Image Credit: RenewAbility Energy

Over the past few weeks I’ve written about various strategies to produce hot water efficiently. We’ve seen that tankless water heaters are more efficient than storage water heaters (though are not without their drawbacks), and we’ve learned that heat-pump water heaters produce two to three times as much heat per unit of electricity consumed as electric water heaters that rely on electric resistance heat.

But the unfortunate reality is that even with the most efficient methods of generating hot water, we still lose the vast majority of that heat down the drain. Domestic hot water is a once-through product. I’ve seen estimates that 90% of the heat in hot water is lost down the drain. Dan Cautley, an energy engineer with the Energy Center of Wisconsin, says that drain water “may be one of our largest untapped resources.”

It turns out that we can do something about that. In the right application, drainline heat exchangers allow a significant portion of the heat from hot water going down the drain to be recovered.

How a drainline heat exchanger works

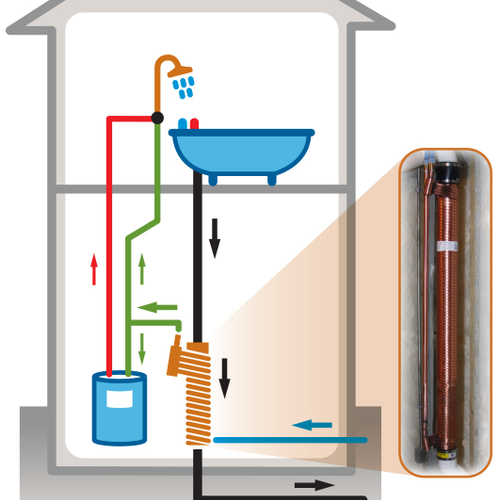

The process is pretty simple. A special section of copper drainpipe is installed beneath a shower (typically the largest hot water use in a home) or other hot wastewater source. This section of drainpipe has smaller-diameter copper piping wrapped tightly around it. The cold-water supply pipe leading into the water heater is diverted so that it flows through the small-diameter copper pipe.

When hot water is being pulled from the water heater to supply the shower, the water going into the water heater is preheated by the wastewater going down the shower drain. If it’s a tankless — rather than storage — water heater, the incoming water temperature will be higher, so less energy will be required to get it up to the needed delivery temperature — thus saving energy (though the tankless water heater has to be thermostatically controlled and, thus, able to deal with inlet water of varying temperature).

The man who invented the drainwater heater exchanger, Carmine Vasile, called the product a GFX, for “gravity-film exchange,” recognizing that water going down a vertical pipe forms a film that clings to the inner walls of the pipe where the heat can effectively be transferred through the copper to the supply water.

Several versions

There are four manufacturers of drainline heat exchangers that I’m aware of: Vasile’s original company, WaterFilm Energy of Medford, New York, and three Canadian companies: EcoInnovation Technologies of St-Louis-de-Gonzague, Quebec, which makes the Eco-GFX; ReTherm Energy Systems of Summerside, Prince Edward Island; and RenewAbility Energy of Kitchener, Ontario, which makes the Power-Pipe.

Most of these have a single 1/2-inch copper pipe coiled around a length (typically three to five feet) of 2-inch or 3-inch diameter drain pipe.

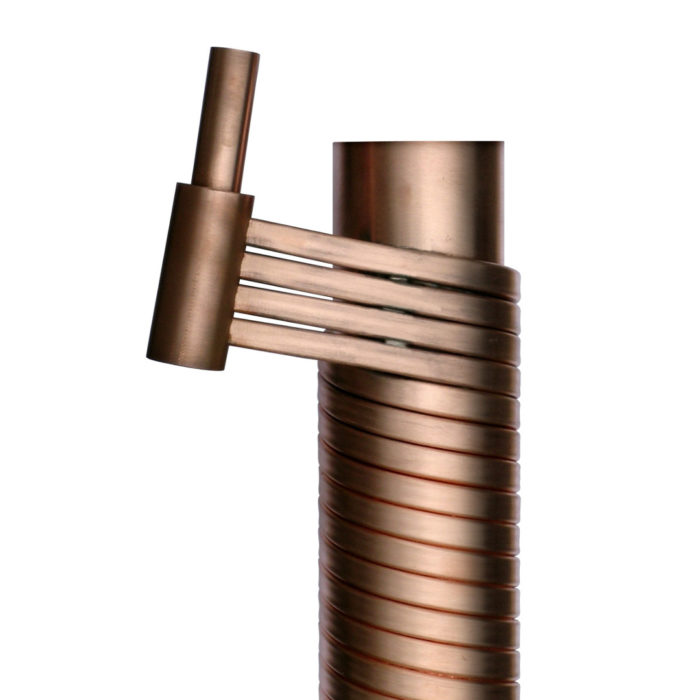

The Power-Pipe is a little different than the others. It has a header that splits the supply pipe into four smaller, square-cross-section pipes that provide more surface area for heat transfer.

