If only Kevin Hoene’s choices for a new roof boiled down to a choice between an EPDM membrane and metal, his life would probably seem a whole lot simpler.

But Hoene, building a new home in Illinois and on the boundary between Climate Zones 4 and 5, will soon be weighing the pros and cons not only of different roof coverings, but also of what type of insulation to use, whether it should go above or below the roof sheathing, and whether the roof should be vented or unvented. In other words, nothing seems off the table.

“Our house is being built near the boundary of Zone 4 and 5 in Illinois with a 1:12 pitch metal roof,” Hoene writes in a Q&A post at GreenBuildingAdvisor. “I’ve done a lot of research on low-slope roofs because our builder does not have a lot of experience with flat roofs.”

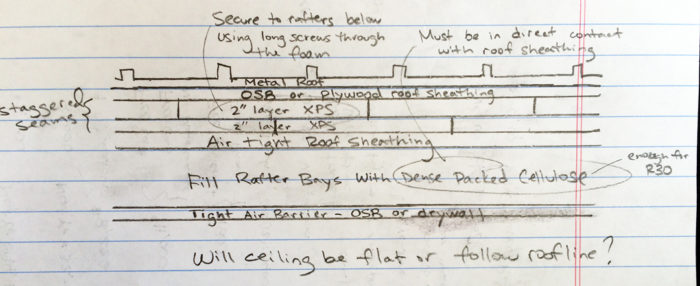

After reading a couple of articles on the topic by GBA Senior Editor Martin Holladay, Hoene is leaning toward an unvented roof assembly (see the sketch above), which would include cellulose insulation in the rafter bays and 4 inches of extruded polystyrene (XPS) rigid insulation above a layer of airtight sheathing. That would be followed by a second layer of OSB or plywood sheathing and, finally, the metal roofing.

“Does the diagram look like a good approach?” he asks. “Any details that I should pass along to our builder about the roof trusses?”

Those questions are the start of this Q&A Spotlight.

Choosing the type of roofing

A first step, Holladay suggests, would be finding out whether the type of metal roofing Hoene is considering can be installed on the roof he’s planning. The pitch is very low — rising only 1 inch for every 12 inches of run — and some…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

15 Comments

Follow up

As the homeowner of the project in question, I'd like to follow up about how we ultimately proceeded. After much discussion, we chose to do an unvented assembly. Our roofer used 90 mil EPDM on top of 1/2" densdeck on top of 2" polyiso on top of 7.5" EPS on top of asphalt felt.

With the insulation at the roofline (and the vertical walls insulated all the way to the roofline), the attic is completely inside the conditioned space.Your article cites the need for venting with inside air. This takes me back to the use of recessed can lights. Since the barrier is now at the roofline and not at the ceiling, is there no longer a need for an airtight ceiling? is it acceptable to use can lights now? Will can lights actually be beneficial because they will help ventilate the attic space with inside air?

Response to Kevin Hoene

Kevin,

Q. "Your article cites the need for venting with inside air. This takes me back to the use of recessed can lights. Since the barrier is now at the roofline and not at the ceiling, is there no longer a need for an airtight ceiling?"

A. First of all, I am less convinced that Peter Yost or Brian Knowles that the type of attic you are describing -- an unvented conditioned attic that is entirely within the home's thermal envelope -- needs any kind of venting, especially when all of the insulation is on the exterior side of the roof sheathing. I'm not sure what purpose this venting with interior air is intended to serve. While it's true that some attics insulated with open-cell spray foam on the interior need to be deliberately conditioned with a home's HVAC system to lower the chance of moisture accumulation in the sheathing, your roof assembly has no open-cell spray foam.

So, here's my advice: don't worry about "venting" this unvented conditioned attic.

You can install all the can lights you want in your ceiling. Both sides of the ceiling are indoors, so you aren't penetrating an air barrier.

Night-sky radiation

This comment could be misleading:

"In cold climates, white membranes and white metal roofs can be associated with significant night-sky radiation and much cooler attic spaces."

Almost any roofing material except shiny metal will have high thermal emissivity. For example, http://coolroofs.org/documents/ICCtoCRRC-HeatWavePowerPoint_3of3_.pdf lists black, gray, and white EPDM as having 0.86 or 0.87 emissivity. Absent some special treatment, any shingles or asphalt coating or EPDM will experience about equal night-sky radiation and cooling as a result.

The difference is just how much solar heating it gets during the day. If a roof starts out very hot from the solar gain, it won't end up as cold at the end of the night. And the black roof certainly absorbs more solar radiation: 94% vs. 31% for the white EPDM.

