Over the last couple of years, there’s been a lot of buzz about the SANCO2, a newer type of air-source heat-pump water heater (HPWH) from ECO2 Systems. Instead of the more common stand-alone HPWH, it’s a two-part system comprised of compressor installed outdoors and a storage tank located indoors. Developed about 15 years ago by Japanese HVAC manufacturer Sanden (now reincarnated as ECO2 Systems) and the Japanese government, the HPWH uses CO2 as a refrigerant, which has a Global Warming Potential (GWP) rating of 1; CO2 is the gas used as the reference measurement for all other greenhouse gases. Even some newer types of refrigerants have a GWP of 124, as rated by the U.S. Environmental Protection Agency.

The compressor will make hot water in outside temperatures of down to -25°F. It’s also extremely efficient: its first-hour rating is higher than any other water heater: the 43-gal. model, pictured above, can provide 63 gal. of hot water in an hour and has a fast recovery time. The company also claims that the unit is 80% more efficient than electric resistance heaters and 40% more effective than hybrid HPWH’s. Depending on the price of your electricity and your hot water consumption, the return on your investment can be within five years.

Lean set of early adopters

So why isn’t everybody and their uncle running out to buy one? For one thing, they are expensive–unit cost ranges from about $5000 for the 43-gal. model to a little more than $6000 for the largest 119-gal. unit.

“The Sanden/SANCO2 units don’t seem to be getting much traction in the residential space,” says building science consultant and GBA contributor Jon Harrod. “I think the big obstacle is the price tag. It’s hard to justify that cost for what might only be $50-$100/year savings over a standard heat pump water heater.

Residential designer and GBA steward Mike Maines has a similar sense. “They are expensive and my clients always seem to be on tight budgets; spending a few thousand dollars extra to get slightly more efficient hot water is rarely something they want to consider.”

“They do appear to be gaining more popularity in multifamily buildings,” Jon notes, “where one or a few heat pumps can heat a large storage tank that serves many units.”

Beyond the price tag

Additionally, because SANCO2 units have two separate components, they take more materials and time to install (contributing to their expense) than a standard heat pump water heater, which extracts heat from the air in the room where the water heater is located, transferring the heat to water in an insulated tank. For a split-type system like the SANCO2, plumbers must install not only the tank, but also the compressor, which requires some kind of mounting system, similar to that of an HVAC heat pump system. There are also the connecting water lines, power hookups, shut-offs, etc.

To some people they might seem too complicated. But installation is nothing out of the ordinary. “It’s really basic stuff for plumbers,” says Josh Salinger, founder of Birdsmouth Design-Build. An early adopter of the SANCO2, Birdsmouth has installed one in nearly all of its projects over the last few years. Asked what he likes about the model, Josh says: “From an architectural perspective, the tanks are very compact. They don’t take up a lot of space, so you have options of where to install them. The unified HPWHs require a specific amount of space, plus they dump a lot of cold air and noise into that space, so there can be comfort issues as well.”

If there’s a recurring complaint about the SANCO2, it’s that the system is somewhat vulnerable to freezing. When it first appeared on the market, customers in cold climates reported that the water lines between the compressor and tank were freezing, and occasionally rupturing in sub-zero temperatures. The company has addressed the issue by integrating heat-tape insulation to cover the exposed lines, and providing freeze-protecting relief valves that purge the lines. If a freeze is accompanied by a power-outage, however, the compressor becomes vulnerable. John Miles, managing director of ECO2 Systems, stated that the company does advise pairing the SANCO2 with electrical backup.

Mike Trolle, founder of BPC Green Builders, seconded that recommendation. His company has installed a dozen SANCO2 water heaters, and the only issue they’ve experienced is when they get hit with the double whammy of an extreme freeze and no power, the compressor pump will freeze, even when protected by the relief valves. For that reason, he says that they only recommend the SANCO2 units when there’s backup power.

What about serviceability and maintenance? We heard only from Josh Salinger on that front. He says that one of the good things is that if the compressor goes, you can just swap it out, rather than having to take the whole thing apart. The warranty is 10 years on refrigerant parts, 15 years on the steel tank.

