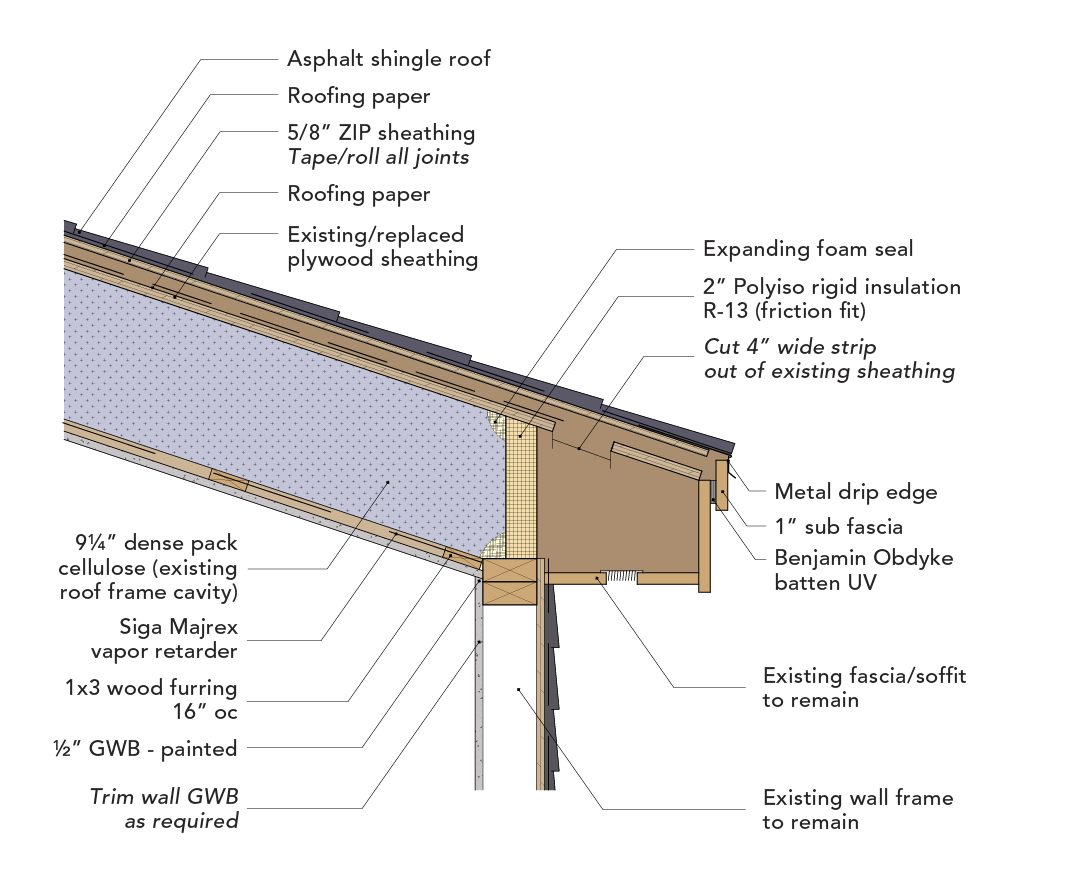

Image Credit: Images #1 and #2: Studio-tm.com/construction blog — Project: splyce.ca

UPDATED on April 8, 2016

There are lots of ways to insulate a low-slope roof, and most of them are wrong. In older buildings, the usual method is to install fiberglass batts or cellulose on top of the leaky ceiling, with a gap of a few inches (or sometimes a few feet) between the top of the insulation and the roof sheathing. In some cases, but not all, there is an attempt to vent the air space above the insulation to the exterior.

It’s rare for anyone to inspect the roof sheathing — unless, of course, the boards gets spongy enough to be noticed when the building is re-roofed. If there were any way you could squeeze into the tiny attic under the flat roof, however, you would probably see evidence of mold or rot.

Defining our terms

What’s a low-slope roof? It’s a roof that is flat or almost flat. While some sources define a low-slope roof as one with a pitch that is less than 3 in 12, ASTM (in Standard E 1918-97) defines a low-slope roof as one that has a pitch that is less than 2 in 12.

This type of roof is common in urban areas (for example, on triple-deckers in Boston and row houses in Philadelphia), as well as in the Southwest. Some of these roofs have parapets — perhaps on just one side of the roof, or perhaps on three or four — while others have no parapets at all.

These roofs are either framed with deep roof trusses, or are framed with roof rafters that are separate from the lower ceiling joists (creating a cramped attic between the flat roof and the ceiling). In some of these buildings, the attic is high enough to allow a person to climb into the attic through a hatch; in others, the…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

187 Comments

Some observations that were not publishable

Good job.

Whenever you do research you always have the recorded findings and then some side observations — never enough for publication, but they get filed away for later (or not). We had two pertinent observations in this Arizona study, without enough support to draw publishable conclusions:

1) Venting didn't work. It may have had a slight effect of warming the underside of the roof, but with low-slope it's all wind and no buoyancy, and at night the air is quite still. Plus, they were adding vents without adding an air space. Not helpful and not publishable.

2) Cellulose insulation was installed in one single case. The cellulose was at the bottom of the assembly rather than at the top, of course. That assembly had no problem at all and stayed really dry. I think we underestimate the impact of even seasonal moisture storage in cellulose.

Bill Rose

I sure hope that nobody is

I sure hope that nobody is still building "vented flat roofs" nowadays.

steel deck + vapor membrane and exterior insualtion is the only way to do it.

Martin: just a quick thought,

Martin: just a quick thought, the same "dew point" rule/calculation applies to roofing assembly then walls ?

If so, it would mean that some quantity of interior insulation could be possible even if within the final vapor membrane ?

I do like the steel roof deck used a a reflective radiance material though ...would loose this property if packed up with some insulating materials ??

Dimensional Stability

Martin,

Thanks for the great article. I noticed in the photos that the roofers/insulators are using sheets of EPS installed in staggered layers that are considerably smaller than an average 4'x8 sheet, but you didn't touch on this detail in your article. The Manual of Low-Slope Roof Systems, has a great section explaining the importance of using smaller insulation boards to improve dimensional stability. For example, the National Roofing Contractors Association (NRCA) recommends using rigid insulation boards that are 2'x4' to reduce stress on roof membranes. Lstiburek does a great job explaining why rigid foam insulation expands and contracts in his "correction" to Foam Shrinks, and Other Lessons. The Manual of Low-Slope Roof Systems also has valuable information on inverted (IRMA) or protected membrane roof (PMR) systems that readers in more extreme climates may find interesting. Plus the manual contains more great info on the pitfalls of ventilating low-slope roofing and the authors do a great job hammering home the importance of preventing ponding with adequate slope and drainage.

So it looks like the roofers/insulators in the photos got the smaller rigid foam boards right; however, there doesn't appear to be a structural air-barrier at the roof sheathing. Perhaps they are relying on SPF or SIGA tape below...any thoughts?

Readers may appreciate the article: Breaking With The Code for more observations regarding the typical ineffectiveness of ventilating low-slope roof assemblies.

Response to Jin Kazama

Jin,

Q. "Does the same dew point rule/calculation apply to roofing assemblies as walls?"

A. No. All of this is explained in my article, Calculating the Minimum Thickness of Rigid Foam Sheathing. While most of the article talks about walls, there is a section ("Is there a similar chart for unvented cathedral ceilings?") that talks about roofs.

The reason that the recommendations differ for roofs is that rafters are usually deeper than studs. It's common for rafters to have more insulation than studs; that makes the sheathing colder, which means that the rigid foam has to be thicker.

Response to Skylar Swinford

Skylar,

Thanks for the added information, and for the useful links.

You're right that the roof in the photo would probably have benefited from an air barrier between the roof sheathing and the insulation (or at least taped plywood seams).

For more information on dimensional instability in roofing foam, see my July 2000 article on the topic, "Shrinking Insulation Boards Plague Roofers." The article was published in the "Notebook" section of JLC; scroll down to the end of the section to find the article. (The article is also shown in the attached image.)

The link to your article "Shrinking Insulation Boards Plague Roofers" doesn't work. I hope to avoid that problem on a warm roof installation.

Nils,

I have updated the broken link. I have also attached an image with the relevant part of the article. Thanks for letting me know about the broken link.

I hope the shrinkage problems have been solved since that article was written. A slight decrease in R value is nothing compared to 3 inch gaps in the insulation. Thanks for the image. My eyes glaze over when told to subscribe to another publication as was the case when I clicked on the link.

