Virginia Tech’s entry, FutureHAUS Dubai, emerged as the winner in the inaugural Solar Decathlon Middle East last month, outscoring entries from 14 other groups.

In an announcement, the university said the project was the result of years of research and development and relied on the contributions of more than 100 students and faculty members. Virginia Tech prevailed despite a warehouse fire that destroyed an early prototype and wiped out years of work, forcing the team to start from scratch in early 2017.

The U.S. Department of Energy launched the Solar Decathlon competition in 2002 to encourage collegiate teams to design high-performance solar-powered houses. The program has since expanded into international competitions in China, Africa, Europe, Latin America, the Caribbean, and the Middle East.

Student and faculty teams, aided by corporate sponsors, design and build the houses, take them apart, and then reassemble them at the competition site. In this case, between one and two dozen students and faculty spent a total of 44 days in the desert outside of Dubai, United Arab Emirates, assembling the building and then competing in 10 different categories.

It was the second international win for Virginia Tech. Its LUMENHAUS won the 2010 Solar Decathlon Europe competition in 2010.

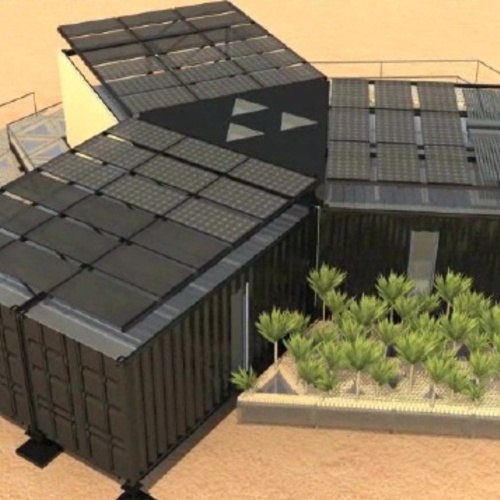

A video posted at Virginia Tech’s website describes the house as a 900-square-foot structure built from nine modular “cartridges.” The house is packed with cutting edge amenities, including:

- Kitchen counters and cabinets that can be adjusted in height, making life easier for people of different heights and physical abilities.

- An induction range set beneath a countertop surface that can be used as a cutting board.

- Sensors, displays and touch screens that connect the house to the Internet of Things.

- Building-integrated photovoltaics and a battery bank.

- A kitchen backsplash composed of three TV screens, allowing users to access recipes or monitor appliances via a touchscreen.

- A drone hatch that allows deliveries directly into the home.

A new way of building

Interactive high-tech features are a key part of the house. But the heart of the design is the modular cartridges containing essential mechanical and electronic systems that can be assembled quickly on site, says team leader Joseph Wheeler, co-director of Virginia Tech’s Center for Design Research.

“Our house overall has two big ideas,” he said in a telephone call. “We’re proposing a new way to build, and we’re proposing a new way to live.”

Cartridges are built from structural insulated panels (SIPs) with a core of closed-cell polyurethane foam. The exterior is a tempered glass rainscreen with a 2 1/2-inch gap behind the glass; the interior is finished in prepainted panels of medium-density fiberboard (MDF) that snap into place once the cartridges have been tied together.

He described the design as a hybrid system that solves problems inherent with both panelized construction, in which houses are made from prefabricated roof, wall, and floor pieces, and big-box modular construction. Panelized components are made in factories off site, but still require specialized trades to complete the work after the buildings are assembled. Modular houses are built with large components that complicate over-the-road shipping. None of the cartridges developed by the Virginia Tech team is bigger than 3 feet wide, 12 feet long, and between 8 and 10 feet tall. They can be hoisted onto a standard flatbed truck with a forklift. The interior finish work required in conventional construction — trim, drywall, painting, mechanical and plumbing installations — has been eliminated.

There are separate cartridges for kitchens, bedrooms, home offices, and bathrooms. Each is prewired or preplumbed, completely assembled, and ready to be plugged into a central spine that ties them together into a whole.

Wheeler likened the assembly of FutureHAUS to building with Legos, the plastic building blocks that snap together to form houses, vehicles, and other creations.

