Roof modification from I-Js to Truss and WRB

Back ground:

Building in a rural area, I had no idea how difficult finding people and materials would be to build an energy efficient home. Over the last year I have read and referenced many articles from GBA. Now I’m taking control of my build. (The builder backed out) I built our house in “Sketchup” during the design faze so my wife could “see” what the rooms looked like. Now I continue to refine the detail down to the studs and sheets to set placement for the build.

I’m refining details and sourcing materials as I document the procedures needed to build. This should make it easier to learn and teach builder/carpenters. I plan to start with a mock-up wall with window.

Passive House Style, 46’x32′ zone 4

Basement: Superior Walls Xi basement, Dense pack cellulose, South&East walkout

Main floor and Loft: 2×6 AF modified, Roxul comfortBatt insulation, Zip system,

4” Roxul ComfortBoard80, ¾ batten board rain screen,

Hardie board or Engineered Wood Siding

All dry wall will be an air sealed barrier, ADA

Windows and doors: triple pane from Prossimo LLC

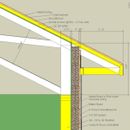

Roof: Hip roof 12-6 pitch, Cathedral ceilings,

1) Roof modification question:

Original roof plan: 16” I-Joists, Dense pack cellulose, European fabric WRB,

2×4 vertical purlins to vent, OSB, synthetic underlayment, metal roofing.

I want to change to:

Raised heel parallel truss, Zip system for WRB,

The builder is knows trusses, never worked with I-Js. Zip system seems easier, the complete envelope will be sealed the same way.

The truss will give me 20 1/2” inside the cords, to attach webbing for blown cellulose, leaving a 3.5” gap above and below for bulge. R-60+ -R-70.

2) Will the Zip system on the roof release enough vapor?

I was planning 1/2” green ZIP the complete envelope, I read the brown releases less vapor.

3) My idea was to stop 2×4 purlins 1″ from the hip rafters, leaving a 2″ air gap below the OSB to vent to the ridge. Or should I stop the purlins 2” from the hip rafters?

No one in the area, 1.5-2 hour radius does Dense (or any) pack cellulose. I will contact GreenFiber to ask their opinion, (looks like I might do the cellulose work.)

I welcome any comments, corrections or criticism, that’s why I’m here.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Gary,

If you want to create a ventilation channel for your roof, you can, but it can be tricky. I don't think it's easy to attach a ventilation baffle to the underside of the 2x4 top chords of this type of truss. You may be able to do it. What material will you use to create this ventilation baffle?

Assuming you can install a relatively airtight, relatively rigid ventilation baffle that leaves a 3.5 inch air space between the top of the insulation and the underside of the sheathing, you'll need soffit vents and a ridge vent. If you do that, the ventilation channel handles any moisture that makes it to the top of the insulation.

Q. "Will the Zip system on the roof release enough vapor?"

A. If you have a vented roof assembly, the Zip sheathing isn't designed to "release vapor." The ventilation channel will handle any moisture that makes it to the top of the insulation layer. The vapor permeance of the Zip sheathing in this type of roof assembly is irrelevant.

Q. "My idea was to stop 2x4 purlins 1 inch from the hip rafters."

A. I'm lost. Purlins, by definition, are parallel to the ridge. You refer to "vertical purlins," but I don't know what those are. If this is a hip roof, that makes ventilation difficult -- so the first step is to describe your roof (gable, shed, hip, or something else).

It looks to me like Gary is planning to sheathe the trusses conventionally, strap with 2x's along each rafter, and then place metal roofing on conventional OSB. I've used similar systems for cathedral ceilings and as long as there is an excellent, variable permeance membrane at the interior (for a cold climate, anyway) it seems to work fine and technically meets code. I-joist rafters can be a pain to work with; parallel chord trusses are easier in my experience, though you'll need to net each truss to contain the cellulose. (Side note--dense-packing deep rafters is not a DIY-friendly project.) If you're lucky you'll be able to clear-span with the trusses and avoid a ridge beam.

Your first approach, with the sarking membrane instead of Zip, with either I-joists or parallel chord trusses, is also a good approach, though some engineers don't like to separate the sheathing from the rafters/trusses. The sarking membrane is much more vapor-open than Zip and is not that hard to install, and in general I prefer it to your other approach, though I've used both depending on the situation.

Michael,

Thanks for your comments. Your interpretation of Gary's somewhat confusing post appears (upon re-reading) to be correct.

For GBA readers who have never visited the United Kingdom, it may be worth pointing out that "sarking" is the British term for roofing underlayment. Some European builders use the term "sarking membrane" for the new high-tech membranes used above the rafters in insulated sloped roofing assemblies -- assemblies that sometimes have no sheathing above the rafters.

I agree with you, Michael: Ventilating above the roof sheathing can work, as long as you remember to specify a vapor-permeable roofing underlayment.

Martin,

Yes, I repeat, “Roof: Hip roof 6-12 pitch”, “ stop 2x4s “vertical battens” 1" from the hip rafters”.

I know a hip roof is hard to vent “under” the sheathing, I do not plan to do this. I was looking for an alternative to putting on a membrane as a WRB. (Which you don't like.) Venting will be done above the trusses.

I have seen houses online totally sealed with ZIP system, roof included, “vertical battens” for vent and then a second sheathing OSB and roof covering. So this is wrong? And ZIP wouldn't release any vapor from a sealed space?