Expanding on Martin's response to Jin Kazama

Not only are the insulation depths bigger, in a roof assembly there is an extremely low-permeance exterior finish surface (the roofing material itself) that is often wet with dew/rain/snow anyway. Literally ALL drying of the assembly is toward the interior in an unvented roof.

This can be true of wall assemblies with foil-faced foam on the exterior too. The IRC prescribed minimums are just that, MINIMUMs, not optimal, not necessarily the best. Personally I'd normally shoot for more exterior R, and a more vapor-permeable exterior R. (EPS is about permeable at R15 as XPS is at R8) When there are foil facers in the mix I prefer to go 25-50% more than the IRC prescriptive min- margin counts.

But the moisture buffering of cellulose also counts. At IRC prescribed minimums there's a real difference in the seasonal moisture cycling of the sheathing between mineral/glass wools and cellulose (any density) for the fiber layer of the stackup. Bill Rose's second observation in the first comment is not a fluke.

FWIW: A few years ago I dense packed a portion of the underside of 2x10 rafters 12" o.c of a north side flat roof shaded by the taller portion of the building. It has tapered EPS on top of the roof deck under a membrane that has since been replaced. Other parts of that roof had ~R10 rock wool batts between the rafters. Some of the roof decking on the portion with the batts became punky and had to be replaced during the re-roofing, but so far the dense-packed portion remains solid. This is in a building with low occupancy rates and few interior moisture sources, and though the foam/fiber ratio wouldn't cut it from a code point of view in a residential building, I'm not too worried- it seems to be doing the job.

Seriously, how much more

Seriously, how much more labor is is to make a vented roof and install cellulose/batts on ceiling than

it would be to simply use more rigid insulation on top.

With the current EPDM and other membrane prices and technology ...

I am considering a balasted ( pebles ) epdm on top of a "to be determined" R value of rigid insulation

that will be fastened to the steel deck through a peel stick membrane that will serve as inside vapor barrier.

I don't see how one could do simpler than that labor wise.

wood sheathing has no place in a roof, always ends up leaking somehwere and then it needs to be torned out again whereas a leak on a steel deck can usually be fixed without destroying the roof.

Bill's Sample of One

I realize it would be dangerous to draw much of a conclusion from the one cellulose-insulated roof, but it certainly is interesting and begs for more investigation. Bill H. is chuckling to himself somewhere in the background.

A 12" SIP can solve all the moisture issues and support itself

An EPS structural insulated panel for the roof/ceiling system can really make it easy. Because of all the issues it solves, the extra cost is warranted. If the engineering is done right, the SIP will save a lot of money on roof joists and beams because of its inherent stiffness.

A SIP is also the most elegant way to eliminate thermal bridging at the roof/wall connection.

At R-48, however, it's a little less than optimum. Is anyone making a 12" polyurethane SIP? Or a 16" EPS SIP?

Cover it with white EPDM, and you should be good for 50-70 years, even in hail country.

Response to Kevin Dickson

Kevin,

As I wrote in the article, "The insulation methods [for low-slope roofs] are similar to those used to build an unvented cathedral ceiling." And in my article on cathedral ceilings, I wrote, "Another possibility, of course, is to build your roof with structural insulated panels (SIPs)."

SIPs are rarely used for commercial low-slope roofs, because they are more expensive than the more common approach (installing rigid foam on top of the roof sheathing). The other problem with SIPs is the tricky matter of sealing all of those seams.

Considering the higher cost of SIPs and the seam-sealing problem, most designers will probably stick with more conventional approaches to insulating low-slope roofs.

Low-Slope Venting: "All Wind, No Buoyancy"

Bill, Martin:

If we define 'low-slope' as 'flat, or nearly so', do we state a pitch < 1 in 12 ?

And to avoid a nerd-fest on that definition, the question is this: At what pitch would we expect buoyancy / air density differential to create ventilation air movement worth considering as a mechanism for drying ? (ignoring for discussion wind pressure differentials as a factor, and assuming Joe's 6" air space as entirely inviolate/ extant, except for dust and pollen particles, and the stray African Swallow carrying coconuts.)

Response to Rich Backus

Rich,

Your question may be of interest to researchers, but probably not to builders. For builders, such hair-splitting falls into the category of "misplaced accuracy."

If you are worried that your roof won't get enough air flow for proper venting, the solution is simple: build an unvented roof.

For a builder, a low-slope roof is like pornography for a Supreme Court justice: you know it when you see it.

Air-cooled insulation

Martin:

Isn't free ventilation pulling perimeter air up and through "dog-houses" reducing the insulation value of the fiberglass/cellulose insulation layer? Moving air is the enemy of effective insulation...

Response to John Walker

John,

Q. "Isn't free ventilation pulling perimeter air up and through "dog-houses" reducing the insulation value of the fiberglass/cellulose insulation layer?"

A. The degree to which wind-washing degrades the performance of air-permeable insulation depends on many factors. Ideally, the incoming ventilation air is introduced above the top of the insulation layer; if this is the case, then a ventilated low-slope roof is no different (at least in theory) from a ventilated attic.

In a classic ventilated attic, wind-washing does slightly degrade the performance of the insulation near the soffit vents -- especially if the insulation is fiberglass, and especially if there is no wind-washing dam. If a wind-washing dam has been installed, or if the builder has chosen cellulose insulation instead of fiberglass, the thermal degradation caused by wind washing is much less.

In general, there are three ways to minimize the negative effects of wind-washing:

Choose cellulose, not fiberglass

Install wind-washing dams near soffits

To make up for possible wind-washing effects, make the insulation a little bit deeper than you otherwise would.

Open vs closed-cell foam on underside of a low-slope roof

Good morning.

Planning an addition in Montreal, Canada, with a low-slope roof (Soprema modified bitumen roofing on plywood or OSB on engineered joists).

Was planning on spraying about 6 inches of closed-cell foam on the bottom of the plywood deck (as air and vapor barrier).

I am being told that 12 inches of open-cell foam on the bottom of the plywood deck (as air barrier) with a paint vapor barrier may be a better option.

The logic, as I understand, is that if there is a leak in the roof and closed cel foam was used, the owner will have no idea of the problem. The moisture will be trapped above the foam and the plywood runs the risk of rotting.

However if open-cell foam was used with a paint vapor barrier, if a leak occurs, there is a much better chance that the owner will see a stained ceiling and take action before rot sets in

Any thoughts/comments? Thanks in advance!

Response to Marc Daniels

Marc,

I strongly urge you to choose the closed-cell spray foam.

In your climate, open-cell spray foam (which is vapor-permeable) allows interior moisture to reach the roof sheathing by diffusion. Over the course of the winter, the sheathing can get wet enough to begin rotting.

One solution that was recommended in the past (even I recommended it until I learned why it is bad advice) is to spray vapor-retarder paint on the underside of the cured spray foam. The only problem with this solution is that it doesn't work.

Engineers at the Building Science Corp. conducted tests that showed that vapor-retarder paint only works when you spray it on gypsum drywall (a smooth surface). When you spray the paint on an uneven porous surface like cured spray foam, it is worthless as a vapor retarder. The interior vapor goes right through the paint.

One possible solution (if you really want to use open-cell spray foam) is to cover the cured foam with a layer of gypsum drywall, and then to spray the drywall with vapor retarder paint.

Better yet, just choose closed-cell spray foam.

More information here: Creating a Conditioned Attic.

Response to Martin Holladay

Thank-you Martin.

I was not clear in my description. As for the open cell foam option, the plan was to fix drywall to the bottom of the engineered joists and then apply a vapour barrier paint to the drywall. The idea being that if there is a roof leak, the moisture would travel through the plywood roof deck and through the open cell foam and down to the drywall. The owner would then be aware of a leak and would able to fix before rot sets in.

I would prefer to use closed cell foam. The concern in this case is that if there is a roof leak, water would be trapped in the plywood deck by the closed cell foam. The owner would have no idea of this until the plywood deck would rot out.

Further thoughts?

Response to Marc Daniels

Marc,

The question you raise is a thorny one. Many people have proposed the same theory: that roof leaks will show up faster if you use open-cell foam rather than closed-cell foam.

Maybe. However, I have my doubts that the situation is as simple as the theory proposes.

I used to work as a roofer, and I know from experiece how hard it can be to trace a roof leak by looking at ceiling stains.

