Cathedral ceiling assemblies and unvented conditioned attics often suffer from problems with damp roof sheathing. For years, building scientists have been proposing a variety of solutions to these damp sheathing problems. One possible solution (at least in hot climates) is to abandon the practice of installing ventilation baffles under roof sheathing, and instead to promote a new kind of ridge vent called a vapor diffusion port.

A vapor diffusion port — also known as a vapor diffusion vent, a diffusion vent, or a vapor vent — is located at the ridge of a gable roof or at the hips of a hipped roof. In some ways, a vapor diffusion port resembles a ridge vent. Like a ridge vent, a vapor diffusion port requires the roof sheathing to be cut back for several inches on both sides of the ridge. Unlike a ridge vent, however, a vapor diffusion port is airtight.

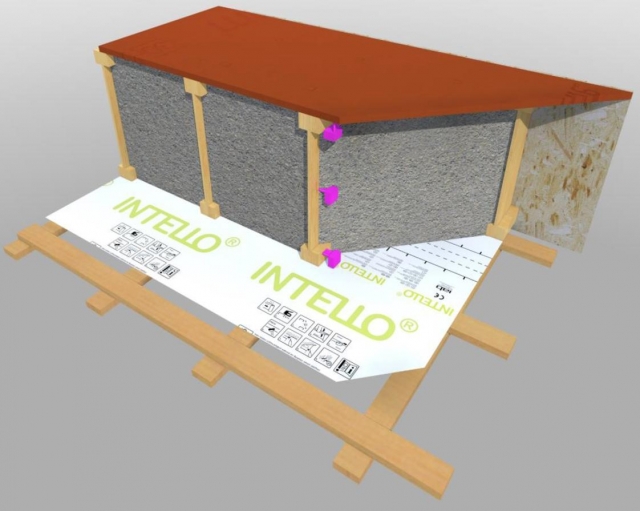

After creating open slots near the ridge — by either stopping the roof sheathing short of the ridge, or by cutting back the roof sheathing where necessary — workers cover the open slots with a vapor-permeable material like vapor-permeable roofing underlayment or gypsum-based sheathing. This vapor-permeable material is taped to the OSB sheathing on all sides, ensuring an airtight installation. Finally, the vapor diffusion port is protected by conventional ridge vent flashing.

Attics and cathedral ceiling assemblies with vapor diffusion ports don’t need soffit vents. In fact, if you are retrofitting vapor diffusion ports into an older house, you have to seal the soffit vents carefully. The aim is to create a relatively airtight attic.

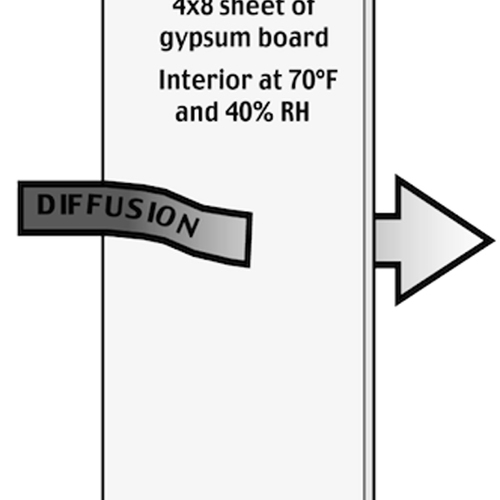

Here’s the theory behind vapor diffusion ports: moisture in attics or cathedral ceiling rafter bays tends to concentrate near the ridge. Whenever the outdoor air is less damp than the air at the top of the attic, a…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

37 Comments

How does one cover what amounts to a 24-in. wide hole at the ridge? Gypsum sheathing won't hold roofing nails and standard ridge shingles are 12 in. wide.

Patrick,

First of all, you don't need a 24-inch-wide hole at the ridge, as you can determine by looking at the lead photo in my article, and as you can determine by reading what I wrote. (I wrote that Lstiburek "recommends that for most roofs, narrower slots are just fine: 'How big should the vent area be? Turns out the same vent area we have been using for airflow vented roofs —1:600 of the ceiling area.' He also advised, 'Any off-the-shelf ridge vent [flashing] works.'")

