Image Credit: David Murakami Wood

Editor’s note: David and Kayo Murakami Wood are building what they hope will be Ontario’s first certified Passive House on Wolfe Island, the largest of the Thousand Islands on the St. Lawrence River. They are documenting their work at their blog, Wolfe Island Passive House. For a list of earlier posts in this series, see the sidebar below.

Although there is always more to do, at the end of 2017 and after a year of living in our passive house, it’s a good time to reflect on the whole process.

This place was the product of a shared dream between Kayo and I to create a sustainable and comfortable family house, and an experiment for all of those involved. Sitting here on a late December morning after a night when the temperature dropped to an unusually cold -24ºC (-11ºF), without wind-chill, and looking out on the sun shining on a half-metre of snow, while feeling totally comfortable inside at 21ºC (70ºF), we think we’ve achieved our dream and the experiment has been a success! We would even stand by the revised cost estimates we produced back in December 2015.

BLOGS BY DAVID MURAKAMI WOOD

A Performance ReportHeat Recovery VentilationSiding and a PorchReady for RoofingAdding the InsulationBuilding With Cross-Laminated TimberWindows, Doors, and UtilitiesThe EnvelopeWolfe Island Passive House — An Introduction

There are some remaining problems. The first is a building envelope tightness issue due to a manufacturing fault. The Optiwin Motura sliding door, which was a prototype, has never sealed as tightly as it should, and last winter and this, we’ve resorted to sealing it up with gasketing and tape to maintain the building envelope.

However, this is fixable: Optiwin has been as thorough and responsible as ever, and not only issued us a partial refund for the door but also provided a very detailed analysis of the fault and how to remedy it, which we will be putting into place in the spring. I don’t think anyone else considering using Optiwin needs to worry about this — as I said, our door was an early version and the current models are already better.

A problem with the porch

The second issue was noticed by Malcolm Isaacs, our Passive House consultant, in checking the performance report by Anthony Mach. He reckoned that the passive solar heat gain in winter is not as good as it was in the calculations we made. In other words, the house is not as warm as it could be. It’s not actually something we find uncomfortable, it’s more an optimum performance issue.

The reason, we think, is that the downstairs porch roof overhang does not have quite the exact height, angle, and extension as in the original design. However, this means that to remedy the (small) differences, we’d almost have to rebuild the porch completely. There were at least two points at which things were changed in the design process that could have affected this, and as we were working not only with an architect and builder but also a Passive House design consultant and engineer, as well as a manufacturer (for the pre-fabricated CLT structure), there were even more communication issues to manage than in a normal build.

These communication issues can be crucial and really, all calculations need to be checked and recalculated every time there is a change. And, of course, when you are working with any kind of pre-fab, there is a point after manufacturing has started that you can’t change anything about that any more and any changes from that point onwards have to be adaptations to what you’ve had manufactured.

Had we known about the issue with passive solar heat gain, we probably would have had under-floor heating installed. In fact, we probably should have done that anyway as a kind of reserve. Had we done this, we probably wouldn’t have needed the little Thermolec air heating system we have as part of the ventilation system.

We were assured that it would be so warm anyway that underfloor heating wouldn’t make any difference. That’s not really true in practice but it’s warm enough so we aren’t complaining! Again, at this point it would mean substantial rebuilding (ripping up and relaying our lovely wooden floors) to do this. The lesson is: lay the underfloor heating even if you end up not using it. It’s better to have the possibility than not.

Small design issues

The other remaining problems are small design issues that people thinking about building a Passive House, or even just any house, should note. The first is that although we really like our open-plan downstairs space, and visitors love it, Kayo would now want a more specific dedicated work area or work room. What we did design was inadequate. It’s difficult to see how we could have done this just by tweaking the design we have. So, if we were starting again, we would include this as one of the essential elements and design around it, as we did with the kitchen.

The second minor element does relate more to Passive House design, and it is the way the entrance works. We have an amazing Austrian-manufactured Passive-House-certified front door from Tarredo. The only problem is that you still have to open it and once you open it, it doesn’t matter how insulated the door is.

Of course, no one leaves the door open very long in winter in any house, but any heat loss is a problem in a Passive House in very cold climates. Back when we were still thinking about rebuilding our old house, we had designed what we referred to as an “air-lock” (like in space-ships), which was essentially an insulated porch outside the building shell. It had insulated doors to both outside and inside. Somehow, that element got lost when we moved to designing an entirely new house.