Some roof leaks show up as ceiling stains or ceiling drips immediately. Those are the easy cases.

Far more common are the roof leaks that start slow and aren't noticed for a year. This happens all the time, even with conventional building materials like wood framing and cellulose insulation. When the ceiling stain finally appears, it can be 20 feet sideways from the leak. Water moves, and water does tricky things. Many building materials are absorbent, complicating the situation.

It's even possible that closed-cell foam, being more waterproof, is more likely to protect vulnerable building materials from damage than open-cell foam.

The fact is, there are too many variables to make a clear-cut ruling on this issue. The bottom line: no matter what type of roofing, sheathing, or insulation materials you use, you want to repair any roof leaks as fast as possible. Sometimes fast repairs are possible because the owners are paying attention, and sometimes fast repairs are possible because of luck.

Other times, even when you think you're paying attention, a hidden roof leak can do considerable damage before anyone notices.

Finally, if you are really worried about this issue, there is a simple solution: design a building with a ventilated, unconditioned attic, and go up in the attic with a flashlight regularly to inspect the roof sheathing.

Response to Martin Holladay

Thanks again - very much appreciated!

Insulating a cool, self-drying, vented, low-slope roof

I own a mid-century modern home in the Seattle area with a 1/12 pitch roof over vaulted ceilings separated by 2x6 joists with R13 batt insulation, venting at the soffit and ridge, and a condensation issue that started after the modified bitumen roof was replaced last June with a white TPO membrane. I've been reading all of Martin's articles and I'm still not satisfied that I have the best solution. It seems that the root of my condensation problem is that we've lost sight of the self-drying properties of a torch down or modified bitumen roof assembly because we're so focused on cool roofs using membranes with lifetime material warranties. If you read some of these articles below, you'll see that the heat absorbing properties of these older roof systems are part of the design. You may also notice the precautions for colder climates in the U.S. Department of Energy Guidelines fo Selecting Cool Roofs.

http://web.ornl.gov/sci/buildings/2012/1995%20B6%20papers/090_Desjarlais.pdf

http://www.epdmroofs.org/attachments/2012-jan_coolroofscausecondensation_dregger_wr01123.pdf

http://www1.eere.energy.gov/femp/pdfs/coolroofguide.pdf

Unfortunately, I put complete trust in my roofer and now I have a leak free lifetime roof that condensates inside and doesn't dry out very quickly. In my search for a solution, I've found that most, if not all, of the technical documentation for TPO membrane are focused on commercial roof assemblies and they require an "adequate" insulation layer above the roof deck. It seems to make sense that some insulation above the roof deck would be appropriate when replacing a modified bitumen roof with a cool membrane roof to make up for the difference in solar reflectance and thermal emittance properties. However, residential roofers tend to dismiss the need for insulation above the roof deck as a waste of R value. What do you think? If I re-roof again this summer, should I go back to modified bitumen or should I add a layer of insulation above the roof deck and use a darker color of TPO or PVC? I've also considered replacing the batt insulation, either with a dense packed blow-in-blanket system followed by 3" of rigid insulation above the roof deck or maintaining the vented system with 4" of closed cell spray foam above the ceiling, or 4" of rigid insulation sealed in above the ceiling. These other options are a lot more expensive and are still not foolproof. I've already ruled out the option of removing the ceiling to fix the problem from underneath because it's too disruptive.

Response to Confused Homeowner

C.H.,

The problem you are experiencing is described in my article, under the subhead, "If you forget to vent the attic, lots of things can go wrong."

In those paragraphs, I describe how white membrane roofing stays colder than dark roofing, encouraging condensation. Building scientist William Rose describes this type of roofing as a "sky-powered cooling coil," while "the fiberglass insulation is like a dirty condensate pan. The roof sheathing gets so cold that it is sucking wetness out of dry air."

Soffit-to-ridge venting doesn't work on a low-slope roof, as my article explains. For all intents and purposes, your roof assembly is unvented. The solution, as you correctly realize, is to install rigid insulation above your roof sheathing.

Since your roofer recommended a defective roof assembly, your roofer should fix the problem at no charge to you.

Insulating a cool, self-drying, vented, low-slope roof

Since you said, "for all intents and purposes, your roof assembly is unvented", would you recommend converting to an unvented roof assembly? I've observed that dripping and other signs of condensation damage are concentrated under roof bays that have inadequate venting. This leads me to believe that my venting does work, but it needs to be improved with additional vents above and below my chimney and skylight. I'm also afraid of what might happen in a completely unvented roof assembly if I fail to completely seal off air leaks from the ceiling.

If I stick with venting when I re-roof, then should I keep the R13 fiberglass batts if they seem to be in decent shape? Or should I replace the batts with closed cell spray foam or rigid polyiso that has been cut to fit? Both approaches would provide the benefit of a higher R value and the disadvantage of making any future changes, such as electrical wiring, more difficult. Spray foam would create a better moisture barrier, but it's more expensive and I think it would likely involve use of harmful hydroflourocarbon (HFC) blowing agents.

Response to Confused Homeowner

C.H.,

Q. "Would you recommend converting to an unvented roof assembly?"

A. Your R-13 batts do not provide anything close to minimum code requirements for roof insulation. In your climate zone (Climate Zone 4C), the 2009 IRC calls for a minimum of R-38 insulation. The easiest way to provide the insulation you need without disturbing your interior finishes is to install rigid foam insulation on top of your roof sheathing and to seal your vent openings.

Q. "If I stick with venting when I re-roof, then should I keep the R-13 fiberglass batts if they seem to be in decent shape? Or should I replace the batts with closed cell spray foam or rigid polyiso that has been cut to fit?"

A. You don't want to install polyiso between your rafters. (Polyiso is best installed in a continuous layer, not cut into narrow strips as you propose.) Since R-13 is insufficient, you should choose a method of insulation that allows you to achieve R-38 or more.

When it comes to venting this type of roof assembly, I stand by the advice given in the article. The only way you can make venting work on this type of roof is if you can maintain a gap of at least 6 inches between the top of your insulation and the underside of your roof sheathing, and if you can cut a 2 ft. by 2 ft. hole in the roof sheathing near the center of your roof, so that you can install a doghouse above the roof to act as a vent outlet.

So I understand the 6" ventilation space between roof sheathing and insulation. I understand vents in eaves as well as dog house or cupola at top (versus ridge vent). But if your roof rafters are 2x8's, you allow for 6" of space between roof sheathing and insulation then the insulation will have to be installed between each roof rafter, separating each bay between the eave and the ridge (and therefore minimal flow between rafters) Does the cupola suck air out of the entire ventilated space even if each rafter space is separate from the next? Or would the cupola only suck air out of the rafter space in which it is attached directly to?

M Hunt 11,

If you are building a new building, you need to plan ahead -- and ideally, to include an attic (albeit a short one) that is deep enough for at least 6 inches of open space between the top of the insulation and the underside of the rafters.

If you are talking about an existing building with 2x8 rafters, I doubt whether a vented assembly makes much sense (unless the ceiling joists are far below the rafters -- far enough for the needed ventilation space above the insulation layer). If you have a tight space with 2x8 rafters, you'll either need to install closed-cell spray foam against the underside of the roof sheathing, or a thick layer of rigid foam on the exterior side of the roof sheathing.

Thank you, Martin. Is it fine to have a 100% impermeable roof? (i.e. metal panels, impermeable ice and water shield, sheathing and then closed cell spray foam on the interior?) There doesn't seem to be any way for it to dry but I suppose the hope is it never gets wet to begin with? Also, how do you repair a roof with closed cells spray foam on the interior if the decking needs to be replaced?

MHunt11,

Martin addressed that situation in this article:

https://www.greenbuildingadvisor.com/article/sandwiching-roof-sheathing-two-impermeable-layers

M. Hunt,

Malcolm's link will prove useful to you.

If you end up with rotten roof sheathing due to a roof leak, repairs are always possible--although the roofers who perform the repairs may use some foul language.

Working from above, you can use a Sawzall to cut through the sheathing that needs to be removed, along with the associated glued-on foam insulation, as long as you are careful not to saw through the rafters or truss chords. (Directly above a rafter, the roofers would use a circular saw with the depth of the cut adjusted to the thickness of the rotten sheathing.)