Finally, Nick Whatley, a Maine homeowner who has worked with Mike Maines, has purchased two SANCO2 water heaters, is very satisfied with their performance, but he suggests that if you have a manually started generator and you are leaving town in the dead of winter, it might be a good idea to purge the system before you go. Just in case.

________________________________________________________________________

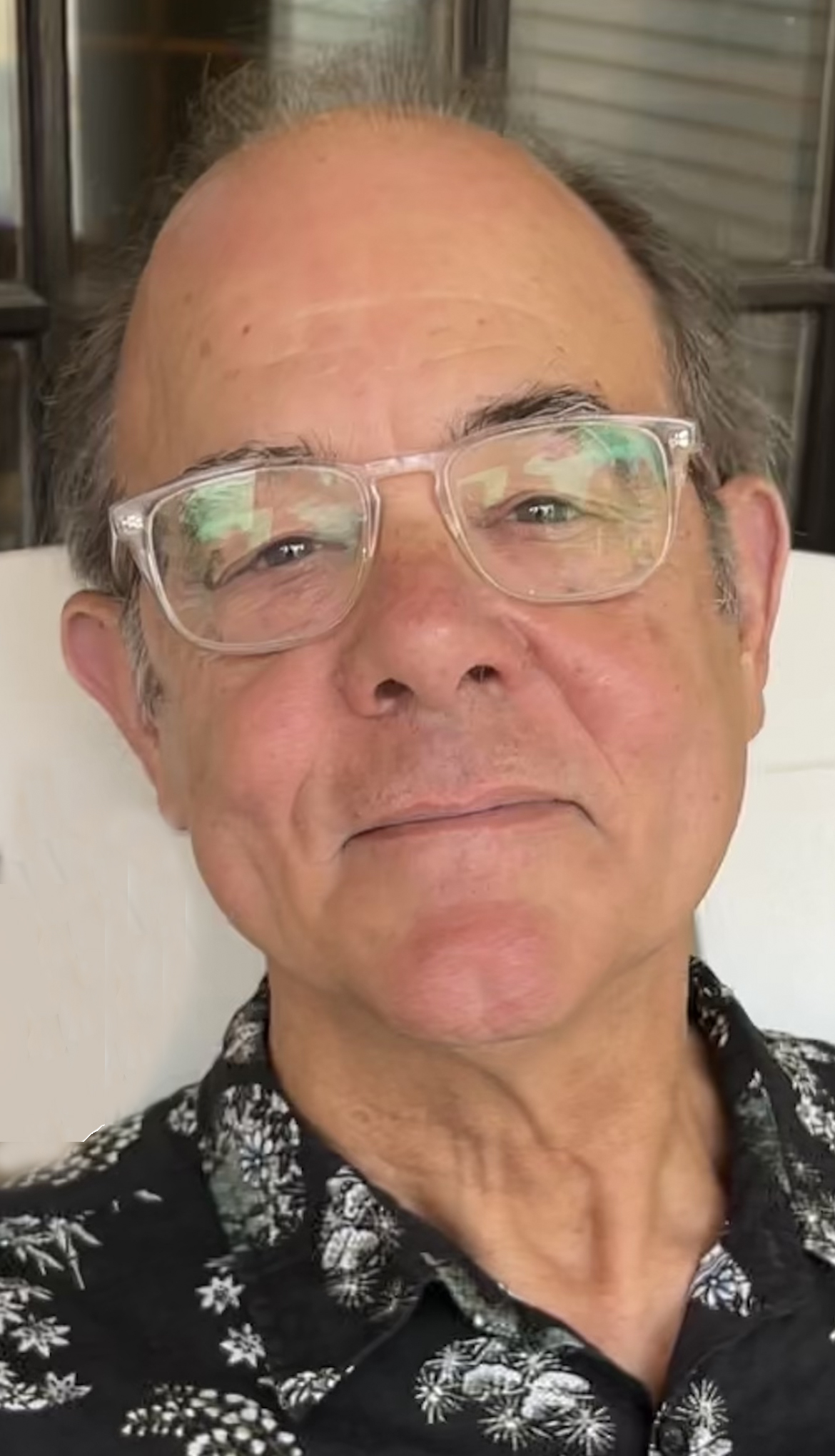

Chuck Bickford is a contributing editor. Photo courtesy ECO2 Systems.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

84 Comments

It seems like these have such limited appeal: too expensive, not efficient enough, too unreliable and niche. Some technologies just stink.