Most of these manufacturers offer various lengths and diameters of drainline and can accommodate different supply pipe diameters.

No moving parts, nothing to wear out

The beauty of drainline heat exchangers is that there are no moving parts, nothing the wear out, and nothing to get clogged. Only fresh water goes through the small-diameter supply pipes; any hair or other materials pass through a standard, smooth drain pipe.

Maximizing recovery efficiency

According to an article in Environmental Building News, heat recovery efficiency can be as high as 60% — which can effectively double the water heating efficiency. Just how much benefit a drainline heat exchanger will provide will depend on usage patterns and how the plumbing in a house is configured.

For the highest rate of heat recovery, it is ideal if all household members use the same shower (or have several showers that drain through the same vertical length of drainline). It helps if the water heater is in a basement (or beneath the showers and close by, so that there is minimal length of supply piping from the heat exchanger to the water heater).

These systems are even more cost-effective in schools and commercial buildings that use a lot of hot water: school shower facilities, health clubs, laundromats, commercial kitchens, etc.

Cost

Installed in a new home, drainline heat exchangers typically cost $500 to $800 (including installation). Costs in multifamily buildings should be lower. In some states there are rebates available for such systems.

Alex is founder of BuildingGreen, Inc. and executive editor of Environmental Building News. He also recently created the Resilient Design Institute. To keep up with Alex’s latest articles and musings, you can sign up for his Twitter feed.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

25 Comments

No recovery from batch users

might be worth pointing out that there is no (well, very little) recovery from batch users like a dishwasher or washing machine; in that case it drains first, then refills, so all you pick up is maybe some residual heat in the drain pipe, rather than a constant heat exchange.

But an efficient DW probably uses about 1 minute's worth of shower hot water, so maybe no big deal there.

A couple of the options above recommend different plumbing, i.e. not just feeding the hot water tank. The RenewAbility docs say to "plumb all freshwater to the home through the Power-Pipe except the kitchen sink" - I can't quite wrap my head around that, why would I want to preheat the water in my toilet tanks, for example?

Response to Eric Sandeen

Eric,

You wrote, "there is no (well, very little) recovery from batch users like a dishwasher or washing machine."

To which I might add: or baths.

Longevity?

I wonder how the efficiency of these units holds up after a few years. Almost all drain lines eventually get coated with soap scum etc. over time...and fresh water lines can become scaled if your water has any minerals in it... Seems like this could drastically reduce the heat exchange.

$500 to $800????

I can't imagine how this would make sense for the average household.

What's the cost?

Alex,

I think that the prices you quoted are for materials only -- not the installed cost. A quick Google search shows:

Power-Pipe 3 in. x 48 in. Drain Water Heat Recovery Unit - $649

Power-Pipe Drain Water Heat Recovery - 4" Pipe x 48" - $975

Energy Savings Calculator

The Canadians seem very big on these things. Here's a calculator done by The Centre for Energy Advancement through Technological Innovation (CEATI) :

http://www.ceati.com/calculator/

I agree though the materials are pretty expensive - pity about all that copper I guess.

Pricing

The Power-Pipe product is the most complex of these systems, so I'm guessing that the others are less expensive. But I didn't track down detailed pricing.

Supply line temperature

would seem to be a variable affecting efficiency and ROI. The colder the supply, the more valuable the heat recovery.

Another off thought, here in

Another off thought, here in a cold climate my warm drain water is heating my home on it's way out of standard drain line. I have check this, and by the time the water exits it has left much of the added heat in my home. So the basic drain already is doing what these devices do, which is to harvest some energy. Still, neat idea.

A couple more thoughts

The colder the inlet water, the more effective one of these will be - hence their popularity in Canada.

Somewhere I recall reading that these require a 4+ foot vertical section of drain line, so they can't be fitted in single story slab on grade homes. Is this still true?

In a related vein, heat pump water heaters are highly effective in the sunny south, but the use case is weakened in cold climates owing to longer recovery times and "theft" of space heating energy. I wonder if a HPWH could be somehow configured to extract heat from departing drain water?

Along the lines of what AJ described, could a section of copper drain line be finned in a manner similar to baseboard radiators so as to heat surrounding air? Another variant might be to wrap a cowling around a finned drain line and operate a small fan whenever the drain line warms to a predetermined temperature, perhaps 80 or so. That would deal with the batch issue raised earlier.

Using recovered heat for a HPWH

Curt,

I haven't done any calculations, but it's an interesting idea--simply dumping that waste heat into the basement air, though I'm sure the heat transfer wouldn't be as efficient as water-to-water exchange. I believe the GE GeoSpring HPWH has a fitting so that air can be ducted to it--enabling you to pull warmed air from some other location.

