ABOUT INSULATION

Thicker is better

In cold weather, a puffy parka holds in your body heat. Insulation does the same thing for a house. The thicker the insulation, the better it works to reduce heat flow from the inside of a home to the outside during winter, and from outside to inside during summer.

The thermal barrier of a home should consist of a continuous layer of insulation on all sides—including the lowest floor, the exterior walls, and the ceiling or roof.

Doubling the thickness of insulation will double the insulation’s R-value, cutting heat loss in half. Each time the insulation layer is doubled in thickness, this rule applies. The energy saved per year by doubling insulation from R-10 to R-20, however, will be considerably more than the energy saved by doubling insulation from R-20 to R-40, because of the law of diminishing returns. In some cases, like an attic, it’s worth piling on more insulation because there is plenty of room. It’s much more expensive to add that much insulation to exterior walls.

It takes more than just insulation to slow heat

Stopping air leaks is just as important as — maybe more important than — adding insulation. Unless builders prevent air from leaking through walls and ceilings, insulation alone won’t do much good. Not only are drafts uncomfortable, but air moving through insulated cavities can cut the efficiency of the insulation by as much as 50%.

Some insulation types make good air barriers, and some don’t. In all cases, it’s best to keep the insulation tight to the air barrier.

THERMAL BRIDGING IS CONDUCTION IN ACTION

When there is no insulation in a roof or wall, the framing is the most insulated part of the assembly. It has the highest R-value. Softwood lumber has an R-value of 1.25 per inch, so a 2×6 stud has an R-value of almost 7. As soon as you put insulation between the studs or rafters above R-7, however, the framing becomes the weak thermal link. If the framing cavities are filled with closed-cell spray foam insulation, the insulation has an R-value of about 36. At that point, the studs or rafters become a glaring weakness in the design.

Building scientists call this phenomenon “thermal bridging” because the studs or rafters bridge the space between inside and outside the thermal envelope.

If you look for it, thermal bridging can sometimes be seen from either inside or outside.

Inside, it can cause a problem called ghosting, or cold stripes behind the drywall during winter. These cold stripes can encourage condensation that leads to the accumulation of dust particles on the drywall; eventually, visible vertical stripes may form. Outside, you can see the effect of thermal bridging in snow-melt patterns on roofs and drying patterns on walls.

A continuous layer of rigid foam installed on the inside or outside of a wall or roof drastically reduces thermal bridging through the framing.

R-VALUE MEASURES HOW WELL INSULATION WORKS

Heat flows from hot to cold; it can’t be stopped, but it can be slowed

If we measure the rate at which heat flows through a building material or building assembly—for example, a wall or a roof—we can calculate a number (the R-value) to indicate its insulating ability. The higher a material’s R-value, the better the material is at resisting heat flow through conduction, convection, and radiation (outlined above). Insulation manufacturers report R-values determined by tests following ASTM standards (for example, ASTM C518).

Common insulation types and their R-values

Residential insulation materials have R-values that range from about 3 to 7 per inch. The amount of insulation installed in any given building assembly depends on the climate, the part of the house being insulated, the project budget, and local code requirements.

- Batts and blankets: R-3.1 to R-4.1 per in.

- Blown-in and loose-fill insulation: R-2.6 to R-4.2 per in.

- Rigid foam: R-3.6 to R-6.8 per in.

- Closed-cell spray foam: R-6 to R-6.8 per in.

- Open-cell spray foam: R-3.5 to R-3.6 per in.

Green homes go beyond code minimum

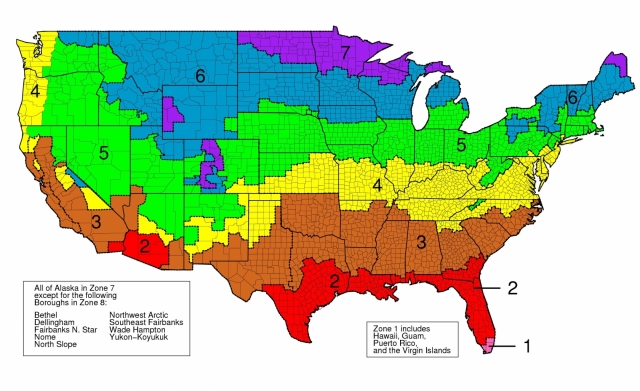

The U.S. Department of Energy has developed a list of recommended insulation levels for different climate zones. The climate zones are represented on the map (click to enlarge).