I'd love to see CO2 refrigerant in a 'conventional' heat pump water heater format.

For sure - rolling the dice on a burst pipe is hardly worth the marginal savings.

My understanding after looking into these a bit is that they're actually the most efficient HPWH systems around -- and in cold climates they're also not "stealing" heat from the inside, and in fact can be used in combination systems to provide some amount of additional heat to the house. Of course, cold climates are where their biggest weakness shows -- the whole "run the water to the outside and try to keep it from freezing" thing. That, combined with the cost, is why I decided not to get one, despite otherwise loving them from a technical perspective. CO2 as a refrigerant in this application is brilliant, and I'd love to see either a more typical indoor-only packaged unit using CO2, or better yet a split system using CO2 (of course the high pressures involved make servicing / installing CO2 split systems tricky, but I think it's starting to gain some traction in large commercial applications like grocery store cooler systems, so maybe in a few years we'll see the tools and skills trickle down into the residential market.)

Just because you can install the compressor outside, doesn't mean you have to. I replaced a Steibel Eltron with a refrigerant leak with a SanCO2 last year. The efficiency benefits of being outside vs. the risk of damage during a hard freeze+power outage just aren't large enough in my book. This is the same reason I went with a Nordic ATW heat pump for the house.

So far, the unit is at least 20% more efficient than the unit it replaced and also much quieter (not that the sound level matters given where it's located). More details in this FB post: https://www.facebook.com/justin.gibbs.560/posts/pfbid0wK6XmzWmhp4n2T9Va5KrCJkmuw6csQQDbKPa6RNsD3Z7XDp2y4HVz1157d7tgYRel

I like that idea and wanted to learn more but the link doesn't work for me--shows it as "only shared with a small group of people".

Sorry for the late reply. I just updated my FB post to be public. Let me know if it still doesn't work for you.

In hotter climates it makes no sense to bring extra heat indoors (Sanden), vs capturing existing indoor heat with your water heater (conventional HPWH). In colder climates it makes no sense to run water lines outside (Sanden) when you can just scavenge heat from inside (conventional HPWH). Why not run refrigerant into the house and put the heat exchanger on the tank? For what the Sanden costs you'd think they could do that?

Any efficiency increase the Sanden offers is going to be offset by the fact it's bringing additional heat inside the house during hot weather (instead of reducing the cooling load). In cold weather its efficiency will be much less than a standard HPWH operating indoors, which depends on the efficiency of your home heating source.

My comments are based on new construction where planning for a conventional HPWH should not present any issues. Results will always vary when incorporating a technology change into existing buildings.

FWIW, I just bought a Rheem 50 gal HPWH for our new build. From what I've read the latest units are much quieter than the last generation. It's going into a basement mechanical room so noise won't be an issue.

"I just bought a Rheem 50 gal HPWH for our new build. From what I've read the latest units are much quieter than the last generation." What have you read and where? What are the latest dB measurements? How does one distinguish between generations?

Sorry about the late reply, my notifications were all going into my junk email folder.

I saw no specific article that referred to this, and I do not believe Rheem has officially acknowledged it either. They do seem to release new "versions" of their HPWH on a regular basis, so I'm not sure how to distinguish between the ones that are noisy and the ones that are not.

My comments are based on reading reviews of the Rheem heaters over the years. It seems the noisy ones came out a few years ago and the more recent ones have not had the noise complaints show up in the comments. A friend of mine owns a noisy Rheem 50 gal unit, he had it installed 2-3 years ago, and it makes a low pitched humming noise while running. It's not terrible, but it is noticeable. I wouldn't want it installed on the same floor I was sleeping on. Fortunately for him, it's in the finished basement of his 2-storey home.

Newer reviews seem to suggest they sound more like a refrigerator running, which is what I would expect... more of a "white noise" type of background din, less noticeable than what a lot of machinery sounds like. Fingers crossed mine is the same low-noise version that people are recently reporting.

It seems like a heat trace that is on the refrigerant pump along with fully insulating that area might help with the concerns. Maintaining an insulated pipe above 32*F with heat trace wouldn't take very much back up power vs actually running the pump and heating a tank of water. Alternatively, backup power for a circulation pump might help too. Assuming your house isn't getting too cold during a medium length power outage...