Martin Wrote:

“ the Zip sheathing isn't designed to "release vapor."

“The vapor permeance of the Zip sheathing in this type of roof assembly is irrelevant”.

Q1 - Does that mean I shouldn't use it on my exterior walls?

They are the same. Wood&Air - ZIP – Air. The wall will have Roxul but permeable.

Martin wrote #3 to Michael,

"Ventilating above the roof sheathing can work, as long as you remember to specify a vapor-permeable roofing underlayment."

Q-There is no underlayment on the ZIP sheathed trusses, right?

then a 1.5" vented air gap, OSB now comes synthetic underlayment to wistand the hot metal roof. right?

Michael,

My cathedral ceiling will have 1 vent pipe going through it. No electric, no lights, only insulation. The dry wall will be totally sealed around edges as per ADA instructions.

Yes, The truss company designed clear-span trusses, No ridge beam.

Michael wrote:

“dense-packing deep rafters is not a DIY-friendly project”

Yes, I read all about it, if it was “ DIY-friendly” I'd be able to hire someone. My job has always been to finish the hard stuff, use to it. Thanks for the heads-up.

Don't get me wrong, I think we all love the “DIY-friendly” days...

Michael wrote:

“as long as there is an excellent, variable permeance membrane at the interior for a cold climate,”

My climate is zone 4, extreme minimum temp 0F to 5F deg. Mixed humid.

The architects plan had no other membrane at the interior.

Q1 - Is that because they used membrane replacing the sheathing?

Martin didn't like membrane. But with trusses at 16” oc, (easier to walk on.) and a builder who hasn't done ZIP yet. I'm leaning towards ZIP sides with a membrane roof.

Q2 – Martin just added, ZIP okay if...

So does that mean I CAN put the ZIP instead of the membrane?

Q3 - My thought was to stop 2x4 “Vertical battens” 1” from the “hip” rafters." leaving a 2” vent,

Now I'm leaning to stop “Vertical battens” 2” from “hip” ridge leaving a 4” gap every aprox 22” along the Hip ridge. Below the OSB, where the 2x4s are absent I'll support with vent-core.

Hopefully I can find carpenters that want to “Learn”...

Thanks Michael,

Gary,

Sorry that I missed the reference to a hip roof in your original post. My mistake. (Sometimes, when a person provides too much information, it's easy for those of us who are trying to help to get a little lost.)

Zip sheathing has a vapor permeance of between 2 and 3 perms. Plywood is a "smart" vapor retarder, with a vapor permeance that varies from 0.5 perm when dry to 20 perms when damp.

Ordinary OSB has a greater range of vapor permeance than Zip sheathing. Like plywood, ordinary OSB has variable vapor permeance, ranging from 2 perms when dry to 12 perms when damp.

In other words, either ordinary OSB or plywood would be a better choice as a roof sheathing (better than Zip sheathing) if you want a vapor-permeable roof sheathing that will allow accumulated moisture to escape from the insulation layer and be removed by your above-sheathing vent channel.

Martin,

So OSB or Plywood with a good permeable synthetic Underlayment.

Q - Seal and tape seams. right?

Gary,

I'm not sure about "seal and tape." Just "tape" will work fine, as long as you choose a high-quality tape.

For more on selecting tapes, see Return to the Backyard Tape Test.

Gary, to answer your questions to me:

Q1 - Is that because they used membrane replacing the sheathing?

>An interior vapor retarder is not required with a vented roof in your climate zone. A variable permeance membrane (sometimes called a smart vapor retarder) is good insurance, in my opinion, but it is not required by code.

I think Martin answered your other questions.

Martin, FYI

After some research, The Perms of Zip System-R vs Zip System, (no foam) panel overlay 12-16 perms, OSB layer is the same as standard OSB 2-12 perms, If you uses the "R" type system with foam that is where the perms are cut to < 1.0 perms. NOW is get it...

, as per below email from Huber.

Gary,

Thank you for your question about ZIP System sheathing and tape. ZIP System sheathing is comprised of an OSB wood substrate with an integral water-resistive overlay fused to the face of the panel during the manufacturing process. The overlay on ZIP System sheathing is 12-16 perms, and the wood portion of the panel, being OSB, will have a similar range of permeability as regular OSB. As conditions become more damp, the permeability of the panel will increase.

Please feel free to contact me with any further questions or concerns you may have.

Thank you,

Ben Richardson

Product Application Specialist

[email protected]

Gary,

What Huber doesn't always tell customers is the permeance of the Zip Sheathing. Instead, they like to tell you the permeance of the overlay, and then they like to talk about the permeance of OSB. No one cares about these values. (Huber is afraid that the low permeance of Zip Sheathing will scare away customers.)

The permeance of Zip Sheathing (not Zip R, just ordinary Zip Sheathing) is 2 to 3 perms.

Yes, you are right,

Martin wrote: "ordinary OSB has variable vapor permeance, ranging from 2 perms when dry to 12 perms when damp."

Huber Wrote: "the wood portion of the panel, being OSB, will have a similar range of permeability as regular OSB"

Dry they are similar, but,

Regular OSB I need an underlayment to cover. Zip Sheathing underlayment is included,

Perms being similar, Zip would be easier and a tighter envelope.

Am I missing something?

Gary,

Huber talks about "the wood portion of the OSB" -- but the panel with the facing behaves differently from "the wood portion of the OSB." I don't think Zip sheathing ever hits 12 perms.