Batts, Dense Pack, and Exhaust Fans

Thanks to your advice, my solution is becoming much clearer. I understand that I'm not required to bring my mid-century home up to 2009 IRC standards, but achieving R-38 or higher does seem like a worthy goal. One concern about sealing the vent openings is that the 3.5 inch thick R-13 batts have probably been in place for over 45 years and are likely not achieving the stated R value. They also leave two inches of available space in the 2x6 joist bays. Should I replace the R-13 batts with 5.5 inch thick R-21 fiberglass batts or with a dense packed R-24 blow-in-blanket system (BIBS)? Also, since all this insulation will make my house tighter, I'm planning to replace my contractor grade bathroom exhaust fans with Panasonic WhisperFit 80 cfm fans to help control indoor humidity levels. Since these fans are 5.5 inches high, I'm concerned about how much insulation they would displace below the roof deck. Would it make sense to build dropped soffits above my shower and bathtub for exhaust fans so that only the ducts will need to penetrate the ceiling?

Response to Confused Homeowner

C.H.,

Q. "One concern about sealing the vent openings is that the 3.5 inch thick R-13 batts have probably been in place for over 45 years and are likely not achieving the stated R value."

A. Obviously, sealing up the vent openings would not be a solution if that were the only action you performed. Clearly, you need to add R-value to the existing assembly.

Q. "Should I replace the R-13 batts with 5.5 inch thick R-21 fiberglass batts or with a dense packed R-24 blow-in-blanket system (BIBS)?"

A. Either choice would be an improvement over what you have, but neither choice would meet minimum code requirements. Only you can decide whether you can afford to do better.

Q. "Since these fans are 5.5 inches high, I'm concerned about how much insulation they would displace below the roof deck. Would it make sense to build dropped soffits above my shower and bathtub for exhaust fans so that only the ducts will need to penetrate the ceiling?"

A. No one should ever install a bathroom exhaust fan in the insulated bays of a cathedral ceiling. You have two choices: you can build a soffit under the existing ceiling, or you can install a wall-mounted exhaust fan (assuming that your bathroom has an exterior wall). The fan should be installed as high in the wall as possible.

2/12 roof--to vent or not to vent

I am building a ranch style home in the Chicago area (zone 5) with a low slope roof (2/12). We are installing a white TPO or PVC roof. My builder recommends going with a non vented roof using closed cell insulation to seal air leaks and meet energy codes. My architect recommends going with a vented roof using blown in cellulose to meet energy codes. I was leaning toward the vented roof until the architect drew in this linear cupola that ruined the lines of the house. I was hoping to have my house featured in Fine Home Building and not Mother Earth News. But I also don't want to be featured as an example of what not to do.

How much rigid foam do I need to install on top of the roof to prevent the condensation effect that was describe when using the white membrane roof?

Can I go with a standard low profile ridge vent and get the needed draw on a 2/12 roof?

Or should I go with the closed cell and pray the installer seals it all off and lays it on thick?

Response to Robert Vandermolen

Robert,

I stand by the recommendations given in the article. If you want a vented roof, you need the doghouse. If you don't want the doghouse, build an unvented roof.

Rigid foam above the roof sheathing is a much better approach than spray foam under the roof sheathing (since the rigid foam addresses thermal bridging through the rafters). This is a standard approach for commercial construction, so talk to a roofer who handles commercial roofs.

If you want to put all of your insulation above the roof sheathing, you can just consult the code books and do the math; I imagine that you will need at least R-38 in your climate zone. If you want to combine rigid foam above the roof sheathing with fluffy insulation below the roof sheathing, you will need to install at least R-20 of rigid foam above the roof sheathing in your climate zone.

Weighing options to achieve similar R-Value

I'm almost comfortable with the idea of replacing the R-13 batts in my 2x6 roof bays with dense packed insulation, either cellulose or fiberglass, plus adding at least three inches of polyiso on top. This article by Joseph Lstiburek both confirmed this approach as well as scared the heck out of me.

http://www.buildingscience.com/documents/insights/bsi-043-dont-be-dense

Here are some of the options I've considered for increasing the total R-value of my roof assembly from least expensive to most expensive...

1. Keep R-13 batts and add 4" of polyiso above deck

2. Keep R-13 batts, fill cavity with dense packed fiberglass or cellulose , add 3" of polyiso above deck

3. Keep R-13 batts, add 2" fiberglass batts, add 3" of polyiso above deck

4. Remove R-13 batts, fill cavity with dense pack, add 3" of polyiso above deck

5. Remove R-13 batts, add 1" of closed cell spray foam above ceiling, fill cavity with dense pack, add 3" polyiso above deck

Would you rule out any of these options? Which option, if any, would you choose?

Response to Confused Homeowner

Confused,

As long as you follow the advice in this article -- especially concerning the minimum ratio of foam insulation to fluffy insulation -- any of your proposed options will work.

The minimum R-value requirement for your layer of rigid foam insulation or spray foam insulation depends on your climate zone, so I can't evaluate your proposed foam thickness choices without more information.

Your choice will also depend on whether you are willing to replace your roofing.

In terms of performance, the best option would be option #4 -- as long as 3 inches of polyiso meets the minimum R-value requirements for this approach in your climate zone.

No parapet wall on one side - how does insulation stay on roof?

This might seem like a silly question, but how do insulation boards above the sheathing stay on the roofs that don't have parapet walls all the way around? Will the ballast be sufficient?

I have a low slope roof where we've left the low side without a parapet wall, so it acts as one big scupper. Just thought about the XPS on top and wondering how I keep it from 'sliding' off? If I go with a green roof as ballast, this gets even trickier as my dirt will wash off for sure?

Response to Jerry Chwang

Jerry,

Rigid insulation is attached to the sheathing with cap nails or cap screws (available at any roofing supply house). The perimeter of the roof is usually trimmed with flashing. If these concepts are new to you, you should hire a roofing contractor.

Best option for a newly constructed low-sloped roof

The more I read this and other sources on the subject of insulating, the more certain I am that it can be very easy to get it wrong. I have a 100 year old craftsman house in Tacoma (Marine 4C) that is in need of major updates (siding, windows, insulating, and roofing). I am about to start my remodel-redesign which includes changing the architectural style from craftsman to modern. The first phase will include complete removal of the 8/12 gable roof structure. In its place I will be constructing a shed style 1/12 roof structure with gray TPO roofing. The new attic space will have a 60” tall wall on the high side (North) and a 34” tall wall on the low side (South) leaving plenty of space to access all areas. I-joist will span between the two walls creating a 9 ½” cavity below the ¾” OSB deck. The current ceiling has R21 High Density glasswool batts between the 2 x 6 joist and it has ½” drywall below. There are numerous penetrations in the walls and ceiling, (plumbing, can lights, electrical, bathroom fan) none of which were carefully sealed by the previous owner.

Along with replacing the roof structure, I will also be removing and replacing all of the siding and many of the windows. I will be adding 3” of exterior rigid insulation and an open rain screen. The exterior insulation will run up the walls to the roof overhangs.

The existing attic is unconditioned and vented and shows no signs of moisture issues. Given my location and planned redesigned roof structure, what would be the least problematic approach to take after doing my best to seal all of the wall and ceiling penetrations in the attic:

1. Add more insulation to the ceiling and keep the attic space unconditioned and vented. If so is there any benefit or harm in adding a layer of rigid insulation between the OSB deck and TPO roofing?

2. Add 6” of rigid foam between the OSB deck and the TPO roofing making the attic space part of the conditioned volume by removing the existing batts and eliminating venting.

3. I’ve got it all wrong and should instead do this…

One additional note, I am trying to do all of this while my family continues to live in the house so it is important to have very limited disruption to the interior space.

Response to Ron Stanley

Ron,

I stand by the advice given in my article; the details of your house don't change my advice.

Considering the penetrations you list, and the fact that your roof lacks a doghouse, it makes the most sense to follow the usual practices of commercial roofing and to install all of the insulation above the roof sheathing. If 6 inches of rigid foam is enough to get you to your minimum code requirements for R-value, then that's the way to go.

Don't forget to seal your attic vents and insulate your attic walls.

Response To Martin Holladay

Martin thanks for the response and this article. I have read and reread this article and all of the suggested linked articles. I have been finding it difficult to determine which advice applies for my application (low sloped roof over an attic space). I did not know that a 1/12 sloped roof would not vent soffit to soffit and would require “dog houses” mid span. I shared the details of my house because the multiple references to attic size “tiny attic” and “cramped attic spaces” made me wonder if my larger attic volume changed the equation in any way. I trust your advice and will go with the unvented more commercial style roof assembly.