In his field studies, Lstiburek experimented with very wide vapor diffusion ports. You can read about these experiments in his article, "Venting Vapor." The article includes photos to show how he covered these wide slots. I'll reproduce two of these photos below.

I think he wants us to go 1/150, just ask Joe.

yes, he has revised his recommendation

It doesn't look as bizarre as I may have thought. I wish I could have been there when Dr. Joe was explaining the truss design to the counter person at the lumberyard.

Patrick,

I'm not sure what you mean. Conventional roof trusses were used, as far as I know. The trusses weren't modified. The Building Science crew just installed 2x4 rafters over the vapor diffusion port to support OSB and shingles.

I get it now. Is there something to keep animals out of the cavity above the diffusion vent?

Patrick,

Above the diffusion port, you install conventional ridge vent flashing. Commercial ridge vent flashing usual comes with some type of screening to keep out the squirrels.

Thanks for your lengthy explanation on this issue. I do have follow-up questions based on you statement "If a roof with vapor diffusion ports includes some air-impermeable (foam) insulation, the air-impermeable insulation can be either directly above the roof sheathing or directly below the roof sheathing. This insulation should not block the vapor diffusion ports"

1. Just to be clear, a non-ventilated and conditioned attic with air-impermeable insulation (foam) IS NOT REQUIRED to use vapor diffusion ports, right? Operative word is IF.

- You said, "The vapor-impermeable insulation does not have to meet the minimum R-values listed in Table 806.5 (presumably because the vapor diffusion ports reduce the risk of moisture damage to the sheathing)"

2. Per R806.5 in CZ3, we need 1" R5 min. rigid foam on top or bellow of the roof decking, does this means we can use 1/2" R3 min. or none at all? We actually use 1" R5 min above sheathing on flat roofs, 1.5" on tile or metal pitched roofs to match the 2x4 nailer above the sheathing of the roof perimeter and 2" R10-13 CC under sheathing for shingled roofs.

- You said: Lstiburek, "first began experimenting with vapor diffusion ports in Juneau, Alaska, in 2001, in response to ridge rot problems in SIP roofs with leaky seams. ", and also, in Chicago and Houston, the roof framing was rafter bays. That make it easier to keep the permeable insulation against the decking. What I don't see is how to insulate a non-vented, conditioned attic with a open web truss system, with permeable insulation against the roof decking and vapor ports..

3. Do we use "wet" applied cellulose or fiberglass only? Does manufacturers warrant the hold of 12" R38 insulation against the roof decking from gravity pull? I know by experience, trying to hold dense pack cellulose in a truss system roof with wires or net is like hanging your coat on the line in the middle of winter.

Armando,

Q. "A non-ventilated and conditioned attic with air-impermeable insulation (foam) IS NOT REQUIRED to use vapor diffusion ports, right?"

A. Correct. You can use the conventional approaches you have always used if you want -- for example, an adequately thick layer of rigid foam above the roof sheathing, or an adequately thick layer of spray foam on the underside of the roof sheathing, without the vapor diffusion ports.

Q. "Per R806.5 in Climate Zone 3, we need 1" R-5 min. rigid foam on top or bellow of the roof decking. Does this means we can use 1/2" R-3 min. or none at all?"

A. Yes -- but only if you include a vapor diffusion port, and only if you follow all of the restrictions listed in the code (and listed in my bullet points.)

Q. "What I don't see is how to insulate a non-vented, conditioned attic with a open web truss system."

A. That's your problem. If it makes no sense to use the vapor diffusion port method, you don't have to use it.

Q. "Do we use 'wet' applied cellulose or fiberglass only?"

A. The vapor diffusion port system allows you to use any air-permeable insulation you want, including fiberglass, mineral wool, or cellulose.

