Image Credit: Oak Ridge National Laboratory

By this time next year, if all goes well, builders will be able to tap into a unique source of online advice for designing exterior walls that deliver high energy efficiency with minimal risk.

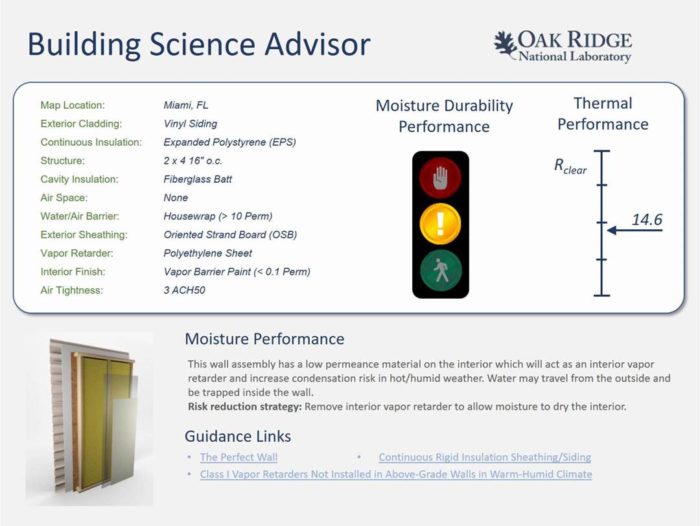

Building Science Advisor, already in the works for a year and a half, is still at least six months away from completion. But when it’s up and running, the interactive website will blend real-world advice with computer simulations to help builders choose the least risky path to high-performance.

Spearheading the project is André Desjarlais, the program manager for Building Envelope and Urban Systems Research at the Oak Ridge National Laboratory. The target audience, he says, are builders who are nervous about the risks associated with building tighter, better insulated houses. He heard plenty of those misgivings through Building America, the Department of Energy program that addresses building science questions for residential construction.

“Through the grapevine, we got a lot of feedback,” Desjarlais said by phone. “Builders were saying, ‘I’m really nervous about the changing of the building codes. You’re adding insulation; you’re making the wall systems more airtight. You’re forcing me out of my comfort zone. How do I know this is going to work? How do I know I’m not going to get into problems.’”

In a survey conducted by the Home Innovation Research Labs, the research arm of the National Association of Home Builders, builders were asked what kept them up at night. “Moisture in walls, moisture in attics, were one and two,” Desjarlais said. “The survey agreed with our casual observation of what people were telling us.”

Builders, it seemed, wanted more than an online library of research papers or a stack of magazine articles before diving into the world of energy-efficient construction.

Computer simulations weren’t enough

At first, Desjarlais and his colleagues thought they could build a huge database of wall systems using computer simulations alone. The Building Envelopes Program at Oak Ridge already had loads of data on various wall systems. Why not turn that into an online library accessible to builders?

Because, they realized, lots of builders don’t trust computer simulations. One reason is what’s politely called the “garbage in, garbage out” effect: however good the computers and software may be, loading information into a modeling program improperly will never produce anything but inaccurate results. Computer modeling is especially contentious among builders when it comes to predicting how high-efficiency buildings, such as those built to the Passive House standard, will actually perform.

“There are some people out there who go out of their way to bad-mouth computer simulations,” he said. “What I think what they’re really bad-mouthing is there are a lot of people out there who are not skilled enough to do that sort of exercise, who don’t have the knowledge to appreciate the outcomes of the selections they make to run the computer simulations.

“The tools are correct from a physics perspective,” he continued. “We’ve validated the tools so many different times, whether they be on masonry systems or stick-built systems. We’re confident that if you do it right it works. But a couple of people who yell louder than most have gotten it into the builders’ minds that these computer models just don’t work.”

Developers thought the solution was to anchor the program in the expert opinions of builders in the field and fill in the gaps with computer simulations when the information was incomplete or contradictory.

Getting advice from builders

Desjarlais and his group began looking for builders who could contribute information based on their experience. Over the course of a year, they solicited builders at conferences and trade shows, giving them a “teaser” of what they hoped the tool would do and eventually collecting the names of some 200 builders who said they were willing to help.

These builders became the beta testers for the Building Science Advisor. This past August, Oak Ridge sent a link for the in-development web tool and asked for comments. The comment period ended in early October, with about half of the original list of builders taking the time to go over the site and sending in their comments.

“We got everything from ‘This is the best thing that ever happened,’ to ‘You guys are stupid, this has already been done,’ and everything in between,” Desjarlais said.

Developers are still going over the comments with the goal of creating some general rules that would be useful to other builders. “What we want,” he said, “is a good a compilation of expert advice as we possibly can put together.”

