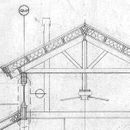

Insulated cathedral ceiling for a pole barn

Dear Martin Holladay,

I read your article about insulating a pole barn with great interest, and I hope you can help me figure out how to build an unvented, well-insulated cathedral ceiling in the new pole barn style barn. I used the typical pole barn style of construction with the roof trusses paired around the vertical poles, except that I’ve flanked the poles with conventionally framed 2×6 wall bays on either side of the poles making them interior posts holding up the high roof. Then, I have two shed roofs framing in below a band of clerestory windows at the high bay. (See Section) At the high bay roof, I’ve run 2×8 roof purlins continuously over the top of the trusses. (I don’t know the name of this technique) but it leaves the trusses completely exposed. I now have to insulate the unvented cathedral rafter spaces above the trusses and my plan was to uses rigid poly-iso board cut to fit in each rafter space (Stacking pancakes I believe you called it) and then a 6 mil. vapor barrier and followed by a layer of gyp bd. Roof sheathing is 5/8” OSB followed by a synthetic waterproof membrane and standing seam roofing.

Will I have problems with this assembly and if so, what would you recommend as a solution?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Barry,

It would be helpful if you told us your climate zone or geographical location.

It sounds like you want to create an unvented cathedral ceiling assembly. As you may know, I don't recommend the cut-and-cobble method (or the "stack of pancakes" method) for unvented roof assemblies, because of the risk of moisture accumulation and rot.

For more information, see "Cut-and-Cobble Insulation."

It's unclear to me whether you have a plan for an interior air barrier. You mention gypsum board -- but it sounds is if the gypsum board is interrupted by roof trusses, so the gypsum board can't act as an air barrier.

Since this is an unvented assembly, I think your only alternative is to install some closed-cell spray foam on the underside of your roof sheathing.

For more information, see this article: "How to Build an Insulated Cathedral Ceiling."

Thank you so much, Martin, for your reply. And of course I should have told you Climate Zone 6, NE Wash. State, sorry. So the air barrier was the 6 mil. poly beneath the GB, unless I'm mistaken. Is spray foam my only alternative?

Barry,

Polyethylene is usually a poor air barrier, because it is easily damaged on the job site, because builders rarely seal seams in the poly, and because it generally gets perforated by fasteners.

Akos is correct that you can use a fluffy insulation product like fiberglass, mineral wool, or cellulose -- but only if you can figure out a way to include a ventilation channel between the top of your insulation and the underside of your roof sheathing. This ventilation channel needs to connect to soffit vents at the bottom and a ridge vent at top.

If you can't establish this ventilation channel -- it's code-mandated if you install a so-called "air-permeable" insulation -- then you'll need to install closed-cell spray foam.

If you want to stay with batts, you can make a vented assembly with 2x4's on flat at 45 deg to your purlins, see the details in the video here:

https://www.greenbuildingadvisor.com/question/parallel-chord-trusses-for-vaulted-roof

It might also be worth it to put a layer of plywood above the purlins with taped seams as your air barrier, it would work much better than trying to detail 6mil poly around the beams (which will leak no matter how careful you do it).

With R28 batts, that would be around an R23 whole roof assembly.

If you fill the 2x8 with closed cell spray foam, that will bump you up to R29 whole roof, but that is a very expensive roof.