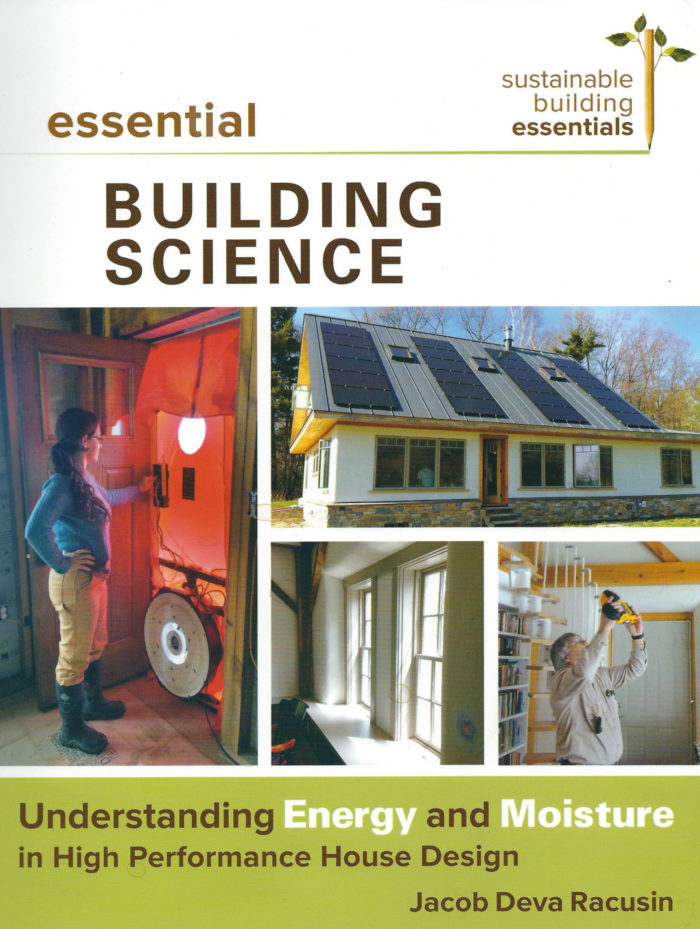

Image Credit: New Society Publishers

Jacob Deva Racusin, a Vermont builder and educator, has just written a book called Essential Building Science. The book aims to provide builders — especially so-called “natural builders” — with a basic understanding of the ways that heat and moisture flows affect residential buildings. (The book is available from New Society Publishers for $34.95.)

Racusin is one of three partners who founded a company in Burlington, Vermont, called New Frameworks Natural Building. Racusin, a member of the Northeast Sustainable Energy Association (NESEA), is a builder who “gets it.” He is well versed in house-as-a-system thinking. Among the mentors he credits are GBA contributors John Straube and Marc Rosenbaum.

Racusin’s construction company takes an admirable approach to air sealing — an approach that more builders should emulate. In his book, he writes, “We use the blower door frequently during the building process. During new construction, we use the tool at least once, if not multiple times, to make sure we are on target with our air-sealing goals; this allows us to correct the installation of all of the various materials and components prior to finishing.”

Racusin has posted at least one comment on the GBA site, and he’s familiar with the Pretty Good House idea. In fact, a table in his book listing residential standards and certification programs includes a line for the “pretty good house.”

Racusin’s book aims to accomplish two goals. His first goal is to introduce building science concepts to builders. Racusin describes the various ways that heat and moisture flow into and out of a building: for example, he explains the stack effect and discusses vapor permeance. After these introductory chapters, Racusin focuses on his second goal: providing advice on building assemblies (foundations, walls, and roofs), mechanical ventilation systems, and heating systems.

The book is an important introduction…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

7 Comments

Response to Review

Martin,

Thank you for taking the time to publish a review of my book, I appreciate your consideration! I am responding to some of the critiques that you brought up.