For more information on climate zones, see All About Climate Zones.

Houses heated by natural gas, fuel oil, or an electric heat pump should use the R-values set out by the DOE and listed below as a base. Because electric heat is relatively expensive, houses with electric resistance heat need more insulation than shown in the table below.

In some parts of the country, minimum code requirements for insulation already (or may soon) exceed these DOE recommendations. For example, the 2009 International Residential Code requires cold-climate builders to include a minimum of R-20 wall insulation and R-15 basement wall insulation.

DOE recommended R-values for various parts of a house

| Zone | Attic | Wall | Floor | Slab edge | Basement wall (framing cavity insulation) | Basement wall (continuous rigid insulation) |

|---|---|---|---|---|---|---|

| 1 | R-30 to R-49 | R-13 to R-15 | R-13 | R-4 | R-11 | R-10 |

| 2-3 | R-30 to R-60 | R-13 to R-15 | R-13 to R-25 | R-8 | R-11 | R-10 |

| 4 | R-38 to R-60 | R-16 to R-21 | R-25 to R-30 | R-8 | R-11 | R-4 |

| 5 | R-38 to R-60 | R-16 to R-27 | R-25 to R-30 | R-8 | R-11 to R-19 | R-10 to R-15 |

| 6-8 | R-49 to R-60 | R-18 to R-27 | R-25 to R-30 | R-8 | R-11 to R-19 | R-10 to R-15 |

In any case, green builders almost always exceed minimum code requirements for insulation thickness. Many energy consultants, including Betsy Pettit and Joseph Lstiburek, now recommend that cold-climate homes include R-60 ceilings, R-40 above-grade walls, R-20 basement walls, and R-10 basement slabs.

Some builders go further; for example, an Illinois home designed to meet the rigorous German Passivhaus standard is insulated to nearly R-60 on every side—even under the slab.

AIR AND MOISTURE ARE PART OF THE PICTURE

Insulation can’t work in a wind tunnel

No matter what type of insulation you choose, it will perform poorly if installed in a house that is riddled with air leaks. Because many types of insulation (like loose fill and batts) work by trapping air, leaky walls, roofs, and floors mean poor thermal performance. For this reason, building scientists are fanatical about air-sealing. To get the most out of batts and blown insulation, every house needs an air barrier adjacent to or contiguous with the insulation layer.

Some types of insulation are fairly effective at stopping air infiltration. For example, when rigid foam is used as wall sheathing, it can be an effective barrier, as long as the seams are taped. Spray polyurethane foam creates a very effective air barrier.

But neither rigid foam nor spray foam addresses air leaks at the seams where different components meet, such as under the bottom plates of walls. An air barrier is only effective if all of these seams and intersections are addressed with gaskets, glues, or sealants.

Of all available insulation materials, fiberglass batts are the most permeable to air leakage—so permeable that fiberglass is used to make furnace air filters. Because it doesn’t restrict air flow, fiberglass is often singled out and derided for its poor performance.

In fact, much of the criticism of fiberglass insulation is unwarranted. As long as fiberglass is installed in a house with an adequate air barrier, it will perform well. Fiberglass performs best when installed in a framing cavity (for example, a stud bay or joist bay) with an air barrier on all six sides.

Installation details for high-quality fiberglass batts have been incorporated into the insulation installation guidelines established by the home raters from the Residential Energy Services Network (RESNET).

For every location in a house, there are always several ways to create an effective air barrier. However, not all methods are equally easy to achieve. In many locations, including rim-joist areas, spray polyurethane foam is so much faster than alternative methods that its use has become almost universal among builders of high-performance homes.

Moisture can piggyback on air

There’s another benefit to stopping air: less moisture in roofs and walls. That’s because most moisture problems in walls and roofs are caused by moisture transported by air. Vapor diffusion is a much smaller problem.

