat obtained from a given fuel depends on how efficiently it’s burned. Combustion efficiency varies widely — from as low as 30% for the worst of the outdoor wood boilers to over 95% for a top-efficiency, condensing gas boiler. Baseboard electric-resistance heat can be thought of as 100% efficient — since the electrons you’re paying for in the electric current are converted entirely into heat, while heat pumps typically deliver two to three units of heat energy for every unit of electric energy consumed (these can be thought of as 200% to 300% efficiency, though it’s really a coefficient of performance, not efficiency).

Note that these electric heat efficiencies don’t account for the “upstream” energy costs of electricity generation, such as the waste heat at a coal or nuclear power plant — but for the purposes of comparing your heating costs, that doesn’t matter.

Heat distribution efficiency

To further complicate fuel cost comparisons, a fourth factor is how efficiently heat is distributed. With electric baseboard radiators, the heat is produced right in the room, so the distribution is 100% efficient. Baseboard hot water (hydronic) heat is also usually very efficient, though uninsulated hot water pipes running through an unheated basement can lower that efficiency to some extent.

With a forced-air furnace and ducts to carry the heat, however, the distribution efficiency can be quite low, especially if poorly insulated, leaky ducts run through an unheated attic or crawl space — distribution efficiency as low as 50% is not uncommon.

To calculate the actual delivered efficiency of your heating system, you have to multiply the heat content of the fuel by the combustion efficiency and by the distribution efficiency. For example, if you have a 78% efficient propane furnace and an average duct system running through an unheated attic (65% efficient distribution), your overall efficiency of delivered heat is just over 50% (.78 x .65) — meaning that only half of the energy you’ve paid for is actually being used to keep you warm!

Comparing apples to apples

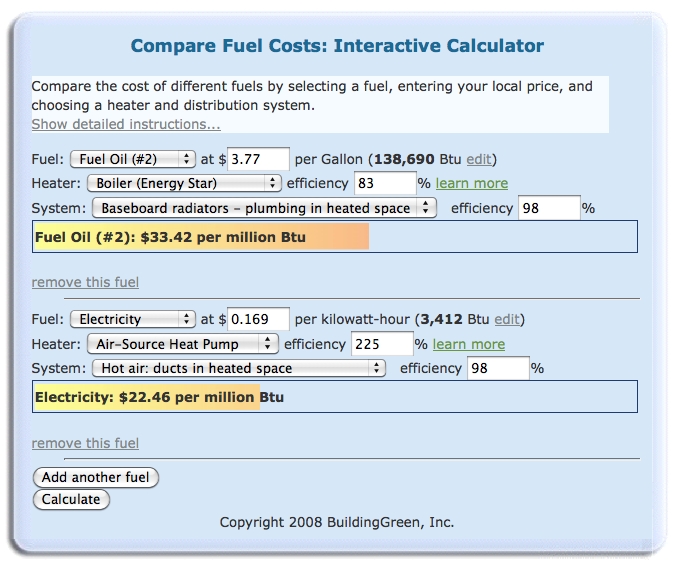

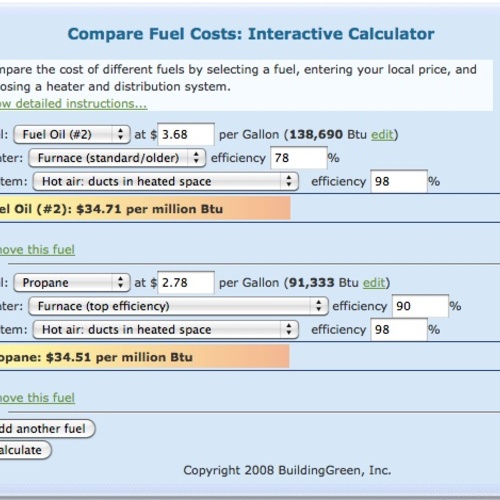

Finally, to compare different fuels (sold, as described above, in different units), you have to convert the costs to an equal basis so you’re comparing apples to apples. The most common standard is dollars per million Btus of delivered heat. The easiest way to do this is with an online calculator like the Heating Fuel Cost Calculator our company provides.

This allows you to enter the cost for a particular fuel, your heating system efficiency, and its distribution efficiency. The end result is a figure in dollars per million Btu that reflects your real costs of delivered heat and allows you to compare that with other options. Say you heat with oil and pay $3.77 per gallon (the average retail price in Vermont last week), using an Energy Star boiler (83% efficient) and hot water baseboard distribution (98% efficient). Your cost of delivered heat with these assumptions will be $33.42 per million Btu.

By comparison, electric baseboard heat at the current Green Mountain Power rate of 16.9¢/kWh converts to $49.53 per million Btu of delivered heat — that’s 48% higher than the oil option above.

Using a heat pump with a coefficient of performance of 2.25 (225% efficient) and ducts fully within the insulated house envelope drops the cost of delivered heat to $22.46 per million Btu (33% less that the oil-heat option).

