Slab-on-grade perimeter insulation, or slab-edge insulation, is one of the most commonly abused construction details. When installed properly, this insulation offers significant improvements in energy efficiency and, perhaps more importantly, occupant comfort. Unfortunately, getting the details of this insulation right can be complicated. Architects and engineers struggle to find easier methods, but far too often the details they come up with are completely ineffective.

How not to install slab-edge insulation

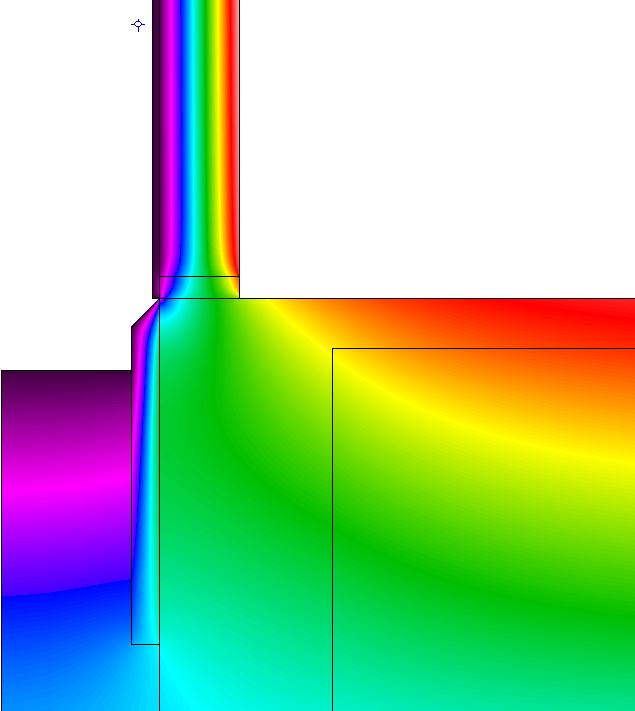

|

|

|

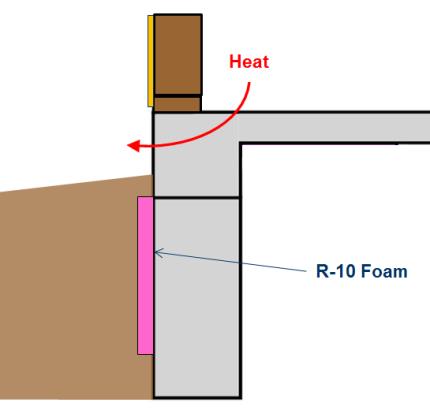

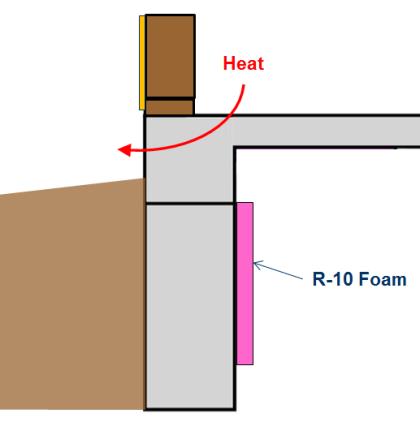

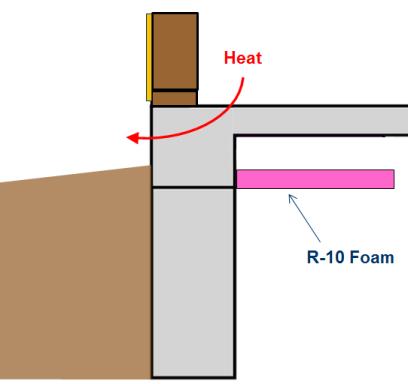

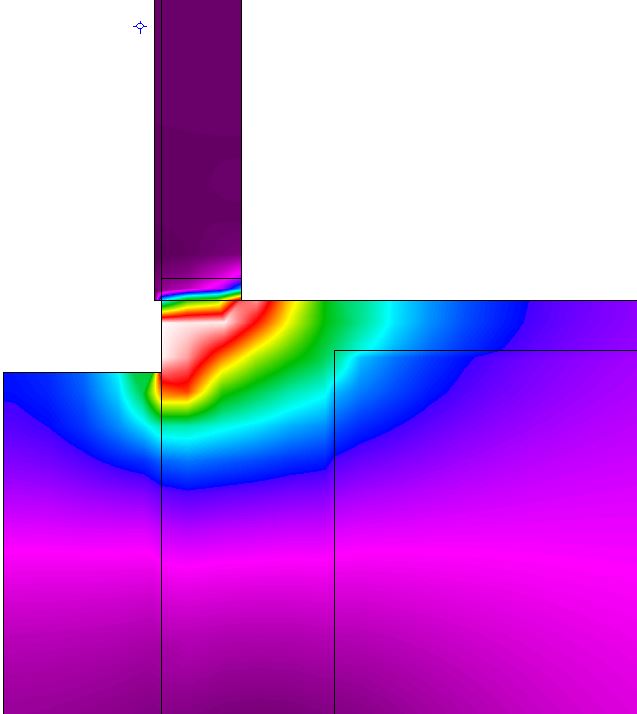

The installation process for the details above is easy, which is probably why they are used so often. They don’t require protection of the insulation or exotic concrete forms. The problem is that they are utterly useless—you can easily see where wintertime heat loss will occur in the drawings. These three methods provide no measureable insulating value. When energy raters and inspectors see applications like this, they should rate it the same as the slab having no insulation at all.

What the building code says

Section N1102.2.10 in the 2018 International Residential Code (IRC) and section C402.2.5 of the 2018 International Building Code (IBC) contain specific requirements governing the installation of slab-edge insulation. Here is what it says:

N1102.2.10 (R402.2.10) Slab-on-grade floors.

Slab-on-grade floors with a floor surface less than 12 inches (305 mm) below grade shall be insulated in accordance with Table N1102.1.2. The Insulation shall extend downward from the top of the slab on the outside or inside of the foundation wall. Insulation located below grade shall be extended the distance provided in Table N1102.1.2 by any combination of vertical insulation, insulation extending under the slab or insulation extending out from the building. Insulation extending away from the building shall be protected by pavement or by not less than 10 inches (254 mm) of soil. The top edge of the insulation between the exterior wall and the edge of the interior slab shall be permitted to be cut at a 45-degree (0.79 rad) angle away from the exterior wall. Slab-edge insulation is not required in jurisdictions designated by the building official as having a very heavy termite infestation.

This language has remained unchanged since the 2006 codes.