Moisture can accumulate in a wall or ceiling when warm, humid interior air leaks through cracks in the shell. When this exfiltrating air encounters a cold surface—for example, OSB wall sheathing—the moisture in the air can condense into liquid and puddle in the wall cavity. The same thing can happen in summer, when warm, humid outdoor air leaks through cracks in the wall. If the home is air-conditioned, the moisture in this infiltrating air can condense when it reaches any cool surface—drywall, ductwork, etc. The best way to limit this type of moisture migration is to install an effective air barrier. If air isn’t leaking through cracks in a home’s walls and ceilings, the problem is nipped in the bud.

FURTHER RESOURCES

Fine Homebuilding

Environmental Building News:

Insulation: Thermal Performance Is Just the Beginning

Oak Ridge National Lab:

ORNL Whole Wall R-Value Calculator gauges the energy implications of type of framing, spacing, and thermal bridging.

Home Energy Magazine:

Insulation Inspections for Home Energy Ratings covers RESNET’s insulation guidelines.

Wall R-Values That Tell it Like it Is — More information on whole-wall R-values.

Energy Star Homes:

Thermal Bypass Checklist — Air-barrier requirements for fiberglass-batt jobs are also included.

Green Building Advisor:

Bird’s-Eye View

Image Credits: Ty Keltner, Cold Climate Housing Research Center

Heat always moves from warm to cold

Most places in North America aren’t a comfortable 67°F to 78°F. To stay comfortable, we heat and cool our houses. Insulation slows the flow of heat into or out of a house.

While heat can move three ways (conduction, convection, and radiation) it rarely moves in only one of them. Except in outer space, all three mechanisms are working together in varying degrees.

Different insulation materials have different success at slowing these heat-flow mechanisms.

See below for:

R-VALUE MEASURES HOW WELL INSULATION WORKS

THERMAL BRIDGING IS CONDUCTION IN ACTION

AIR AND MOISTURE ARE PART OF THE PICTURE

Conduction

Image Credits: Dan Morrison

Heat flows through materials by conduction

Conduction is the flow of heat energy by direct contact, through a single material or through materials that are touching.

Substances that conduct heat readily are called conductors, while substances that don’t conduct heat readily are called insulators. Metal is a good conductor; foam is a good insulator. Wood falls somewhere in between.

Convection

Convection is the movement of air (or another fluid) in response to heat

When air or a liquid is heated, it expands, and therefore becomes less dense, so it rises. The rising warm air displaces cooler air, which sinks. When the motion is constant, it’s called a convective loop.

Woodstoves and windows cause convective loops by heating or cooling (respectively) the air closest to them.

Even in homes with airtight walls and ceilings, convective loops can feel like a cool draft and be uncomfortable to the people in the room.

Convective loops can occur inside poorly insulated wall cavities, too, degrading the performance of the insulation.

Radiation

Image Credits: Freerangestock

Radiation heats objects, not air

Radiation is the transfer of heat by electromagnetic waves that travel through a vacuum (like space) or air.

Radiation cannot pass through a solid object like plywood roof sheathing. When the sun shines on asphalt shingles, heat is transferred to the plywood sheathing by conduction. After the plywood has been warmed by conduction, it can radiate heat into the attic.

Radiant barriers are materials (for example, aluminum foil) with a low-emissivity (low-e) surface. Although radiant barriers have a few applications in residential construction—they are sometimes integrated with roof sheathing—they are rarely cost-effective when compared to conventional insulation options.

RELATED ENCYCLOPEDIA ARTICLES

Insulating Roofs, Walls, and Floors

OTHER CONSIDERATIONS

Insulation can stop air

Some insulation types act as air barriers, while others act like air filters. If you choose an insulation that doesn’t stop air flow, it’s important to install an adjacent air barrier material.

Best to worst at stopping airflow:

Spray foam

Rigid foam

Cellulose

Blown-in fiberglass

Fiberglass batts

SHOULD INSULATION STOP VAPOR?

Vapor permeability can be a good thing or a bad thing — vapor retarders slow wetting, but they also slow drying, which may be more important. As long as you design a roof, wall, or floor assembly with these concepts in mind, then almost any type of insulation can work. More on Enclosure Design.

Least to most vapor permeable:

Foil-faced polyisocyanurate

Closed-cell spray foam

XPS

EPS

Open-cell spray foam

Cellulose

Blown-in fiberglass

Fiberglass batts

For more information on vapor barriers, see:

- Vapor Retarders and Vapor Barriers

- Forget Vapor Diffusion — Stop the Air Leaks!

