ABOUT SPRAY FOAM INSULATION

Spray polyurethane foam (SPF) is better than any other type of insulation at reducing air leakage.

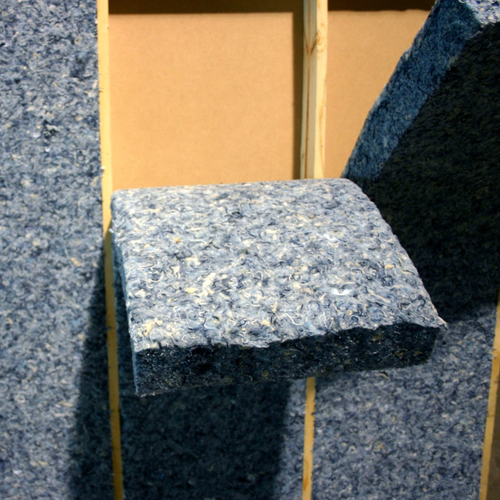

With foamed-in-place insulation, it is relatively easy (though not inexpensive) to fill wall and ceiling cavities completely. Closed-cell spray foam provides a higher R-value per inch (6.5) than less expensive insulation types like cellulose and fiberglass (3.5 to 3.7).

Most spray polyurethane foam is called “two-component” foam. Two ingredients—conventionally called “A” and “B” components—are mixed on site using special equipment mounted in a trailer or truck. Heated hoses convey the components to a mixing gun that sprays the chemicals on the surfaces to be insulated.

A chemical reaction begins as soon as the chemicals are mixed. The liquid mixture foams, expands, and eventually hardens.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

56 Comments

Spray foam pricing

First, I want to commend you on your great post. It is very informative for someone looking for the basics and even has a few good points beyond your average consumer, like the information regarding ignition barriers and code compliance.

One thing I wanted to mention was that I think your price point is a little high and that might deter people from considering spray foam. As a project manager for a spray foam company for years I can tell you that we offer 0.5 Lb. open-cell foam at around $.25/board foot. We even offer a 1.0 Lb. open-cell foam for less/the same cost as you quoted the 0.5 Lb. foam for above. The 1/0 Lb. open-cell foam has an R-value of almost 5.

There is significant competition in our region (New England) and through research we have seen stiff competition as far as pricing goes. For consumers, you should know that there is NO set price for spray foam. The more you have done, the cheaper it will be.

Foam and Panels

Great information.

We made the move to polyurethane foam structural insulated panels over 12 years ago and have never looked back. We are confident that we are providing our clients with the best insulation available.

open cell

i understand from my installer that there are different weights of open cell spray foam which are more thermally efficient and also help structurally. any info on either. also how much of a difference does it make if the roof rafters are completely covered versus say 3 1/2 inches between rafters

Different densities

Richard,

I think you are talking about different densities, not different weights.

The denser the foam (up to a point), the greater the R-value per inch.

The thicker the foam, the higher the R-value. If you don't cover the rafters completely, your roof assembly will have thermal bridging through the rafters, which is undesirable.

best method to isulate

I am planning to finish my basement. I plan to to put one inch of XPS foam on the floor and then Home Advantage 23/32 CAT Enhanced OSB Sub-floor (from Homedepot) on top of it.

Then I plan to build a 2×4 stud wall with 1.5 inch gap between the concrete and the stud. I plan to get all my electrical work done before I get 2 inches of closed cell foam sprayed against the concrete.

Additionally I plan to use blown in fiberglass in the remaining cavities between the stud. I plan to put house wrap stapled to the studs and blow the fiberglass insulation from the top.

I want to keep my basement real warm. I was planning to do cellulose but then I read to not use cellulose where moisture could be an issue.

As of now my basment is pretty dry or visibly dry . Its a new construction less than 2 years old.

Can you advise me if I am going in the right direction? I live in Iowa

Looks like you're on the right track

Anonymous,

Your plan will work.

spray foam

I live in south louisina and just raised my home eight feet off the ground. Want to insulate, but not sure what to go with - open cell or closed cell because it is outside and it is humid where I live. What is the best choice?

Reply to Chris

Chris,

Either will work. Get the highest R-value you can afford -- and be sure that the R-value of the installed insulation AT LEAST meets minimum code requirements.

spray foam

We have just finished using open cell spray foam in our house and received an outstanding air leakage rate of 1.32 ARC. Most of this air tightness is atributed to the spray foam.