If I understand the information in this article correctly (You can install a more moderate layer of rigid foam insulation (2 to 4 inches) above the roof sheathing, supplemented by a layer of vapor-permeable insulation below the roof sheathing) along with the information regarding minimum rigid insulation for unvented roofs (Table R806.5 specifies the minimum R-value for the foam installed on top of the sheathing -- R-10 for Climate Zone 4C) than can I go with 4” of rigid polyiso – R value of 23.6 according to the new LTTR on top of the deck and then move my existing R21 glasswool batts up to the bottom side of the deck for a total of R44.6? I already have enough 4” thick polyiso to cover the roof deck and it would be great if I did not need to add another 2-4 inches on top for both cost and aesthetic reasons.

In the future, would there be a problem with adding more vapor permeable insulation to the underside of the deck? It seems some people suggest having a 2/3 outside to 1/3 inside insulation ratio. I believe this is to keep from isolating the warm side of the deck and turning it into a cold surface that could allow condensation to occur.

Response to Ron Stanley

Ron,

If you install R-23 of polyiso above the roof sheathing in your climate zone, your roof will exceed the minimum requirements for above-sheathing foam -- giving you a big margin to work with if you decide to add thicker fluffy insulation between your rafters. I think you will be fine.

If you really want to perform the dew-point calculations to show how far you can go with your plan, here is a link to an article that tells you what you need to know:

Are Dew-Point Calculations Really Necessary?

moving forward with the unvented roof assembly

Martin,

The roof deck is built (3/4 inch t&g osb above 9.5 inch I-joist), the 4" polyiso is on site, and I'm looking for a few last words of advice. There was a mention in the comments and your article of placing an air barrier directly on top of the roof deck and below the rigid insulation. This is also described in, "Complex Three Dimensional Airflow Networks" By Joseph Lstiburek but not much detail about the airflow barrier is given. Also, many articles speak to using multiple layers of rigid insulation, offset, to eliminate "pathways". My plan, maybe not a good one, had been to put the insulation directly on top of the osb deck, put a layer of densdeck above the insulation, and fully adhere the tpo to that. I could change the assembly to - osb deck, air barrier, 4" polyiso, additional 1" polyiso that is faced prepared for fully adhered systems, and then tpo. My questions are: Is the air barrier recommended and if so, what type of product do you suggest? How important is it to have multiple layers of offset insulation if an air barrier is used?

I am also having trouble finding any information on the best way to build up the outer perimeter of the roof deck to form a nailing base for fascia, gutters, and flashing. Do I just build up using 2x4's or lumber to the height of the rigid insulation?

Mounting Solar on Low Slope Insulated Roof

I'm hoping to install a solar array after re-roofing my low-slope roof but I'm a little worried about heat loss from the mounting brackets that would be bolted into the roof deck. I will have an R-24 blow-in-blanket-system in the 2x6 joist bays below the plywood deck and 3 inches of poly iso above the roof deck covered by a PVC membrane. How concerned should I be about thermal bridging from the mounting brackets? I suppose my alternative would be to use a ballasted system for mounting solar panels. A ballasted system would not penetrate the membrane and poly iso, but it would likely be a lot heavier since it uses bricks to hold the rack system in place.

Low slope unvented assembly

Working on a townhome project. GC is onboard with doing unvented attic space below the low-slope trussed roof assembly. Climate zone 5B. Looking at using ccspf on underside of roof deck w/ white EPDM topside. Appears to be a viable assembly according to: http://www.buildingscience.com/documents/digests/bsd-102-understanding-attic-ventilation

but I am concerned that there is no drying potential and any roof leak will probably go unnoticed.......thoughts?.......thanks.

Response to Graham Swett

Graham,

Your chosen approach is one of the standard approaches for insulating an unvented low-slope roof assembly, and it will work.

Most commercial roofers prefer to install rigid foam above the roof sheathing, because that approach costs less, and still allows the roof sheathing to be inspected from the interior when necessary. But you can do it your way if you want.

You wrote, "I am concerned that there is no drying potential and any roof leak will probably go unnoticed." There are lots of things to worry about in life -- and if you're really worried about that issue, you should have built a steep roof over a ventilated attic.

Response to MH

Thanks Martin........as architects we are tasked with having to balance the demands of the client, the market, the planning and development dept, the building codes and a host of other factors that do not always align to allow us to take the path of least resistance. All we can do is approach the final design with intelligence so that the final built environment does not become a drain on the end user and a black-eye and potential law suit for the design/development team........thanks for contributing to the brain trust.........

best way to insulate a converted attic with a flat roof

Hello Martin,

I am in the middle of converting my attic into living space when I started researching about possible ways to insulate the ceiling/roof and I was reading your article with great interest! Thank you for bringing some more light to this challenging topic!

Despite the many good suggestions, I am still not 100% sure about the best way to tackle my particular problem. Here are a few facts:

The house is located in St Louis, climate zone 4,

built in 1880, with original sheating, the flat roof is Modified Bitumen with a white coating) the sloped mansard roof to side is black slate. The slate is new and the flat roof is good for another 5-7 years. The ceiling joists are 2 x 10 in size and I am planning to attach the ceiling drywall directly to save as much ceiling height as possible.

The 2 attached pictures might give you a better idea...

In order to get the R-30 for the ceiling, I could use fiber glass batts or rolls, but that would negate any form of ventilation between insulation and sheating. From what I understand the best option might be the insulation with rigid foam on top of the sheating....but there is still some years left on the flat roof, I am planning to put the insulation on top of the sheating while putting on a new flat roof with new sheating...

My questions are: What is the best and most cost effective, interim (5-7 years) insulation until I will put the new roof on?

Is it better to coat the flat roof with a darker coating to avoid the "cooling coil" effect?

Should I insulate the walls or between the sloped rafters or both?

And what type of vapor barrier is best to use in my particular case?

I also thought about creating a space of 3 inches between insulation and sheating by using 2x4 as spacers and putting a layer of rigid foam boards2-3 inches, sealing all the gaps with closed cell foam and fill the space underneath with fiberglass, than the vapor barrier and the drywall. But I might not reach R-30..

Thanks for any suggestions!

Reponse to Sascha Zerbin

Sascha,

In Climate Zone 4, the 2009 International Residential Code calls for a minimum of R-38 ceiling insulation, not R-30.

I suggest that you insulate along the roofline rather than attempting to insulate the kneewalls.

Since you will be creating an unvented insulated roof assembly, you can't use fiberglass or a similar air-permeable insulation. Your only two choices are spray foam insulation or a combination of spray foam insulation and air-permeable insulation.

For more information on this type of insulation challenge, see How to Build an Insulated Cathedral Ceiling.

thanks for getting back so quickly!

Hello Martin,

the 09 IRC is amended in St Louis when it comes to insulation...

Would it be possible to use rigid closed cell boards combined with closed cell spray foam instead of just spray foam? This way I could reduce costs by 80%!!

And which class of vapor barrier/retarder would you recommend?

regards

Response to Sascha Zerbin

Sascha,

The method that you are proposing is called the "cut-and-cobble" approach. It is not recommended for unvented cathedral ceilings because of the risk of moisture problems and rot.

To read more about the method, and to read warnings about its use for cathedral ceilings, see Cut-and-Cobble Insulation.

If you decide to install spray foam insulation, you only need a vapor retarder if you choose open-cell spray foam. (Closed-cell spray foam is already a vapor retarder.) The usual vapor retarder for installations of open-cell spray foam is a layer of vapor-retarder paint installed on drywall. (The drywall is necessary for fire protection.)

Don't attempt to install the paint on the cured spray foam -- that method won't work. It has to be installed on drywall.

I'm getting a little worried here...

While researching what you've called the cut-and-cobble method, I stumbled across this blog posting. After reading the article and then every comment, I'm a bit worried about our roof installation.

We recently purchased a low-sloped (1 in 12) house in Zone 4C (Portland Oregon, Multnomah County). This 1950's house had a leaking torch-down roof...so at our roofer's advice we steered towards TPO as a replacement surface. After tearing off existing roof to the decking, what they installed was...listed in order from decking up: 2" PolyIso, FR-10 underlayment, 60Mil GenFlex TPO.

Since we had opened the house's interior (total gut; for new electrical & plumbing, and replacing wall-insulation), our roofer then advised us to install new high-density batts in-between 2x6 joists; leaving 1" of airspace between batts and roof deck underside. We then needed to open the soffits a minimum 1", and use a 1"-2" circular saw to open up as much blocking as possible, as close to the top plates as we can get.