Tim_O

I'm not sure... I see any application of heat trace as a remedial solution to something that wasn't designed or installed properly. Heat trace also fails, and it fails without you knowing it, so that you only find out when the pipes are frozen or burst.

Until the power goes out! While the Rheem or AO Smith is perfectly safe indoors for longer for thousands less.

When there is space for it, I agree. On the project mentioned at the end of the article there was only enough interior space for a tankless gas heater, and they didn't want gas. Many of my projects don't have the interior space required for a tank-style HPWH.

Sure - but the Sanden also eats up indoor space. Straight resistance seems the best option for when HPWH doesn’t work out.

It depends on your priorities.

You can always get a hpwh that can run in resistance only mode, and use the resistance

Running a HPWH in resistance mode only is the worst of all solutions. You pay HP prices and get resistance efficiency.

Of course you are in the northeast so the integrated compressor/tank style HPWH needs more space as it has to draw air from interior spaces in the winter.

But in many warmer parts of the country where the temp rarely if ever drops below freezing, HPWHs can be installed with exterior supply and exhaust. Mine is in a 3x3 exterior vented closet.

It does kick in to resistance mode for the 10-15 days per year it gets close to freezing outside, but the rest of the time it's only running as a heat pump.

I suspect that with the innovation happening in the heat pump space now, we'll eventually have traditional format HPWHs that - like the SanC02 -don't need any resistance backup heating elements.

In warm climates you'd want the HPWH inside so you get the free cooling.

The only climate where it makes sense to put the HPWH outside is one where it's always warm enough outside for it to run in heat pump mode, but you don't need air conditioning. I don't know any place that has such a climate.

@DCcontrarian coastal California (like right on the coast, not the roasting inland microclimates) is a place you can externally vent HPWHs. I suspect coastal areas of the Pacific Northwest are similar, and that HPWHs mostly live in unconditioned garages.

"Coastal California (like right on the coast, not the roasting inland microclimates) is a place you can externally vent HPWHs. "

Can, or should? I would argue it should only be done in a climate where you never use air conditioning.

I'll concur that coastal California would usually work. However most new houses still have egregious cooling loads and therefore AC. That said, I'd be wary of anything mechanical in the elements there. The salt is brutal...

Space is money. I'm in DC, a very high-cost location, and high-end custom building costs about $400 a square foot. What's a water heater, four square feet? For that money you can find the space.

Custom construction costs are still only $400/sf in DC? They are closer to $500-600/sf for custom construction here in Seattle. And there are some small home builders in the area using Sandens for their high-performance DADUs.

This is the only HPWH I can find that comes in a short configuration (38.5") that could replace the lowboy electrical water heater under my stair landing. I have limited options in a small house without a basement.

Unfortunately, with HPWHs, you have to pick between keeping your winter heat or free summer cooling and dehumidification. If money was no object, I suppose you could have 2 compressor units - one inside and one outside, and flip some valves over to switch between the two. Without mini-splits and PV, it would bother me to be using my wood heat to feed an integrated HPWH.

That's a good point: the option I like is the Nordic split air-to-water systems. The desuperheater is inside, so the cooling provides free hot water during the summer and during the winter months the heat comes from outside. But it makes the most sense to be part of a whole hydronic system and is expensive.

On that note - I recently came across these and was intrigued. Basically does the same thing you describe but with standard AC systems.

https://hvac.place/Heat-Recovery-Units_c_370.html

I’m not sure why these aren’t more popular, they fit American homes so much better than air to water.

I wonder how they compare in overall efficiency to running a hybrid water heater indoors during the summer.

@dc

I'm curious as to the section of IRC (??) that requires basements to be conditioned. It will definitely have an effect on my projects -- I see lots of basements. Do you have a citation handy?

Ideally, to heat water, you should be taking heat from inside the house in summer, and outside the house in winter. But I have two questions:

1. In summer, what is the efficiency difference between having some sort of heat recovery device on your air conditioning, versus just running a HPWH indoors?

2. In winter, what is the efficiency difference between having a heat pump to heat your hot water that has an outdoor compressor, versus having a regular heat pump to heat the house and then using a HPWH indoors that uses house heat?

