Image Credit: Fine Homebuilding

UPDATED and CORRECTED on 9/22/2011

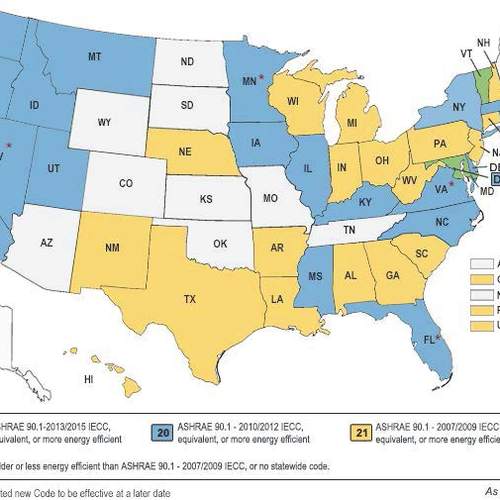

Are you ready for the 2012 code? Each revision of the International codes tends to ratchet up energy performance requirements, and the 2012 revision is no exception.

Although its adoption may be a long ways off in some jurisdictions — after all, many rural areas of the U.S. still have no building codes at all — the 2012 International codes may become law in some areas as soon as next year.

What’s new?

The 2012 code requires more insulation, a tighter envelope, tighter ducts, better windows, and more efficient lighting than the 2009 code.

Here is a summary of the important changes for residential builders in the 2012 International codes:

- While the 2009 codes required that 50% of lighting fixtures in a new home to be so-called “high-efficacy” fixtures (fixtures using a CFLs or equivalent), the percentage has been raised to 75% in the new code.

- Duct tightness requirements have become more stringent.

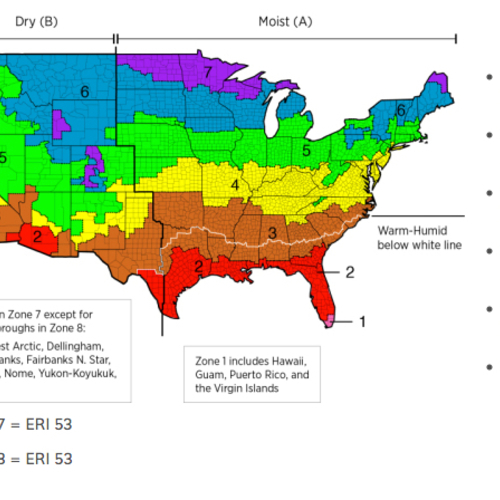

- Blower-door testing requirements have become mandatory and more stringent; the 2009 threshold of 7 ach50 has been changed to 5 ach50 for climate zones 1 and 2, and 3 ach50 for homes in all other zones.

- All homes in zones 3 through 8, and some homes in zones 1 and 2, will be required to have a whole-house mechanical ventilation system.

- In many climate zones, window glazing U-factor and solar heat gain coefficient (SHGC) requirements have been changed.

- Wall insulation requirements have become more stringent in climate zones 3, 4, 6, 7, and 8; for the first time, builders in climate zones 6, 7, and 8 will be required to install exterior rigid foam insulation (or to use some other comparable wall insulation strategy).

The bottom line: every new home will need to be tested with a blower door, every cold-climate builder will need to come up with a strategy to stop thermal bridging through studs.

Chapter 11 in the IRC

The 2012 IRC still includes energy efficiency requirements in Chapter…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

21 Comments

Your last paragraph says it all

Thanks for the nice overview of the 2012 IECC - I like that the bar is being raised, but I agree that it's all in the enforcement. If we enforced our current energy codes there would be a big improvement in efficiency. Rules are only as good as the people policing them. Here's to hoping that the cops on the beat will be well trained and have incentives to make people play by the rules.

Looks like we'll be back to building moldy walls...

I have run a number of calculations, using real-time data, that show clearly that using just 1" of XPS foam (R-5) on the outside of a 2x6 wall in a cold moist climate (like that around the Great Lakes) will cause moisture to condense on the inside of the wall sheeting. It will remain as condensation for months at a time, especially on the north side of the house. The Washington State Energy Code made this same mistake two years ago. They ran all their tests in Western Washington (coastal zone 4), where the winter temperatures are much milder. Of course it worked fine here, but in Eastern Washington (zone 5, a little bit of zone 6) the first condensing surface is inside the fiberglass portion of the wall. History has proven that OSB can be a very good petri dish.