As far as I know, you are correct about these drainline heat exchangers requiring a vertical drainpipe run, so would not work to capture heat from a first-floor shower in a slab-on-grade house.

Preheating the cold water makes sense when you think about it

The manufacturer recommends: "plumb all freshwater to the home through the Power-Pipe except the kitchen sink". Meaning both the hot and cold should run thru it.

This is actually pretty smart of them, and I think the Power-Pipe folks were the first to think of it.

When you think of all the ways that the home uses water, the shower is the only situation where you can recover heat from the exiting drain water. When you're showering, that's a fine time for prewarmed water to travel in the cold pipe. It makes you use less hot water.

At all other times you won't get significant unwanted prewarmed water in your cold pipes. Just think about it. When a toilet flushes, that's cold water, so it won't warm up the replacement water.

If both hot and cold are piped thru the Power Pipe, you're giving it about twice as much cold water volume during the shower. A counterflow heat exchanger like this will extract significantly more heat from the exiting stream if the incoming flow is doubled.

Now for my question, why not the kitchen sink?

Response to Kevin Dickson

Kevin,

Q. "Why not the kitchen sink?"

A. Because on a hot summer afternoon, when you want a cold glass of water to quench your thirst, you don't want warm water coming out of the kitchen tap just because Junior is taking a shower.

Frankly, if I'm brushing my teeth, I don't want warm water out of the cold tap of my bathroom sink either.

Another Response to Kevin Dickson

"If both hot and cold are piped thru the Power Pipe, you're giving it about twice as much cold water volume during the shower."

Sure, but you only want that heat coming out at a few select places - like the inlet to the heater or the outlet of the shower. Anything else might be picking up more heat, but then wasting it at the endpoint, no?

I can see piping it to both the shower cold tap and the hot water inlet, but I still don't see the point of sending it to every other cold water destination.

$1000 snakeoil contraption.

$1000 snakeoil contraption. Prove to me It's 100 year worth. To save water hot or cold take a military shower.

Response to Eric Sandeen

"I can see piping it to both the shower cold tap and the hot water inlet, but I still don't see the point of sending it to every other cold water destination."

You're right, that would be the best way to pipe the thing. Marc Rosenbaum's experience in another article explains how it would be fairly easy: https://www.greenbuildingadvisor.com/blogs/dept/guest-blogs/getting-hot-water-part-3

You have to have home-run piping, at least to the showers.

Since home run piping is still so rare, I'm speculating that the manufacturer's directions come from not wanting to get into the details of doing it exactly right.

The longevity issues & others

It's a piece of copper drain, which has a very long working life. At shower/bath dilution factors, the fact that they are rinsed regularly with surfactants (shampoo) it's crud-film buildup that would impede heat transfer is extremely slow compared to say, a kitchen sink where copious amounts of greasy-oily stuff may be dumped with regularity. Somewhere I'd read that a DOE estimate (done in the '80s or early '90s) was that the heat transfer degradation to 75% of the original day-1 performance would take 4-5 decades.

Payback is much sooner than that, and relatively short years if heating with high-priced electricity or high-priced propane (not so much with low-priced gas.) An net-present value type financial analysis using (comparatively cheap) 7 cent electricity at various use-volumes and different models can be found here:

http://www.renewability.com/uploads/documents/en/analysis_dwhr_minnesota.pdf

But the payoff is also in apparent capacity and water heater recovery times (if tank heater is used). In moderate water temp areas it can turn a standalone gas-fired tank heater into "endless shower" type capacity.

Since most models are only in the 50% heat return range or less, the amount of pre-warming in cold-water areas only takes it up to about room temp, but it can hit tepid-water warmth when the incoming water is 60F or higher. You're essentially splitting the difference between ~100-105F drainwater and the incoming water temp- if you have 35F incoming water and 105F (steaming hot shower) going down the drain, the pre-warmed "cold" side is 70F. But if your incoming water is 65F it'll bump into the 80s. It's not a disaster to have it feed the entire cold water distribution to the house, if that simplifies plumbing it in, otherwise having it just feed the cold lines the bathrooms + the input to the HW heater works (which is how I have it set up at my house with a 4' x 4" PowerPipe.) At my central MA incoming water temps it's never exactly "warm" water, it's roughly room-temperature water, which isn't much of an issue for brushing teeth, eh? That's about the same temp that the cold distribution lines stagnate to anyway- would you really waste a couple gallons of water just to brush your teeth with the coldest-possible water in summer (with or without a drainwater heat recovery?)