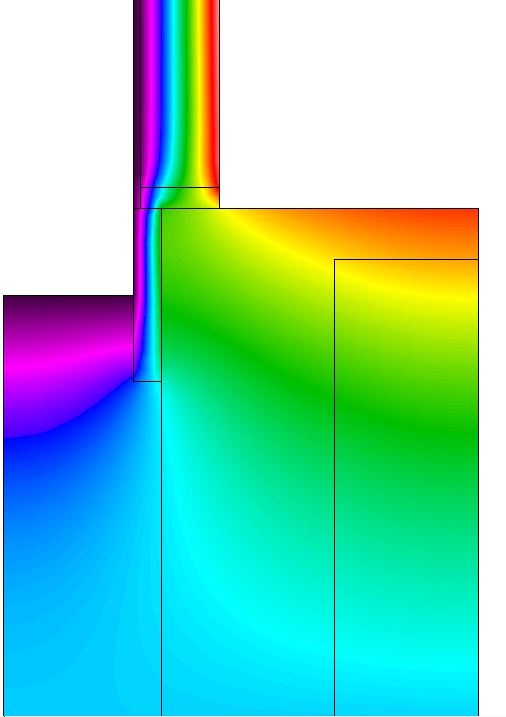

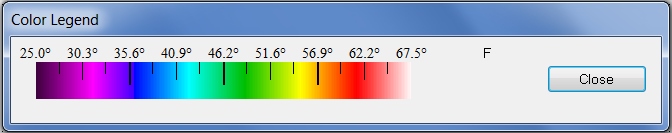

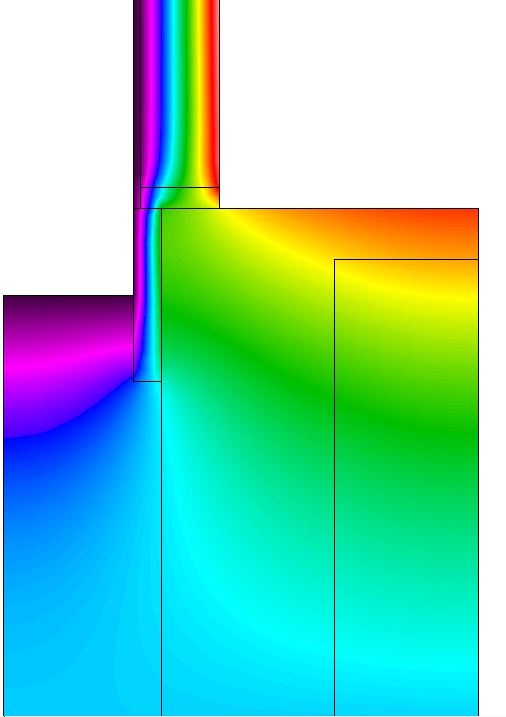

Temperature cross-section

The image below is a cross-section of an uninsulated slab edge with a 2×6 wall with R-19 cavity insulation and the bottom plate installed flush with the edge of the slab (more on this to come). The colors represent different temperatures, as you can see in the legend above. These images were produced using software from Lawrence Berkeley National Labs called Therm. It calculates steady-state heat transfer and the resulting temperature profile of an assembly using finite element analysis.

At a glance, this demonstrates the importance of proper slab-edge insulation. It is often mistakenly assumed that material as solid and thick as concrete must provide excellent protection against the elements; not where heat flow is concerned. It takes an entire foot (12 inches) of solid concrete to achieve only R-1. Soil is only slightly better. In contrast, solid wood is about R-1 per inch.

There is a path of only six inches from the inside, bottom of the wall through the concrete. This yields an R-value of only 0.5. Contrast this with the R-19 insulation in the 2×6 wall. Such a concentrated area of heat loss is what creates the major comfort issue for owners of slab-on-grade buildings.

It’s not hard to see why the energy code considers this problem area of the envelope such a high priority. Yet simply meeting the IRC requirements may not be the most cost-effective path to an efficient slab.

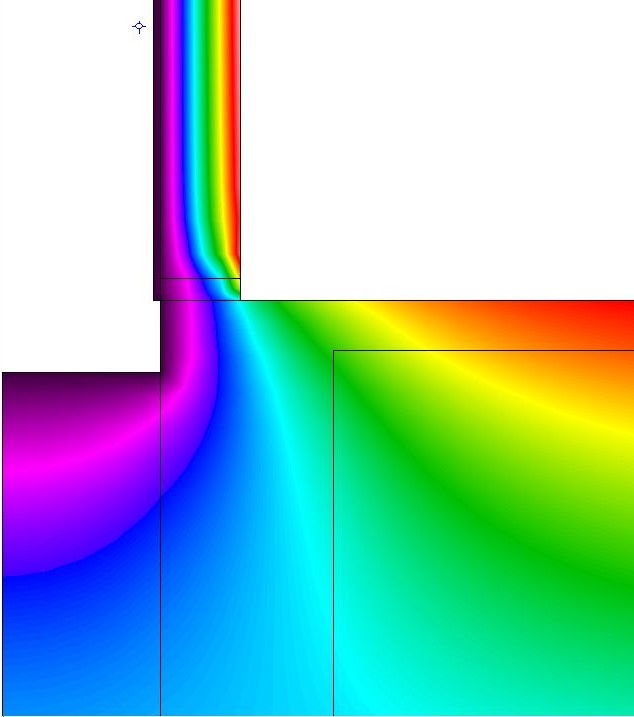

In Climate Zone 4 (CZ-4), the IRC prescribes R-10 slab-edge insulation to a depth of 2 feet (measured from the top of the slab down). The IRC also allows you to chamfer the top edge of the foam up to 45° to provide drainage, although this decreases the effectiveness somewhat. The temperature just inside the wall is now 54°F, a bit more comfortable.