The solution for Eastern Washington is to go up to R-7.5 foam. Then the first condensing surface, in all but the most extreme weather, is inside the XPS layer, where there will be no moisture to condense.

We really need to get Government out of the business of telling us HOW to build homes. Just give us the energy targets we need to meet, and let industry compete to come up with the best solutions. If you can't run an energy calculation on your proposed building design, you should not be in the business of building houses. I know that is a little hard-assed, but it just isn't simple any more.

Regarding the blower door test requirements, i agree that this is a good goal, however I have seen very few homes, other than SIPS or ICF homes, that could meet that goal. Again, we have to get much better, or get out of the business.

Re: blower door test threshold...

Joe Lstiburek has a recent article that's more or less about blower door testing and how tight is "just right" from a public policy ("code") perspective. http://www.buildingscience.com/documents/insights/bsi-053-just-right-and-airtight/ Back in the '80s, he was helping giant production builders regularly achieve ~3.0ACH50 without too much trouble. It certainly doesn't take SIPS or ICFs. in my experience, it doesn't take much at all. The small production builders I work with are now regularly achieving 2.0-3.0ACH50. The more performance-oriented builders I work with are now regularly achieving ~1.0ACH50...all with 2x construction.

Regarding the lack of a ventilation requirement in the code combined with increased air-tightness requirement - that's just stupid. I hope that builders will follow either: a) common sense or b) established building science and install controlled ventilation systems rather than: c) save a buck and say, "code doesn't require it!"

2012 IECC

The new code is reasonable as far as the energy efficiency standards and 3 ach50 is a good infiltration target. I would guess the average new home constructed in the Twin Cities is somewhere around 2 ach50. We have no mandated infiltration test but the MN code has called for a continuous air barrier for many years. Builders have complied with the code and will find the 2012 IECC quite easy to meet with just some minor wall detail changes and a few other energy upgrades.

The standards set in the 2012 IECC will give homes built under the new code a substantial efficiency increase over their business as usual counterparts. Reducing air infiltration in new homes is a very low cost way to make homes more comfortable and energy efficient.

Response to Ted and John

I used to argue with Joe Lstiburek on a similar point -- why does the code still allow builders to install interior poly in climates where interior poly can get you into trouble? Joe answered, "The code doesn't tell you how to build a good house. All it does is establish the minimum legal requirements."

In other words, don't expect the code to tell you how to build a house. So, if you're a builder, don't look to the exterior foam requirement as a guide. That's the minimum -- not the R-value that will keep you out of trouble. Similarly, don't forget to install a ventilation system! Builders who wait for the code to require a ventilation system before installing one aren't using their brains.

Ted, your point about reminding builders to use exterior foam of an adequate thickness to keep the OSB above the dew point in winter is a good one. I'll edit the text of my article to reflect that point. Thanks to both of you for your comments.

Blower-door test results

I did not mean to imply that most builders could not achieve 3.0ACH50, just that they currently do not, and furthermore, that most simply have no understanding of why they should.

There is a huge information gap in the building world. I am often accused (rightfully so) of viewing the world through my own glasses (whatever color those may be). Because the light is so bright down here, I fail to see that I am really at the bottom of a very deep, dark hole, and I am all alone down here. Many of you who participate in these discussions are also in holes of your own. We are working like moles, digging and building, building and digging, and doing it very well. We fail to recognize that others are up there on the surface, building and building, with no clue what we are doing down here. We are so enlightened that we fail to recognize the darkness that exists at the surface, in the "real world".

Reply to Ted Clifton: Blower-door test results

Things are picking up...

A significant part of my time is spent talking to builders about airsealing. I'm now finding that they know the subject is becoming increasingly important for their business but they still don't have any idea of what ACH values that they should target, or how to get there other than a foam can and a caulking tube. And if thats where they start dealing with ACH, then so be it. At least it starts for them.

There have been significant unseen progress in airsealing so far 2011. Here are a couple of mile stones:

- My vendor SIGA has announced that they are hiring 2 reps for the west coast. Details at: http://www.smallplanetworkshop.com/siga-employment/. These reps will be doing nothing but teaching airsealing to builders.