From what I'm reading here, it appears our installation is likely to encounter moisture/condensation issues... Am I understandings things correctly?

Response to Gregg Berkholtz

Gregg,

If you have rigid foam above your roof sheathing, you definitely don't want a ventilated air gap underneath your roof sheathing. So the first order of business is to close off the soffit vents in an airtight manner.

The second issue concerns the decision to combine a layer of rigid foam above the roof sheathing with air-permeable insulation under the roof sheathing. This approach can work, but according to code requirements, the air-permeable insulation has to be in direct contact with the roof sheathing. Here's how the code reads: "In addition to the air-permeable insulation installed directly below the structural sheathing, rigid board or sheet insulation shall be installed directly above the structural roof sheathing as specified in Table R806.5 for condensation control."

Your rigid foam sheathing is fortunately thick enough for your climate zone, but the gap between the fiberglass and the roof sheathing is a code violation (as well as bad practice). You should bring this fact to the attention of your contractor, who is responsible for following the building code.

Response to Martin Holladay

Thank you greatly for the information. The idea of an unvented roof is completely foreign to me - so your feedback greatly helps us better understand things.

Since we have enough rigid foam sheathing above the roof deck (2"), it sounds like our best course of action is to focus on the void boxed between our rafters and roof sheathing/drywall.

In 1/3rd of the house, we've already drywalled, so it's damage control: it appears our most reasonable path is to drill & blow-in a dense cellulose to fill the gap between fiberglass bats and roof sheathing, and then seal openings once complete.

For the rest of the house, we had originally planned on a 1-2" airspace between batts and roof sheathing. Since that part of our project is just beginning (two roofs to deal with - one is on 2x6 & the other on 2x10 rafters), it appears we have additional options.

Modeling after your article's recommendations:

1) Install 5 1/2" high-density batts in the 2x6 space; filling the cavity. Then covering the rafters with plastic just before putting drywall up (this was also suggested by an insulation installer that visited today).

2) Cut-and-cobble with spray foam to to fill the gaps between boards and rafters.

3) Fill cavity with dense pack (e.g. a bib system)...this was the preferred recommendation of today's insulation installer.

I get the impression that cut-and-cobble would actually leave an airspace with 2x6 rafters (we have access to 3" PolyIso boards at $10/sheet). We understand its extremely labor intensive, but at this point its cost and damage-control for us.

There's another space where we have 2x10 rafters, still under a 1/12 flat roof. Today's insulation installer also suggested using 8 1/4" high-density batts (R30), plastic, drywall; and leaving venting/soffits open. With what I'm learning these past few days, I'm not sure how I feel about that recommendation.

Our goal is to not tear off the roof surface, again...if at all possible.

Response to Gregg Berkholtz

Gregg,

You're getting closer to understanding a good roof assembly -- you are almost there. There is one remaining problem: you definitely don't want interior polyethylene with this type of roof assembly. An interior vapor barrier is a no-no.

While vented roof assemblies are designed to dry to the exterior, unvented roof assemblies are designed to dry to the interior. Polyethylene would interfere with the assembly's ability to dry to the interior.

The theory behind wall and roof assemblies with exterior rigid foam is explained in this article: Calculating the Minimum Thickness of Rigid Foam Sheathing.

On the underside of your roof assembly, it's always a good idea to pay attention to airtightness. You want your drywall layer to be airtight, but not vapor-tight. To make sure that the assembly is airtight, don't install any recessed can lights, and make sure that you seal carefully at all wiring penetrations and plumbing vent penetrations.

There are lots of articles on the GBA site that delve deeper into these issues, including:

Questions and Answers About Air Barriers

Vapor Retarders and Vapor Barriers

Forget Vapor Diffusion — Stop the Air Leaks!

Do I Need a Vapor Retarder?

Response to Martin Holladay

I thought an interior vapor barrier might be a bad option, especially with a TPO roof membrane; where would any moisture escape? Although the plastic sheeting was recommended by yesterday's installation installer, so thank you very much for reinforcing my thoughts on this.

In addition, my understanding of the bib system they recommended also sounds like it'd be a problem; their design would use tyvek to hold blow-in cellulose. What's strange is that our installer said he "cleared it with his technical/legal department" while we chatted (he was exchanging photos and TXT messages). They sounded so convincing...

For our situation, to get something better than the ~R12 from existing 2" PolyIso above the roof deck, it sounds like packing the space with un-faced high-density insulation might just be our least-cost option, as long as we're careful to seal all top-plate/blocking edges (and any interior or top/bottom-plate holes) with expanding spray foam.

I'll dig into your links this afternoon - the information is much appreciated!

[Editor's note: To read the answer to this comment, and to read subsequent comments, advance to page 2 by clicking on the number 2 below.]

Response to Gregg Berkholtz

Gregg,

Your most recent comments show a new misunderstanding. Unlike polyethylene, Tyvek is not a vapor barrier. Tyvek is vapor-permeable, and won't cause any problems if you install it on the interior side of your roof assembly.

However, Tyvek isn't a good choice for holding cellulose in place when dense-packing cellulose between framing members -- because Tyvek is an air barrier. When an insulation contractor uses a blowing machine to pack insulation between your rafters, the blowing machine pushes the insulation with a huge amount of air, and that air has to go somewhere. That's why experienced cellulose contractors use an air-permeable membrane (for example, InsulWeb) as netting to hold in the cellulose. For more information on this topic, see How to Install Cellulose Insulation.

I'm beginning to wonder whether you have selected an experienced contractor to help you, or whether you are getting advice from someone who is in over his head.

Response to Martin Holladay

You're right, of course, about the Tyvek - I don't know what I was thinking when typing that part out. After all, it's why we wrapped the exterior walls with that stuff...heck, my wallet is made of Tyvek; sweat still gets to the paper on hot days.

Your point about trapped-air during the blowing process is an excellent one. In hindsight, it's an obvious question; where is all that air supposed to go during installation - although I didn't put two&two together until your feedback. Thank you for taking the time to reframe that. This is now a screening criteria as we sort through contractor proposals.

As for finding a qualified insulation specialist, it seems we could summarize desirable professional qualifications (at least for my needs/goals), as someone whom has training/experience specific to "unvented low-sloped 1 over 12 TPO roof".

It's too bad you're not in the Portland Oregon area - I'd be arranging an appointment with you ASAP.

Rigid PolyISO board is a vapor barrier?

Gosh, it's difficult to find a qualified local installer...

Just met with another installer, he insisted that 3.25" of R-MAX R21 rigid board installed via cut&cobble (e.g. with all edges sealed by expanding foam) would be our best option to insulate rafter space under the roof deck. He was confident we'd have sufficient vapor control with just the ~2" gap between roof deck underside and cut&cobble rigid board. This advice, specifically engineering a gap between roof deck underside and cut & cobble rigid board, appears to violate code (IRC R806.5). This consult was from a local contractor insulation supply house (fairly large company; 6 regional locations...apparently made it past legal...) - bid was for materials only...

Tonight, I came across your article discussing how rigid board acts as a vapor barrier: https://www.greenbuildingadvisor.com/community/forum/general-questions/21111/using-polyisocyanurate-insulation-exterior-home

This leads me to conclude that rigid board's vapor barrier properties effectively disqualifies cut&cobble for a TPO coated low-slope roof assembly, especially when there's 2" of rigid board already above the deck sheathing.

Looks like our best strategy is to totally scratch the cut&cobble method, and proceed with packing a 5.5" rafter space with air-permeable/unfaced insulation just prior to drywalling. Our main options seem to be:

1) 5.5" high-density R21 batts.

2) 6.5" R22 batts (e.g. to counter insulation settling effects?).

3) dense-pack blow-in insulation.

As for the rest of your points, there's a clear need to be mindful of:

1) Never use a "vapor barrier" paint on unvented roof/ceiling assemblies.

2) Use closed-cell expanding spray foam before batt installations to ensure air-tightness at all wall and top-plate penetrations into the ceiling (e.g. electrical wiring & plumbing vents). Also ensure air-tightness around any ceiling penetrations (such as code-required single light/junction box per room...maybe a switched outlet is a better option...).

As for meeting insulation code, R33 (2" Poly + R21 batts) certainly exceeds the requirements for a 1950's structure remodel, so I believe we're doing great there.