Q. "Does manufacturers warrant the hold against the roof decking from gravity pull?"

A. No. That's the builder's problem.

Second response to Armando:

Concerning your point about trusses -- "What I don't see is how to insulate a non-vented, conditioned attic with a open web truss system" -- at least one manufacturer (Owens Corning) has developed a solution to your problem. For information on this system, see my 2015 article, "Can Unvented Roof Assemblies Be Insulated With Fiberglass?"

When Owens Corning introduced their “ProPink High Performance Conditioned Attic System,” building codes made the system illegal. Now that vapor diffusion ports have been recognized by the 2018 IRC, this approach can be used in Climate Zones 1, 2, or 3 -- as long as the ridge has a vapor diffusion port, and as long as it is a simple gable roof without valleys.

I appreciate your responses, I guess I dismissed your article in 2015... having said that, I can see in my crystal ball with the reality of labor shortage, skill, education and honesty where this is heading, with only a handful of builders doing it right, and the majority of consumer getting shafted. This is not any different than the common application 5.5" r19 oc foam against the roof decking for conditioned attics in CZ2-3, allowed by building officials and raters.

Martin,

How does exterior insulation tie into this roof assembly? In your article creating a conditioned attic you mentioned:

“If you insulate between the rafters, Although I don’t recommend it, it is possible to install all of your sloped-roof insulation between the rafters. Using air-permeable insulation (like fiberglass) is risky, since it allows moisture-laden air to reach the cold roof sheathing. If you want to use air-permeable insulation in this location, you have two choices: include a ventilation channel between the top of the insulation and the underside of the roof sheathing, or install rigid foam insulation on top of the roof sheathing to keep the sheathing warm. (Don’t do both, since these two solutions are incompatible.)”

I am building in a hot-humid climate 2A and was wondering if the addition of a ventilation diffusion port eliminates the incompatibility of the two types of insulation solutions mentioned in the article.

I have been talking with a few local builders familiar with the climate and they install blow-in insulation with netting directly under the roof sheathing (no air gap) and then install exterior roof insulation on top of the roof sheathing. However, over time the blow-in insulation will seperate from the roof due to gravity and essentially create an air gap between the insulation and the underside of the roof sheathing. With that said per the creating a conditioned attic article this would not be a recommended practice, correct?

Thanks!

User 7119046,

First of all, can you tell us your name? (I'm Martin.)

Building codes require, and building scientists insist, that when you are combining rigid foam above the roof sheathing with air-permeable (fluffy) insulation like fiberglass or cellulose underneath the roof sheathing, the fluffy insulation must be in direct contact with the roof sheathing -- and has to stay that way.

This is true whether or not you choose to install a vapor diffusion port.

You are correct that it's tricky to figure out a way to make sure that the insulation stays in contact with the roof sheathing, which is one reason that this method is rarely used with a truss-framed roof. (It's more common if your roof has conventional rafters.) The most common solution is to use the dense-pack method when installing the fluffy insulation -- a method that requires a very strong membrane or drywall on the interior.

Martin,

My apologies for not introducing myself or changing my username in previous posts.

My name is Steven, pleasure to speak with you!

1)Can you elaborate on your previous response (#12)? You stated "fluffy insulation must be in direct contact with the roof sheathing", however in In your article creating a conditioned attic, you mention you need an air gap. Is it acceptable to eliminate the air gap if we are installing rigid insulation on top of the roof sheathing when using air permeable insulation below the sheathing?

2)Also If this route is selected and the vapor diffusion port is omitted, is drywall recommended on the bottom of the truss-framed roof?

https://www.finehomebuilding.com/membership/pdf/6256/021221068.pdf

Steven,

Q. "You stated 'fluffy insulation must be in direct contact with the roof sheathing.' However in your article 'Creating a conditioned attic,' you mention you need an air gap."

A. You are confusing two different types of roof assemblies -- unvented roof assemblies and vented roof assembles.

Vented roof assemblies require a ventilation gap between the top of the fluffy insulation and the underside of the roof sheathing.

Unvented roof assemblies can be created several different ways, but if you are interested in combining rigid foam above the roof sheathing with fluffy insulation underneath the roof sheathing -- one common way of creating an unvented roof assembly -- then the fluffy insulation must be in direct contact with the underside of the roof sheathing.

