Dave B plans on installing a range hood in the kitchen of his new house so any evidence of the blackened redfish or pan-seared scallops he might want to cook can be quickly whisked away.

The house will be tightly air sealed, and Dave wonders which of the two Broan kitchen fans he is considering—moving 250 and 390 cubic feet of air per minute respectively—would be best, and whether he should provide a source of makeup air for them.

“I seem to get conflicting information regarding if the unit needs makeup air,” Dave writes in a Q&A post. He wonders whether a clothes dryer also will need some kind of makeup air.

That’s the topic for this Q&A Spotlight.

Even some manufacturers don’t get it

Dave isn’t the only one who’s confused by what he’s heard. Martin Holladay points him toward two articles on this topic that GBA has published in the past (see the “Related Articles” sidebar below). One of them describes the frustrations of a homeowner whose 1,200-cfm range hood was so powerful that it pulled ashes out of the fireplace. She wanted to know what could be done about it.

In poking around for answers, Holladay learned that the manufacturer of the GE Monogram range hood offered no guidance on the topic of makeup air, and in telephone calls to the company, various representatives basically had nothing to offer.

So the problem is not new and not unique.

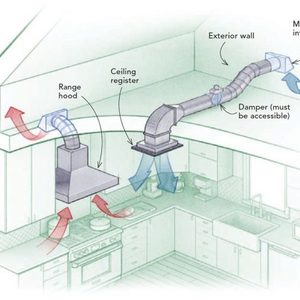

That said, Tom Wheeler notes that range hoods that exhaust less than 400 cfm do not require makeup air, and Dave’s own research suggests that even in a tight house—one with an air leakage rate of 1.5 ach50 or less—no makeup air should be needed for a vent hood with…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

25 Comments

Not surprised by the results but still interesting. When the cook top is on an island the hood definitely needs to be have a 6 inch over-hang on each side due to the cross currents. In addition 36-inches from the cook surface is typically considered the maximum height .

I noticed the minisplit on the wall, pointed right at the range and hood. It would be interesting to see the same setup with the minisplit operating.

Interesting catch Peter.

Alex noted during the testing that they must have the mini-split off when they use the range hood; it's just too disruptive to hood capture when the mini-split is on.

Sorry we did not test with it on, though...

As poor as these results are with a fog machine, the reality with fine particles (the ones most detrimental to health) will be even worse. Proximity of the hood to the cook top is probably the most important criterion. In the one case here you've got no hood, and a register on the ceiling - that would be what, at least 60" away? That register might as well be in the adjacent room for all the difference it will make. The other scenario looks still to be about 36" above the surface; way too high. To even have a chance, the hood should be at most 20" from the cook top. I know manufacturers given recommendations like 30", but that is simply because they still want to sell the range hoods. If they told the truth, and it came down to having a range hood positioned 16-20" above the cook top in order to function properly, most people would just pass on it. Or more likely, they'll buy a different brand that has the decency to lie to them. Aesthetics will trump functionality in the minds of 99% of the population.

Far better would be a fan that could be lowered when needed

Never would have thought of that: task exhaust.

Very clever!

Peter

Instead of ACH50, why not use CFM50? ACH50 is linked to the building volume, range hood flow isn't. From CFM50 you can use the building leakage curve (or better yet a multi-point blower door test) and find out what pressure the hood's (purported) flow will create on the house. BPI publishes depressurization limits*, some as low as -2 Pa, depending on the presence of certain types of natural draft combustion appliances. They don't mention fireplaces/woodstoves, though, but I believe they are also in the single-digit range.

Without any fireplaces/etc it's a matter of the depressurization you want to limit to, and how that may affect the exhaust hood's performance (flow). They're just fans, and the flow of any fan depends on the resistance of the ductwork it's connected to - and the house counts as ductwork (the "return trunk", if you will). Compared to everything else in a high-performance house, where every last detail is carefully thought through, range hoods are very hard to handle. There are just too many variables to reasonably deal with: exhaust ductwork resistance, house/makeup side resistance, and how the fan responds (ie, the fan curve - but that's not published for most range hoods), not to mention hood capture efficiency, positioning, recommended flow, etc. Which is a bit of a shame, considering how important they are to the air quality in a home.