A simpler alternative

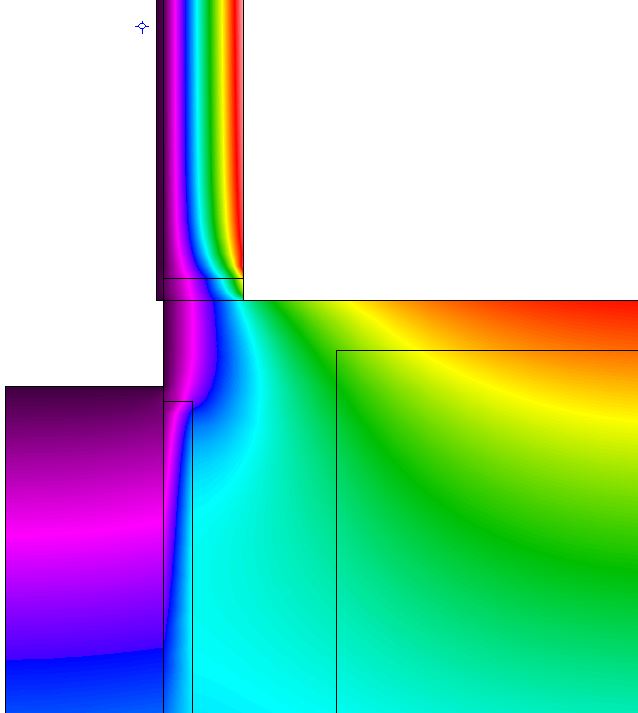

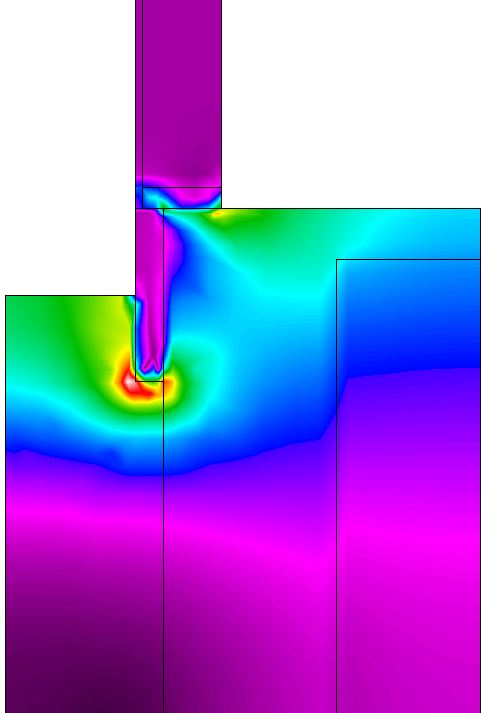

If the builder uses the Performance or ERI path to IRC compliance rather than the prescribed code, is there a simpler alternative that might offer acceptable results? The next example shows insulation extended just 12 inches down from the top of the slab.

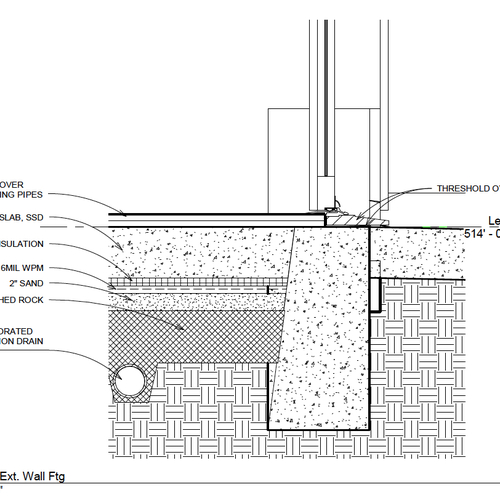

If you use 2x10s to form the slab, the forms can be elevated and the insulation can simply be placed on the form prior to placing the concrete. No additional insulation is placed in the trench footing. Two-inch foam is quite strong and will hold back the weight of the concrete without adding taller forms.

The image above also shows the 2×6 wall cantilevered to flush the face of the sheathing with the face of the foam thereby avoiding the chamfer. One can see that just twelve inches of foam provides a result that is superior to the code prescribed method with chamfered foam. Now the inside corner is 57°F, the best performance yet. The software that many energy raters use confirms this result. If one compares the prescribed two feet of foam (placed like the image above) with just one foot in CZ-4, the results are within 96%. Ask your rater to try it on your plans.

Another detail that is often overlooked is that the entire building envelope must be insulated. This includes the separation between the house and any attached garage (whether the garage is insulated or not). This necessitates using a separate pour for the garage with slab-edge insulation placed in between. If both the interior slab and the garage slab are to bear on the footing, the intervening foam will hit the top of the footing. This is no problem when using just one foot of foam. The garage floor can also be placed a couple of inches lower.