All of this is explained in detail in my article, "How to Build an Insulated Cathedral Ceiling."

Q. "If this route is selected and the vapor diffusion port is omitted, is drywall recommended on the bottom of the truss-framed roof?"

A. What is "this route"? I'll assume you mean, "an unvented roof assembly that combines rigid foam above the roof sheathing with fluffy insulation under the roof sheathing."

There are many kinds of truss-framed roofs. You can use parallel-chord trusses, scissors trusses, or conventional attic trusses. In general, the type of roof assembly which (I think) you are considering requires an air barrier on the underside of the fluffy insulation. This can be taped drywall, but other air barrier materials are possible. If you are choosing a ceiling finish, a wide variety of ceiling finish materials can be chosen, as long as you have an air barrier on the underside of your fluffy insulation.

Since "BSI-088: Venting Vapor" (https://buildingscience.com/documents/insights/bsi-088-venting-vapor) came out in July 2015 I've been waiting to see if vapor diffusion vents would work in cold climates, climate zone 6 in particular.

I know at the time this article was written it was still climate zones 1-3.

But this recent article "BSI-097: De-Icing Ice Dams" (https://buildingscience.com/documents/building-science-insights/bsi-097-de-icing-ice-dams?utm_source=Building+Science+Corporation+List&utm_campaign=cac2c7b03e-BSC+Newsletter+Issue+%23102_COPY_01&utm_medium=email&utm_term=0_194890bc8c-cac2c7b03e-63881393) suggests they work in cold and very cold climates, albeit in a slightly different application.

Thoughts?

Brent,

The limited application that Lstiburek mentions in that article is when a "vented over-roof" is installed over a failing cathedral ceiling. Lstiburek is basically retrofitting a conventional vent channel (not a diffusion vent) on top of an existing roof that is failing, in hopes of limiting ice dams.

Lstiburek isn't advocating the use of vapor diffusion ports for this new vent channel. He is only advising that in this specific type of retrofit, it makes sense to seal the old ridge vent (the one under the new over-roof) with a retrofitted vapor-permeable air barrier membrane to cover the old ridge vent. The idea is to air seal the old ridge vent to prevent too much air from being drawn through the fiberglass batts that were never air sealed in the first place, and to allow the new (conventional) vent channels to take over the function of keeping the roofing as cold as possible.

Make sense? It will when you look at the illustration.

One final point: This isn't a recommended detail for new construction. This is an emergency solution for a building where normal air-sealing remedies are impossible.

Thanks for the reply Martin. I get that it is an emergency retrofit and the vapor-permeable air barrier material installed over the old ridge vent is intended to reduce air leakage while allowing some drying to the new vented over-roof. But it is still applying the principle of vapor diffusion vent in a cold climate, is it not?

Brent,

Q. "It is still applying the principle of vapor diffusion vent in a cold climate, is it not?"

A. Not really. The ventilation space in the "over-roof" pulls more outdoor air than usual past the vapor-permeable membrane, increasing the drying rate through the membrane and keeping the assembly safe. Without the vented over-roof, the assembly would behave differently -- and wouldn't necessarily be safe.

I wouldn't want to live in a house like this, with a poorly detailed fiberglass roof assembly. It's a mess. But Lstiburek's retrofit saved it from ice dams.

Hi all,

I'm trying to understand if a vapor diffusion port ever makes sense with insulation on the attic floor, in a retrofit situation with poor soffit venting. Clearly IRC 2018 or BSC articles don't discuss this. This is in climate zone 2A.

Our roof has quite a few valleys and lots of gables. No soffits, just solid blocking in the rafter bays. Venting is via gable-end vents (and two solar powered fans near the highest ridge). The costs to convert it to a conditioned attic (air-seal and put insulation over the sheathing etc) were too high (like over $150,000). There are no signs of condensation or rot on the sheathing (other than in one spot which clearly has bulk water coming in from the top). Sheathing for the most part is 1050s 1x6 shiplap, other than a newer section with plywood. Only ducts in the attic are for a dehumidifier (HVAC now via mini-splits). Currently asphalt shingles, but planning a new metal roof.