1963 Low Slope Roof & Silver Coat

Hello Mr. Holladay, thank you for answering questions and keeping this thread active. We recently bought a 1963 home in the Pacific Northwest that has a low slope roof. It currently has a torch down roof that appears to be fiberglass based (you can easily see the fibers throughout the rolled-out sheets). My roofer recently installed a vent for our range hood fan and while he was up there I asked him about the condition of the roof. He said it was decent but that it was getting old and would need replacement in a couple of years. As a way of extending its life, possibly for another 5 years or so, he suggested silver coating the roof to keep the temperature and UV down as well as to seal any current small cracks/etc.

Previous to this, the inspector we used during the purchase of the house noted after peeking into what areas of the tiny attics were accessible (parts of the house have no attic due to vaulted ceilings) that the condition of the trusses and sheathing were good for a house that age and he noted no excess moisture or any mold. I have since verified this above the kitchen after installing some can lights and additional insulation (only 2" rock wool was originally installed) in the small attic there as well as in the adjacent family room w/ a vaulted ceiling. The roof is vented throughout - a continuous saw-fit vent runs down the length of the low ends of the roof and this connects to each of the cavities in the vaulted ceiling areas as well as to the small attics that exist. I'm not entirely certain about the vaulted areas but in the attics there are a few mushroom vents near the top of the roof. I am not sure how air escapes the vaulted ceiling areas as there don't seem to be vents in those areas... (There may be a cavity common to those areas at the peak of the roof and above the glue-lam beam that runs down the spine of the house on the inside and this may connect to the attic spaces...)

My question has to do with the silver coat and your mention of cold roofs causing moisture buildup. If I apply a silver coat to this roof to extend its life, I am worried that its temperature would drop dramatically, causing condensation from this point forward in time, leading to mold and structural damage due to moisture buildup. Would you agree with this concern or do you think the venting is probably sufficient?

Thank you.

Response to Adrian Nicolici

Adrian,

I don't have a clear understanding of your ceiling insulation.

Since you tell me that you have a cramped but vented attic, I assume that the insulation is against the ceiling, with air above the insulation, and that there is no insulation against the roof sheathing. Is that correct?

You wrote that the house originally had 2 inches of rockwool -- again, I'm assuming that the insulation was installed on top of the ceiling -- and that you have installed "additional insulation." What type of insulation did you add? Where was it installed?

It sounds like you have an imperfectly vented low-slope roof with fibrous insulation above the ceiling. If you install a reflective coating to make your sheathing colder, the sheathing could certainly begin to rot.

Rather than investing in a coating to lower the temperature of your roofing and your roof sheathing, you would be better off sealing your roof vents and installing rigid insulation above the roof sheathing, followed by new roofing.

1963 Low Slope Roof & Silver Coat

> no insulation against the roof sheathing. Is that correct?

Correct.

>again, I'm assuming that the insulation was installed on top of the ceiling -- and that you have installed "additional insulation." What type of insulation did you add? Where was it installed?

Correct - on the ceiling. Additional insulation was more rock wool on top of the old, still on the ceiling. but only in areas with an attic.

>If you install a reflective coating to make your sheathing colder, the sheathing could certainly begin to rot.

Yes, I think you are right. I will stay away from this option.

>Rather than investing in a coating to lower the temperature of your roofing and your roof sheathing, you would be better off sealing your roof vents and installing rigid insulation above the roof sheathing, followed by new roofing.

This does seem to be the frequent fix from what I've read and its on my list when the roof will eventually need to be replaced. For now, to extend the life of my current roof, I think I will simply coat with something like Gaco silicone coating which comes in dark colors and will not reflect the heat away from the roof but still seal nicely and protect against UV. A cheap short term fix:

http://www.gacoretail.com/gacoroof.html

How much insulation would I need to install on top of the existing roof after sealing the vents in order to keep the previously vented spaces from getting too cold and condensing moisture? I would like to minimize the affect on the appearance of the house... Does regular latex paint inhibit moisture transfer back into the house? Is sealing the ceiling (no pun intended) very important after such a modification?

Thanks.

Spray foam Roof in Philadelphia

Martin,

I am getting bids for spray foam for an unvented low slope roof in Philadelphia (zone 4). Most of the SPF contractors I speak with are pushing 10 inches of open-cell to reach R38 in the roof assembly. I was leaning towards doing around 2.5 in of closed-cell for an R15 and doing R30 in fiberglass batts on top.

Which assembly would you prefer using? Is there a benefit to one or the other?

Response to Mike S

Mike,

I'm not quite sure why you are proposing "2.5 in of closed-cell for an R15 and doing R30 in fiberglass batts on top." I hope that was a typo. When you combine closed-cell spray foam and fiberglass batts, the fiberglass batts go on the bottom, not the top -- and the two types of insulation have to be in direct contact.

Assuming that you get your spray foam/fiberglass sandwich in the right order, either of the two approaches you listed will work. However, the best approach always includes rigid foam above the roof sheathing -- since that approach addresses thermal bridging through the rafters.

for the unemployed, indebted homeowner with a flat roof...

... We have a choice between zero insulation (the status quo) or something, albeit imperfect. My mid-century modern will be torn down whenever I sell - maybe in 10 years? Meanwhile, I had to gut the interior due to a leaky roof and very bad mold problem. With the drywall and ceiling off, now is the time to add some insulation. It's near Everett, WA.

Its a 1:16 low-slope roof (nearly flat), with newish black torchdown on top, a base sheet, and shiplap roof decking. The rafters (joists, trusses) are only 2x8s (so only 7.25" vertical gap). Furring strips run perpendicular below the rafters.

I cant afford exterior insulation and a new roof. My credit cards are maxed out. I'm doing all the work myself.

I'd welcome thoughts on my ceiling "plan", from top down, below the decking:

3.75" air gap below roof decking (best I can do).

Attic foil, permeable, between rafters, draped loosely, resting on...

3.5"Roxul R15 ComfortBatts (atop furring strips).

3/4" air gap due to furring strips

2" RMax polyiso rigid foam , foilbacked, taped seams, R14 (screwed into furring strips)

1/2" gypsum (screwed through foam into rafters w 4" screws)

It has a 25x30' main living-dining-kitchen area, 3' soffits. No ceiling vents between gypsum and roof, only grill-vents in soffits. (I can't afford new holes in roof and added risk of leaks.)

Any suggestions? Things to watch out for? Better solutions for the same money? Thank you!

Response to Liam Knute

Liam,

Some comments:

1. Working from the underside, it's going to be hard to drape the "attic foil" on top of the Roxul batts.

2. I assume that the product you describe as "attic foil" is a radiant barrier that has been perforated with tiny holes in an attempt to address the problem that it is a wrong-side vapor barrier. I don't think that these perforated foil products are as vapor-permeable as the manufacturers pretend. If you want a vapor-permeable air barrier at this location, install a plastic housewrap like Tyvek.

3. Although you plan to include an air gap between the Roxul and the roof sheathing, you don't mention whether there will be any ventilation openings to connect this air gap with the outdoors.

4. The air gap between the bottom of the Roxul batts and the rigid foam is potentially problematic, because it allows air movement. It would be better if you could remove the existing furring strips so that the rigid foam can be directly under the Roxul batts. Then you can install the furring strips underneath the rigid foam, where they belong.

Thanks for your reply. Very much appreciated!

Many thanks for your reply!

I'm wondering if it's even worth doing the rigid-foam at all (for now). Maybe I should just do only the 3.5" R14 Roxul for now. Not up to code (R30), of course, and not as energy-efficient, but up until now (for 50 years) there was essentially no insulation in the ceiling at all (just 3/4" acoustic ceiling tiles), so R14 would be better than before. And the house will be a tear-down for sure, whenever I sell it. Not sure if it's worth the time and money to do the rigid foam, I'll have to think about that.

(I thought of using 5.5" Roxul, for higher R-value, leaving only a 1.75" air ventilation gap on top -- but even with a house that isn't too air-tight that seemed to go against what I've read.)

Correct on #2, the 'attic foil' is a perforated radiant barrier. The goal would be to keep out some of the summer heat coming down from the black roof. (Not a big deal, but I think I could unroll it loosely on top of the furring strips, then stuff the Roxul batts up under it. Tyvek would work for vapor, but no radiant heat effect -- but I'm not sure the foil would help much, anyway.) Previously, the original vapor barrier was a paper/foil, laid with the foil side down!, nailed to the rafter bottoms, above the furring strips. (The wrong way, I think: if anything, it brought down heat into the house.)