A couple of issues to be aware of when using spray foam:

a) Make sure that your house has been well heated prior to installation because the foam expands at different rates as it hits surfaces with different temperatures. If it is cold outside the sheathing may be much colder than the studs consequently the foam may expand more from the sides of the wall cavity creating air pockets in the wall cavity. This can be minimized by an experienced installer.

b) Expanding foam goes into all cavities including gaps in sheathing and electrical boxes. Tape these openings up.

c) Make sure that the over expanded access is properly removed from the walls. We had a junior cutter taking too much off by bending his saw into the cavity. Look closely at the inside wall corners, and ceiling/wall corners to make sure that the foam is properly removed flush with the studs. If it has not been cut back flush it may lead to uneven drywall finishes .

spray foam

The reasons that we chose open cell over closed cell were:

a) Cost

b) Open cell is more copatible with wood in terms of moisture absorbtion

c) Closed cell is typiclly installed as a thin layer of about 2 inched thick where as the full wall cavity application of open cell reduces thermal bridging of the studs.

d) Air tighness is the parimount issue - additional insulation value beyond a 6" stud cavity providing R20 is not really nessesary unless temperatures are very extreme.

Reponse to Nathan

Nathan,

I know that many spray-foam contractors repeat this myth -- "additional insulation value beyond ... R-20 is not really necessary" -- but it isn't true. Heat transfer through an R-40 wall will be at half the rate as heat transfer through an R-20 wall.

response to Martin

Martin,

Yes -it is true that "Heat transfer through an R-40 wall will be at half the rate as heat transfer through an R-20 wall" in theory but there are many variables that are mis-directed in the industry.

Some of them are:

a) Context and relative efficiency - temperature differences between inside and outside and do you need R40 when an R20 wall, that is air tight, will perform sufficiently given that so many other factors in a building are contributing to energy loss?.

b) Cost - In the case of closed cell application - filling the 6" wall cavity instead of only installing 2 inches of thickness, would be better but - it will cost substanitally more and it will not provide double the R value. In fact the R value increase will be around 6-8%

c) R values are not linear per per thickness of insulation. i.e the composition of an R20 wall at 6" thickness will not provide an R40 wall at 12" thick.

d) The reality between actual wall performance and theoretical wall R values is surprisingly lower. primarily due to air leakage through the wall and air movment inside the wall cavity (with batt insiulation).

Response to Nathan

Nathan,

You wrote, "R-values are not linear per per thickness of insulation."

Actually, they are, as a general rule -- assuming that increased thickness does not alter density. There are a few mathematical reasons why this general rule has a few minor exceptions; but as a general principal, it holds with enough accuracy to be a good rule for builders.

Once you know the R-value per inch of a given insulation material, it's pretty easy to calculate the R-value of a known thickness of that material.

response to Martin - R values

Martin,

My statment that "R-values are not linear per per thickness of insulation" was absolutely correct.

Your discussion suggesting that, R value calculated from insulation thickness as an acurate enough method for builders, was exactly my point about mis-conceptions in the building industry. These type of generalizations can lead to wrong conclusions with regard to wall thickness and insulation values.

This is a very important point in a very complex subject, which will require a complex discussion, however there is some good data that explains this issue, provided by the Federal Trade Commision. I will provide more specifics if you want it.

regards,

Nathan

spray foaming rafters, rubber membrane

Is there any concern about moisture accumulation between the foam and the roof deck, say, if the roof leaked? Has it become standard practice to apply stick-on membrane to roof decks when re-shingling? I see them doing it here in N. Florida. Should this added measure be taken if re-roofing at time of foaming rafters ?

Response to Bob Rinehuls

Q. "Is there any concern about moisture accumulation between the foam and the roof deck, say, if the roof leaked?"

A. Yes, many builders and homeowners have expressed that concern. If you want to be able to inspect the roof sheathing for possible roof leaks, it's best to design either an unconditioned attic, or a conditioned attic with all of the insulation located above the roof sheathing.

Q. "Has it become standard practice to apply stick-on membrane to roof decks when re-shingling?"

A. No. In areas subject to ice damming problems, roofers usually install 3 ft. or 6 ft. of peel-and-stick rubber membrane near the eaves, but usually not over the entire roof. Covering the entire roof with peel-and-stick membrane reduces the ability of the roof sheathing to dry to the exterior.