That's right- it's really DAY-sky reflectivity & radiation

The more reflective a high emmissivity roof covering is to the solar spectrum, the lower the average roof temp, resulting in a colder average temp at the roof deck and in the attic below.

But the nightly low temp is barely affected by the daily peak temp, usually limited from going colder than the dew point of the proximate air. A black roof get just as cold as white roof on a clear cold night, but the black roof gets much warmer during the day.

similar question with more slope

Martin,

With regard to venting and insulating an unvented roof, how would your recommendations change for a roof with a 4:12 pitch in a similar climate zone? Assume standing seam metal roofing.

Response to Antonio Oliver

Antonio,

Here is a link to an article that explains everything you need to know: How to Build an Insulated Cathedral Ceiling.

Response to Charlie Sullivan and Dana Dorsett

When I interviewed Bill Rose in 2006 about the phenomenon of sky radiation during daytime hours -- a problem in Arizona with fiberglass-insulated low slope roofs and white roofing -- this is what he told me: "There is nothing standing in the way of the roof radiating out to space. You have a whole lot of heat loss from the roof surface, day and night. With this white roofing, 80 percent of the heat that hits the roof is reflected. The sun can’t keep up with the heat losses to the sky. What you’ve created is a sky-powered cooling coil, and the fiberglass insulation is like a dirty condensate pan."

90 mil EPDM, wow that is a

90 mil EPDM, wow that is a nice roof, I thought I upgraded at 60. The roof field will outlast the tape and flashing, so when you are old and gray and get a leak, make sure they don't sell you a new roof as I am willing to bet that material will outlive you.

Can lights: I am willing to bet even with R50 above, the area between the sheet rock and the roof will get 'cold' and thus you will get 'drafts' . I would gasket them like they are going in a real attic and not worry about it.

Response to Alan Benoit

Alan,

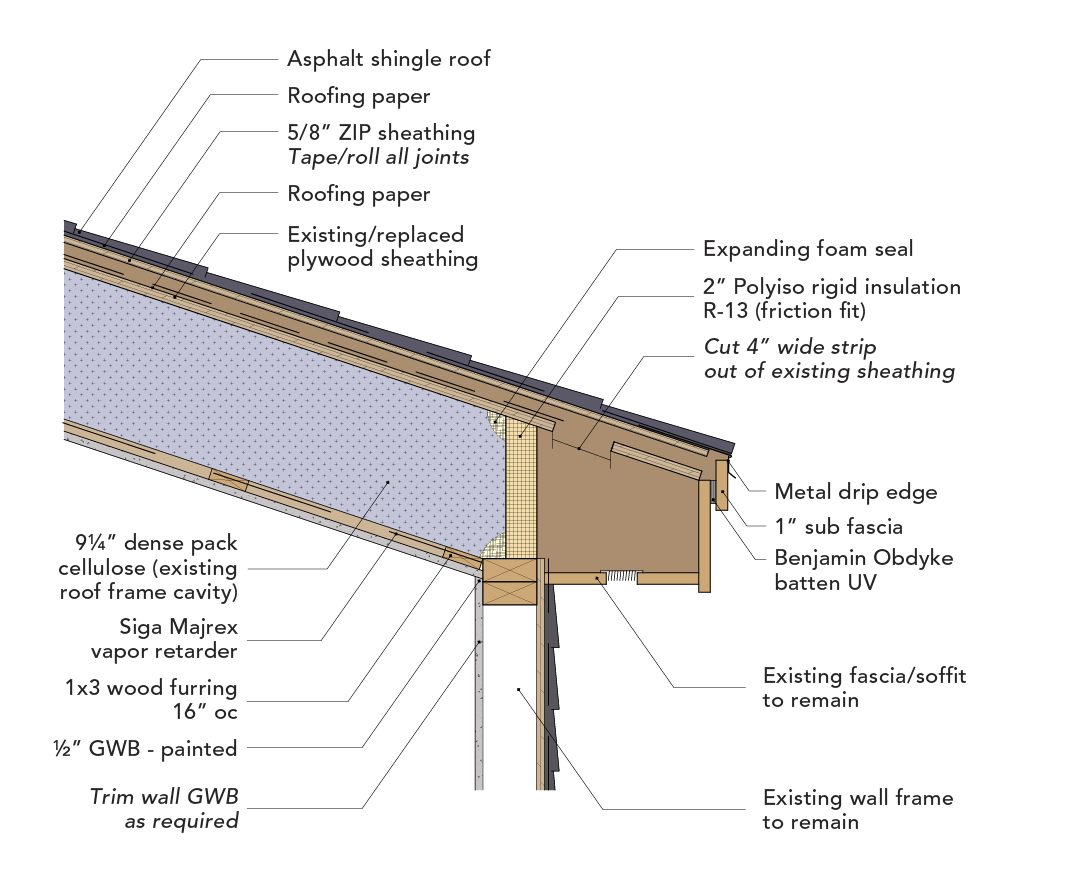

If the upper edge of a low-slope shed roof intersects a vertical wall, the most logical approach (in my opinion) is to detail the roof as an unvented roof.

