Image Credit: Martin Holladay

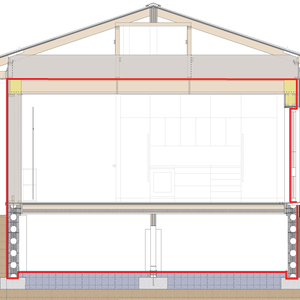

Bill L. is planning a high-performance house in Massachusetts and is wrestling with options for the air barrier, that all-important building detail that enhances both energy efficiency and building durability.

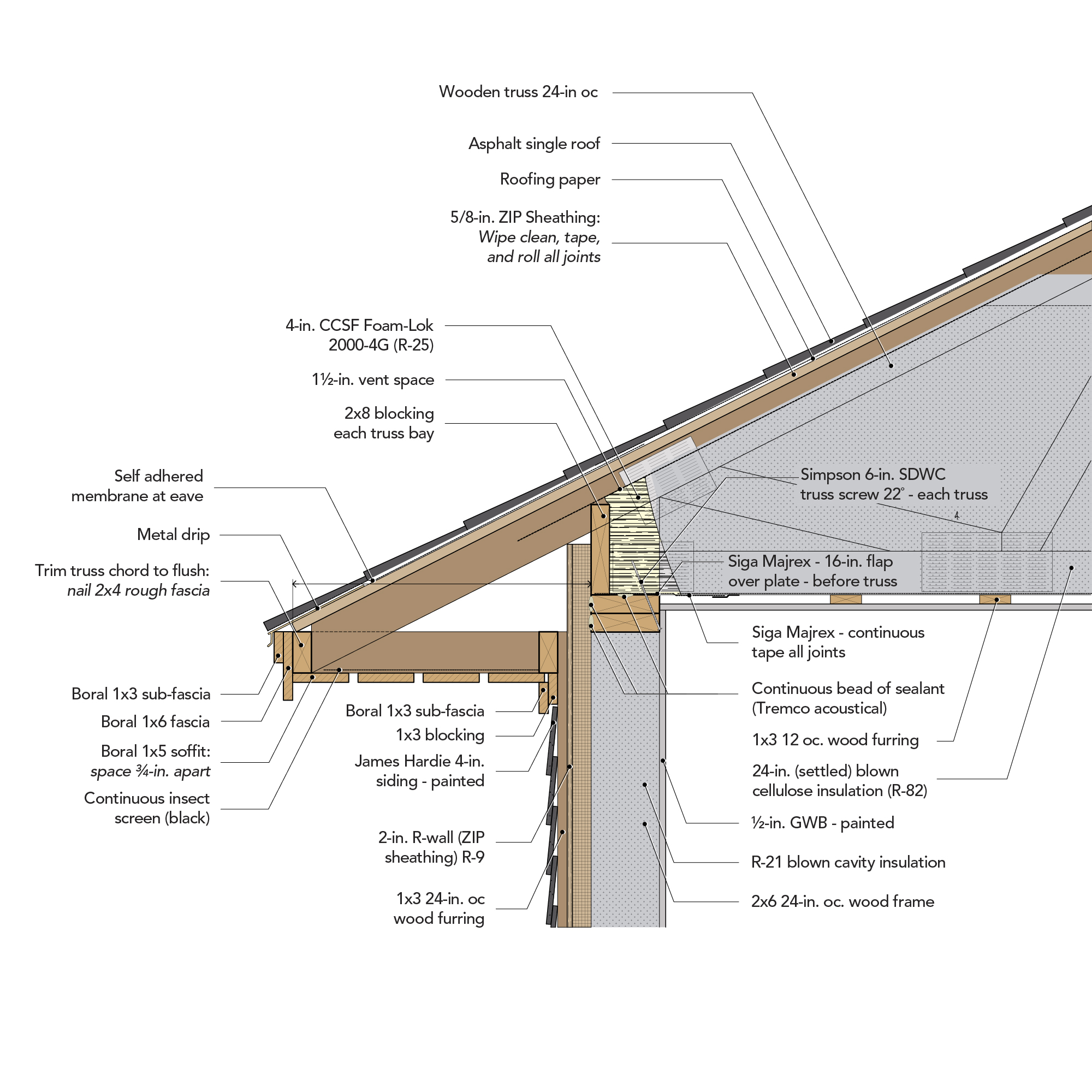

Above-grade walls will consist of a 2×4 structural frame sheathed in 1/2-inch plywood, followed by I-joists packed with cellulose insulation, another layer of 1/2-inch plywood, a corrugated plastic product to provide an air space, and fiber-cement siding. The primary air-barrier plane will be at the plywood over the 2×4 studs.

“I don’t trust tapes or caulking to last long-term,” Bill writes in a Q&A post at Green Building Advisor, “and stapling a sheet material over everything seems a lot less labor-intensive than priming the plywood and taping or caulking all of the joints. It also seems considerably less expensive than Zip sheathing.”

Although Bill had considered using CertainTeed’s MemBrain, it’s proving hard to get where he lives, and he’s not convinced it will be durable enough.

Where does this leave him? That’s the topic for this Q&A Spotlight.

Consider a liquid-applied WRB or high-quality tape

If Bill doesn’t trust tapes to go the distance, suggests Albert Rooks, use a liquid-applied WRB at the sheathing layer. Specifically, he points Bill toward FastFlash, a product made by Prosoco. Rooks says that was used in a Seattle Passivhaus project described in a 2011 GBA blog by Richard Defendorf.

