Image Credit: Fine Homebuilding

A teen whose musical tastes run to head-pounding heavy metal classics? Uncle Ted, whose snoring would wake the dead? Who knows what’s giving Robert Car pause for thought. Whatever it is, he wants to build in some effective sound-proofing.

“I’m aware of using more than one layer of drywall,” he writes in Q&A post, “but is that the only way?”

Increase the mass of the wall

Car is reluctant to add a second layer of gypsum drywall mainly because it will, however slightly, reduce the usable space in the room.

But increased mass is part of an effective strategy for reducing sound transmission.

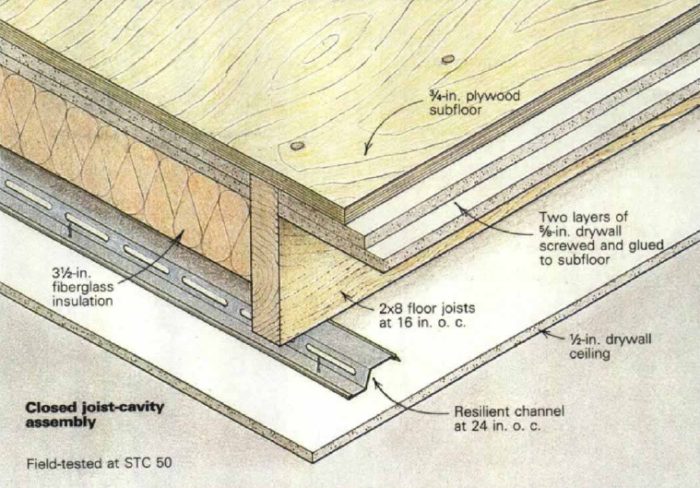

“Here are some good rules of thumb,” writes Robert Riversong. “When the mass of a barrier is doubled, the isolation quality (or STC rating) increases by approximately 5 dB, which is clearly noticeable. Installing insulation within a wall or floor/ceiling cavity will improve the STC rating by about 4 to 6 dB. An airspace of 1-1/2 in. will improve the STC by approximately 3 dB. An airspace of 3 in. will improve the STC by approximately 6 dB.”

A second layer of drywall, often 5/8 in. rather than 1/2 in. thick, along with resilient channel to isolate the drywall from the wall framing, increases mass and reduces sound transmission. Andy Ault, however, suggests three other options.

These are: Celotex SoundStop (a sound-proofing fiberboard), QuietRock by Serious Materials, and something called Soundproofing Mass Loaded Vinyl, manufactured by Super Soundproofing Co.

“We practically make this our [standard operating procedure] in walls between master baths and nurseries/adjoining bedrooms,” Ault writes of SoundStop. “We bond the SoundStop to the framing using an acoustical sealant running horizontal to the framing. Then we tape the joints with butyl tape. Next, we layer the gyp board over that in a vertical orientation. It’s quick, easy, and relatively…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

16 Comments

Sound proofing

What Does Work

Sheetrock is a prime material used in sound proofing interior walls, but it must be used in layers, using silicone caulking between them for maximum effect. The silicone itself performs as a sound dampener to retard vibration transfer. It is inexpensive so you can use it liberally.

• Apply a thick layer of silicone to all stud surfaces before applying the sheetrock. Use screws to attach the sheetrock to the walls as it allows you to create fewer holes than you would need to if using nails.

• Apply a second layer of sheetrock, using a thick coating of silicone in between. As previously mentioned, mass is important for sound proofing so the thicker the wall, the better it works.

As for space, the space in the wall cavity will have excellent sound proofing qualities because without having something solid to vibrate, the sound will dissipate into the empty space.

Using sheetrock when sound proofing interior walls is efficient and inexpensive and doesn't take up a lot of room. It is a permanent solution that won't need repairing or maintenance and you can decorate it to suit the appearance of the room. Remember windows, skylights, doors and floorboards when sound proofing a room because they will potentially be the downfall in your efforts. Depending on just how sound proof you want or need the room to be, they will be fairly important considerations in your master plan.

