Blocking a Thermal Bridge on Slab at exterior Doors

Hey All,

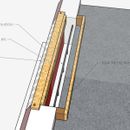

I talked to the GC about dealing with the insulation at the stem wall under the exterior doors. The concrete contractor made, what I would describe as, “notches” in the stem wall (See picture – GBA_DoorSill.jpg).

The GC initially suggested that the vertical insulation, where the tapered edge is, be cut out/down to allow the dwelling’s slab to flow in to the notch. He said then the concrete would be thicker under the door sill and less likely to crack. I expressed my concern about the thermal bridging that this would create. For example, in the winter at the front and back doors we could see a temperature delta of upwards of 50 degrees F from outside to inside.

So, we both agreed to take some time to think through options. I took some knowledge from this forum and put together a detail that I think will work.

– Cut the tapered edge down on vertical, interior insulation.

– Install additional vertical XPS at the exterior side of the vertical, interior insulation. Glue to existing insulation and add a form at the top to hold during pour.

– Add a form for a concrete extension to support the door sill

– Pour behind the Added XPS during garage slab pour

The interior floor will have PEX tubing for a radiant system — to be installed later. The garage side will also be insulated.

What do you guys think about the details attached?

Thank once again.

WD

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

uh oh, may I have stumped the forum? Surely not. Any thoughts on this?

Sorry, it's kind of a complicated problem and I'm up to my eyeballs with complicated problems for my clients, so sometimes it's hard to put the mental energy in here. Despite your description and images, it's not crystal clear to me what your current situation is and what your desired outcome is.

I certainly understand the busy factor.

The picture in OP shows "As-Built" (tapered insulation against the stem wall). The contractor recommended cutting the insulation at the opening to permit the conc. to flow out to the garage (to provide a 'solid foundation' for the door's threshold) and just double up the pex at the door.

It doesn't seem very efficient to just allow the heat energy from each door opening (garage, front, back) to flow directly to the outside air.

I am trying to come up with an alternative to this solution (all the 3D diagrams atch'd to OP).

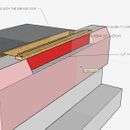

– Cut the tapered edge down on the vertical, interior insulation (create solid foundation for door's threshold).

– Install additional vertical XPS at the exterior side of the vertical, interior insulation. Glue to existing insulation and add a form at the top to hold during pour. (insulate interior from exterior)

– Add a form for a concrete extension to support the door sill (walls are thick due to exterior insulation)

– Pour behind the Added XPS during garage slab pour

Hopefully clarifies...?

I asked a similar question a while back, so maybe that discussion will be of use to you:

https://www.greenbuildingadvisor.com/question/door-thresholds-for-insulated-slab-on-grade

I'm reading this thread now. Thanks Trevor.

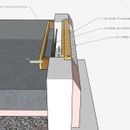

Is this an accurate building section at your doorway? Don't worry about the reinforcing details for now; I'm just trying to understand what you're proposing.

Close...the house slab would be level with the garage slab pour. The garage slab would be formed to drop 3" into the garage. The wall is about 91/4" thick (stem wall is 6"). I included a screenshot of the typical wall section for details on wall.

Ah, much better. There's a reason construction details are usually drawn in section! That looks like a good detail. The weak point is the slab surface; the floor will be cold at the interior of the sill and you could end up with mold/microbial action due to the lower surface temperatures. Could you move the framed wall inward any more? If not, it will probably be ok. The door area is about as good as you can do, in my experience.

Thank you for the input Michael!

I don't think that we can move the framed wall at this point. I like the section detail that we have here. I will finish reading the thread that Trevor_L recommended. The only thing that I want to make sure that we have covered is making sure that there is a place to secure the door threshold. Maybe a piece of PT or Structural composite lumber (i.e. OwensCorning--https://dcpd6wotaa0mb.cloudfront.net/mdms/dms/CSB/10026715/10026715-OC-Lumber-Installation-Guide-for-Residential-Deck-Construction.pdf?v=1692884591000).

So far, it is looking like this will be implemented.

With formwork for a shelf to hold a 2x4 that will be installed later. The 2x4 being secured once the doors are on site and the anchors for the thresholds can be measured. If possible we can install a piece of 2x2 PT (bolted down) with a piece of 2x2 XPS (glued in) for added r value.

That second tapered EPS seems a bit unnecessary...

Freyr, the tapered piece is beyond the doorway and is necessary to reduce thermal bridging to the garage.

Oh yes this makes sense, my bad I thought it was in the doorway

Ok, so I am not a concrete forms guy or anything, but I feel like this is awfully complicated.

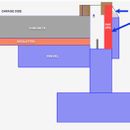

That vertical part of the garage side, how is that formed?

Why not bring the stem wall straight up under the door in one pour?

2x6 or 2x8 under the door sill, both floors poured afterwards

Hide the inside foam with a bit of trim, or move the door frame around and fix it with trim

Hey Gusfhb - I no forms guy either but in the OP I do have a couple of images that show the forms plan. The pour was already set to be two separate pours - house slab then garage.

It sounds like the pour you've described would involve a cold joint between the stem wall and the garage. For reasons that I am not fully educated on, I am not a big fan of those.