Energy cost impact

So what is the effect of these various methods on energy efficiency? REM/Design software was used to simulate annual energy use for a 1,835 square-foot slab-on-grade rancher with an attached two-car garage in Kansas City (CZ-4). The only impact is to heating costs. The results are tabulated below. Four feet of foam has been included to demonstrate the reduced impact with depth. The upcoming 2021 IRC may prescribe 4 feet in CZ-4. With the results from both REM/Design and Therm in apparent agreement, these are significant numbers that justify the additional cost of adding slab-edge insulation as long as it can be accomplished cost-effectively. But again, the most profound improvement is comfort. So 1 foot of slab-edge would save $137/year. But more importantly, this savings represents 40% of total heating costs which yields a substantial increase in comfort.

With the results from both REM/Design and Therm in apparent agreement, these are significant numbers that justify the additional cost of adding slab-edge insulation as long as it can be accomplished cost-effectively. But again, the most profound improvement is comfort. So 1 foot of slab-edge would save $137/year. But more importantly, this savings represents 40% of total heating costs which yields a substantial increase in comfort.

Exterior insulation protection

It should be clear that one cannot simply expose foam insulation to the rigors it is likely to encounter like ultra-violet radiation from the sun and the assault from motorized weed trimmers. Here’s what the IRC has to say about protecting slab-edge insulation:

N1101.11.1 Protection of exposed foundation insulation.

Insulation applied to the exterior of basement walls, crawlspace walls and the perimeter of slab-on-grade floors shall have a rigid, opaque and weather-resistant protective covering to prevent the degradation of the insulation’s thermal performance. The protective covering shall cover the exposed exterior insulation and extend not less than 6 inches (153 mm) below grade.

Protection is commonly provided using sheet metal flashing, though it is difficult to apply and hard to make look good with many visible dents and wrinkles in the metal. Constant contact with moist soil also greatly shortens the lifetime of even galvanized sheet metal. Stainless steel could be used, but the cost would most likely be prohibitive. Some apply a stucco coating to the foam, but its durability would be questionable in the presence of weed trimmers. Another technique is to use fiber-reinforced cement board with a stucco coating and metal flashing under the wall.

A better alternative is Ethylene Propylene Diene Monomer (EPDM) rubber. EPDM is a synthetic rubber that is commonly used for commercial roofs. In its sheet form it most closely resembles a thick tire inner-tube. It is low cost, highly weather-resistant, and long lasting. The typical thickness used is 45 mil.

Many contractors already use EPDM to flash the point of contact between walls and porches and patios. DIY stores sell it in 15 mil thickness for use as pond liners. It is quite paintable and impervious to weed trimmers. The sheets can be laid out on the new slab and cut into strips. The strips are adhered to the foam and the top of the slab using spray, contact cement. Joints can be welded with adhesive specifically designed for the purpose. Folding the material over the top of the slab blocks the path of termites through the foam.

The bottom line

The importance of slab-edge insulation at first seems counterintuitive, but the images from Therm offer vivid confirmation of the transfer of heat under extreme conditions. It is important to understand that the impact of slab-edge insulation decreases with depth and insulating the upper portion that is exposed to outside air is the most critical. Proper insulation protection is a must and special attention must be given to avoid the concealed intrusion of termites.

There are many techniques for slab-edge insulation that have not been covered here. Each has its own unique challenges. The goal of this article is to simply encourage the proper insulation of this important part of the envelope by offering a cost-effective, simple, and long lasting alternative that provides good performance in a variety of locations. This includes between conditioned space and attached garages, porches, and patios.

-Neal Ezell is a third-generation residential contractor with a bachelor’s degree in Engineering Physics. At Ezell-Morgan Construction in Lawrence, Kansas, Neal and his brother Brian build cost-effective homes that consistently rate in the low 50s on the HERS scale. Illustrations and photos courtesy of the author.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

39 Comments

Those heat loss graphics are very helpful in understanding heat loss patterns!

I’ve used aluminum flashing with a baked enamel finish to cover slab edge foam insulation. It won’t rust like steel, is easier to bend, protects against weed trimmers, is inexpensive, commonly available, and comes prefinished. (You should not have vegetation right next to your foundation to necessitate using weed-wackers there anyway! Nor should moisture be allowed to accumulate near your foundation and siding!)