Q. "Should this added measure be taken if re-roofing at time of foaming rafters?"

A. I wouldn't do it.

Is pricing current info (2010)?

We're doing a kitchen/bath renovation. We're in Massachusetts, and have high wind on this particular wall. But, we can't afford to do the whole house right now, so is this a waste of $? Won't the cold just get in through the other 3 (uninsulated) walls?

Also, I'm wondering... Is this website is being regularly updated? A local installer (in Oct, 2010) in MA quoted over twice the price you list here. "Open cell alone ~$1.35 per sq ft for R-13. Or a 'hybrid method' using 2inch closed cell for R-13 followed by 1.5inch open cell for R-6. Hybrid is $2.85 per sq foot for R-19 rating". Maybe installers are charging higher prices to profit from those trying to meet government energy rebate by Dec 31?

Being green is hard. But, this site is helping.

Response to Biff

Biff,

It's almost impossible for any Web site to keep current with pricing information. Moreover, prices for residential insulation vary widely across the country. When comparing two different regions, prices can easily differ by a factor of 2 or 3.

Here's how to determine the local price: call three reputable contractors and ask for bids. Now you know your price.

Closed Cell Foam in attic and in crawl space

I live in Baton Rouge LA with a very old and drafty house. There is no blockages in the walls between the crawl space and attic. Lots of critters just come on in. I would like to used closed cell sprayed under house to warm up floors and block moisture. I would like to spray closed cell into attic, but am afraid of enclosing attic due to moisture build-up. Can I spray closed cell against the attic floor in same way as installing bats, thus leaving my venting the same as it always has been. Other ideas? Thanks.

Response to Joe Keegan

Joe,

Q. "Can I spray closed-cell against the attic floor in same way as installing batts, thus leaving my venting the same as it always has been?"

A. Yes.

Spray foam

Is it safe to use the can spray foam around electric outlets. I had an electrical inspector tell me I couldn't get the foam on any romex wire.

Spray foam on Romex

Greg,

Spray foam is used around Romex wiring all the time. However, it is a code violation to install spray foam inside of an electrical box. Your electrical inspector was probably concerned that the foam would fill some of the space inside the box -- a violation.

Not sure I did enough.

I'm in the process of redoing my basement and read through the posts. I took out one inch styrofoam covered by 1/4 " beadboard and installed 2X4s and plan on putting in fiberglass batts between them(r-13) with 1/2 in drywall over top of that. Do you think I will see a significat increase in heat control? Should I have done more?... it's a little after the fact, but still curious to know if I will see a big difference based on your experience.

Thanks,

Eric

Response to Eric

Eric,

I'm afraid you got it backwards.

You "took out one inch styrofoam [XPS] covered by 1/4 " beadboard [EPS]." Oops -- you should have left those in place -- those are appropriate insulation materials for a basement.

Then you write that you "plan on putting in fiberglass batts." Oops -- big mistake. Fiberglass batts are inappropriate for insulating a basement wall.

Combine closed and open cell in wall

Would it be possible to use 2" of the closed cell and then 3.5" open cell in my new construction in order to get the benefit of higher R value and vapor barrier but at a lower cost.

Response to BP

BP,

It would be possible -- but it would be more expensive than just installing the closed-cell foam.

Closed-cell and open-cell foam require different chemicals -- and usually different trailers or installation trucks, and often different contractors. So your suggestion requires two trips to the site -- two trucks -- two contractors -- and much higher deployment costs. You'll pay more doing it your way.

Spray foam applied directly to chimney

I don't even want to ask this question but... several years ago we hired a local contractor to spray high density foam on the roof deck and walls of our unfinished 2nd floor. We realized that the job was done poorly and cut an access into the attic space to assess things. We realize now that they spray foamed directly to the chimney (no flashing). The chimney is currently used for a woodstove and DHW venting. The DHW will go away but wood stove will remain. My question is, how bad (unsafe) is this? I have found information on foam exposure to fire but have not been able to find anything about temperature ratings in general (i.e. what happens on prolonged exposure to high temperatures).

thank you

Response to Leslie Badger

Leslie,

Your spray foam installer made a mistake.