- A group of good smart guys I like have opened another company (and are a competitor to me) in NYC. They have brought in another excellent airsealing line from the top notch german company: Pro-Clima. These guys are at: http://www.foursevenfive.com/ and they will be teaching airsealing in order to build a market.

- Earlier in the month I spent a day at the Tremco headquarters in Cleveland OH. They have brought over products and people from a sister company in Germany. The company makes products for airsealing known in Europe as Illbruck Trio expanding foam tape for windows and doors. It will be marketed here in the US by Tremco as Exoair Trio. My company is one of the first in the US to stock it and I can tell you that we will be doing a lot of teaching to the mid-market builders, window manufacturers and dealers. Tremco has put significant resources behind the project and we all hope to make great progress. In order for us to be successful, air sealing will need to become common practice.

I've attached pics of the lab and testing equipment that has just been completed in Cleveland. We can "call out" a wall for large projects, get it built and tested for both weather and ACH. They've created a program that will compute full envelop ACH based on the performance of a section. In one picture, you can see a full ACH number, but it's not true to the wall section. When I took the pic, they had just changed some parameters and it was "charging up" for a new test. The wall section in the picture tested at 0.36ACH 50. It was for a PH project somewhere in NY. The 3 guys in one of the pics are in charge of getting the Trio off the ground. At left is Jeorg who is over here from Illbruck in Germany for 18 months to help get it off the ground.

With all of this activity, combined with the other companies working on spray membranes, there is more going on to supply products and knowledge for airsealing. A lot of guys are betting that there is a future in it.

I think you can count on more daylight coming...

Simplify

Part of the problem is that a lot of goals sound overly complicated. To most people, builders, and even many of us architects, 3 ACH50 doesn't mean anything. If you explain this to a client they will be lost before you start. The system needs to be revised on a scale system to make it simple for everyone to understand these concepts and give them a score on some tangible scale.

Another problem is as Ted said, when wrapping a home with rigid or even mixing rigid and fiberglass in the same cavity, you run the risk of condensation between materials. Many installers of spray foam applications understand the minimums but there really needs to be more guidance with wall assemblies and their dew point with a safety for substandard installation. With the new requirements of incorporating continuous insulation in any assembly, clients and builders are trying to get creative to satisfy the requirements in the most cost effective way. We need more guidance on dew point requirements and unusual assembly combinations. This is to not only avoid moisture issues, but also as a tool that building officials can follow to allow these wall assemblies in place of prescriptive energy requirements.

For those of you unfamiliar, the Washington State Energy Code, it is already requiring many of the same changes listed in the 2012 Energy Conservation Code such as blower door test requirements, increased insulation requirements, and continuous insulation requirements.

Response to Nicholaus Baxter

Nicholaus,

When building scientists hear builders or architects complain, "But it's complicated!", the usual answer is, "There's no substitute for study." If you are an architect who completed four years of college and a graduate degree in architecture, you can figure out the minimum R-value of your foam sheathing.

A couple of comments

Mr. Holladay,

Thank you for this post. A lot of work is being done on the 2012 IECC and it is good to have a reliable source for information on it. However, there are couple of clarifications that might be helpful.

1. I received my new copy of the 2012 IRC a couple of weeks ago. The 2012 IRC doesn't simply reference the IECC; it reprints it word for word. As a result, builders won't have to buy an extra book.

2. The code does address mechanical ventilation although in a roundabout and confusing manner. First, the ventilation requirements are in the 2012 IRC; the 2012 IECC simply sends you to the IRC but doesn't actually tell you where to look. In Chapter 3 of the 2012 IRC, if a house has an air infiltration value of under 5 ACH50 (i think), it sends you to section 1507.3. Section 1507.3 mirrors (imperfectly) ASHRAE 62.2; which means ventilation is required. A couple of caveats, however. This only works if the jurisdiction adopts the IRC as part of the code. Some states like Illinois, only adopt the IECC statewide and this will cause problems. A possible other problem will occur if a state adopts one version of the IECC and a different version of the IRC. If a state adopts the 2012 IECC but still enforces an earlier version of the IRC, a problem will arise because the mechanical ventilation requirements only exist in the 2012 IECC. There are, alas, bugs that need to be worked out.

Finally, the 2012 IECC, in climate zones3 and 4, the above grade wall requirements have been bumped up to either R-20 or R13+5. For most builders on this site, that's a minor change. However, for many builders, it represents a big step. It is also important because the majority of construction in the country are in these two climate zones.