I’d really recommend to anyone building a Passive House in a cold climate to think about this. Especially around the holiday season when you have people coming and going, the front door gets opened a lot more than you’d like from a Passive House point of view! The plus side is that the more parties you have, the more all those people in your house also heat it up. However, whichever way you are thinking about it, you have to factor people and behavior into your design.

The good news is that this particular problem is easily resolved. We think what we will do is create a closed-in porch space outside the front door. We’ve got room. The only question is whether we make it permanent or seasonal and removable.

No regrets on the fundamentals

There is really nothing that has happened in this year of living in our new Passive House that has made us regret or rethink the building process or the big decisions we made in the design.

The Zehnder ERV is a minor miracle. The air quality in the house is so good that it almost makes us forget the mold-infested air we used to put up with as normal in practically every other house we’ve ever lived in. It just keeps working in the background with minimal need for maintenance (occasional cleaning or replacement of filters).

We still totally recommend using cross-laminated timber for the structure. However, we don’t think it’s necessary to use it for all interior walls. Combining CLT for the main structural walls, with more standard stick-frame and drywall for the other interior walls, would make for a more flexible design that would allow you to do things like changing your mind on where electrical sockets etc. go — and even where the walls themselves go.

However, we know that Canadian manufacturers, at least in the east, are still not capable of doing the precise factory-cutting that we had done. Someone needs to make the necessary investment to do so, because CLT should be a standard material in home building here considering Canada’s timber resources and need for well-insulated homes in a world where we are at the end of the era of limitless oil and gas for heating. Were anyone to use Canadian CLT, however, you wouldn’t be limited, as we were, by the dimensions of shipping containers. You could be more flexible with your design. A lot of things in our design started from this, which meant we went down a certain route.

We would still have the same advice for those considering using CLT as we had in this post back when it seemed that disaster was afflicting our build in January 2016: don’t start building in the fall in a climate like this, and do wrap your CLT structure in a breathable, water-proof housewrap as soon as it’s up.

The roof was probably too complicated

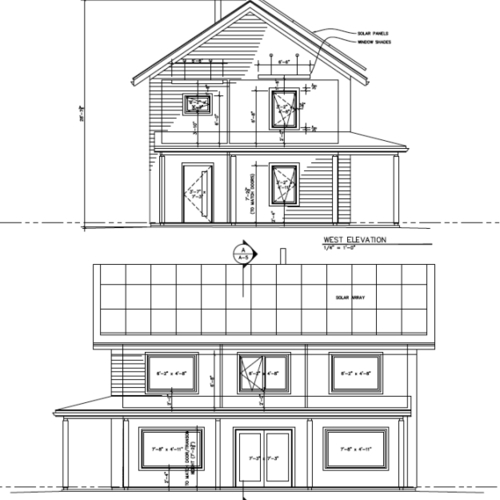

The roof might also be something I would rethink were we starting again. We designed it to fulfill several functions: to be at a good angle for generating solar power in the shoulder seasons and winter, to provide shade for the upper-story windows in summer, and, of course, to be able to contain enough insulation.

Originally, we were not going to use CLT panels for the roof, but the horror stories we heard about the practices of truss manufacturers around here convinced us to give it a go. With CLT roof panels, we got added structural strength, which will mean the weight of any number of solar panels is no problem. However, we had to have a floating rafter design (read this and this in order to retain the overhang.

This looks beautiful but it was very complicated to engineer and caused the insulation installation to be much more difficult — cutting the wood-fiber insulation we used into exactly sized triangular sections was not easy (especially in the depths of winter). Had we started with CLT as our primary material, we might have made different decisions here: we could have gone for entirely different roof designs, and gone for ground-mounted solar panels, and considered other ways of shading. However, just aesthetically, I really like our roof and I like the fact that it goes against the grain of having roofs finish flush to the walls.

In the end, we have a beautiful, sustainable, high-performance Passive House, which we love and which works. It was a long journey getting here but it was worth it. We will keep occasionally updating this blog with things that we are doing (we’ve still got to install a PV system in 2018, for a start) and performance updates, but in general there probably won’t be more than a post a month in 2018. And we’re always very happy to be contacted with questions from other people considering building sustainably.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

0 Comments

Log in or create an account to post a comment.

Sign up Log in