Another approach is to build a cupola or ventilated doghouse in the middle of the low-slope roof -- an approach championed by Joe Lstiburek.

For more information on either of these approaches, see Insulating Low-Slope Residential Roofs.

What if it is a lean-to roof and runs into a vertical wall?

I am working on 3 projects currently where we have a low sloping roof like the one discussed above that terminates against the gable end of the house; think typical Vermont vernacular. We are creating a well ventilated space above the well-insulated, low-slope roof and have vertical 3/4 strapping creating a drainage plane for the gable end wall. Keeping water, rain and snow out of the vent space prevents us from connecting the two air spaces and thus the low-slope roof needs its own vent at its higher termination against the wall. Are there systems/details/techniques others have used that work for this application? I've seen some ridge-vent like systems available, but wonder how they work under wet snow, etc. Here's a preliminary section detail...

Follow up to Martin Holladay

Thanks Martin,

Actually it was my attendance at Joe Lstiburek's building science seminars this year that have driven me to VENT these roofs, when I would have normally designed them as warm roofs. His guidelines for roofs in areas of more than (I think) 50 inches of average annual snowfall, he suggest venting the roof to avoid ice dams. He has been retrofitting many roofs in ski resorts out west that are dealing with huge ice dams. This happens when the insulation of the snow on the roof is so thick that is traps the heat and overpowers the roof's insulation values causing melt at the roof surface; and so on. Maybe what I'm referring to isn't truly a low-slope roof; as they are all 3/12 or 4/12 pitch, but the challenge to venting them still remains...

Thank you again,

Alan

Response to Alan Benoit

Alan,

A standing-seam metal roof is at a very low risk for ice dams -- especially if the roof has no valleys.

Day/night clear sky radiation

I'm not measuring roof temperatures that are in line with Bill Rose's comment, quoted by Martin, on white roofs and sky radiation. Bill says that the sun can't keep up with the radiant heat loss from a white roof in the desert. After reading that comment, I went out to check my roof. The air temperature is 42 degrees outside, right now, at my desert New Mexico home, at 6,300 ft elevation, and the sky is a cloudless, clear blue. The wind is blowing 16 mph, the humidity is 35%, and the dew point is 20 degrees, according to the online weather station nearest me. Sunset is 45 minutes away, so the sun angle is low.

I just measured the temperature of a section of white metal roof, and got a reading of 73 degrees. I'm not sure I can trust the reading, but the metal feels warm to the touch. On the shaded side of the roof, the metal feels cold. It seems to me that the sun is keeping up pretty well with sky radiation and conductive heat loss. I don't think I will be getting any condensation under this roof, while the sun is out, today. In full summer sun, this white roof is uncomfortably hot to touch, although I don't have a numerical measurement. Bill's comment doesn't match my experience. While I don't get up on my roof that often, I've touched the hood, door, and roof of my white cars hundreds of times in all seasons. They always feel warmer than the air temperature, if the sun is shining.

Alan

There are number of ways to vent a lean-to roof - some more practical than others. I'd suggest one of these two for venting at the end wall flashing:

1.

- Fur out the end wall flashing that covers the top of your roofing panels with strips of 1x3" material so that there is a cavity created behind the vertical portion which is open to the roof air space below.

- Fasten a Cor-A-Vent strip to the outside of the end wall flashing near the top.

- Counter-flash above this with a Z flashing bent to cover the Cor-A-Vent.

2.

- Treat the end wall flashing as though it were one half of a metal ridge cap.

- Leave a gap at the top of your roofing panels open to the airspace below.

- Apply vented closure strips to the top of the roof panels, and cover with the end wall flashing.

Day/night clear sky radiation

Martin,

What you quote Bill saying about sky radiation makes more sense than the quote in the article... Perhaps "night" was a mistake in the article. The visible color only matters during the day.

Derek, some whites reflect near IR in solar radiation, but some absorb it. It sounds like yours absorbs it whereas the ones Bill refers to are probably the "cool roof" materials that reflect the full solar spectrum.

Log in or become a member to post a comment.

Sign up Log in