- Do I Need a Vapor Retarder?

For more on the vapor permeance of insulation materials, see the Building Materials Property Table at BuildingScience.com.

INSULATE OUTSIDE THE BOX

Although residential wall insulation is traditionally installed in stud cavities, the best place to locate wall insulation is outside the frame. This exterior insulation reduces the thermal-bridging effect that studs have in a wall, because each piece of framing can act as a thermal bridge through the cavity insulation. These thermal bridges seriously degrade the performance of the wall.

The thermal-bridging effect can be partially addressed by using rigid foam sheathing—usually 1 in. or 2 in. of XPS or polyisocyanurate. Even better are wall designs that place all the insulation—6 in. to 10 in. of rigid foam—outside the framing.

When insulation is outside the frame, framing materials stay warm and dry. When stud bays are not filled with insulation, the work of electricians and plumbers is greatly simplified.

Houses with foam sheathing should not include an interior polyethylene vapor retarder.

OTHER THERMAL BRIDGES

Uninsulated slab edges

Window frames

Wall and roof penetrations

12 Comments

Insulation under basement slab

In Joeseph Lstiburek's book on Bldg in Cold Climates he shows numerous examples of slabs w/ no insul under and one with insul above the slab under a wood floor and one w/ 2' of insul around the perimeter. I thought most everyone on this sight was advocating for complete layer of insul under slab! Joe's book is often quoted so I presume his work is respected. Why the (drastic) difference in suggested building methods? Am I wrong in thinking insul under a full bsmnt slab is fundamental t an energy efficient dwelling. (In a cold Climate 6A SE B.C. Can)

Response to Richard Clark

Richard,

I agree with you: it's best to install full horizontal insulation under a basement slab. You'll never regret it, and you won't be able to easily add it later.

Subslab insulation

Martin, I agree with you about subslab insulation, but wonder about your conclusion I thought you might easily add foamboard insulation on top of the slab if the home is already built with an uninsulated slab and then a wood floor on top of the board insulation. Wouldn't that work just as well, or very close?

Response to Robert Nemoyer

Robert,

You are right that it is possible to install a layer of rigid foam on top of a concrete slab, followed by a plywood subfloor. However, this method costs more than installing rigid foam under the slab, and leaves the homeowner with less flexibility about the final ceiling height.

A long time coming on this comment I'm sure, but as this article is still as important as the day it was written, can I ask about the correctness about the continuous insulation on the basement exterior walls in zone 4?, or maybe zones 1,2,3? The dip from R10 to R4 seems odd, as one would expect more R as you travel further north through the zones.

Thicker is not better! Doubling the amount of insulation will double the R-Value, but so what? Doubling the insulation from R-19 to R-38 does NOT cut the heat loss in half (50%) it cuts it by around 3%! Add more insulation to an attic space because you can is a poor recommendation unless you have a lot of money you don't know what to do with.

ptombarrett,

If R-value is a measure of resistance to heat loss, how does doubling the R-value not halve the heat loss?

ptom,

It depends how you look at it - what the 100% are!

If you double the R then the heat loss through that particular part goes down by half.

If that part was originally only responsible for 6% of the total heat loss - then the whole heat loss will drop down by 3% - both statements are quite correct.

I guess the consensus is:

- if we talk about larger areas /high fraction of total heat loss) and if it is "cheap" to double the R

--> do it (like blown insulation in an vented attic)

- It is better to have some decent R all over then to go "above board" in a certain place alone and neglect other areas

wastl,

That's a generous interpretation of Ptom's post.

"- if we talk about larger areas /high fraction of total heat loss) and if it is "cheap" to double the R

--> do it (like blown insulation in an vented attic)

- It is better to have some decent R all over then to go "above board" in a certain place alone and neglect other areas"

Useful advice!

ptombarret,

Please explain how you arrive at the 3% reduction. I guess we talk about different assumptions.

regards

Agreed, insulation is often a terrible investment because of diminishing returns once you have some minimal amount of existing insulation.

Hi Paul,

"it all depends" Your minimal amount and mine can be quite different, and with solid reason either. We have to be careful..

What Martin Holloway wrote about is also generic - newbuilt and retrofit - again different rules.

regards

Log in or create an account to post a comment.

Sign up Log in