Desjarlais said there are at least two other web-based tools designed to give builders similar insights. One, created by a company called IBACOS, is called Perform. It offers an online library to its client base of mostly production builders. The other online tool is the Wall Thermal Design Calculator developed by the Canadian Wood Council.

Desjarlais said one important distinction is that Building Science Advisor rules will be created with the help of dynamic rather than steady-state calculations. Dynamic calculations, he said, take into account the constantly changing conditions that affect buildings rather than relying on brief snapshots of climate and performance. The Canadian design tool, he said, doesn’t include very challenging building scenarios. Although it uses WUFI simulations, it’s focused on wood construction with low energy loads.

“You can’t find anything that doesn’t pass there,” Desjarlais said of the Wall Thermal Design Calculator. “Everything passes. If I use very low moisture loads, I can make anything pass. What good is that?”

(A spokeswoman said the Perform library has information on more than just wall systems, but access to the library isn’t free.)

How the tool will work

Building Science Advisor will include recommendations for between 80 and 90 cities around the country, spread out geographically and climatically as best its developers could manage. Although the number of data sets is low, Desjarlais said the hope is that builders who can’t find the city where they plan to build will be able to find a city with a similar climate — in a neighboring state, say.

Desjarlais said developers want to put their money into describing the maximum number of potential wall systems rather than a long list of building locations.

A builder planning a house in Maine, for example, could choose one of two cities as a starting point. After logging on, the builder would begin specifying building components — framing, insulation, and cladding, for example — and get an idea of how risky the wall might be. In the end, Desjarlais says the tool will treat systems “probabilistically” to give builders the odds on whether a particular wall system will result in moisture or other problems.

“No one else has done that in the past,” he said. “Instead of saying, ‘This wall passes and this wall fails,’ you say, ‘Eighty-seven percent of the time this wall is OK, and 92% of the time this wall is OK,’ and so you can give people a better indication of what how close you are to getting into trouble.

“Then, this is André’s vision, you can start playing some ‘what ifs,’ ” Desjarlais continued. “What if I get rid of this component and put a cheaper component in? My risk goes up by 5% but I just saved a dollar a square foot. It gives builders some useful information they can work with and make their own decisions. They can make the decision based on data as opposed to whim, or whatever.”

Computer modeling still plays a role, but mostly when there isn’t enough information coming in from builders, or the information is contradictory or unclear. “One of the interesting things about getting information from so-called experts is how frequently the experts disagree,” Desjarlais said. “We can use computer modeling to get to solutions where we have a disagreement of opinions, or for a family of systems where there isn’t enough wisdom.

“Hopefully the tool will tell them the same thing that their own experience tells them. If we can do that in 90% of the cases I think we’ll be in good shape.”

The website will not make an attempt to predict the costs of various wall systems, Desjarlais said — at least that’s the case at the moment. Material and labor costs associated with different wall types is out of date as soon as it’s published, he said, and individual builders will be far better suited to collecting that information.

Desjarlais said that he hopes the website will go live by next August. It probably will be hosted at the Building America Solution Center. Access will be free. (To read a GBA review of the Building America Solution Center web site, see A Web-Based Information Resource From the DOE.)

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

2 Comments

The jury is still out

It will be interesting to see whether this proves to be a useful tool or not. I heard Eric Werling give a presentation on the Building Science Advisor tool at the Envelopes conference in Clearwater Beach, Florida on Dec. 6, 2016. The example that Werling shared with the group -- a way that the new Building Science Advisor tool could help builders stay out of trouble -- was a brick veneer wall in Fort Worth, Texas, built with no air space between the brick veneer and the OSB sheathing (see the image below -- a slide from Werling's presentation). The advice provided by the tool developed by ORNL: "To ensure moisture durability add at least a 2 inch ventilation cavity between absorptive cladding and sheathing."

Evidently, the researchers at ORNL didn't realize that this gap behind brick veneer is code-required, and has been recommended for decades as standard practice by the brick industry.

I'm not saying that the gap is always there -- we all know that mortar droppings sometimes clog the air gap. But the insight of ORNL researchers in this case wasn't particularly brilliant. Most builders would respond, "Well, duh" to this advice.

.

Great update

I believe the BSA is developing a great idea, by providing free information to many folks that don’t have the knowledge or resources to help design a safe wall (and hopefully roof) assemblies.

Even though 2015 IRC tables R806.5 and R702.1 provide general information to avoid condensation, in some areas of the country, like the Southwest, you could have 2 or 3 climate zones with in one county alone, and being able to get this information in about 2 minutes and free online, is awesome.

I also hope they follow thru with folks that made an input back in August, as they said they would by mid-September, and so far nothing. I participated by describing the typical wall assemblies that I specify in my work, but found that common options were not available, and I thought our assemblies were very simple. If I recall correctly, there were no options for roof assemblies neither. I believe roof condensation is more common than wall condensation.

Log in or create an account to post a comment.

Sign up Log in