“They experimented with this concept in the ’60s with modular kitchens,” Wheeler said. “They never worked because we weren’t ready for it. It was still too crude, and it wasn’t integrated. What we have now with FutureHAUS is a cartridge system where it’s almost like building with Legos. These cartridges are like prewired and prefinished Lego pieces that contain the program of the house.”

Pieces can be assembled in a single day with the help of a crane. In Dubai, the full team needed just a week to complete the house, half of the time allotted by competition rules. The core of the house was up and running and producing electricity in just two days, with the rest of the construction time devoted to fussy details, such as arranging outdoor gardens and installing interior wall and floor panels.

“One of the reasons for our success in Dubai was that the house was completely prefinished before we arrived,” Wheeler said. “It was prewired. It was preplumbed. It was a matter of stacking these Legos into place and tying in all the subpanels. In two days we were generating power from the sun.”

Staying cool in a very hot place

The design challenge in Dubai was intense sunlight and very high solar heat gain. Although outdoor temperatures during the competition were into the 90s, summer temperatures can creep up to 115°F.

The team’s strategy was to protect the house from direct solar gain, not only with the glass rainscreen but also with a roof canopy containing the 15 kW photovoltaic array. The edge of the canopy extends over the walls by 5 feet, protecting them from direct sunlight for most of the day.

Around the outside of the house is a fence of vertical stainless-steel latticework, a nod to the privacy and decorative structures common to the region called mashrabiya. The privacy screens also help shade the house when sun angles are low, in the morning and the late afternoon.

Each side of the house has an outdoor space. The patio on the south side of the house contains a garden. These spaces are typically important gathering spots at night when temperatures are cooler.

![]() Wheeler said that the combination of R-27 walls and a roof of R-40 or more, plus the protection from direct sunlight, helped make the house unusually efficient. Mechanical cooling is provided by a 1 1/2-ton minisplit (a system with an output of 18,000 Btu per hour).

Wheeler said that the combination of R-27 walls and a roof of R-40 or more, plus the protection from direct sunlight, helped make the house unusually efficient. Mechanical cooling is provided by a 1 1/2-ton minisplit (a system with an output of 18,000 Btu per hour).

Wheeler was disappointed that the house couldn’t be there for the hottest time of year. He’s convinced that the insulation and roof overhangs would have kept the house comfortable even when outdoor temperatures were substantially higher.

Another key to the project’s success, Wheeler said, was the work done by Virginia Tech’s Center for Power Electronics, which developed a system for optimizing solar output from the PV array. Competition rules limited output from the system’s inverter and put a premium on managing loads. This was especially tricky at night when the system’s 15 kW lithium ferro phosphate battery bank had to carry all loads.

CPES devised a system that would inform the team when to boil water, when to do the laundry, when to charge the electric vehicle, and when to feed the meter, Wheeler said. CPES also found a way to allow components made by different manufacturers to communicate with each other. As a result, the team could select the best inverter on the market, the best charge controllers, the best PV modules — all without regard to who they were made by.

Those two system advantages were the team’s “ace in the hole,” Wheeler said, allowing Virginia Tech to far outdistance the energy performance of its competitors.

A more promising future for building

Wheeler, who is 52, has been at Virginia Tech for 25 years and has guided three Solar Decathlon teams. He sees the technology advances reflected in FutureHAUS as a new direction for residential building, one that could address a variety of challenges facing the industry.

Houses built with small, self-contained components are far easier to alter than conventional site-built designs, which can be renovated or enlarged only at high cost after they are finished. Adding, or subtracting, square footage in a cartridge house should be relatively simple, Wheeler said, making it possible to adapt a structure to the changing needs of its occupants.

“We’re proposing that in the near future you could potentially go on Amazon, order up your kitchen, order up your bathroom, select a ship date and have those components shipped to your builder on the site,” he said. “They arrive and they’re simply plugged into the house installation.”

There is, of course, the question of cost. Developing and building FutureHAUS added up to more than $1 million, making the cost on a per-square-foot basis a little intimidating. But, says Wheeler, it’s misleading to use that metric for a house like this; much of that price tag was in developing technologies that didn’t previously exist, plus the inherent costs of competing in a Solar Decathlon abroad. By using the same technology and less expensive finishes, a one-bedroom, one-bath cartridge house could be built for $88,000, he said.