Response to Isaac Elnecave

Isaac,

Thanks for providing the useful and important corrections. I have corrected my article in light of the information you provided.

I have also looked up the 2012 IRC references you provided. Here they are:

2012 IRC, section R303.4.

Mechanical ventilation. Where the air infiltration rate of a dwelling unit is less than 5 air changes per hour when tested with a blower door at a pressure of 0.2 inch w.c (50 Pa) in accordance with Section N1102.4.1.2, the dwelling unit shall be provided with whole-house mechanical ventilation in accordance with Section M1507.3.

2012 IRC, section M1507.3.

Whole-house mechanical ventilation system. Whole-house mechanical ventilation systems shall be designed in accordance with Sections M1507.3.1 through M1507.3.3.

M1507.3.1 System design. The whole-house ventilation system shall consist of one or more supply or exhaust fans, or a combination of such, and associated ducts and controls. Local exhaust or supply fans are permitted to serve as such a system. Outdoor air ducts connected to the return side of an air handler shall be considered to provide supply ventilation.

M1507.3.2 System controls. The whole-house mechanical ventilation system shall be provided with controls that enable manual override.

M1507.3.3 Mechanical ventilation rate.

The whole-house mechanical ventilation system shall provide outdoor air at a continuous rate of not less than that determined in accordance with Table M1507.3.3(1).

Exception: The whole-house mechanical ventilation system is permitted to operate intermittently where the system has controls that enable operation for not less than 25-percent of each 4-hour segment and the ventilation rate prescribed in Table M1507.3.3(1) is multiplied by the factor determined in accordance with Table M1507.3.3(2).

Nicholaus brings up common misconception...

I don't think Nicholaus was referring to the possible sub-standard installation of the fiberglass insulation inside the rigid foam insulation, but to the possible sub-standard installation of a spray-foam layer as an air-seal (flash and batt system) in the stud cavity. Nevertheless, it begs comment on the fact that sub-standard installation of fiberglass batts inside the rigid foam insulation could actually improve the vapor profile of the wall, even though it would hurt the thermal effectiveness of the wall. How could this be?

If the thermal effectiveness of the fiberglass portion of the wall insulation is lower, the dew-point will be moved farther towards the outside of the wall cavity. If it moves far enough that the dew-point is in the rigid foam layer, the moisture issue goes away, because the cavity layer will always be warm enough to keep any moisture from condensing.

Likewise, if you have a perfect fiberglass insulation job, inside of a sub-standard flash and batt spray-foam job, your first condensing surface is more likely to also be somewhere inside the fiberglass layer, because the dew-point will be moved back towards the inside.

I agree with Martin, it may be back to school for a lot of Architects, designers, builders, insulation contractors, HVAC contractors, etc., etc.!

Comments from Peter Kulczyk

[Editor's note: I received this comment by e-mail today from Peter Kulczyk, who works on the technical staff of the International Code Council.]

I was reading your Sept 16 article “Musing of an Energy Nerd,” and I had a couple of quick comments.

Just prior to publishing the 2012 IECC and the 2012 IRC, the International Code Council decided to add all the residential provisions of the IECC back into Chapter 11 of the IRC. This happened after the earlier decision at the code hearings to move all of the energy provisions out of Chapter 11.

I do not know many of the details of this move, except to say that at this time the 2012 International Residential Code has approximately twenty-eight pages of energy provisions in Chapter 11 that are pretty much duplicated from the residential energy provisions of the IECC.

Also, in the previous 2009 IECC, Chapters 1, 2 and 3 applied to both residential and commercial, with Chapter 4 being all residential and Chapter 5 being all commercial. This has changed in the 2012 IECC, where now they have a split-format that contains Chapters 1, 2, 3, & 4 for Commercial construction, followed by Chapters 1, 2, 3 and 4 for Residential Construction.

-- Peter Kulczyk

Response to Peter Kulczyk

Peter,

Thanks for your clarifications and corrections. Your explanation about the last-minute changes explains why several sources told me that the 2012 IRC no longer included any energy provisions, but simply referenced the 2012 IECC. I have corrected the text of my article to reflect the information you provided.