Is this use of silicone justifiable? Thank you for the valuable information that you always give. Cheers Mike Legge

Sound proofing rooms

We live in a semi and can hear the bass of our neighbour's alarm clock and some heavy nightly snoring. We ripped out the baseboard and added acoustical sealant, and spray foamed around the outlets. We can still hear a little bit. I was wondering if another layer of 5/8" standard drywall (Certainteed), plus Green Glue would help eliminate the low frequency noise. I'd appreciate any suggestions you might have.

RC1 channel in drawing

the RC1 channel is depicted inncorectly. It is upside down.

Damping Materials in Drywall Assemblies

11/11/10

As someone said, it's not the components, it's the assembly.

Ref Mike's suggestion of silicone, I'd go w/ GreenGlue- it's specifically designed to remain viscous and to be a damping material, whereas silicone is designed as a sealant.. I haven't heard of using GG against studs, but that doesn't seem unreasonable. Definitely between first and second sheet of drywall.

Ref Cathy's question about GreenGlue, go for it- it may not cure your problem, but it's by far the simplest potential solution. I'd consider pulling your existiing outlet boxes and installing old-work boxes that only engage the second (damped) layer of drywall. (Or consider deleting the boxes in that wall.) If you want to get fancier, consider blowing cellulose into the stud cavities- the second layer of drywall will cover the holes. And if you really want to get fancy, install RC1 horizontally across the studs, then add another layer or two of drywall. Do check out the GreenGlue site concerning the potential two-cavity problem. They may advise against creating 2 cavities (studs, then RC1.)

Acoustical sealant options

Green Glue has apparently been successful marketing their product, but there is a less expensive option with even greater name recognition: Sheetrock brand acoustical sealant. The point being this can be a generic item (non hardening sealant) and shouldn't come at a large price premium.

Also, to address Mike's comment above: even with plenty of mass, it's not sufficient for sound to "dissipate" into empty space inside a wall. For an effective barrier to sound transmission, there should be sound absorbing material (fiberglass, rockwool, etc) to convert acoustic energy into heat. A few inches of air will not effectively absorb sound energy and it will pass from surface to surface across an assembly. Even a masonry cavity wall gains several STC points with acoustic insulation in the middle.

GG vs. Sheetrock Acoustical Sealant

Thomas,

Green Glue is different than an acoustical sealant, whose job is to eliminate holes in the barrier, "sound-sealing partitions at gaps, electrical box cutouts," "It dries to a tough but flexible film, forming a long-lasting, resilient, acoustical seal." (Quotes are from http://www.usg.com/sheetrock-acoustical-sealant.html ) If I remember my acoustics, a 10% hole can transmit 90% of the sound energy. (That's a simplistic generalization, of course.)

Green Glue, on the other hand, is a visco-elastic damping material which is applied to the surface of the second sheet of drywall, like Jackson Pollock or a kid putting syrup on a pancake. Then the sheet is slapped against the first layer and fastened w/ longer screws. It's a mildly messy process, although I've done it in a carpeted apartment- I only had to grab the mineral spirits a couple of times.. It's also available in a ready-made drywall/GG/drywall sandwich.

Imagine putting honey on yuor hands and trying to rub them together- your hands are the drywall, the honey is the GG. The sound waves flex the drywall sheets like a speaker cone and the GG is a shear interface- the sheets are trying to move relative to each other, the GG restrains them and absorbs the sound energy, converting it into heat, as you say. The added mass of the second sheet of drywall also helps w/ sound absorption- air is pretty light stuff and it has a hard time pushing something like drywall around.

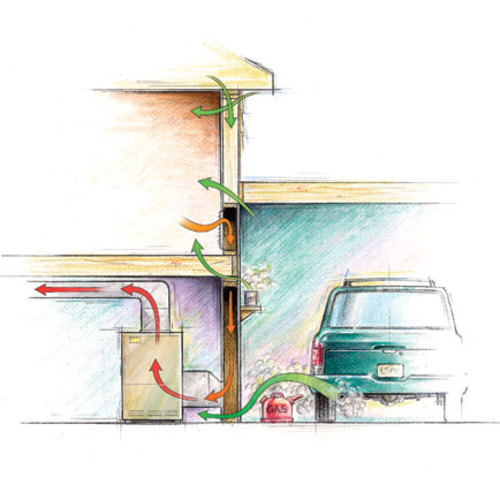

Acoustic insulation sealants definitely help, but they don't disrupt "flanking paths," for example, studs, screws, outlet and light fixture holes and plumbing, which can transmit the sound energy directly from the receiver (the noisy side drywall) to the emitter (the quiet side drywall.) Think of the kid's "telephone," two Dixie cups w/ a string between their bottoms- the bottoms are the receiver and emitter, the string is the flanking path. Smear honey on the bottoms and it will damp the sound.