As a variety of building pioneers have been arguing for years, building houses on site, one 2×4 at a time, is an approach long overdue for radical change. “The construction process is so crude,” Wheeler said, “and it’s been that way. It’s never evolved. It’s about time, since we have the technology — the robotics, the CNC machinery. Why not utilize this to industrialize the building elements of a house? To treat building a kitchen like you’d build an appliance, rather than a pieced-together thing, ad hoc, on site?”

Not only would houses be better built and more adaptable to future needs, but builders would have a way of coping with skilled trade shortages that are already a drag on the industry. When the next building boom comes around, there simply won’t be enough tradespeople to go around, Wheeler said. Adopting the kind of technology reflected in FutureHAUS would make a difference, and winning the Dubai competition is an affirmation the approach works.

“I’m thrilled,” he said. “I’m thrilled. I’ve spent well over five years working on the research for FutureHAUS, the cartridge house, and what this was was a trial. We lost five years of research in the warehouse fire in 2017. Winning validates the cartridge concept, the way we should be building in the future.”

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

7 Comments

Thanks for sharing this event Scott, as always, its an awesome showcase of new technology and how to for the future of our industry. This house has some really cool technology that would be nice to incorporate in all of our houses, and some of my clients have some of it.

Having said that, what I can't get around to is that if the wall and roof assemblies are well insulated, assuming they are tight, for a 900 sf high-performing house, do they really need a 15kW PV system + a 15 kW lithium battery bank, and a 1.5 ton minisplit? Seems to me that all these systems are grossly oversized or we need a better explanation... unfortunately, their website doesn't do that.

Armando,

That's a good question. Solar Decathlon rules are apparently very specific about what tasks the house must be able to do — heat water, dry clothes, charge an electric vehicle, etc. — and that seems to put a high priority on a powerful PV system. I'll invite Joe Wheeler to join the conversation. Maybe he can provide a better answer.

I am guessing when the requirement to dry clothes (Decathlon organizers meant washing and did not include drying?). If the spec was to have a dryer, would love to know the logic behind that.

Peole wear clothes and need to both wash & dry them. Seems reasonable/logical to me that a house would need to be designed to address that need.

Not every location humans live is suitable for drying clothes outdoors all year long, but that doesn't mean the house needs a mechanical clothes dryer. The 2017 Solar Decathlon rules specified (among other things)...

..."Drying several loads of laundry using active or passive drying methods"

https://www.solardecathlon.gov/2017/competition-contests-appliances.html

As long as details of the house were designed to accommodate both indoor & outdoor clothes lines in reasonable locations it could arguably be awarded those points without an appliance.

I expect the rules for 2018 had comparable verbiage, but I didn't find it online in a quick search.

An interesting design full of potentially transformative devices. I know it is supposed to be a showcase for these things, but a place to actually live, I find it's wholesale embrace of the technology of things off-putting. It represents one direction the future can go in, but not one I find particularly enticing.

I like these competitions for the many ideas generated, along with the enthusiasm and experience gained by those who participate. We definitely need better ideas for how to efficiently build living spaces, and more young skilled people with enthusiasm. Modular pieces/cartridges and building in controlled environments are two big elements of future improvements (IMO), and I find this project interesting from that standpoint.

But I backed away when I saw all the "technology of things", as Malcolm says. I don't like it, don't think it's wise to build it into something that's supposed to last generations, and it doesn't seem to address either simplicity or affordability.

Aside: for several years, Ford suffered in customer quality surveys, and most of the problems were associated with the blasted MyFordTouch system that had nothing to do with the car performing car functions. Grrr.

Andrew,

Maybe addressing our misgivings is as simple as having the ability to integrate these devices without making them integral to the function of the house? As you say, I'm happy to own a truck that can synch with a cell-phone, I just don't want to have to do it to open the door.

The other thing that struck me was the glass sheets as cladding to provide a rain-screen. I wonder what goes on behind the glass in terms of temperature build-up or swings?

Log in or create an account to post a comment.

Sign up Log in