Image Credit: North Dakota State University

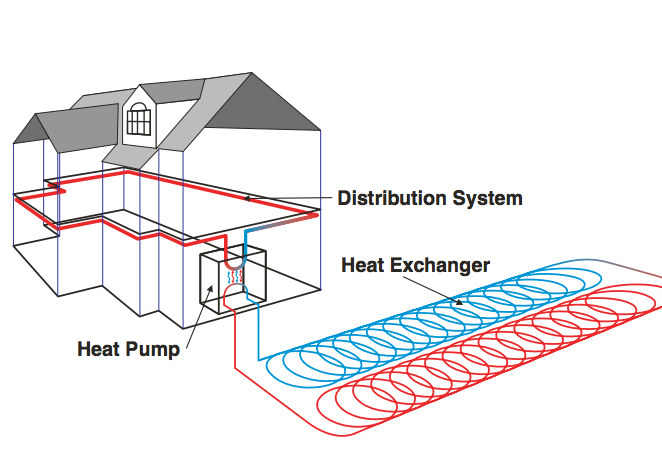

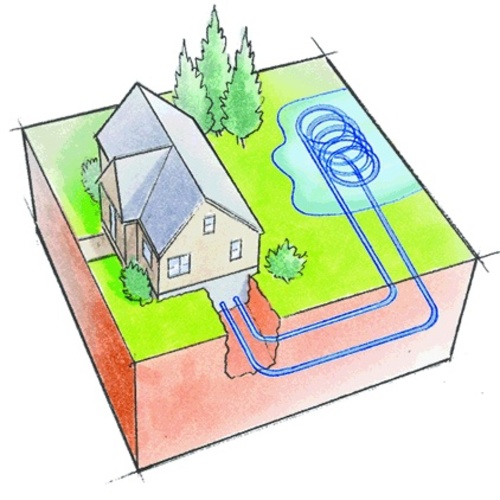

Jordan Garrow is getting ready to build a new house in New York State, on the cusp between Climate Zones 5 and 6, and he’s planning to heat and cool it with a ground-source heat pump. His contractor wants to install a horizontal “slinky loop” heat exchanger, one of several possible options, and Garrow is seeking a second opinion.

A heat load calculation for the house specifies a 4-ton system (one with a capacity of 48,000 Btu/hour), but the contractor wants the heat exchange loops designed as if they were serving a 6-ton system.

“His plan is to do a 6-ton horizontal slinky loop field with a 4-ton heat pump,” Garrow writes in Q&A post at GreenBuildingAdvisor. “He claims that an oversized slinky loop field performs the best. However, I’ve heard bad things about slinky loops, and slinky is the only kind of loop they do.”

It doesn’t seem either efficient or cost-effective to overbuild the field, since that represents a major part of the system’s cost. He’s sought another quote for a horizontal loop using straight lines, as well as a vertical closed-loop heat exchanger, which would be placed in a well. But the local geology is something of a concern.

“I’m worried about the vertical [method] since there is a lot of shale in my area,” he adds, “and I’m not sure how deep the wells could go.”

As a point of reference, the 2,500-square-foot house will have 2×6 walls with fiberglass batt insulation plus R-10 of rigid foam insulation installed over that. In the attic, he’s planning on 18 inches of blown-in cellulose.

How should Garrow proceed? That’s the topic for this Q&A Spotlight.

Oversized slinky option may not be a bad idea

The contractor may have a…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

6 Comments

Interpreting the report

Thanks for the link to the experimental study comparing slinky and conventional loops. Here's a little more detail on what they did and what their conclusions are:

1) They measured for 70 hours, and included a caveat at the end that they can't draw conclusions from that about long-term performance.

2) Per unit length of tube, the conventional "snail type" (on the left in the photo) works better than the slinky loop, during the 70 hour test period.

3) Per unit area of ground, the slinky loop works better, during the 70 hour test period.

Putting aside the question of long term performance, let's first consider which makes more sense--to compare based on ground area or tube length. Normally excavation costs would be more than tubing costs, so for best performance per unit installation cost, the slinky loop makes sense. But if you consider pumping costs, those are proportional to tubing length, unless you do something clever with parallel loop configurations. So the best performance per unit pumping power is the conventional loop, not the slinky loop.

If we consider long term performance, we might want to give up, because we don't have data, but in the long term, the amount of heat you can get out can be approximately estimated by the volume of dirt you can access with the tubing, in order to pull heat out of it. So at that point, the amount of heat you get is roughly proportional to the area you dig up, and what you put in the hole doesn't matter so much. So the slinky loop doesn't help or hurt much when compared based on an equal excavation cost.