But don't take my word for it- go to the GG site http://www.greengluecompany.com/

And no, I don't work for GG- I took an acoustics course in engineering school, so I'm a trained professional now.

Sound proofing

Thanks everyone for your suggestions!

Soundproofing floors

I may have missed it, but what about sound proofing floors between floors in a two story house? The ceiling on the mainfloor is the wooden subfloor in our log house. The sound transmission between the two is amazing. Is there a material we could add to the second floor subfloor?

Thanks for all the suggestions.

Response to NGB

Here are two resources on floors -- from the "Related Content" box on this page:

Controlling the Transmission of Impact Sound through Floors

Quiet, Please

Reducing noise within a room

Most of the discussion centers around room-to-room sound attenuation, but I've been hard put to find information for practical and aesthetic methods of attenuating noise within rooms. Many homes have large great rooms with expansive windows and wood flooring and the internal echoing is disconcerting. We have an open kitchen/dining/family room with windows and flat surfaces that once was carpeted. However, kitchen carpeting went out a decade ago and after we replaced it with cork we can hardly carry on a conversation if there are dishes clanking in the kitchen.

Somewhere, somebody must have some methods, products, or designs that would help this situation, short of redesigning the whole building. I've seen where someone had hung sound blankets on their high ceilings and walls. It worked well, but is hardly aesthetic.

Response to Dbuelke

Dbuelke,

You are asking a legitimate question, and I hope a knowledgeable reader posts a useful suggestion soon.

In the meantime, I can't help savoring the delicious irony ... our great rooms are now so great that the inhabitants are wondering how to overcome the disadvantages of the huge echoing spaces they have bought. It reminds me of those interior scenes of Xanadu in Citizen Kane -- with the huge dining table and fireplace, and all those echoes...

reducing noise in open concept room

Acoustic panels that are covered in air brushed artwork with strategically placed throw rugs and cloth covered furniture can help to alleviate the echo effect in open concept rooms.

STC ratings

Canada's NBC has a plethora of wall assemblies and their STC ratings.

I went for single-layer drywall on 3 5/8" steel studs for my bedroom walls, and added batt insulation for the laundry room.

Putty pads

Don't forget acoustical putty pads for backing electrical outlet boxes before you fiberglass or sprayfoam. It helps a great deal as outlet boxes are like megaphones for sounds traveling between walls. You can also use putty pads to fill small voids inside a wall. I got a pack off of ebay for rather cheap.

I have a finished basement room with (currently) an open, exposed joist ceiling. The main level flooring is 100+ year old hardwood directly applied to the joists. Needless to say, it's loud down there (not to mention the amount of debris that falls through the cracks). What about doing a "perfect wall" assembly on the underside of the joists? Call it the perfect ceiling.

Concept:

1. Air seal and add mass by applying the layers of drywall +Green Glue in the joist bays.

2. Attach 2' x 4' sheets of Comfortboard 80 to the underside of the joists, attaching with lags through 1x3 furring strips. The space between the drywall and Comfortboard provides the air gap.

3. Apply finished ceiling to the furring strips. Our plan was to use T&G Pine.

The Comfortboard w/furring strips would provide both functions of sound deadening and decoupling. Applying the Comfortboard to the studs would give the labor benefit of not having to cut to size and pack into the bays, which are a non-standard spacing in this old farmhouse.

Thoughts?

Back to the article - before investing all that time and money to work on the ceiling, make sure you take care of all the "flanking" noise paths.

Non-expert opinion: lag screws and furring strips won't decouple noise like "hat channel", e.g.,

https://www.soundproofingcompany dot com/soundproofing-solutions/soundproof-ceilings/spc-solution-3-soundproof-ceiling

Log in or become a member to post a comment.

Sign up Log in