If you are using exterior insulation below grade, there’s a good chance you are also using exterior insulation on the walls above grade too. The wall sheathing, any exterior wall insulation, rainscreen and siding will all provide some depth above the foundation or slab edge, making it easier to install slab edge insulation without tapering, or add more exterior insulation.

If you are building R-25 to R-40 exterior walls, your slab edge insulation should be more than just one inch thick R-4.

One issue is preventing termites or other insects from getting behind slab edge insulation or its covering, then getting up into walls undetected. If there were no exterior insulation or other covering on concrete walls or slab edges, you can notice termite tunnels they build on the surface. Copper flashing or copper mesh (sealed to the concrete) could be used as a termite barrier below wood stud walls, to prevent insect intrusion. Copper is toxic to termites as well. What are some standard methods used to prevent insect infestation inside exterior insulation on concrete walls or slab edges, if slab edge or exterior foundation insulation is used?

As Robert points out, in many parts of the country, the impediment to the presented solution is guarding against termites. Some energy loss is the lesser of two evils compared with structural damage from termites.

The EPDM covering is new technique to me. Perhaps it could be combined with the use of a barrier such as Polyguards Term Barrier, which is a peel and stick solution. If, after the forms are stripped, the Term Barrier were applied to the outside of the rigid insulation and lapped over the slab to extend to the interior past the bottom plate, that may create an effective termite barrier. However the Term Barrier is not supposed to be exposed to light for long periods. After the framing and sheathing, the EPDM layer could be applied to the lower 8" of sheathing, extending down to cover and be adhered to the Term barrier. Has anyone done such a detail?

Check out Energy Edge. https://www.eeform.com/

That's interesting. I wonder how their slab-insulated product performs with the amount of sheet metal that's in contact with the concrete slab itself. Perhaps it's not that big of a deal in temperate climates (CZ 3-4) which are marginally heating dominated?

Thanks, Armando. I checked in with Energy Edge today, and it turns out the insulation they utilize is one of my long time favorites - EPS that is impregnated with boric acid. The 98% Disodium Octaborate Tetrahydrate (DOT) resists infiltration by termites. Manufactured nationwide, this product named Performguard https://www.achfoam.com/Technical/Termite-Resistant-EPS-Tech-Data.aspx

is one of the only foams I would trust under a slab. The other is Foamglas by Owens Corning with a higher compressive strength than EPS. https://www.foamglas.com/en

Further, the whole point is to protect the wood, so a healthy treatment of the framing and sheathing with Timbor or Bora-care (non-toxic to mammals) let's me sleep most nights...

Tom Comptom, is a good guy from Wichita, KS. He's a registered Architect that wants our industry to do better. I introduced him to the GBA long time ago. I hope people really take a look at his solution.

My only question is about the PVC form that houses the EPS. I imagine it is UV stable, but PVC can expand significantly with temperature swings, so what kind of movement would we see in the form on a hot August afternoon. Any experience with that?

I wish the forms were fiberglass rather than PVC, both for thermal stability and for noncombustibility.

Contact them, let them know what y'all think about their product. Maybe you have a good idea and they'll listen to you or maybe they have a good explanation on how they do things.

Just received samples from Energy Edge. Product looks simple, sturdy, and logically designed for flashing. Should work, save time, money, and long term energy loss. I think we will give it a try on our next project. A fiberglass pultrusion in place of the PVC could be an improvement, possibly an upgraded alt. depending on project needs. But this product is here now and ready for use.

Joe - I think it would be better you hear the answer from Tom himself. Give him a call, he's very accessible.

Roger that. Thanks.

“[Deleted]”

Just to make sure nobody's reinventing the wheel here on this discussion, GBA had an excellent writeup on protecting foundation insulation exposed above grade. Ten years ago (?!?!?).... wow, time flies.

How to Finish Exterior Foundation Insulation

Options abound for covering up above-grade rigid foam insulation, including one that may surprise you

https://www.greenbuildingadvisor.com/article/how-to-finish-exterior-foundation-insulation

Also, if you're pouring a stemwall slab, rather than a monolithic slab, you have the option of 'hiding' the insulation in the concrete:

BSI-059: Slab Happy

https://www.buildingscience.com/documents/insights/bsi-059-slab-happy

Of course, you run the same risk of the problem of omitting a key piece of insulation as described in this column. I did an investigation where the builder omitted the small slab edge piece... the result was cold slab edges, and floor condensation in the high humidity units.