We're doing considerable air-sealing at the ceiling and intending addition of attic floor cellulose. My concern is that that makes the attic sheathing colder (no longer attic heated by house). I worry that could create additional condensation.

Roofers suggest adding a ridge vent, but not improving soffit/rafter bay venting. That seems problematic, stack effect potentially pulling air from the house, rather than the (random and low) roof edge venting.

Might a vapor diffusion port help here? Or does the (likely) colder sheathing from improved attic floor air-sealing and insulation obviate any potential benefit? Doesn't seem that a vapor diffusion port could make things any worse, and might have some drying benefit for any additional condensation?

Or is only option to somehow install, where we can, something like Cor-a-vent Raft-a-vent (http://www.cor-a-vent.com/raft-a-vent-rs-400.cfm), together with insulation shutes and the ridge vents. That might mean taking back the sheathing ~2/3 feet and doing the work from the top. I hate the thought of messing with the 1x6 shiplap sheathing and since the roofers don't want to do that work, it would mean another trade working in during roof replacement. And given the complex, many gabled structure, it's unclear that soffit to ridge venting would work anyway.

So that brings me back to another, disappointing, option: protecting the roof sheathing by essentially leaving things unchanged, not adding considerable attic floor insulation.

James,

If your sheathing is in good shape except where you had an obvious roof leak, there is no reason to worry about the level of ventilation in your attic. The value of attic ventilation is often exaggerated. For more information on this topic, see "All About Attic Venting."

Performing air sealing to prevent indoor conditioned air from leaking into your attic will reduce, not increase, the chance of condensation on your roof sheathing. Sealing the air leaks prevents humid air from entering your attic -- without that entering humid air, there is no source of moisture, and therefore no condensation risk.

Relax. You don't have to do anything. Just focus on air sealing.

Ommmmmm (me relaxing :) Thanks!

Hi Martin---

Great follow-up article to Joe Lstiburek's article "Venting Vapor." My name is Ray and I am an Architect in L.A. I am currently working on an ADU (detached garage conversion) design in Los Angeles where the existing 18'x20' garage has a hip roof with a 4:12 pitch on all (4) sides. I am proposing an unvented cathedral ceiling to make the space feel as big as possible. My question is regarding the vapor diffusion port area distribution and method for openings; the vapor diffusion port option is codified in the current CRC. My ceiling area (parallel) to the slope, since this is the finish interior surface, is approx. 361.5 sf. 1:600 gives me 0.6025sf or 86.76 si. My plan was to drill (4) 3" diameter holes = 7.07 si per side of the ridge board (evenly spaced) and (16) 3" diameter holes distributed at the ridge/hip intersections with no edge of any hole further than the 12" max. vertical requirement from the highest point of the roof. The total open area would be 141.4 si. The ridge & hip ridge vents for that area will total 132 si. I am considering this solution because it compromises the diaphragm less than a straight cut and I feel it would be a faster install. The 20+ perm vapor permeable, water-resistive underlayment would go over the holes as a sheet held in placed by a metal strap at the lower edge (per Lstiburek article); or can I use a sealing tape?. This is followed by the ridge and hip vents which will cover the holes. Does this sound like a sound solution? Your comments would be much appreciated. Thank you.

User 7669205,

Full disclosure: I have never been involved with a project that has vapor diffusion ports. I'm not an expert. Here's my reaction to your plan:

1. In theory, you can have moisture problems in any of your individual rafter bays, so you need a diffusion port at the top of every single rafter bay. If you intend to drill a series of 3-inch-diameter holes, you'll need at least one hole per rafter bay. If your rafters are 16 inches on center, that means that the spacing of your holes must also be, at a maximum, every 16 inches. Closer spacing -- for example, every 12 inches -- is acceptable, but greater spacing -- for example, every 18 inches -- is not. You don't want a rafter bay without a hole at the top.