So a slinky loop can certainly work well. If you dig up enough area to have good long-term performance, and you pipe it with parallel reverse return sub-loops to reduce pumping cost, and you seal all the joints really well so they won't leak ever, or you bring all of those back to the basement where you an repair the joints if they leak, you can end up with slightly better performance than the same area with a conventional loop system, with the cost adder only being the cost of extra tubing.

But if you consider the problems people fear about bad installations -- problems with long term performance and high pumping costs -- slinky loops can contribute to both. If you use a large quantity of tubing without parallel sub-loops, pumping costs will be high. And the ratio of short-term performance to long term performance is higher with slinky loops, so the good performance in the first month or year could lead the installer to think the designs are working well, even if they perform poorly later on.

So I still don't recommend slinky loops in most cases.

Geo Loops

Sigh, There is nothing to experiment with geo loop designs, it's all been done decades ago. I can't believe people are still installing slinky loops in inappropriate applications. They work pretty good if the ground is completely saturated or better yet submerged in actual water. In any other soil type they simply have too much pipe wall surface area in too small of a space creating a thermal bottle neck. There is a finite amount of energy available in a given cubic foot of earth. The limit for a pipes ability to extract that heat is one pipe about 1.5 - 2 ft from the adjacent pipe. In order for a slinky loop to perform well you have to install anywhere between 1.5 - 3 X more pipe depending on spacing of the coiled loops. All slinkies are really is a waste of pipe.

How deep are the slinky

How deep are the slinky loops. Several years ago it was a very cold winter and in MN and WI the frost was so deep it was freezing water supply lines. I believe the frost line was well over 6 feet deep. It seems the ground could be frozen around a slinky field.

Consider the options

I'd echo the suggestions to build a really good shell and to consider alternate heating and cooling systems. Field research on cold climate GSHPs isn't impressive, in my opinion:

https://www.greenbuildingadvisor.com/blogs/dept/energy-solutions/ground-source-heat-pumps-2010

http://www.builditsolar.com/Projects/SpaceHeating/InField%20PerformanceTestingofGSHP_updated%2011_11_2010.pdf

http://www.geo-exchange.ca/en/UserAttachments/flex585_Rob%20Andrushuk%20-%20Monitoring%20Field%20Performance%20of%20Residential%20Geothermal%20Heat%20Pumps.pdf

http://buildingscience.com/documents/digests/bsd-113-ground-source-heat-pumps-geothermal-for-residential-heating-and-cooling-carbon-emissions-and-efficiency

This link cites other resources in addition to the ones above;

https://www.mge.com/saving-energy/home/heating-cooling/heat-pumps/index.htm

Depth of the slinky install & spacing is more critical!

I installed the first slinky system in PA as a demonstration project back in April of 1994 & we used a trac hoe to carve out (110) foot trenches 42" wide X 5' deep and I added another 18" - 24" of soil on top of the loops as I graded the back of my property The center line of the trenches to the next trench is approximately 15'.

By oversizing the slinky loops another 2 tons you are adding significant pumping resistance & pressure drop which adds to your overall up front installation (trenching, slinky piping, header pipe, fittings, pumps & labor) costs & electric energy costs to operate the loop system. The electric energy required to operate the pumps that continually circulate loop field heat exchange fluid into and out of the GSHP heat exchange unit robs efficiency from the system. I would suggest you consider digging your loops one - two feet deeper to improve the average loop temp in the dead of a cold winter and spread each loop out further from each adjacent loop so each individual loop has a better energy sink to pull from during those long, cold northern winters. Slinky loops that are installed shallow & too close will never work well. John Kauffman of GeoClimate Control out of Danville PA designed my installation & allowed me to spread out the loops a little wider but his initial design was spot on. He has installed thousands of slinky & vertical well pump installations. I have never had a single issue with a pump going bad or with a loop freezing with my 5 ton slinky design that was installed back in April of 1994.

Several of the GSHP manufacturers have electronic design software that can tell you what the extra two tons of loop, pumps, fittings & header pipe will do to the performance & operating costs of your GSHP system. I went deeper & wider with my loops in lieu of additional loops & it has performed extremely well. Good luck with your project.

Fantastic post Robert

Fantastic post Robert Murphy

Always a pleasure to learn something useful here at GBA

Log in or become a member to post a comment.

Sign up Log in