Keep it simple, just heat the cold water for the shower

To keep the installation simple, especially in cases where the shower is not near the hot water tank, why not just heat the cold water supply with the waste heat directly before it goes into the shower? A penny saved is a penny earned... the hotter your cold water, the less hot water you will use in the shower.

On another note - has anyone successfully made one of these from flexible 3/8" copper supply line (ie water cooler supply) wrapped around a copper drain? could use multiple parallel lines to make up for required bulk flow.

Looks like 10 feet of aluminum 3' diameter drain pipe is about $130. Run the shower supply cold water PEX in contact and underneath it ya think?

PEX isn't nearly as good a heat conductor as copper or aluminum. Still, it wouldn't hurt to do that.

Free bathtub heat exchanger vs 40 yr payback.

My kids bathroom has a combo bathtub/shower. In the winter, I have the kids close the drain when they shower, and we leave the warm water in the bathtub overnight. By the next morning when we drain the tub, that water is plenty cold, so we have extracted all the heat plus some humidity. The only downside of this approach is some additional "ring around the bathtub". This approach only extracts heat in the winter, but we take cooler showers in the summer, so there's less heat to be gained in the summer.

The CEATI link gave me an annual savings of $23 with gas, which is overstated since that was for Canadian ground water temps. But even with that overstated savings, that would be a payback period of over 40 years ($900/$23 per yr)

I agree with Gordon Taylor and AJ: For families using natural gas in most parts of the United States, the ROI for this device doesn't make sense.

I see the savings in reducing the energy used by the water heater. That's your carbon foot print and that's your power bill. For this reason I can't see warming any water except what enters the water heater.

I'm a bit skeptical about efficiency clams. The heat exchanger pipe is only a 3~4 feet long and runs vertical. That means the warm waste water passes through it in a second. Is the heat transmission coefficients so good that 50% of its energy can be extracted in less than a second?

>"I see the savings in reducing the energy used by the water heater. That's your carbon foot print and that's your power bill. For this reason I can't see warming any water except what enters the water heater."

Pre-heating the water on the cold side of the shower mixer reduces the amount of hot water drawn from the water heater itself, lowering the total energy used for taking a shower by about 15% as compared to only pre-heating the water entering the water heater.

>"I'm a bit skeptical about efficiency clams. The heat exchanger pipe is only a 3~4 feet long and runs vertical. That means the warm waste water passes through it in a second. Is the heat transmission coefficients so good that 50% of its energy can be extracted in less than a second?"

Yes, they are really that effective. The thermal conductivity of copper is quite high compared to water. In a gravity film heat exchanger the water on the drain side spreads out into a very thin film clinging to the inside surface of the copper drain pipe, which improves the heat transfer geometrically due to the much higher surface area.

Flow rate affects how thick that thin film of water is, and how cold the incoming water is. At slower flow rates the water film is thinner, and the heat recovery effectiveness even higher. At higher flow rates the water film is thicker, for somewhat lower heat recovery effectiveness.

The published efficiency numbers are at the Natural Resources Canada test protocol flow rate of ~2.5 gpm and an incoming water temp of ~40F, 104F at the shower head, with the output of the heat exchanger going to both the shower mixer and the water heater, not just the water heater. The NRCan listed devices are tested and rated by third party testing houses (not the manufacturer) using the NRCan protocol.

The current best-in-class is EcoDrain's V1000 series, which delivers 55% recovery for a 3" x 54" long version, 58.9% recovery for a 4" x 54" version.

https://ecodrain.com/en/products/VT1000/

The former efficiency leading Renewability Powerpipe R-series is still pretty good, delivering 50.1% recovery for a 3" x 54" and 51.0% for a 4" x 54".

http://renewability.com/wp-content/uploads/2017/07/20170913-Power-Pipe-Spec-Sheet.pdf

I have to install one of these in a new build. I doubt the numbers they give. The plumbing to the showers will travel across the ceiling in a drop for about 15 feet in one case and 25 to the other before dropping down the stack into the powerpipe. We are going to try and fit the 96 inch model. I am concerned as well about the longevity of the twisted coil and how long in will last. Semi copper was banned and soft copper as when bent the outer wall is thinned. So id the 10 year warranty because of that and expected wear out time and pinholes will occur..as well as scum forms up in the pipe. As this is a 9 bath house and the master baths are far from the HWT its simply not practical to run to the tank so the heated water will simply feed the colds of the showers. I doubt the payback time listed and I doubt it will ever pay for itself but am forced to instal by a energy advisor..more green smoke and mirrors

So wouldn't it make sense to insulate all drainlines leading to the exchanger and the exchanger itself for maximum performance. All these articles show shiny exposed copper, flashy for sure..

I'm just not sold. 9 bath house seeking efficiency. that's some green smoke!

Log in or create an account to post a comment.

Sign up Log in