And firewood, at $250/cord burned in an EPA-compliant wood stove (70% efficient), converts to just $16.23 per million Btu of delivered heat (see image). The beauty of an online calculator is that you can quickly and easily vary any of the inputs to compare lots of fuels and heating options.

It’s hard to predict the future

Keep in mind that energy costs are volatile. It doesn’t make sense to replace an oil boiler with a propane boiler based only on the heating cost savings given today’s rates, since they could change dramatically tomorrow. But if you’re thinking about replacing equipment anyway, you should consider the fuel costs of the alternatives.

Alex is founder of BuildingGreen, Inc. and executive editor of Environmental Building News. He also recently created the Resilient Design Institute. To keep up with Alex’s latest articles and musings, you can sign up for his Twitter feed.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

6 Comments

How about CO2?

The online calculator is really handy. I did a blog post trying to compare using my boiler to my minisplit for heating - although I didn't have the benefit of your calculator I guess I struggled through it correctly. :) But I wanted to look at CO2 as well as cost.

It'd be nice to see the CO2 output added to your calculator - I guess that would be tougher for some fuels than others.

As an aside, some mini-splits only advertise HSPF; perhaps a way to specify that rather than efficiency would be useful to some?

I hate it when...

... otherwise technical people come up with sentences like:

"Baseboard electric-resistance heat is 100% efficient — since the electrons you’re paying for in the electric current are converted entirely into heat..."

Electrons aren't paid for, consumed, or even moving (beyond the nano-scale vibe, which is smaller in dimension than even the thermal motion of the surface electrons) in the power grid. (Maybe it's just a peevish artifact that comes with a physics degree? :-) )

Eric: Regarding heat pump efficiency numbers, HSPF is a silly number cooked up to merge COP with watt hours & BTUs into a hybrid factor for to converting watt-hours consumed into BTU-out. HSPF= COP x 3.412 BTU/watt-hour. eg:

With pretty-good mini-split with a HSPF of 11, for every watt-hour used by the mini-split you get 11 BTU out . And since you generally pay in kwh, not watt-hours, for every kwh-in, you get 11,000 BTUs out. It has a nominal COP of (11/3.412=) 3.2 at the test-rated indoor & outdoor temps.

But it's not an across the board number- the test is over a somewhat arbitrary set of test conditions, and those test conditions would only rarely be found in a real-world application. For the particulars, feel free to look up DOE Test Procedure in 10 CFR; Part 430, Appendix M (ARI, 2003) ) Most mini-split vendors will also have a spec for COP for at least 2-3 outdoor temps (47F, 17F, and at least one lower), at some other somewhat arbitrary modulated levels of output. But it's generally true that the bigger the HSPF number the better the efficiency will be over a large range of in-situ indoor & outdoor temps & humidity, and across modulated power levels.

Being fully modulating units it's important to note that the part-load efficiency is generally much better at part-load at any given indoor & outdoor temp & humidity condition, and the difference in efficiency at minimum power can exceed 2x that at the full-out compressor & blower speeds at some temperature conditions. See the COP difference @ 35F test between min-blower & compressor speed vs. max speed in figure 5, p. 18 (.pdf pagination) of this document:

http://www.nrel.gov/docs/fy11osti/52175.pdf

what about the blowers?

Does the calculator make any assumptions about the cost of operation? Surely the operation of a 1400CFM fan in a forced hot air furnace adds to the operating cost of the unit, no? Same with the auger and blower in a pellet stove, or the circulators in a hot water system. Perhaps the cost is negligible compared to the cost of fuel - I wouldn't think so in the case of the hot air furnace blowers, but perhaps in the other systems it is a much smaller part of the overall energy consumption picture.

Calculator estimate quite different than actual

We have a mini-split heat pump. I just estimated that the unit used 632 kWh (2.156 MBTU) for heating the house in 2012. At 13 cents / kWh that works out to $85. I tried the calculator. I used 13 cents for the electricity cost. I selected mini-split and ducts in space (there are no ducts), and the estimate was $17.28 per million BTU. 17.28 * 2.156 MBTU = $37. If I manually change the efficiency of the unit to 100% instead the the default 225% then I get a number that is closer to what I'm experiencing. Either my unit is not performing as efficiently as it should be, or the calculator is making an assumption that is not published, such as an unusually warm average outdoor temperature. Just curious if anyone else had come up with vastly different numbers.

Response to Larry Burks

If you assume that your minisplit has a COP of 2.0, then 632 kWh of electrical input produces 4,313,905 BTU of heat.

If you assume that your minisplit has a COP of 3.0, then 632 kWh of electrical input produces 6,470,858 BTU of heat.

Your assumption (that 632 kWh of electricity produces 2.156 MBTU) is only true for electric resistance heaters. When you use a minisplit, you get more heat per unit of electricity.

Response to Martin

Doh, I see my mistake now. I converted kWh to BTU using the standard conversion factor. Thanks Martin.

Log in or create an account to post a comment.

Sign up Log in