Here is a quote from technical specifications prepared by BASF, a spray foam manufacturer:

http://www2.basf.us/basf-canada/productsheets/walltite/wltnms2-E.pdf

"Do not spray polyurethane foam any closer than 75 mm (3 inches) from chimneys, heating vents, steam pipes, recessed lighting fixtures, and other heat sources."

Here is a quote from a document prepared by the Spray Polyurethane Foam Alliance:

http://www.selacaci.org/wp-content/uploads/2011/10/BE-Inspector-Chapter-3.pdf

"Do not apply spray polyurethane foam within 3” (75 mm) of chimneys or flues or other heat producing appliances."

Spray foam applied directly to chimney (2)

Hi Martin

Thank you for the reply and the links. We are definitely aware that a mistake was made (this wasn't the only one). I'm wondering if you have any advice for fixing the problem. What would be entailed in trying to remove the foam from the chimney?

thanks again

Response to Leslie

Leslie,

It should be possible to remove the cured foam and to install a fire-resistant insulation like mineral wool in the resulting gap.

Spray Foam Insulation

I recently did a remodel project for my basement using spray foam insulation. The original builder has used fiberglass, but I wanted the best insulation i could find. We chose closed cell foam because it blocks moisture from getting into the house. It took one day to install and was fumey for about 3 hours. It was pretty cool watching it being done. It comes out as a liquid and then expands rapidly into a foam. It's quick! Then they took a types of saw to shave it flat with the wall studs so we could then go ahead and drywall.

I was very pleased with the installation and I highly recommend it.

Spray Foam - Chicago

We are remodeling a home and have been looking for the right kind of insullation, we know that the spray foam is most efficient but we are tight on budget, we have taked to a company but the cost was pretty high. Curious about the following:

1. Can you recommend a company or two in Chicago?

2. will you recommend we do Closed cell in the roof and something else in the walls for cost savings and what that will be?

3. will you recommend something else for the basement walls since it is pretty cool down there to minimize extreme coolness?

Thank You!

Response to Linda Quarshie

Linda,

The best place to post your question is on our Q&A page. That way, more readers will see your question and be able to offer advice. Here is the link:

https://www.greenbuildingadvisor.com/qa

Spray foam and chimneys

Ms. Badger;

What sort of "chimney" do you have. There are exceptions to the general rule requiring a "thermal" or "ignition" barrier for certain chimneys. I foamed my own tile lined brick chimney, finding the exterior surface temperatures well within the manufacturers fire ratings during operating conditions.

An well qualified and experienced foam applicator is the best source for a particular spray foam application problem and if he goes by the thin information offered, look for another with a greater depth of knowledge and few "rules of thumb".

Spray Foam Info

Starting a new build (1 1/2 basement walkout), all 2x6 exterior walls w/ brick veneer in CZ3. Above grade, would like to do spray foam in 2x6 walls, 1/2" or 1" of rigid foam board on the exterior, and a 1" air gap. Will this require a house wrap or can I do w/o the rigid foam and go with a housewrap? Also, any recommendations about insulation strategies for the finished basement. Thanks!

Response to David Myles

David,

The best place to ask your questions is on GBA’s Q&A page. Here is the link:

https://www.greenbuildingadvisor.com/qa

If you post your question there, the question is more likely to be seen by a wide number of helpful people.

Spray Foam Info

Martin, thanks for the link!

Closed cell spray foam for a residential roof addition

Mr. Martin Holiday,

I am an Architect in Toronto. I am designing a new roof addition to a row house building. Because of existing conditions and the shape of the new roof. It may be easiest to use closed cell spray foam within the areas of the joists. My question is when spray foam is used in this situation do I need to worry about how the joist members may be thermal bridges? It is not common to provide a little bit of rigid insulation to protect the joist members? The additional layer of outboard insulation will require an extra layer of plywood above the insulation which will add to cost.

Do I not need to worry about the outboard rigid insulation to protect the joists when using closed cell spray foam?

Thanks again for your expert opinion.

Lowell

Architect in Toronto

Closed cell spray foam for a residential roof addition

Sorry Martin,

When I say joists I meant roof rafters in my earlier comment.