I don't know the answers, I've never seen an analysis. But I don't think the difference is large, nor am I willing to automatically assume that the HPWH is the less-efficient solution in both situations. However, the HPWH is the far less complicated solution, and less expensive.

Depends on how cold you want your basement. If the HPWH makes it too cold then recovering heat elsewhere will make the basement more comfortable. If the HPWH make the basement the temperature you want then its a simpler option. You could go with the HPWH and if it is too cold try to circulate air through the house to even out temperatures.

Also depends on how well your existing heat pump can power the hot water. If there is no hot water usage at night then it probably evens out the heat pump load rather than requiring more capacity.

In summer the heat recovery is theoretically more efficient. Normally AC moves all the heat outside of the house. With the heat recovery some of the heat is moved into the hot water.

They have a test report indicating a 9% power drop in a 15 SEER AC Unit while heating 20 gallons of water per hour 50F.

I would get this if I lived in Florida or Arizona. I would need to see a report from a cold climate user of this product to consider it in a heating dominated climate.

"Depends on how cold you want your basement. "

In a house constructed to modern standards there is no such thing as an unconditioned basement. So your basement is going to be at the temperature you condition it to.

"your basement is going to be at the temperature you condition it to".

If you have an HVAC zone for your basement then yeah you control the temperature. I personally have never been in such a basement. I managed to control the winter temperature by insulating the floor and could probably open supply vents back up to provide more heat for a HPWH in the winter. I am told in the summer it can make the basement uncomfortably cold. But it seems like there should be a way to solve this with re-circulation.

Again, modern codes require basements to be conditioned. So yes, they have a zone.

This is a non-issue.

For those of us with radiant heating, (I have hundred year old radiators) it’s not an expensive system, I am looking at it to replace my gas boiler.

I thought that the SanCo system was not well suited to hydronic heating? If that is not the case that would be great! Many of us with hydronic baseboards would love a plug and play Air to Water Heat Pump boiler replacement.

It’s for low, really low, load homes. Or you install several together.

It loses a lot of efficiency with a radiant system, I think quite a bit worse than "conventional" R410a or R32 A2W heat pumps. It's only warrantied if combined with a Taco Xblock and if your heating load is less than 8k btu.

From my recollection of a few of their webinars, I believe the efficiency or lack thereof with hydronic heating was tied to the return water temperature. The colder it is, the better it maintains the tank stratification, and with it, maximizes efficiency. So there may be exceptions for all new properly optimized systems, otherwise you're correct.

I've tried to spec this as our climate is about perfect for using it as a combi system, minimal heating load (with no hard freezes) and no need for AC. Even using optimistic math, the potential efficiency gains would provide negligible payback versus standalone HPWH and heat pump for space heating, which also has the benefit of adding AC.

I'm not sure how you fix the efficiency issue. The Radiant system is much more of a constant draw, which causes the heat pump circulator pump to constantly be mixing up the tank. You would need a buffer tank in addition to help sort that out... but then you are talking about an expensive multiple component system, and not sure what the benefit would be.

I'm looking at this for my existing radiant floor system in the Bay Area. They sent me data on COP vs inlet temp vs ambient temp. COP at 47F ambient drops from 4->3 as inlet temperature increased from 50F to 90F.

I think this is true for all heat pumps but I've never seen detailed performance data like that from other vendors.

@tim_O My system is now installed, run by a controller from Harvest Thermal. Two SANCO2s, one 199Gal tank. Not a TACO X-block, just a regular brazed plate heat exchanger and separate pumps which gives plenty of control to maximize heat transfer. I'm pretty much putting all the heat from the SANCOs into the slab so no concern about mixing the tank; the hot water goes in at the top, the heat exchanger pulls from the top and returns to the bottom. The HP pulls from the bottom of the tank.

My radiant return temperature is in the region of 75F.

Lloyd, it will be interesting to hear how this works for you. Given that the output temp won’t get over 140F I think, I’ve heard you may need to repipe radiators so each run directly from a manifold instead of in series. We’re working on this on a retrofit with a good mech engineer now, will let you know how it goes,..

What do you think of the Arctic Heat pump paired with the Sunamp Thermino Phase change hot water battery?

https://www.arcticheatpumps.com/high-temp-hot-water-heat-pump.html

Why couldn't antifreeze be run in the outdoor piping with a heat exchanger inside?