R+value and Damp Wall

Your comments about the added EPS insulation still not keeping the OSB above the dew point it very good. The other delema is if you you put a rainscreen or curtain wall behind the foam as is required in some areas the insulation value is disallowed. We seem to try for a "ones size" fits all regualtion and end up with a hoj-poj of regulations that do not address the overall situation. The existing regulations offer you the option of lower energy bills with a damp wall problem or higher energy with a rainscreen system. What's a guy to do?

Response to Les Cullen

Les,

You wrote, "If you you put a rainscreen or curtain wall behind the foam as is required in some areas the insulation value is disallowed."

I have never heard of any designer, builder, or building official foolish enough to put the rainscreen gap between the foam and the wall sheathing. In all cases, the rainscreen gap goes between the foam and the siding, so there is no reason for the insulation value to be "disallowed."

Fastening Insulation to Crawl Space Walls

This new requirement presents a problem when doing sealed insulated crawlspace, •“Where provided in lieu of floor insulation, insulation shall be permanently attached to the crawlspace walls".

I am a big proponet of sealed insulated crawlspaces having done my first one in 2005 on my own house using exterior foam and found the performance and naturally heated floors a plus. The obstacle I found was in trying to insulate the foundation walls in such a way that termites could not build hidden tunnels (the house was in a cold dry climate where termites were of little concern). The solution I finally came up with was to use batt insulation inside (as opposed to foam on either the inside or outside). The North American Insulation Manufactuers Association publishes recommenations for installation in frame construction that addresses how to insulate crawl space walls by fastening it at the top (sill plate or top of the band), bringing it down and extending it out 2' over the ground (you need to fasten the batts together so there are no gaps between them). To hold it against the wall you place rock or bricks at the turn at the bottom to hold it down. This gave you the ability to go into the crawl space annually, lift the brick and easily inspect behind the batts to check for termite tunnels. By permanently fastening it you could not do that unless your code official considered the attachment at the top to be the permanent fastening.

I have spent quite a bit of time trying to come up with a way to fully insulate a crawl space and not create a hidden place for the tunnels (other than a break in the insulation). If any readers have any ideas on how else to achieve it--please post your suggestions.

Continuous insulation not an absolute

the author's comment that "The code makes no mention of double-stud walls, so builders who choose this method of construction will need to convince their local building official that a double-stud wall complies with the code. Here’s one way to make the argument" perpetuates a common misconception about the IECC. Continuous insulation is NOT an absolute requirement.

Per code, one can easily use a double stud arrangement. Use Section R402.1.3: show that the U-factor for the double stud is equal or less than the frame wall U-factor for your climate zone. OR you can use Section R402.1.4 and do an overall UA calc. Your code officials may try to convince you that only Table R402.1.1 applies. After years of knowing that R-(insert value here) in the cavity complies & everything else fails, everyone needs to adjust to new reality that U-factors, not just straight-up R-values, may be used. Double stud walls can comply even in climate zones 7 & 8.

interesting, but can one use lower nominal insulation?

My numbers say that R20 in a 2x6 wall with a 25% framing factor gives you an effective Rvalue of 12: total wall insulation value (inc R5) is R17. Will one be able to talk the officials into allowing a 2x4 PERSIST wall with 3" of polyiso or will they insist on 4"?

On the other hand, assuming one is installing two layers and simply switches from 1.5" to 2" boards, labor will stay the same and materials will increase by about $0.5/SF, giving you a straightforward payback of that last inch in under 40 years...

Response to Dustin Harris

Dustin,

There is no single answer to your question. The answer depends on the knowledge and flexibility of your local inspector.

You can always choose the performance path instead of the prescriptive path -- although that option will require you to hire an energy rater to run some software.

This is a step in the right direction

Here in Michigan we have been hearing some feedback about the new energy code. There are a lot of builders worried about the changes and how much work it will add to their work loads. As an energy auditing company, obviously this code will be good for our business. What we are trying to do is educate the builders on how this new code can be an added selling point for their homes. Many builders in this area are already doing HERS Index ratings, which means they are already doing some of the required tests. We have been in close contact with the State of Michigan on when this code will be implemented here in Michigan. As of the first of they year (2013) we could still be at least a year out. We will continue to update our site on the projected adaption for Michigan. http://www.greenedgemichigan.com/2012-iecc-code/

Thanks for the great article!

Andrew

GreenEdge of Michigan

http://www.greenedgemichigan.com

Log in or become a member to post a comment.

Sign up Log in