It seems that you missed an important point I made in the first chapter regarding the concept of toxicity. In our green building community, toxicity frequently only extends as far as indoor air quality (IAQ) and direct risk exposure to occupants or builders - a myopic perspective. I believe it is critical we acknowledge more openly the toxicity impacts of our materials prior to and post use in building situation. In critiquing my cautions concerning the toxicity of modern building materials – such as vinyl and foam, as you reference – you evaluate these solely in the context of occupant exposure. My references to toxicity are not only in regards to IAQ but in a more comprehensive, cradle-to-cradle impact perspective, as I explain in identifying criteria for evaluation - the toxicity is certainly there for others to experience. From your review, it sounds like straw bales were the only alternative I suggest – in fact, I reference many alternatives for less-toxic materials, such as fiberglass frames for windows, and fiberboard or mineral board for insulation, among others. I included references regarding nuances of different foam impact profiles for further exploration – including a breakdown of embodied carbon between different insulation materials.

The “optimization” reference in selecting U-values is an appropriate term – certainly as it relates to the occasional need to sacrifice a bit of U-value for the sake of enhanced SHGC or VT, let alone as it relates to cost. Of course lower U-value is better than higher, I state that clearly – but the “optimization” is in the context of evaluating different characteristics. Simply stating “lower U-value is better”, as you suggest, does a disservice to the point of balancing competing priorities in window performance and cost, which was the intention of that section.

To speak to some of the technical errors you cite, the resilience of all-electric heating systems is a relevant concern, and not an error to note. Leaving aside non-electric options such as wood stoves, there is a big difference between the small infrastructure required to provide backup power to the fan and ignition system of an oil boiler and that for two or three mini-split compressors. I took my radon recommendations from state and private radon remediation experts – your article is very interesting to note, and I’m glad my error was on the side of caution!

As for the “debate” around air-tightness – I trust that the rest of the page I devote to discussion of the issue to be accurate and appropriately presented (such as confirming that the majority of professionals agree with your position), and that you simply take issue with whether or not it is settled debate as “technical error”? I do regret some of the errors that slipped through editing, such as the term “vapor barrier” rather than “retarder” as I intended (and reaffirmed in thorough discussion of vapor control), and the Icynene misspelling and classification. I would hope that these errors would not seriously cast doubt in the readers’ ability to trust in the credibility of the book writ large, as you suggest, given the degree of rigor, reference, and accuracy that I have demonstrated throughout in the presentation of this complex subject matter.

Regarding the examples of different building systems, again it seems you missed a couple of important points. I start the conversation around wall assemblies stating clearly “….framed walls, which are the most common style in residential construction in North America.” There is no confusion about my intention here, the leading sentence for an entire section. I regret that this confused you to the extent that it did. All of the examples I used are sourced from a broad survey of both widespread and relevant emerging practices within our building community, many of which I referenced from this publication. As I describe in the introduction, the intention of these examples is to illustrate the function of the different parts of a building enclosure as described in the preceding chapters, including various hydrothermal dynamics of different strategies, to help develop critical thinking skills for builders to evaluate, select, and design their own systems.

This book is intended to be a concise guide, and not a comprehensive manual, as I state in the Introduction. The goals of this book are primarily to unpack the underlying building science of our homes, and to create a framework for decision-making to establish a strategy, based on stated goals. The intention was not to comprehensively evaluate building energy/energy efficiency. I do, in fact, discuss a range of cooling options, including heat pumps, night flushing, and ducted A/C (which are nested within the six pages of mechanical system evaluation you describe), as well as the vapor management implications of air conditioned buildings in hot-humid climates. Heating systems have more to discuss regarding combustion and fuel choice.

The same point is missed in your critique of the purpose of the selection tables, which is to provide information to help enable critical thinking to make decisions based on one’s own goals and values. Your choice to reject sheep’s wool and favor foam expresses your values, and I would consider myself presumptuous to impose my own set of priorities in this regard, particularly over a very wide climate range for the book’s audience. It is interesting that you call out two of the least common materials in your critique of the approach – do you find no value in contrasting advantages and disadvantages of spray foam and cellulose insulation? I appreciate that you don’t hold some of the more alternative materials as worthy of consideration and would prefer a more directive approach to use preferred systems or materials – to this end, I strongly recommend readers read your blog, and the many other resources that are regularly updated with market-specific, research-relevant information that I consistently list in my references. I fear you confuse the intention of the book in that regard, as this is meant to accompany, and not replace, these other resources.