In the case of the SANCO2, you probably lose the warranty. In addition, you would lose some efficiency.

I would want the dehumidification aspects that a drop-in heat pump on a water heater provides in a basement area/home. Thus, giving you a two-for-one effect of efficiency and managing moisture in the basement/home.

Both installs on our projects (WI and IL) performed great until both of them had heat tape failures and froze—in one case the outdoor unit needed to be entirely replaced. Great not having the noise and cooling of HPWH inside, but I’m gun shy now, especially given the expense. No one likes to spend $5k on a water heater only to have to take cold showers in the middle of winter.

We find these systems stunningly efficient. We have three running in 2 10 unit buildings, an 8 unit building and have one in my house doing radiant and domestic. Absoluely zero issues in the three plus years installed. At home, domestic supply is great, but I would call the radiant side radiant warming not radiant heating. Mitsubishi Mini splits do the heavy lifting when it gets cold.

We have a staff procedure for longer power outages (>2hrs) in the multis and at home we will have battery backed up solar.

Huge Fan.

.

I think this should be their niche - small multi family

" The company also claims that the unit is 80% more efficient than electric resistance heaters and 40% more effective than hybrid HPWH’s."

That means a COP of 1.8 vs. 1.4 for a hybrid. My hybrid has a listed COP of 3.4 so I assume that is somehow correcting for the heat that gets taken out of the home and needs to be replaced. But that's only half the year. The other half of the year the effective COP is much higher because it replaces air conditioning and dehumidification.

Air to water heat pumps for hydronic heating have a similar problem with the fluid being exposed to outdoor temperatures and risking freezing. I'll offer two solutions:

#1, plumb a normally-closed zone valve in the water supply to the heater, so that when power is lost the valve closes and the water supply is cut off. Plumb a normally-open valve to an outside drain so that when power is lost the heat exchanger drains. You could also connect a thermostat so that if the water temperature drops within danger of freezing it cuts off the power, which triggers automatic draining. In the old days solar water heaters used to have similar auto-drainback systems.

#2, put the heat exchanger in the house so the water stays in the house. Some units do this already, but you have to run a refrigerant lineset, which complicates installation. I think the manufacturer could run a 24" or so piece of 4" PVC off of the back of the outdoor unit and put the heat exchanger in it, packed in foam insulation. For installation you'd have to make a 4" hole in the rim joist and mount the unit so the PVC lines up with the hole. So installation would be trickier. But operation would be a lot simpler.

"Additionally, because SANCO2 units have two separate components, they take more materials and time to install (contributing to their expense) than a standard heat pump water heater, which extracts heat from the air in the room where the water heater is located, transferring the heat to water in an insulated tank."

I love that we're now talking about standard heat pump water heaters.

As someone else said, in a house with very low heat loss & not a need for a/c, why couldn't you use this for either:

a: hydro-air system

OR with

b: fan coils

In 2000, I built a 3K sqft super insulated Roof/Walls/Foundation/Slab (R60/R30/R20/R10) house that I heated with an instantaneous propane hot water tank (granted water would be hotter) by just installing a coil in the air handler.

I used $500 of propane for heating/hot water.

I installed the 83 gal SanCo2 system a little over a year ago, and I couldn't be happier with it. I admit, I may be the perfect use case, as I live in coastal Northern California, in Eureka, where the temperature year round is between 30 and 75F, with the majority spent between 45-65F. The SanCo2 is extraordinarily efficient, quiet, and robust, and delivers hot water extremely fast. In addition, we are in the midst of a serious remodel, and are able to use the extra capacity of the SanCo2 to run hydronic heating to the bathrooms and mudroom that will be tiled and to hydronic towel warmers, taking significant load off the new Fujitsu ducted mini split system and allowing us to downsize the HVAC unit and simplify ducting. The hydronic portion is accomplished with Taco X Block heat exchangers as discussed at https://www.smallplanetsupply.com/sanc02. We just had the HVAC system installed, and have yet to install the hydronics, and so have not yet realized those benefits, but I'm excited for it. A local design build company took on the install and did a fantastic job, even though it was their first one. Again, I may be the perfect target niche, but I love the system and recommend it to anyone who has it in their budget to install it.

