In Grand Rapids, Michigan, Andy Zbojniewicz is planning a large, high-performance home that ultimately will be powered by a 15-kW solar array. The house will have more than 3,000 square feet above grade, and another 1,633 square feet in the basement.

His immediate concern is how to heat and cool the house.

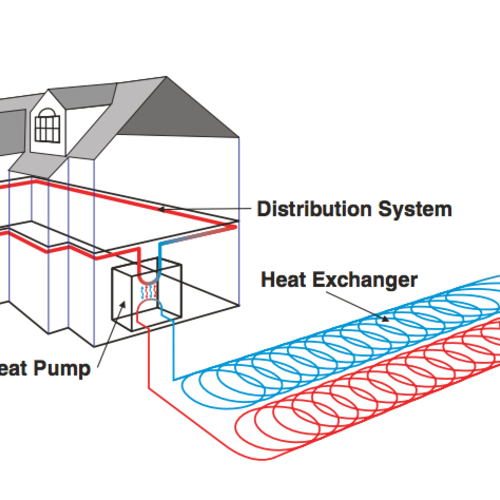

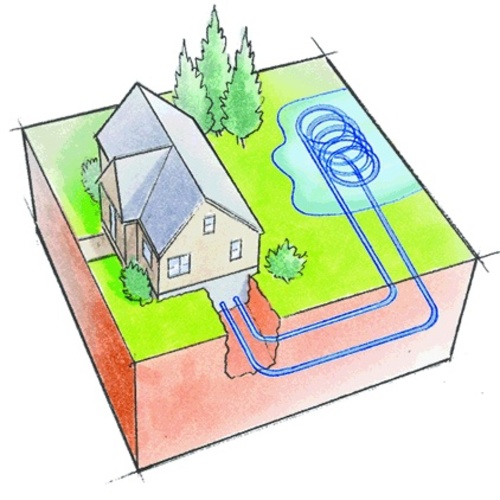

“I was told the home was too large to heat and cool with air-source heat pumps and be comfortable,” Zbojniewicz writes in a Q&A post, “so [I] was primarily looking at geothermal.”

To that end, Zbojniewicz sought quotes from two HVAC contractors for ground-source heat pumps. One of the contractors said the heating load would be 50,797 Btu per hour at an outside temperature (design temperature) of 7°F, and recommended a 5-ton (60,000 Btu/h) heat pump. The second company didn’t provide its load calculations, but suggested that Zbojniewicz would need two 3-ton heat pumps in order to stay comfortable.

“I have a friend who is in HVAC and he feels strongly that I should have radiant tubing run in the basement to help with heating in winter,” Zbojniewicz adds, “and while I was at it I was going to run it in the mudroom, master bath, and three-season porch.”

After doing some reading at GBA, Zbojniewicz realizes there are plenty of critics of both ground-source heat pumps and radiant-floor distribution systems.

“Is there a better alternative to geothermal if I want to have the potential for net zero?” he asks. “If I stick with geothermal, are two 3- ton heat pumps overkill (they’re certainly more expensive)? Should I abort the radiant altogether?”

That’s the topic for this Q&A Spotlight.

There is nothing wrong with air-source heat pumps

The outside design temperature for Grand Rapids, Michigan, is 5° or 6°F, GBA Editor Martin Holladay says,…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

23 Comments

Theinalienable is an awesome last name. Almost makes we want to change mine to match!

I don't disagree with the solutions presented, though i would like to hear how it all turns out, even if its a while from now.

I have wondered how cold air source heat pumps can go, in my case someday i might want to retrofit it. I live near Toronto Ontario, 99% design temp of -20C but we have had -30C and colder in very recent memory

>"...someday i might want to retrofit it."

That "someday" could be "today".

Gree has cold climate mini-splits with capacity tables that go as low as -30C (wet-bulb). Cold climate Fujitsus & Mitsubishis are all specified down to at least -25C (dry bulb). Many minisplits have a specified capacity at -20C (dry-bulb).

Toronto isn't really all that cold- despite the occasional dip below -25C the 99th percentile temperature bin is still only -17C per ACCA tables (https://articles.extension.org/sites/default/files/7.%20Outdoor_Design_Conditions_508.pdf ). The -20C would be a 99.6% design temp (ASHRAE tables peg the 99.6% design temp at -19.4C at the airport: http://cms.ashrae.biz/weatherdata/STATIONS/716240_s.pdf ).

Go ahead and use -20C if you like.