2. I don't know what you mean when you write that "water-resistive underlayment would go over the holes as a sheet held in place by a metal strap at the lower edge." All roofing underlayment is water-resistive. What matters is not that the underlayment is water-resistive -- what matters is whether the underlayment is vapor-permeable. (Later, you refer to an underlayment with a minimum permeance of 20 perms -- so it looks like you're going to select the right underlayment.) You don't need a metal strap -- you just need to seal the seams of the underlayment with a durable tape that is airtight. Talk to the underlayment manufacturers, and ask for a recommendation on a compatible tape.

Thank you Martin!

Cheers ---Ray

Any reason (assuming Zone 3 Hot Dry Climate) the vapor diffusion port shouldn't work with metal roofing assuming a continuous ridge vent and all other details as described above?

Separately, If the vapor diffusion port is at the ridge of an unvented enclosed rafter assembly (rather than an attic) filled with air permeable insulation how does 806.5.2.10 not apply?

The 2018 IRC appears to (me) only reference the unvented attics application of vapor diffusion ports:

R806.5.2 - In Climate Zones 1, 2 and 3, air-permeable insulation installed in unvented attics shall meet the following requirements:

R806.5.2.10 - The air shall be supplied at a flow rate greater than or equal to 50 CFM (23.6 L/s) per 1,000 square feet (93 m2) of ceiling. The air shall be supplied from ductwork providing supply air to the occupiable space when the conditioning system is operating. Alternatively, the air shall be supplied by a supply fan when the conditioning system is operating.

Edgar,

Vapor diffusion ports are not approved for attics with horizontal insulation on the attic floor; they are only approved for unvented cathedral ceiling assemblies (that is, insulated sloped roof assemblies). This is established by R806.5.2.8.

Section R806.5.10 is poorly written and ambiguous, and therefore impossible to interpret. An understanding of grammar and syntax is insufficient for the reader to understand what the code writers meant by "The air." All I can come up with is something like this: the code writers meant "the air" to mean, "When vapor diffusion ports are installed at the top of a sloped insulated roof assembly above an unvented attic, the attic will be supplied with air meeting the requirements established in the following sentence. The air..."

Turns out California didn't include any of the language regarding vapor diffusion ports at the ridge in the 2019 CBC 1202.3 at all.

https://codes.iccsafe.org/content/CBC2019P4/chapter-12-interior-environment#CBC2019P4_Ch12_Sec1202

Great, thanks Martin. While I agree with you regarding ambiguity, I fear the code fails so entirely to describe their application in an unvented enclosed rafter assembly as to be indefensible. Given 806.5.2 is clearly inclusive only of attics and all (attics shall meet the following conditions) of the sub code I see little hope for selling an unvented enclosed rafter assembly with vapor diffusion ports to my building department.

By the way, Mr. Lstiburek answered my first question regarding metal roofing as being acceptable in a separate communication.

Hi Martin,

I’m in Climate Zone 3B here in Los Angeles. Edgar is correct in that CA didn’t include any of the Vapor Diffusion Port language in their latest code. But, CA’s code has some additional things not included in the International Code.

https://codes.iccsafe.org/content/CBC2019P4/chapter-12-interior-environment#CBC2019P4_Ch12_Sec1202.3

#5 includes: “No insulation shall be required when roof tiles, wood shingles or wood shakes, or any other roofing system using battens and no continuous underlayment is installed. A continuous underlayment shall be considered to exist if sheathing, roofing paper or any continuous layer having a perm rate of no more than one perm under the dry cup method is present.”

1. Does this code mean that they want the attic to ‘dry to the outside’ by ensuring there is no vapor barrier as the underlayment?

Since we are in a Wildfire area we are looking to install an Unvented Boral Steel Shingle roof. The Boral roof installation details adding a Ridge Vent - almost exactly like the diffusion port but WITHOUT the vapor barrier. According to Boral’s installation they say that the airflow created by cutting the sheathing next to the ridge and allowing attic air out is a “critical area of installation” - they say “Make sure the air-flow path from the attic space is not restricted.” They specifically say airflow and not vapor flow. But they also detail their ASV “Above Sheathing Ventilation” as allowing air flow to rise up underneath the steel tiles to and out the ridge. I’m not sure why they they want the attic air to also pass out the ridge vent - at least as far as why it’s necessary for a proper steel roof installation (see attached images).

