The federal government is ramping up efforts to cut greenhouse gas emissions with the Federal Buy Clean Initiative, a plan to use the government’s enormous buying power to force wider use of low-carbon building materials. Although the strategy initially will affect only federal construction and paving projects, experts say that ultimately it will give residential builders much easier access to building materials that help dampen global warming.

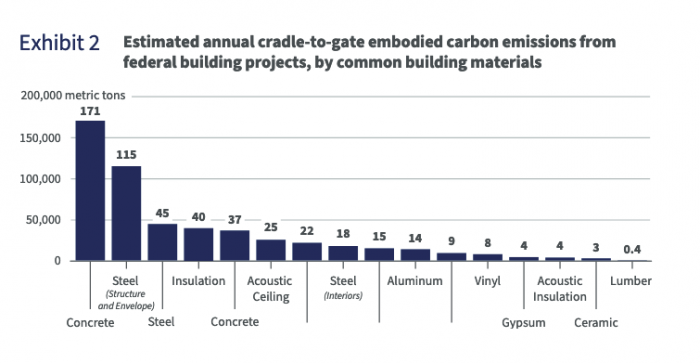

In September, the government announced it would make it a priority to purchase low-carbon alternatives in four key material categories—concrete, asphalt, steel, and flat glass—on federal building and transportation projects. The targeted materials are responsible for nearly half of all manufacturing greenhouse gas emissions in the U.S. and represent 98% of the construction materials that the federal government buys annually.

The government later detailed how it planned to use billions of dollars from the Inflation Reduction Act and the Bipartisan Infrastructure Bill to lower greenhouse gas emissions with incentives funneled through a number of federal agencies, including the departments of energy and transportation, and the General Services Administration.

The effort reflects the growing awareness that carbon emissions that occur as building materials are mined, manufactured, and transported are just as damaging as emissions that result from heating and cooling buildings. Over the short term, experts like Chris Magwood of Builders for Climate Action argue, embodied carbon is a more important consideration than operational carbon if the aim is to head off catastrophic climate change.

The government’s goal is to cut its carbon emissions in half by 2030 and bring net carbon emissions to zero by 2050.

So far, the White House has laid out a variety of programs that in time will require government agencies to choose low-carbon materials. To date, only the General Services Administration (GSA) has put policies in place that set actual limits on embodied carbon. The new rules, which affect concrete and asphalt purchased for GSA projects, went into effect in March.

What does this all mean for residential builders? At the moment, not much. Builders of single-family houses and small multi-family buildings certainly order concrete and steel—the two most significant carbon emitters among building products—but not on the scale of a highway project or office building. And single-family homes are mostly wood-framed structures that already are made mostly of bio-based materials with relatively low amounts of embodied carbon.

But experts like Anish Tilak, a manager of the Carbon-Free Buildings program at the Rocky Mountain Institute (RMI), believe that in time the Buy Clean initiative will make low-carbon materials more widely available for everyone and spill over into other material categories, like insulation. (Tilak was one of three authors of this RMI report on how federal building projects can reach zero embodied carbon.)

“First and foremost, it’s an industrial decarbonization policy,” he said in a telephone call. “Buy Clean is a demand inducer, just using the purchasing power of the government to show producers that this is where the market is headed and accelerate competition among industrial producers of building producers to achieve lower carbon in their products.”

It promises the same kind of impact nationally as California’s strict emission rules have had on the auto industry. Because of its size and population, the state has an outsized clout that prompts manufacturers to make efficiency improvements for cars and trucks that ultimately affect the entire country. The same could be true with building materials; once the government requires low-carbon choices on its own projects, the changes will spread to the industry in general.

Accurate carbon reporting is key

Tilak thinks an important part of the shift toward low-carbon materials will be a greater reliance on environmental product declarations (EPDs), which are verified third-party assessments of a product’s environmental impact. EPDs quantify such things as greenhouse gas emissions and ozone depletion, among other things.

The Leadership in Energy and Environmental Design (LEED) program of the U.S. Green Building Council was instrumental a decade ago in getting manufacturers to report emissions, Tilak says. Now, a greatly expanded number of EPDs have been created and are available through such channels as the Carbon Leadership Forum’s EC3 tool and the BEAM Estimator, a project of Builders for Climate Action.

Setting carbon limits for building materials purchased by the government won’t be possible until EPDs are required from suppliers. Once that information becomes generally available, regulators will be able to set benchmarks for different product categories and then create targets for suppliers to meet. That, Tilak says, will be the focus for the next five years.

Sasha Stashwick, director of industrial policy in the Natural Resources Defense Council’s Climate & Clean Energy program, called EPDs the foundation of the entire Buy Clean vision, allowing an apples-to-applies comparison of products. Once suppliers are required to include EPDs along with their bids, they will be competing not just on cost but on embodied carbon as well. EPDs also will make it possible to compare foreign and domestic versions of the same material—steel, for example—so producers know where to make investments to bring domestically produced goods up to par in areas where they are lacking.