*see "Technical Standards for the Building Analyst Professional", CAZ Depressurization Limits table on page 14. Not explicitly for this purpose, but I think still a valid reference for depressurization limits.

Good points Cramer.

Latest blower door test of my home was around 1100 cfm50; pretty sure Alex said his home was 600 cfm50.

In my home, I have an atmospherically-vented fuel oil boiler, which I have done a worst-case depressurization test on (see: https://www.greenbuildingadvisor.com/article/combustion-safety-and-the-worst-case-depressurization-test).

For Alex's home, with no real combustion appliances, I can't think of any problems with intermittent pressure of -11 Pa during kitchen range hood use.

Peter

As pointed out in the text, the experimental setup doesn't much mimic real-life cooking fumes. It's not even close. The splatter and smoke coming off the cooktop is typically rising straight up, with very little horizontal velocity, with toroidal convective looping induced around the rising column of hotter gases.

Spraying fog from the side at 5-10 feet per second is just silly- there isn't a lot meaningful information to be gathered there. Running the experiment by heating something in a pan in on the cooktop to create the fog/smoke would be more relevant, since it would introduce the same convective forces in magnitude & direction as when cooking.

The reason I moved the fogger 5 feet away from the center of the cooktop and fogged only a 5 second burst was to have the "slug" of fog drift and slow as it crossed the cooktop. The fog's velocity was not constant as you imply.

Sorry you feel that no meaningful information was gathered; I still think that we got useful info from the test. I certainly agree that the test could be improved and made more meaningful. Many of my wingnut tests improve over time as critiques are offered. Thanks for yours.

Peter

>"...Sorry you feel that no meaningful information was gathered.."

I don't feel that, nor is that what I wrote. Rather:

"..there isn't a lot meaningful information to be gathered there."

"...isn't a lot..." isn't the same as "...no..." or "none".

At the risk of being repetitive...

The experiment as-performed doesn't even remotely simulate the conditions of the actual intended use of the exhaust fan, so it doesn't really tell us much about it's performance relative to that use. As pointed out in the conclusions, "Air flow is complicated." Starting off with an unrealistic lateral flow induced by a point source injection of fog relatively far from the fan and having zero cooktop heat induced convection doesn't demonstrate how air flows in a real cooking situation (and I suspect it differs by quite a bit.)

I was thinking along the same lines as Dana. Besides the horizontal velocity, you don't have the rising column of heated air and smoke that naturally comes off of the stove and pan. That's going to deliver the smoke far more efficiently towards the hood and somewhat encapsulate it with entrained air around the margins of the rising column.

I haven't got time to test it myself right now, but the juice that makes the smoke would probably make perfectly good smoke if placed in a hot pan on the stove. If you added a measured amount, you could probably get a pretty well-controlled shot of smoke that would be entrained in the heated air column rising from the pan. Seems like that would be more representative of real-world behavior.

Great idea Peter.

I also don't have the time right now to do another round of tests but would love to try your approach-thanks.

Peter

I'd be curious to see the amount of grease that builds up on that light fixture after a few dinners. I must admit I've never seen a ceiling mounted grill used as the range exhaust intake. I'm sure it's designed to be one, I've just never seen that before.

It reminds me of a lecture I attended 30 years ago on the evolution of the fireplace and they showed a slide of a large banquet hall that had a central fire pit and a hole in the roof overhead.(it was from the 12th century I believe). The next slide showed how the invention and inclusion of a chimney and moving the fire to an exterior wall improved the indoor air quality (maybe 13th century).

Did you design/build this kitchen with this intake grill or did the house come with it?