Always interesting to see real world examples of failures, thanks for sharing.

Carl Seville used the interior-side approach when pouring the slab on his home in termite prone Metro-Atlanta.

https://www.greenbuildingadvisor.com/article/movin-on-up

Of course the back-filled slab is more expensive so only expect to see it on custom homes.

I also installed a Term barrier over the entire slab as well as between the foundation and the bottom of the exterior sheathing. Termites are pretty nasty in Georgia.

Kohta: could you explain why your drawing on the right shows vertical foam on the inside of the foundation wall, under the slab? Isn't the slab already thermally isolated?

Can you make the THERM files available?

+1 on thermal bridging (ie cold spots) creating a condensation/moisture risk.

An important detail and one we've solved using ICF (we're building in the area West of Ottawa Ont.)

We use 8" ICF block, cut out a portion of the inner face of that block and thus use the ICF as our perimeter form (no need to remove, no carting of form boards from job to job...). As with most ICF it's quick and easy to install, easily accepts rebar etc.. Additional rebar ties the concrete in the ICF portion into the thickened edge just inside the ICF and you have a nicely insulated slab edge that's super easy to assemble. This method also makes detailing the sub-slab insulation and vapour barrier easy. Exact details may vary from job to job based on wether or not we're also detailing for radon, have in-floor heating etc.

Here's a quick sketch of one such example:

Has an engineer signed off on a chunk of foam in the middle of a thickened edge not having a significant structural effect?

It seems to me that LBD's design would work structurally the same as an ICF perimeter wall with slab mono-pour, without the sloped segment of concrete to the interior of the ICF. Which I also don't like due to risk of cracking as a mono-pour, but I do like it when the slab is poured separately.

I had no idea that EPDM is an effective termite barrier. Makes me wonder what other flexible materials might also be effective.

I too was surprised to read this, so I googled a bit, and found an LSU site that states "...membranes are not reliable barriers since Formosan subterranean termites are known to chew through many noncellulosic materials they do not eat, including foam insulation, mortar, plastic, rubber and others." [https://www.lsuagcenter.com/topics/family_home/home/lahouse/my_house/building%20a%20high%20performance%20home/hazard%20resistant/termite-resistance-one-line-of-defense-isnt-enough]

It would be interesting and useful to learn more information about how the author of this GBA article came to include EPDM/rubber as a termite barrier.

Well, if they chew through mortar, can they not chew through concrete? Looks like metal is the only safe material. Or maybe fiberglass.

They don't chew through concrete but they can pass through surprisingly small shrinkage cracks that often develop in concrete.

Yes, we've had the detail reviewed and stamped. The load bearing wall bears primarily over the 8" reinforced ICF core and the horizontal rebar pcs. 24" o.c. provide a tie between the two parts of concrete that are separated. We have also on occasion cut that inner face down further than shown in the drawing so there's more than 4" depth at that point.

We did one such job this past Winter with the perimeter poured separate from the inner concrete slab which allowed us to raise the walls (garage style) and then heat the interior and pour concrete once the sub-slab detailing and electrical/plumbing rough-ins were done.

We have also used this detail on a 2 storey build with the ICF bearing directly on bedrock. That particular home was done 11 years ago and I was recently back on the premises. The slab surface was finished as finished floor (in-floor heat) and there are no cracks, no issues with walls or support of any kind...

As in all such slab on grade builds the preparation and compaction of sub slab granular is critical and must be carefully undertaken.

> The load bearing wall bears primarily over the 8" reinforced ICF and ...

With the weight of the house bearing mostly on 8" of eps/soil, I'd expect the slab to crack above the ICF foam and then stabilize as the rebar takes effect. Maybe that's a saw cut above it?

I agree that sitting on bedrock (and some soils) is stable, even with small 8" bearing areas.

Many fantastic comments here. I am always irritated when you watch DIY shows that involve energy efficiency and they don’t first tell you where they are. When I go on vacation, my family hates it btw, I always like to go by and look at some local construction to see how they do things in a different climate. No matter where you’re from, everyone thinks their climate conditions are difficult. I can’t imagine trying to build a home in Ontario. I would definitely hire Lanark. Super cool post.