Lowell

Lowell,

I don't know if it's

Lowell,

I don't know if it's common or uncommon, but installing a layer of rigid foam above your roof sheathing in order to interrupt thermal bridging is always a good idea, and is preferable in all respects to a roof assembly without any rigid foam above the sheathing. If you decide to install rigid foam above the roof sheathing, you shouldn't use closed-cell spray foam under the sheathing; either use open-cell spray foam (which is vapor-permeable) or a fluffy insulation like cellulose, mineral wool, or fiberglass (any of which will allow the roof sheathing to dry to the interior).

For more information on this topic, see How to Install Rigid Foam On Top of Roof Sheathing.

Flat Roof Assembly with outboard rigid insulation

Martin,

Sorry to ask again. My flat roof assembly is as follows:

-2 ply mod-bit roof on

-fibreboard protection board (Atlas HS coverboard) on

-5" polyiso insulation glass face Atlas ACFOAM 3 ( 2 layers offset and stagger joints) on

-1/2" plywood on

-7-1/4" LVL roof joists 16" O.C. fill joist cavities with 5-1/2" fibreglass insulation on

-1/2" drywall

My questions:

1. Should I use Grace Ice and Water shield on top of the plywood or should I use a vapour permeable resistive membrane since I have batt insulation in the joists?

2. I talked to a building product supplier for WALLTITE spray foam, he is suggesting to use 2" or 3" of closed cell spray foam in the joists areas instead of the batts insulation. He says it will work with outboard rigid insulation. There is a location of a cantilevered floor area with steel beam so I may need to use spray foam to protect the steel beam. I would then be convenient continue to spray in the floor joist cavities and then apply 5" of polyiso outboard of the bottom cantilever floor sheathing.

I hope I described the above clear enough.

Thanks again.

Lowell

Response to Lowell Lo

Lowell,

Q. "Should I use Grace Ice and Water shield on top of the plywood or should I use a vapour permeable resistive membrane since I have batt insulation in the joists?"

A. There is no need for this air barrier layer to be vapor-permeable, since there will be no upward drying. Grace Ice & Water Shield is fine.

Q. "I talked to a building product supplier for WALLTITE spray foam, he is suggesting to use 2" or 3" of closed cell-spray foam in the joists areas instead of the batts insulation. He says it will work with outboard rigid insulation. There is a location of a cantilevered floor area with steel beam so I may need to use spray foam to protect the steel beam. It would then be convenient continue to spray in the floor joist cavities and then apply 5" of polyiso outboard of the bottom cantilever floor sheathing."

A. You can use closed-cell spray foam that way if you want, although you should realize that the spray foam will prevent the roof sheathing from drying inward. This approach should only be used if the roof sheathing is bone dry, because it will never dry when sandwiched in this manner. Most building scientists would prefer to see fiberglass rather than closed-cell spray foam under the roof sheathing in this type of assembly.

If you want spray foam, open-cell spray foam would be better than closed-cell spray foam in this assembly, because open-cell spray foam is vapor-permeable.

If you install fiberglass batts, it's better to choose 8-inch-thick batts, not 5.5-inch-thick batts, because you want to fill the rafter bays and keep the fiberglass in contact with the roof sheathing.

Thanks again Martin.

Lowell

Thanks again Martin.

Lowell

open cell spray foam

Sorry to email yet again Martin.

If I go with open cell spray foam, would I be able to use that for insulating around the steel beam or would closed cell be better in that application? I am in Toronto.

Lowell

Response to Lowell Lo

Lowell,

In general, cantilevered steel beams are a nightmare. If part of the steel beam is in contact with exterior temperatures, then it's best if the interior portion of the steel beam is covered on all sides with insulation. This is generally impossible (because the interior portion of the cantilevered beam generally supports a load, meaning that you can't wrap the steel beam in insulation on all sides).

If you provide a sketch, we can discuss the steel beam. In some cases it makes more sense to try to insulate the portion of the steel beam on the exterior side of the penetration rather than on the interior side of the penetration.

In most cases, closed-cell spray foam is preferable to open-cell spray foam for this application, because there is no advantage to allowing moisture to be able to reach the cold steel.

Martin,

I know cantilever

Martin,

I know cantilever steel is a nightmare. I am reviewing and stamping the design by another Architect. That's another story.

How do I attached the image of the detail for you to review?

Lowell

Martin,

Can you see this

Martin,

Can you see this detail with the link below?

http://www.lowelllodesign.com/2016/06/09/cantilever-floor-detail/

Response to Lowell Lo

Lowell,

The beam is not cantilevered in the way I imagined (if I am reading the detail correctly). It looks like all of the beam is in an insulated soffit.