You have done a terrific job of highlighting criticisms of the content, some appropriate (which I appreciate your bringing to light) and some I believe are taken out of context, or are simply inaccurate. I would have hoped to have seen more in the review that actually describes the contents of the book to the readers in more detail, as there are significant sections of the book that are entirely absent from the review; I greatly appreciate your recognition and support of the work of our company, and validation of the principles of the book in the first section. I beg the reader’s understanding for the handful of errors that may be present, and trust that there is far more to offer of value to the interested builder, designer, or homeowner for having used this book as a resource.

Jacob,

That was an

Jacob,

That was an excellent, respectable response to a book review that was basically a compliment sandwich from a reviewer that forgot that two slices of bread are required to make a sandwich.

-Steve

Thank you, Steve. If anyone

Thank you, Steve. If anyone who has read this far would like a more complete description of the book's contents and approach, I would be happy to provide excerpts. In fact, mention this review, and I'll give you a discount ;)

Dubious about some fiberglass claims

I'm a fan of fiberglass reinforced window frames, and so I was embarrassed to read the almost content-free claims in the linked article, "Debunked: 3 Myths About Fiberglass Windows", which, among others, offers this curious assertion: "Even if additional coating is applied, ensuring that your finish materials were made with care and quality will guarantee an unfading and fresh look for your painted windows. As a result, the paint does not peel easily". No supporting evidence is offered for this logically-challenged statement, and the links in the other myth descriptions are very superficial.

Unlike Martin's experience, all the weather-exposed fiberglass ladders that I see in my sun-drenched region show some sun damage, and as do perhaps half of the fiberglass boats that I see. Fiberglass composite materials are not inherently UV resistant. The most common resins used in fiberglass products deteriorate in the sun, so manufacturers add various UV stabilizers. Some work better than others. I hope that all manufacturers of fiberglass window frames have formulations with sufficient UV protection. Jacob Deva Racusin expresses skepticism. I couldn't find any testing to confirm or deny my hope. Does reliable documentation exist, comparing long-term exposure for fiberglass windows from various manufacturers?

Response to Jacob Deva Racusin

Jacob,

Thanks for providing an author's perspective. Interested GBA readers should, of course, read your book and judge for themselves whether my perspective reflects actual flaws in the book or my misunderstandings. (It should come as no surprise that authors and reviewers often have a different perspective.)

Concerning just one of the materials that your book calls "toxic" -- PVC, otherwise known as vinyl -- interested readers may want to read my article, “Vinyl Windows and Vinyl Siding.” Suffice it to say that many green building experts who have taken a life cycle analysis approach to the vinyl question have concluded (as did the USGBC) that “The evidence indicates that a credit that rewards avoidance of PVC could steer decision makers toward using materials that are worse on most environmental impacts, except for the case of resilient flooring, in which sheet vinyl and VCT are worse than the alternative materials studied for most environmental impacts.”

Response to Derek Roff

Derek,

I'm willing to admit that I may not have chosen the best link to reinforce my point about the durability of pultruded fiberglass. That said, my own direct experience with fiberglass window frames, fiberglass ladders, and a fiberglass canoe are the direct opposite of yours. None of these objects show the slightest deterioration in spite of years of exposure to the weather.

I just skimmed this book. It seems to be a reader-friendly overview that gives a practical perspective on modern green building. I think it is unfortunate that it has technical errors. It would be great if there were a new edition that corrected these. A few not noted yet:

1. The discussion of "dynamic R-value" implies that the thermal resistance of typical insulation values drops at low temperature, but in fact, essentially all insulation materials (with the exception of polyiso) do the reverse--the thermal resistance goes up a low temperatures, as noted in the report cited in the book for that point.

2. Fig. 2.4 shows thermal radiation going through windows. That's not how it works. Radiation goes to the window surface, but then has to conduct through the glass before the transferring between panes and then transferring to the environment, primarily by convection from the outer surface.

Log in or become a member to post a comment.

Sign up Log in