Requiring suppliers to produce EPDs isn’t the same thing as setting maximum carbon levels in delivered goods. But Stashwick says there is evidence that an EPD requirement by itself makes an impact.

“We actually have a lot of evidence now from the private market that just requiring EPDs alone, like doing nothing else, but just requiring that transparency at time of bid, results in lower emission materials being used in construction projects,” she said in an interview.

She cited a case study from Washington state that concluded an EPD requirement for concrete reduced carbon emissions used in certain buildings by 20%. “There was no carrot or stick,” she said.

Stashwick also thinks that public procurement policies that make carbon emissions part of the bidding process also will lower costs for everyone.

“One of the features of public procurement,” she said, “is that maybe if there is a green premium initially for these de-carbonized products, that procurement drives that premium down because it drives supply up. And what we see are spillover effects into the broader market. Once you are manufacturing low-carbon concrete, let’s say, because you are bidding into a GSA-funded building project or a state-funded transportation project, you’re going to be selling that material into a broader market.”

She continued: “Those materials become more prevalent, cheaper, and more readily available for all construction projects, whether they are publicly funded or not.”

What building codes could do

The principal code-writing organization in the U.S., the International Code Council, is focused on operational carbon, not embodied carbon, with its International Energy Conservation Code. Energy efficiency standards reduce greenhouse gas emissions by lowering heating and cooling bills, but no consideration is given to the embodied carbon in the buildings themselves.

This year, Tilak said, the New Buildings Institute spearheaded an unsuccessful effort to have embodied carbon standards written into the International Building Code, which does not apply to one- and two-family dwellings (GBA has asked for comment from the New Buildings Institute). There is apparently no effort underway to include limits on embodied carbon in the International Residential Code, which does apply to single-family and small multi-family projects.

Lauren Urbanek, deputy director of Clean Buildings in the NRDC’s Climate & Energy Program, said that one of the proposals that has come up in the current code revision cycle is a required disclosure of operational carbon. But it’s been tough sledding.

“Even getting the builders to agree to having just the number on the information panel of the house has been an uphill battle,” she said. “Homebuilders are very hesitant to accept any kind of change when this is a new concept for them, and they don’t want to be ones to explain this to consumers.”

The National Association of Home Builders, a powerful lobby and trade group for residential builders, has long been focused on keeping the initial cost of buying a house low while leaving issues like embodied carbon untouched. “They’ll fight it, but they’ll do it if required,” Urbanek said of low-carbon standards. “Once it’s required, then that’s where it becomes an industry standard. They are not going to be the ones who are out in front on this.”

Urbanek, who has covered the ICC code development process in her posts at the NRDC website, added that some progress might be made through so-called stretch codes at the state level. Voluntary stretch codes are more demanding than a base code and result in higher energy efficiency. New York and Massachusetts are among the states that have adopted them, giving communities there a way of adopting more stringent building requirements when the IRC and IECC are slow to evolve.

California has addressed the emissions problem directly with Assembly Bill 2446. It requires the state’s Air Resources Board to develop by 2025 a means of measuring and then reducing the carbon intensity of materials used in new buildings—including single-family houses.

Together, the Federal Buy Clean initiative, product changes prompted by required EPDs, and optional stretch codes at the state level will in time make low-carbon materials more common. Eventually, Tilak said, carbon limits are likely to be included in residential building codes that affect just about everyone.

“At some point it should be included in the building codes,” he said. “The code is adopted in even the most conservative localities, so that would have a pretty transformational impact.”

Scott Gibson is a contributing writer at GBA and Fine Homebuilding magazine.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

3 Comments

"The White House initiative will make low-carbon building materials more common and less expensive", is a contradiction in the same sentence. As someone who has studied environmental economics through modern times, there is no such thing, either philosophically or practically. The more ANY thing is regulated by the government, the higher that thing costs, in both the short and long term. The least costly and best solutions are driven by the market, not by the government edicts. If building officials want to 'dictate' carbon solutions, simply reducing new home sizes which would solve two problems, affordable homes and carbon reduction. Low interest rates and safety edicts have already doubled the cost of single family homes and will, once again, slow the industry to a grind. The solution is worse than the disease.

Tocker,

There are many examples that disprove your statement that "The more anything is regulated by the government, the higher that thing costs."

Air bags on automobiles were quite expensive before they were mandated by the U.S. government. Once air bags were mandated, the cost per air bag began dropping steeply.

Martin, Airbags isn’t the ‘thing’. Affordable, reliable transportation is the ‘thing’, the requirement for which there was a demand signal. Car prices jumped significantly and significantly more than just the cost of building an airbag. Why? and why was it necessary? It wasn’t, but we are constantly told by DOT how it saves so many lives.

Log in or create an account to post a comment.

Sign up Log in