2. Any idea why they would be specifying that the install needs airflow from the inside the attic out the ridge vent? Again, wildfire area - I’d prefer not to have airflow.

3. According to the CA Code, It seems that building the roof systems on battens (as well as meeting conditions 1-4 of course) would be adequate for an unvented roof (and technically not require any insulation). Does that sound correct?

Whether or not this is adequate, we have 2 Cathedral Ceilings with mineral wool on the underside of the sheathing, and plan on adding rock wool to the underside of the remaining roof in the attic.

4. Another option seems to be building the system with battens AND a Vapor Diffusion Port - as it’s similar to Boral’s install method though we would add a vapor barrier over the port. Would this be a safer idea?

5. The last option seems to be installing the roof with or without battens and using Boral’s new Sol-R-Skin Blue underlayment. (https://boralroof.com/components/underlayment-products/sol-r-skin-blue/). The literature states that this product “provides R5.5 insulation rating recognized by California’s Bureau of Household Goods and Services (BHGS) and qualifies as above roof deck insulation for California’s Title 24 Part 6 Energy Code.” I assume though that this underlayment is a vapor barrier? And this installation would require the underside of the sheathing to be insulated?

6. Out of all the installation options, which do you think is the best for an unvented metal shingle roof in a Wildfire area?

Thank You for your time

Joe

Joe,

You've got a lot of complicated questions. It's important to note that I'm not an expert on the California code.

Q. "[One part of the California code] includes: 'No insulation shall be required when roof tiles, wood shingles or wood shakes, or any other roofing system using battens and no continuous underlayment is installed. A continuous underlayment shall be considered to exist if sheathing, roofing paper or any continuous layer having a perm rate of no more than one perm under the dry cup method is present.' Does this code mean that they want the attic to ‘dry to the outside’ by ensuring there is no vapor barrier as the underlayment?"

A. I assume that the California code is referring (in the quoted sentences) to a roof assembly that is designed to dry to the exterior. Note that concrete roof tiles and wood roof shingles are vapor-permeable, unlike steel roofing. My confusion arises with the code language "no insulation shall be required." That language is confusing. It must mean, "no insulation shall be required in a specific part of the assembly that the code writers forgot to mention" -- because you always need either ceiling insulation or roof insulation.

Q. "Any idea why they would be specifying that the install needs airflow from the inside the attic out the ridge vent?"

A. That's the most typical way attics are detailed all over the country. It's called a vented unconditioned attic. Air enters at the soffit vents and exits at the ridge vent. In such an attic, the insulation is on the attic floor.

Q. "According to the CA Code, It seems that building the roof systems on battens (as well as meeting conditions 1-4 of course) would be adequate for an unvented roof (and technically not require any insulation). Does that sound correct?"

A. I have no idea. It's certainly true that if you want an insulated roof assembly to dry to the exterior, you need to choose a type of roofing that is vapor-permeable (for example, concrete roof tiles or wood shingles). All homes require ceiling insulation or roof insulation.

Q. "Another option seems to be building the system with battens AND a Vapor Diffusion Port - as it’s similar to Boral’s install method though we would add a vapor barrier over the port. Would this be a safer idea?"

A. No. If you install vapor diffusion ports, you absolutely don't want a vapor barrier over the ports. Vapor diffusion ports only work if water vapor can diffuse through the port. So you need some type of fabric that is airtight but vapor-permeable -- definitely not a vapor barrier over the port.

Q. "The last option seems to be installing the roof with or without battens and using Boral’s new Sol-R-Skin Blue underlayment. (https://boralroof.com/components/underlayment-products/sol-r-skin-blue/). The literature states that this product “provides R5.5 insulation rating recognized by California’s Bureau of Household Goods and Services (BHGS) and qualifies as above roof deck insulation for California’s Title 24 Part 6 Energy Code.” I assume though that this underlayment is a vapor barrier?"