Interesting Scott. When you move a fireplace from a central location to an exterior one, at least in cold weather, you lose quite a bit of stack effect. Lots of gable-end fireplaces have draw problems while the old center hearth ones don't.

To say that I designed our kitchen exhaust system is definitely an overstatement. I admit I treated it pretty much like a bath exhaust fan and it was what we could afford. But it seems to do the job.

In the videos of my kitchen exhaust, particularly near the end, if you look closely or zoom in, you can see the fog rolling off the bowl of the light and into the grille of the exhaust. We really don't clean that light much more than once a year. I suspect that having both the light and the exhaust up at the ceiling level means less airborne grease actually makes it up to either.

Peter

Scott,

I think the use of chimneys had far more effect on IAQ than relocating the fireplace to the outside walls. Center fireplaces with chimneys work just fine, and you capture the mass effect of all of the masonry inside the structure. As Peter pointed out, gable end chimneys often suffer from draw problems. I've also seen them being far more prone to downdrafting when the fire's not lit.

That said, a stove and hood located on a wall rather than in the middle of the room are going to perform far better than an island location because you don't have the cross-drafts. Thermal mass is not a factor. Neither is backdrafting because most have automatic dampers.

An observation; I have a heat pump in the kitchen just like Alex. Great location in terms of heat flow, but I now warn all my clients to beware of odors being trapped in the filters when they are located so close to the cooking element. I learned this lesson when my wife recently burned some turkey bacon while we were chatting with friends outside.

The heat pumps were running at about 300 cfm churning out cool air and ended up sucking in the odors. This took days to clean out by washing every surface we could reach in the unit and soaking the filters in vinegar.

On high speed these units can move over 500 cfm which doesn't take long to clog things up and cause trouble.

When it comes to fans, you need to always test under worst-case depressurization. It also matters on whether you have a gas water heater and/or whole house furnace naturally vented. I am afraid that readers will not consider those as "appliances" and only consider a gas range.

What are the expectations of the fan? Remove the heat, smells, etc. BPI recommends a minimum of 150 cfm for hood fans. Where is the makeup air coming from? Assuming there is an attic that is outside the envelope, probably a lot from the attic and the top plate area or the basement rim joists.

I think the question is two-fold: Is there enough makeup air? And are you OK with where that makeup air is coming from?

GE Monogram does sells a make-up air kit just for this reason!

https://www.geapplianceparts.com/store/parts/spec/JXMUA6

This brings up two questions for me: The first is how this changes with gas ranges (which both require air for combustion and MUST evacuate exhaust gases) and how range hoods compare to downdraft vents. Downdrafts are much closer to the cooktop, but they pull air to the side (like the smoke machine) when the grease, smoke, etc. is going up.

These are gross generalities, of course. There are ranges and there are ranges, and great variability in cfm among downdrafts.

Mike.

"There are ranges and there are ranges"

And with the differences come different consequences: https://www.greenbuildingadvisor.com/article/the-hazards-of-cooking-with-gas

This was a great article: lots of angles covering the vagaries of kitchen range exhaust. I would add to this the number of people in the home and the usage rate of the range when requiring heavier exhaust: multiple gas burners on with frying action on one or more. THAT is when you need to put the coals to it!

In my home(1.0 ach 50) our Whirlpool exhaust looks nearly identical to the farm kitchen in this article except it is a 4 speed and top rate is over 700 cfm. My wife and I are only occupants and we rarely use the top speed, but it is THERE when we need it and WE open the window. It happens rarely though, usually we just have it at the 2nd level speed but still open the window. Our year is spent with 6 mo in winter with the air exchanger bringing in fresh air at around 90 cfm; 4 mo with no air exchanger on in swing months and two months or less with the AC on in the summer and exchanger again bringing in fresh air. With the small amount of total occupancy time with the kitchen fan on and the windows letting in UNconditioned air we just ignore the TINY extra energy cost. Bigger fish to fry. Propane used for in floor heating, HW heating, and range burners which sit 33" below the hood. We are short people but that height is still necessary to prevent visual and psychological interference of the hood front with our cooking needs.