On #3, the only 'formal' external ventilation opening to the outdoors currently is a few (3? I haven't counted) 3"x8" rectangular vent openings in the soffits. I could add more of these? Or some in the fascia boards? (I'm trying to avoid poking new holes in the roof if I can.) The soffits and house in general are not particularly air-tight (board-and-batten exterior, ship-lap sheath/siding, no Tyvek yet, etc.), although I am slowly working with Great Stuff and caulking to seal up major cracks, but there's a long way to go (I'm not even going to try and seal the board-and-batten, so that's major 'ventilation' -- and heat-loss -- right there.)

For the walls, given that the drywall is already removed, my intention given time and money constraints (correct me if I'm misguided!) is to staple Tyvek around each of the studs and to the interior side of the shiplap sheathing (which is covered on the exterior by cedar board-and-batten siding outside), before putting 3.5" Roxul in the walls. A nuisance, but I don't have the money or manpower right now to remove the cedar siding and put the Tyvek outside the sheathing (where it belongs).

Just to enlighten me, if I do go with both Roxul and foam for the ceiling, what's the concern in point #4 about the 3/4 air gap (furring strips) between Roxul and rigid-foam? I'm guessing it's that with (relatively) open air movement, the insulation value is cut way down (unless it were airtight which it won't be)? That's one reason I'm thinking maybe don't bother with the rigid-foam for now (save the money until I can do an external/second-roof solution, maybe in 5 years).

I wasn't sure if the Roxul would stay in place in the ceiling rafters, without the furring strips to hold it up, but I just tried and it does seem to work! Friction trumps gravity. :-) (I tried to attach a pic that shows a Roxul batt in place above the furring strips -- it seems to hold in place even if it is pushed well up above them.) Good to know.

Again, thank you very much for your insights. (I know there's a lot of higher-end and maybe more interesting projects out there. Making-do is where I'm at, and I greatly appreciate your thoughts on this old house.)

Response to Liam Knute

Liam,

Q. "The original vapor barrier was a paper/foil, laid with the foil side down!, nailed to the rafter bottoms, above the furring strips. (The wrong way, I think)."

A. You're wrong. If a builder includes an air space with a foil radiant barrier facing the air space, then the radiant barrier will raise the R-value of the air space, regardless of which side of the air space the foil is installed on.

Q. "The only formal external ventilation opening to the outdoors currently is a few (3? I haven't counted) 3"x8" rectangular vent openings in the soffits. I could add more of these."

A. Your plan does not comply with the recommendations in my article. These openings will not provide the ventilation you seek. If you proceed with your plan, your roof sheathing boards are at risk of moisture accumulation and possible rot.

Q. "What's the concern in point #4 about the 3/4 air gap (furring strips) between Roxul and rigid-foam? I'm guessing it's that with (relatively) open air movement, the insulation value is cut way down (unless it were airtight which it won't be)?"

A. Yes, that's what I am worried about. You are setting yourself up for convective air currents, or for the creation of air pathways that allow interior air to find cracks in your wall assembly or roof assembly.

Thanks again! (Update: turns out chimney chase has 2 vents!)

Sorry for the slow reply. I mainly want to reiterate my thanks for your reply (and the broader service you provide to so many people, on so many topics).

In case this is of assistance to anyone who stumbles across this thread:

On closer inspection, it turns out my roof *does* have something of a doghouse/cupola vent, embedded in the side of the 6' wide chimney chase (above the roof)! Never having looked at them closely, I'd assumed they served some chimney function. But in fact, as far as I can tell, they are there to vent out the dead air space between the roof and ceiling. The vents open down into the area where those joists rest on the edge of the chimney (as revealed by shining a light at night).

This 1958 house was ahead of its time in some ways (I think built off of Popular Mechanics or similar designs) -- e.g., radiant heat in copper pipes embedded in concrete floor, still functional today (recently pressure-tested).

Thanks for clarifying the foil radiant barrier.

I wonder if the ship-lap roof deck dries out faster than does a modern plywood/OSB deck?

The black torchdown (on a base sheet) also allows some vapor to pass through, unlike modern PVC membranes.

Due to time and financial constraints, for now I'm forced to make a compromise and omit the rigid foam. (N.B. this is not recommended, I know.) So, only 3.5" R15 Roxul* for now, and hoping the 3.75" air gap will vent enough moisture until I can afford to do it right (new roof, rigid foam on top). Not the best, but perhaps better than zero insulation -- provided there is adequate ventilation in the joist area.

(*Canadian 3.5" Roxul is rated R14, in the USA the same dimension Roxul is rated R15. Not sure if there are any differences in product, or if the difference is in the rating systems.)

Thanks again, and best wishes for the holidays.

Response to Liam Knute

Liam,

Q. "I wonder if the shiplap roof deck dries out faster than does a modern plywood/OSB deck?"

A. Yes, it probably does. It will certainly be better able to withstand a few wetting/drying cycles than OSB.

I know it's unconventional and not ideal...

My house is a mid-century modern that seems to have done well for the previous 50+ years, but due to the severe winter we are having here - just North of Boston maybe 3 miles from the coast (so Zone 5 or 4 Marine?) we encountered an ice dam that backed up to a leak for the first time (during our tenure here).

Obviously I don't want to encounter this problem again, but it got me thinking not only about the cause, but how to reduce our very high heating bills.

Last year we put R-30 fiberglass rolls over anything existing in the area of the attic we can easily access...basically the middle of the house.

The 3/4 of the house which is not cathedral ceiling has a rise of I'd say 1 foot to every 4 feet (1/4?) but 10 feet from either end there is a structural beam which pretty much blocks off those last 10 feet from normal size human access, making it pretty much impossible to get in there to insulate.

Based on the icicle pattern outside around the time the leak occurred I suspect that the supplemental heater we had running in one of the cooler end rooms contributed to the melting causing the ice dam (it was above said cool room). So we stopped running it for the time being.

The attic is unconditioned with hatch access and contains A/C unit and ducts. The original existing insulation is/was insufficient and typical of the time - fiberglass not extending beyond the tops of the joists. There is a ridge vent and soffit vents (although Springtime will now merit checking these out to see if the amount that appears to be there is actually there and adequate). There is also a powered vent at the top that can be switched on/off. Roof is newer with a single layer of asphalt

shingles.

I would blow cellulose into those areas, but am very concerned about accidentally shooting it right over the soffit vents and blocking them since access is so bad.

Then I considered sliding polystyrene boards back there as best we could (thinking something is better than nothing) but saw a post somewhere indicating this could be a bad idea because of the air gap between the 2 insulations that would allow condensation to occur on the bottom of the poly board. They suggested, though, that plywood would be acceptable since it is more absorbent than the poly. So, would using, say, luan to slide more fiberglass into place back there work?

I am trying to think outside the box a little due to the constraints we face, but do want to do right by the house. I don't want to cause a problem trying to fix one and I am not looking for a major project - interior (ripping out ceilings, etc) or exterior (decent existing roof). But maybe there is something to be done when the time does come for a new roof? Given that this was not really in the budget at all, and I'm not looking for a major project, what, if anything, can you suggest about how to proceed with this area?

Response to Insulating Dilemma

I.D.,

When it comes to ice dam problems, halfway measures don't work very well. If this attic has ductwork and an air handler, and if enough snow is melting to cause leaks, it's time to seal your vents and to install thick insulation above your roof sheathing. It won't be cheap, but that's what you have to do.

During the roofing work, have your roofing contractor remove 4 or 5 sheets of plywood or OSB so you can enter the attic from above. Have an air sealing contractor waiting in the wings. You want to seal all of your air leaks; then you want to re-install the roof sheathing, put down about 6 inches of rigid foam, a second layer of roof sheathing, and new roofing.

Halfway measures

Martin,

Thank you very much for your quick response. I will absolutely take that under advisement. I believe that having had this experience we are now better prepared (alert) to avoid the ice dams in the future. It will be a matter of keeping the snow off the edge area and watching the total amount of snow up there. We had it collect to quite a depth - I'd say maybe 3 feet in one area and no less than 2 every where. The insulating properties of the snow itself probably contributed to the melting in the area above the heater. Very unusual weather making this scenario 'possible.' It is in trying to reduce the heating costs that I am even considering what might work for "halfway measures."

low slope roof with insufficient tapered polyiso