A. I'm not familiar with the product. But if you want to know the product's vapor permeance, you should contact the manufacturer and ask for their technical help hotline. If the manufacturer is reputable, they should be able to tell you whether it is vapor-permeable.

Q. "And this installation would require the underside of the sheathing to be insulated?"

A. I'm not sure if I understand your question. But it's certainly true that R-5 roof insulation isn't enough, so you would need more insulation somewhere in the assembly (or on the attic floor).

Q. "Out of all the installation options, which do you think is the best for an unvented metal shingle roof in a Wildfire area?"

A. It's certainly possible to build an unvented sloped roof assembly -- see, for example, "Five Cathedral Ceilings That Work." If your roofing choice is tripping you up because the roofing must be installed over a vented assembly, my advice would be to choose a different type of roofing.

“[Deleted]”

Hi Martin, thanks for this article. We're detailing a vapor diffusion port on a home in climate zone 3B in Los Angeles, CA in a high fire risk zone. We're using titanium FR as the underlayment under heavy clay mission tiles. The sheathing (and underlayment) was cut out to slightly exceed the 1:600 rule (but not as much as the 1:150), near the ridge and we're planning to install Delta Fassade SA (perm rating of 50) as the vapor permeable membrane.

Our roofer is not planning on installing any sort of ridge vent flashing over the port - is that recommended and what would that detail look like on a mission tile roof? The port is high enough to be mostly under the mortared portion of the ridge, at least everything except parts of the hips.

Thanks, Curtis

Curtis,

Your roofer is omitting an essential detail. You need ridge vent flashing over the ridge to make sure that the moisture at the ridge can escape. As Joseph Lstiburek explained in the article, “Any off-the-shelf ridge vent [flashing] works" -- but there has to be ridge vent flashing.

Your roofer can contact the manufacturer of your concrete roof tiles to get advice on ridge vent flashing. Here is a link to one product:

https://www.bestmaterials.com/PDF_Files/Quarrix_Tile_RidgeVent.pdf

I was curious about a couple of comments in the body of the article and the comments section.

1) that vapor diffusion ports are not approved for attics with horizontal insulation on the attic floor.

The wording in R806.5.2.8 shown in the 2018 IRC code through ICCsafe.org indicates for Climate Zones 1-3:

Where only air-permeable insulation is used, it shall be installed directly below the structural roof sheathing, on top of the attic floor, or on top of the ceiling.

This is similar to the wording in Joe Lstiburek’s January 2101 paper GM-2021, Guide for Building Conditioned Unvented Attics and Unconditioned Unvented Attics…

2) that a vapor diffusion port approach won’t work on a complicated roof with valleys or dormers.

In the February 2016 paper titled Field Testing of an Unvented Roof with Fibrous Insulation, Tiles, and Paper Diffusion Venting by Kohta Ueno and Joe Lstiburek, the test house near Orlando Florida appears to have a complicated roof, including valleys (Figures 15 and 27). I realize this test house is configured to provide a direct comparison between portions with a diffusion-vented ridge and an unvented roof ridge, but it appears to be a very complicated roof. I recognize a vapor diffusion port would be more effective with a simple, uncomplicated gable roof / attic that has no valleys. However the approach seems like it could still be effective with a more complicated roof, particularly with dehumidification.

Thanks, Mark

Mark,

The facts in this article are based on the best information available in 2018, when the article was written. I spoke at length with Joseph Lstiburek when researching this topic. As I reported, "Lstiburek ... pointed out another limitation of the vapor diffusion port approach: 'This is not good for tricky roof geometries,' he said. The approach works best on a simple gable roof. It also works on some types of hipped roofs, but it won’t work for a complicated roof with valleys or dormers."

It's possible that research since 2018 has indicated that the vapor diffusion port approach can work for some attics with insulation on the attic floor; if so, it's news to me.

Log in or become a member to post a comment.

Sign up Log in