As opposed to others taking such exception to Peter's admittedly subjective smoke test I felt it offers the following:

-- "hey, look that smoke is billowing up near the ceiling and it is not coming back around into the intake! . . . a LOT of it just passes by towards the hallway in the distance. " That shows that even at high flow the draw from any distance at all is minimal. Thus reinforcing Ramsay in that 1000's of cfm is really required to EFFECTIVELY draw air from any distance at all.

-- I agree with Trevor too! It is simply not practical (or wife-friendly) to build and install an effective low cfm(less than 1000 cfm) kitchen fan hood. It would be too low to be able to see the food you are cooking and require really big filters-- instead of the 10 x 12" thingee in MY hood!

-- The videos were great because the apparent failure of the hood to draw under nearly any condition allows all who viewed them to LEARN; it will inspire others who want to go the next step how NOT to run the smoke generator and how to make THEIR hood adjustable: use cardboard walls taped around the edges of the hood which could extend down towards the range. By adjusting the depth of extension one could again LEARN just how much enclosure with what cfm is truly effective. . . instead of guessing.

-- motivation for others to go the next step in smoke testing. Something far more worthwhile than calculations. . .

Nice job Peter.

I don't mean to single you out, since this language is pretty pervasive in discussing homes, but can we, as a community, come up with some better ways to say what we mean than the phrase "wife-friendly"?

If we want to say that the rangehood would be too low and unpleasant to cook with, we can say that directly.

If we mean something is ugly, we can just say that it's ugly.

Folks of all genders and relationship statuses can care about aesthetics, pleasant cooking experiences, and whatever other things we use "wife-friendly" to reference.

The "wife-friendly" language often reinforces a trope that the husband is practical but aesthetically clueless, while the wife is impractical by aesthetically minded. This doesn't do anyone any favors. (In addition to the fact that plenty of folks who are neither husbands nor wives live in homes).

Thanks for expanding on my original question, it gives me more to think about. Although the wingnut testing isn't the most accurate compared to real life usage, it was still interesting to see. My thoughts are to go with a slightly larger fan 390cfm and when on high crack a window if needed. I think I would rather have the larger speed available, than not. I wonder in a tight house 1.5ach or less how large a fan you could run before it stop meeting it's expected flow rate, and if there is any extra stress on the motor? Thanks again Scott and Peter for adding to the neverending kitchen fan dilemma.

Once I finish my house, I'll let you know if I made the right decision.

Some suggestions:

-- opening a window won't much change the local airflow streamlines but changing the physical configuration nearest the intake WILL: My suction area on my hood is NOT a simple rectangle but a rectangular slot 3/4" wide-- 16" x 11" rectangular opening. I can EASILY see fumes from cooking rushing up into the slot when it is on high-- 750 cfm

-- the empirical testing you are doing is the best form of analysis. You do not require a mathematical model; it is real life.

-- the centrifugal fans used in this application have nearly no effect on motor amp draw regardless of air moved. It is, in fact, reasonable to believe that amp draw is reduced somewhat as the air intake is throttled down.

-- a true test of the phenomenon you describe(throttling a fan) could easily be done. Take a simple centrifugal fan mount it on the interface of a 6 ft cube box (cardboard wood even work!) with an an opening with a damper on it. Mount a low pressure sensor(able to read 0 to 0.4 " w.g.) between box inside and outside. Traverse a hot wire anemometer or similar velocity meter across the fan outlet. . .

Experiment: run the variable speed fan up in RPM and measure output in cfm(velocity meter traverse, 10 points across the flow) and record the pressure differential from the sensor. If desired, place an amp-probe on the fan motor and record amp draw also as you record 5 settings from zero to full RPM. Plot the pressure vs Fan speed or measured air flow.

You do not need to do a WHOLE house experiment is the point.

Log in or become a member to post a comment.

Sign up Log in