One detail I did not show is one we do on our custom homes with radiant heat. We do the 1 foot on the edge and take the 3 feet remaining and fold it over flat on top of the footing extending inwards for a total of 4 feet of perimeter insulation. We then layer foam over the entire floor so that all parts of the structure are on foam. For single story we use 25 psi foam. For 2 story we use 40 (yes, it is stamped by and engineer). My own home is done this way. 7 years on, no problems. Just make sure your load is only a third to a fourth of the foam rating to allow for creep. Our radiant consists of only 4-5 loops around the perimeter using a combi-boiler. Plenty to heat the home in winter whether I use my mini-splits or not. Our winter design temp is 9 degrees F.

Great article and one of particular interest to my company. We have always constructed our slab foundations as "stemwall slabs" and insulated them as shown in the building science corp's detail in Kohta's post. Termites in South Carolina are ravenous and out of curiosity regarding the EPDM layer used in Kansas, I called my termite pro to ask him if the thought it would work. His answer - "in Kansas, yes". He went on to say that he has seen termites eat through polymer sealant materials as thick as his thumb in SC.

So - what are the best products anyone has seen to protect the top of the perimeter foam that is like a concrete "expansion joint" around the perimeter of the slab and under the framed wall. We treat all of our walls 3' vertically from masonry contact with Boracare.

Carl - I tried checking out polyguard's Term Barrier page, but their page is in the process of being rebuilt.

I did not realize that termites would dominate this discussion. In Kansas, we do not have Formosan termites, just subterranean. I am not an entomologist but I would find it hard to believe that anything could chew through 45 mil EPDM. A pack of wolves would have no chance. The idea of the barrier is to route the termites path where they must build a tunnel on the outside of the EPDM so that they can be seen. Not sure how logical termites are, but this seems to be much simpler than chewing through thick rubber. If termites are that much of an issue, I would think that pretreatment would be a must.

I'm wondering if 15 mil be good enough for this application? Or would 45 mil be needed? Could this be doubled as a sill sealer somehow?

As if so often the case with "solutions", the solution for one problem in one discipline creates a problem for another discipline, one step forward one step back.

Overhanging the bottom plate 2" certainly won't work for 2x4 walls, which thankfully aren't used much anymore. With 2x6 framing it's possible but causes structural engineering problems in high seismic and wind zones. It forces crews to place anchor bolts at tight tolerances and leaves very little edge distance between bolts, holdowns and slab edges.

Can it be made to work? Certainly, but the "solution" must be comprehensive. It must work for all disciplines involved, not just one.

Also, the solution needs to account for different conditions, such as the need for a thermal break between a garage slab and the adjacent slab in the conditioned space of the house.

Others have already pointed out the termite issue.

I note that the website for the Energy Edge product (which looks very interesting - as it solves the issue of finishing the insulated slab edge in much the same way a masonry cavity wall does, and I intend to share it with my colleagues, though I don't know how well the exposed PVC holds up to sun exposure).

This raises a related question: How does one provide insulation at the slab edge at a building entrance, especially one that has to comply with ADA, especially when the slab has to bear on the foundation wall for structural reasons?

Is the cantilevered edge of the bottom plate an issue for the structural engineer? How much can you cantilever?

Yes and no. IRC table R602.3(5) shows the required stud size and spacing for different situations: https://codes.iccsafe.org/content/IRC2018/chapter-6-wall-construction#IRC2018_Pt03_Ch06_SecR602.3. I have not had pushback from code officials when the required stud size is sitting on the plate; for example, a 2x6 with 3.5" on the plate and 2" overhanging. I have had a licensed engineer approve a 6" overhang, using specific details. But I don't know of anything specifically addressing this in the IRC.

badmechanic,

Canadian codes allow 1/3 of the plate to cantilever.

We are in Climate Zone 3 and our design doesn't have any slab edge insulation nor insulation beneath the slab. The thickened-edge slab is directly below a conditioned crawl space foundation and conditioned garage. Average annual temperature is 60 degrees F. Should we be adding slab edge insulation and insulation under the slab? Consultants on the project say more insulation is overkill. Without simulation of the heat loss I can't say for sure.

Slab insulation is not required by the IRC in your climate zone. Adding insulation would almost certainly save energy but the return on investment of doing so could be relatively low.

Log in or create an account to post a comment.

Sign up Log in