If a mini-split is sized with even 1.2x margin on the load at -20C it will almost always cover your load to some temperature below -25C before it begins to lose ground, even if the capacity tables for that don't go that low.

Today i have other priorities. I was thinking about starting a Q&A thread about my insulation situation since i have a government inventive that will cover it but i have century old home concerns. They did the energy audit a few weeks ago and i got the e-mail that i am eligible on Friday but have not looked it over yet.

I also have an almost new furnace and other renos and problems that take priority but someday.

Can you elaborate on what wet bulb and dry bulb mean in this context?

At cold temperatures the difference between WB & DB temps isn't very much, but it's historically common to specify the capacity using WB, since the wet bulb temp determines how much time it will spend in defrost. The AHRI protocol for testing heat pump efficiency specifies both WB & DB, but the capacities are specified using the DB temps. For instance:

https://nonul.mylinkdrive.com/files/MSZ-FH09NA_MUZ-FH09NA_Submittal.pdf

Note the ARHI DB + WB test conditions listed in the table on page 4.

Our 99% design temperature is -18C and entering our fourth winter, our cold climate heat pumps (Fujitsu) have never had a problem putting out heat, even when much colder than the design temperature.

Stephen,

Been reading many of your old posts in regards to your build in Maine back in 2015. I am in the process of new construction myself and (set to begin moving dirt in next month) and am also a fellow Mainer. I had a few questions regarding the ductless Mini-pumps I would love to get your opinion on. Would you mind sending along your email? Mine is, [email protected]

Hope to hear from you

Aaron

> Radiant-floor heating...It is not more efficient.

With a heat pump or condensing boiler, I disagree. Large radiator = lower supply temp = more efficient.

A radiant floor may (or may not) have enough radiator mass to prevent effective setback. Both the mass and the heat source matter.

> “If you are looking at air-to-water geo-exchange, then you can add a water tank (thermal mass), resolving any heat pump over-sizing issue other than cost,”

A typo. Should be "at to-water heat pumps, then".

The potential to realize the benefit of increased efficiency with a heat pump supplying a radiant floor is higher than it used to be, now that we have variable speed air to water (chiltrix) and water-to-water (hydron module) heat pumps. Especially set up with an outdoor reset, they can run at very high COP much of the time. The benefit they get from using low-temperature water is even more than what you get with a condensing boiler.

Air to air heat pumps are pretty clearly able to provide sufficient capacity for homes with your (approximate) heat load. That said, it should be more of a concern for you to look at distribution of that heat. Martin is quite wise in saying he would go with a single head in a central air distribution system. This will make a lot of decisions commonplace to the HVAC people. I also believe it will make the overall comfort of the home better than discrete heads.

I also support the idea of induction cooktops most vigorously. We are at high altitude and only have propane as a gas option. We do miss having a good burner for the wok, but now that we have induction compatible pans, gas is the past.

As for heating. My own home is quite similar in size, with an equally large basement that is 80% below grade. Your's seems to be half exposed, so loads may be very different. We have a large percentage of glass area and a design load at -10F of 19,000 BTU/Hr. For a number of reasons, we went with cove heaters in all rooms and avoided the clearly more energy efficient mini-splits. The primary reason is the room layout and three levels to deal with. Some people have referred to our floor plan as a rabbit warren, which is a bit far, but we definitely do not have an open floor plan. Secondly, outrageously high installed costs and sketchy support options during the years we committed to design choices.

With now three winters experience I can say that discrete heads and mini-splits would have been a very poor choice for us. Many recommendations would have had us place heads in maybe two locations per floor, which for our floor plan would result in strong temperature gradients from room to room. The air distribution we installed was intended for fresh air not heat distribution so a "return" path for each room is not provided. A central core with pickup at the third level is our choice for balancing air quality. For us it works well and we don't have the sound of a central blower to live with. ( a personal phobia of mine)

The relevance to any home design is how the heat input will be distributed and how it is lost. I do believe that more than a few postings on GBA have cautioned about difficulties with hallway located mini-split heads getting sufficient heat to bedrooms, particularly when doors are closed at night. Martin has mentioned the failure of the Magic Air Arrows to live up to diagramatic expectations in several contexts which bear re-reading. It also supports why he suggests a central head with standard air handling layout.