I installed a 119 gal tank and single compressor for a hybrid system (domestic hot water and hydronic heating) for my house here in the SF Bay Area. It works well but is a little undersized for our heating load on the coldest nights, or what counts for cold around here, that is. We have an older, somewhat leaky house (despite our best efforts to insulate and seal). To add in extra BTUs for the coldest nights, I installed a 7kw resistance heater on the system side of the hydronics. It works well. We have never had a problem delivering enough domestic hot water or heat.

That said, I did make one mistake in the install by mounting the compressor in our attached garage (in order to keep our garden area tech free) and adding in extra ventilation. Like some on this discussion, I thought it would be good for keeping the garage cool in the summer. But what happens is that in the summer, the system is so efficient we hardly get any cooling effect. But in the winter, the compressor runs a lot to keep up with the heating load and turns the garage into a refrigerator, often much colder than the ambient exterior air. And since the garage is attached it cools one of our interior walls, which produces noticeable cooling in that part of the house. I am planning on moving the compressor outside to solve the problem.

The Sanden system provides far to little heat flux for all but the tiniest super insulated homes so won't work. You could use an air to water heat pump however expect to get significantly less heat from the radiators as water temps will be lower. Depending on the radiator sizes that might be OK, they will just be delivering heat at a greater duty cycle. Air to water heat pumps intended for hydronic space heating generally deliver water at a max temp of 125 F and I bet your current boiler is way hotter. What you propose is a non-trivial problem and you will want to do your homework to see if it makes sense.

Back to heat pump water heaters, read the reviews before buying. It appears that traditional American heat pump manufacturers like Rheem and AOSmith are luddites when it comes to any complex technology, and have fallen prey to offshore manufacturing quality issues. If you like rolling the dice, go for it but it is clear that these folks do not know what they are doing. Seriously, read the reviews. Sanden devices MAY be reliable but wow, what a price tag. I concluded some time ago that this tech will not pay back and adding another panel or two to a solar array and buying a regular old electric storage heater is the smartest approach.

On the other hand, I don't see any fundamental reason why a water heater is more complex than a refrigerator. Refrigerators are mature technology, manufacturers have no problems cranking out models that are efficient, quiet and durable.

Speaking of that, I'm wondering how the new LG Inverter HPWH will stack up to the current models here in the North American market. LG makes a pretty decent fridge and mini-split, at least compared to the HPWH brands in this market.

Is that a water heater in the US?

The LG unit apparently just came to market a few months ago. I stumbled across a press release (from a year or two ago) a while back and did some Google detective work. I think it's been out in Europe a few years already. They've shown up in the lists of HPWH qualified for state/federal rebates.

There's a scant few short YouTube videos from a company in PA that's been installing them (Vertex Mechanical?), and that's about all the info I've found for this country, other than a vendor or two that has them available for sale. I don't think they've really hit the market yet. This is one of the vendors I found, with an actual price:

https://www.rapidhvacparts.com/products/aphwc501m-lg-inverter-heat-pump-water-heater-58-gallon

https://lghvac.com/residential-light-commercial/product-type/?productTypeId=a2x2S00000Cp3DH

It does look like a stainless fridge, but that also makes it the most attractive unit on the market, if that's important for the installation location.

LG does not make a pretty decent fridge. The compressors have been a nightmare for years and years. LG washers however are rock solid.

There are lawsuits against LG for their refrigerators using their "Linear" compressor.

Rheem and AO Smith are first and foremost corporations that are for profit and beholden to a holding company (Rheem) and shareholders (AO).

So they are likely to focus on producing mature and profitable products. Call ‘em luddites but you should understand who they are and what they do beforehand.

The price needs to come down a lot, or the incentives need to go up. I have a triplex in VT (oil tankless coil) and the basement can’t quite fit an 80 gallon stiebel eltron or Rheem. I’ve been following SANCO2 since they came out, but with falling oil prices and the outrageous cost of these units, it’s not going to happen. The simple payback period is longer than the warranty. The NPV is terrible. And the studies I’ve seen for real world efficiency put it at more like 1.8-2.5 in a cold climate, rather than 5 or whatever (I’m thinking about that study from BC.) All in all, I would love to have one, but it doesn’t make sense right now. I’m hoping we start getting high-temperature (17o-180) air-to-water heat pumps in the next few years and then I’ll just replace the whole oil boiler all at once.