The coldest part of the beam is the top of the beam. (Is that a fixed window directly above the beam?)

As I wrote earlier, closed-cell spray foam would be better than open-cell spray foam for this purpose -- because the closed-cell spray foam has a higher R-value per inch, and because the closed-cell spray foam is vapor-impermeable.

Yes. Martin. The soffit area

Yes. Martin. The soffit area under the cantilever floor area is insulated and the window above is a curtain wall window system. I am hoping 2" of closed cell spray foam would be enough around the entire steel beam. Here is the detail again, I change the link location.

http://www.lowelllodesign.com/2010/06/09/cantilever-floor-detail/

Corners With Foam

I'm getting ready to spray foam into my walls. Each corner consists of a void between two common studs. Do I:

a) Figure out a way to fill those voids with foam? or

b) Seal the tiny cracks between the studs and leave the voids empty?

Thank you,

Ben

Response to Ben (Comment #50)

Ben,

Did you frame your corners as shown in this link?

Outside corner detail

This is done to make it possible to insulate an outside corner. More information here:

Advanced framing: Insulated corners

If you screwed up the framing, you'll have to drill holes through the studs to allow this void to be insulated.

Reply to Martin

Thanks Martin. Somebody else screwed up the studs back in 1972. I've been told they were the premiere custom home builder of their time.

Guess I'll have to drill the holes. The alternative I had in mind was to run HVAC tape in the corner and Cadillac on like it didn't matter.

My other question was gonna be this. We ripped all the drywall out after Hurricane Harvey and we found some latent termite damage from some time back. One of the common studs in one corner is pretty well eaten to shreds. I was gonna brace it but then I read about more modern framing practices and I read how each stud is a thermal bridge. So now I'm thinking that I won't bother with it because the house hasn't fallen down and the foam might help a little. Unless you say to brace the stud. Then I'll do it, Martin! :)

Ben

Carpentry Conundrum

I have to insulate my walls at the end of this week. That does not give me time to procure slow-rise foam, so my stud cavities will be filled with foam before I'm ready to fill the corner voids. I will not be able to drill straight through the corner studs. Instead, I will have to remove material where the studs meet. What sort of tool do you envisioning me holding while I create space to pump foam into my 1972 corner voids?

Response to Ben (Comments #52 and #53)

Ben,

You need to hire a carpenter. I'm afraid you are in over your head.

When you wrote that you are tempted to ignore termite damage, because maybe studs aren't necessary and anyway studs contribute to thermal bridging, I was worried. Now, with your latest question about insulating an outside corner, and what tools you need, I'm really worried.

If you don't have the patience to slowly fill the void with spray foam through holes drilled in one of the studs, you could (if you were an experienced carpenter) use a Sawzall to remove one of the studs and re-frame the corner as a two-stud corner. Then you could either insulate the void with a fiberglass batt or simply present the two-stud corner to the spray-foam contractor as an accessible corner.

But if this isn't intuitively obvious, you don't just need a Sawzall -- you need to hire a carpenter.

Martin,

There is no

Martin,

There is no carpenter. I described a situation where drilling through the studs would not work. I was hoping you would provide guidance on creating access at the point where the studs meet. "Try a sawzall," or, "Drill it with a so-and-so." All the rest of your response was unnecessary.

I can't recall whether this website was free. Perhaps I need a financial advisor, too. Do you have an unsubscribe link, or do I need to send you a web development guru?

Ben

Response to Ben (Comment #55)

Ben,

I know there is no carpenter. But some jobs need one. Homeowners can't do everything.

If you cut the nails holding one of the corner studs to the bottom plate and the top plate with a Sawzall, you can use a flat bar (or a flat bar plus a wrecking bar) to pull the stud off the sheathing nails. Either re-use the stud, or buy a new stud, and install the stud with toenails as shown in the link I provided in Comment #51 (this link: Outside corner detail).

As I wrote earlier, an alternative is to drill a series of holes in one of the studs, and to fill the void slowly from the bottom up with canned spray foam. You'll need a lot of cans. Stop every now and then and let the foam cure before returning to the task. Trim off any excess that pushes through the holes.

Log in or become a member to post a comment.

Sign up Log in