Radiant floor heat, though scorned by many, does have the virtue of putting heat into the rooms evenly and without reliance on air movement. It will also place warmth in the very rooms with the highest losses through walls and windows - bedrooms with closed doors. A long cold winter's night with a closed bedroom door will not faze radiant floor heat (or cove heaters). It is, however, a very costly and mechanically complicated way to get even distribution of the heat created by whatever method. By the estimates I did in preliminary design work, quite a bit more costly. It also adds a subtle threat of leaks to deal with over time as well as complicate flooring choices.

I think rather than going on about whether mini-splits can heat in cold climates, it would be of greater value to have discussion of how to be successful with various floor plans. Many people chiming in are happy with the choice of a mini-split, so lets get more details of how they succeeded in keeping all the rooms comfortable. If they had a failure, cover that, too. Keeping more mistakes from happening will only increase the chances of designs adopting them.

Guys guys! That's me! I made the highlight reel!

Also, I changed my name to be my actual name...

Radiant floor heat does have the advantage that it is run at lower water temperatures. This fact should make it stand out. If you are looking to use an air source heat pump, most of them can’t make water at high temps. The highest I have seen is the one from sanden and even that is 150 deg water temps.

Also radiant off floors/walls/ceilings does not use up floor space. This is clearly an advantage over a large cast iron rad.

>"The highest I have seen is the one from sanden and even that is 150 deg water temps."

Sanden's CO2 refrigerant heat pump's compressors are capable of making 180F water, but efficiency (and more importantly, capacity) takes a hit at those temps. But if you really REALLY need 180F, it can do it.

Regardless it seems the BTU output is only really appropriate for a passive house or other airtight home.

Also in terms of performance: for my area (westchester county by) the price of electricity is 3-4x that of natural gas. I wouldn’t be surprised if this ratio is similar for most of the country. Anyways, if the worst case cop isn’t at least 3ish, it’s not obviously dollar efficient to operate.

This isn't always about lowest cost.

I’ve read enough GBA articles to know a proper manual J calculation needs to be made but how does one actually get this done? It seems that most residential HVAC contractors will either say it’s not necessary or lie to your face and make one up. Is this practice unheard of by your average local HVAC company?

Find a third party rater, someone who does this for a living, and stakes their reputation on being right.

I used Building Knowledge.

You actually need a Manual J, S, T & D.

Andy,

Here is a link to an article that directly addresses your question: "Who Can Perform My Load Calculations?"

Thank Martin, I must have missed that article but it was right on. I have now found a local RESNET HERS rater that should do the trick for me.

Doesn't look like you investigated or are going to install any passive solar techniques for heating, cooling and light. How about solar hot water for that radiant zone and some free hot water? Wood stove with heat exchanger or hot water loop to assist. Dish half the PV you are going to purchase and invest in these free sources of heat and hot water. Install as much DC low voltage stuff as you can, then the money you save can buy you more PV in the future if needed.

Tom,

You seem to be under the misapprehension that a solar hot water system provides free hot water. It doesn't. It provides hot water that is much more expensive than hot water created by other types of equipment. Moreover, choosing equipment that operates on low-voltage DC power rather than AC power makes no sense for anyone except someone who lives off the grid.

For more information, see "Solar Thermal Is Really, Really Dead."

Well all my shw customers love their systems, especially those who've had them for 30 years or so and keep them operational for the benefit of free hot water as well those who I have added heating to the system. Not to mention the number of solar showers and pool heating systems I have installed over the years.

As far as DC, low voltage lighting can be used by anyone, on or off grid, not to mention all the electronics that run off of DC converted from AC. Next time the power goes out, don't go to your car to charge your cell phone.

Personally the best thing one can do is invest in the air tightness and insulation of the house. Shrink your demand, shrink your demand and shrink your demand one more time. Then if you have the money left over, by all means invest in ground source but as mentioned by others its becoming completely unnecessary with modern air source heat pumps that are available today. Something else that I see that breaks my mechanical inclined heart is building these big extravagant houses on a 10 cent millionaire budget. For some in site in NW Iowa (-12*/96* design temps) when I run houses through wright soft, my average cooling demand is 1500 sqft per ton of cooling on the main floor. My worst case scenario house, all open concept, stretched out across half a football field, 20' ceilings and windows to no end and ducts in the attic is 800 sqft per ton on the top floor and 976 on the main with 1259 in the basement. Theses are designed around R19 insulated walls, r38 in the attic (every seam of duct work sealed and wrapped in R8 and berried deep in the blown in) and semi tight construction. pretty basic and stamped out designs....more than enough room for improvement in construction and then there for the mechanicals...

Log in or become a member to post a comment.

Sign up Log in