“The approach is not inexpensive, but the quality is exceptionally high,” says Rooks. “We sell it at The Small Planet Workshop, but I’m sure you can find a supplier in your local market at Prosoco’s website.”

But in the end, Rooks adds later, “good quality tape is still (in my opinion) the simplest ‘go to’ material for turning sheathing into an air barrier.”

“I…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

13 Comments

Sealant / Adhesive

As was alluded to, the International Building Code prohibits the attachment of wall sheathing by adhesives in Seismic Design Categories D and higher. In addition, APA recommends against gluing plywood or OSB wall or roof sheathing to framing. Wood structural panel manufacturers recommend a 1/8” gap between panels to accommodate the natural expansion of plywood and OSB. The 1/8” gap helps to reduce the risk of the panels buckling out of plane. Adhesive attachment can restrict expansion of structural panels and lead to buckled sheathing. Before applying sealants to wall sheathing, builders should check the sealant manufacturer’s technical literature to ensure that the sealant will not act as an adhesive or otherwise compromise the effectiveness of the panel edge gapping.

MemBrain rating

Martin,

After speaking with CertainTeed tech support, I was able to get their ASTM E2178 test results for MemBrain. Elyse Inglese (Technical Marketing Manager) said it is 0.0019 L/s*m2 (0.0004 cfm/ft2). So 1/10 of the limit but 8x worse than Intello.

Unless this is a typo, 0.00004 cfm is better than intello which is rated at: Airtightness ASTM E2178 ≤ 0.004 cfm/ft².

I'm trying to reach Elyse to clarify.

in terms of vapour permeance:

intello:Vapour permeance ASTM E96-A 0.17 US perms

Vapour permeance humidity variable EN ISO 12572 < 0.13 - 13 US perms

membrain: Water Vapor

ASTM E96

Desiccant Method <1.0 perm

ASTM E96

Water Method >10 perms

According to the Intello Plus spec sheet (from 475 website) Air permeance ASTM E2178 is 0.00005 cfm/ft^2

compared to 0.0004 for Membrain (according to Matt's post), which does work out to a factor of 8 difference in favor of Intello.

Intello is made by Proclima. The Proclima website has this value for both Intello and Plus:

Airtightness ASTM E2178 ≤ 0.004 cfm/ft²

Airtightness EN 12114 tested

It seems we've uncovered a discrepancy in the reporting then, unless the product being spec'd on the ProClima website differs from the one on 475.

3M was mentioned as a good joint tape for sheathing. Is 8067 what is being referred to here? The acrylic based tape. Trying to avoid Siga if possible because of cost. Any alternatives for cheaper and more accessible? 8067 is readily available and affordable on amazon.

https://www.energyconscious.com/3m-all-weather-flashing-tape-tan-slit-liner-2-in-x-75-ft-12573.html

$6 cheaper than Amazon.

I believe PPG Gripper will make it work very well.

Kevin,

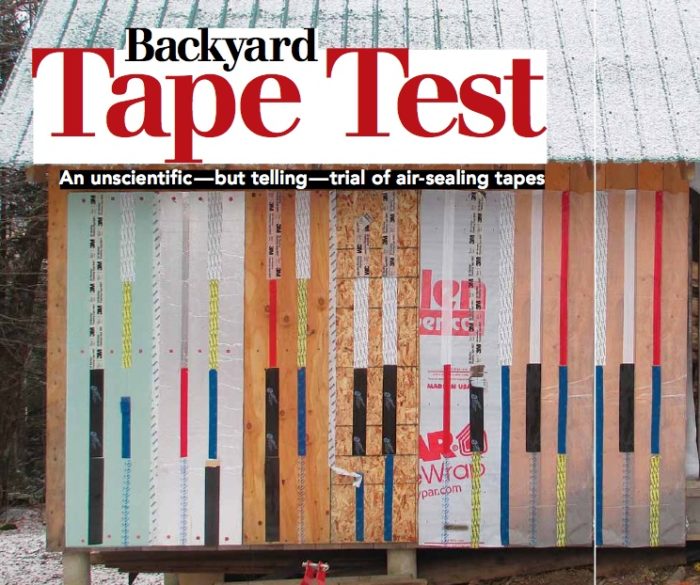

You may want to read the article I wrote called "Backyard Tape Test." Here is the link: "Backyard Tape Test."

(That's the article that included the photo that Scott Gibson used to illustrate this Q&A Spotlight discussion.)

In my article, I discuss several products, including 3M All Weather Flashing Tape #8067.

Hi Kevin, the 8067 looks exactly like the tape used in this backyard study. It is readily available on Amazon as you said and in Canada various suppliers sell it. I used 8067 extensively in my house and it popped up many times in my blog (flatrockpassive.blogspot.ca). Its extremely tenacious. you'll tear it apart trying to get it off anything. I found it to be a great tape for both interior and exterior. 4" is great for general taping, and I have also used 6" and 9" for flashing window sills and other air sealing.

David,

As I just noted in my comment to Kevin, the tape in "the backyard study" was, indeed, 3M All Weather Flashing Tape #8067.

If you want to read my article, here is the link: "Backyard Tape Test."

I called 3m to see if their tape sticked to PT plywood - they didn’t know. Does anyone have experience here or know about this application. 3m 8067 to PT plywood.

Very cool! I’ll have to get this and tape my joints. And yeah I used this a little on my windows too - as well as another acrylic based tape called Gtape (3040bk) made in Japan, also really good stuff, actually I like it better thank 8067.

Log in or become a member to post a comment.

Sign up Log in