When I last looked into Sanco2 their paperwork said the warranty is only valid if purchased from and installed by one of their approved installers. I'm hesitant to buy a water heater I can't install and maintain by myself, particularly with so few approved installers and with only a 10 year compressor warranty when a well maintained resistance water heater can last indefinitely.

ECO2 Systems helped me find a plumber, provided the training to the plumber, and made arrangements for drop shipping the hardware from a distributor to my home for installation helping me save money. The SanCO2 heat pump is lower maintenance and the warranty is better than the all-in-one HPWH plus the stainless steel tank is maintenance free as has no anode rods or coils you have to replace or go bad. In the long run I hope the SanCO2 will save me money. See my post in the comments.

“[Deleted]”

“[Deleted]”

SANCO2 has been selected by "Harvest Thermal" to create a hydroair system that combines heating & hot water use ...

https://www.smallplanetsupply.com/harvest-thermal

It's a great idea. But it seems like they need a bigger tank if water is going to be the battery. Otherwise hot showers are going to ruin everything. And a bigger outdoor unit for enough hot water to heat an entire house.

Air -> compressor (refrigerant) -> Water -> Air

has lower efficiency than just skipping the water. But they are talking about radiant floors as well- maybe they will end up sticking with radiant heating.

I installed an SanCO2 HPWH in August 2023 in my Tallahassee, FL garage. It's quiet, efficient and produces more hot water than we had with a NG water heater it replaced. Here is an article that includes a picture describing the installation and our journey in converting our NG home appliances to electricity powered by a PV system and net metering: https://www.cleanenergy.org/blog/kent-wimmer-bringing-the-heat-as-part-of-the-clean-energy-generation/. The SanCO2 system is perfect for temperate climates. Having the heat pump in the garage next to the tank creates short water pipe runs saving installation coat and improves efficiency. Plus it keeps the exchanger fins clean and clear of outdoor debris, plus it cools my unconditioned garage which is nice in the summer. Additionally I got a $2K clean energy tax credit that paid for nearly all the installation cost. I'm betting it will last twice as long as an all-in-one HPWH so I will save hardware replacement costs in the long run.

It would seem to me that installing a heat pump water heater in an unconditioned, enclosed space gives you the worst of all possible worlds. If you're not using it for space heating you want it inside the building envelope. If you are doing space heating it needs to be outdoors, otherwise you're cannibalizing your indoor heat.

Having this split system heat pump and tank in our unconditioned two-vehicle garage seems to work just fine in our moderate climate in Tallahassee. This unit is not used for space heating, only heating potable water used in our home. We have a separate air to air heat pump for heating and cooling (it would have been nice to have a unit that serves HVAC and hot water). The garage has sufficient volume of air as required by the manufacturer and the garage door it isn't air tight. If I notice the garage is cooler than the outside air, I just open the garage door to let in the warmer humid air. In the winter, it almost never gets lower than the 40s in the garage so the efficiency of the HPWH remains high. In the summer the garage heats up to the upper 90s when we park our hot cars in the garage so the SanCO2 acts as an air conditioner cooling down that space is an added benefit. Lastly, because the SanCO2 produces hot water so efficiently and the stainless steel tank is so well insulated (the tank is in the garage as well), the unit generally runs only once or twice daily for about 20 minutes.

"Seems to work fine" are words that are directly antithetical to the premise of this web site.

"It would have been nice to have a unit that serves HVAC and hot water." That unit is called a heat pump water heater.

When we replaced our AC and natural gas furnace in March of 2021, I wasn't successful in finding a supplier and installer of a heat pump HVAC that could also provide hot water for the home (Samsung sold them in Europe and Asia, but not North America) so we had a air to air HP HVAC installed. Two years later I had to replace our 20-year natural gas water heater. Since I have a PV system that is producing more than we are consuming, I decided to source a HPHW. The system needed to stay in the garage where the gas water heater was installed. I decided due expected shorter service life and greater maintenance issues of all-in-one HPWH, I went with the SanCO2 split system in the hope that over the service life of the equipment it would pay off. Efficiency of the HPWH is only a part of my decision to go with a SanCO2. Please excuse my foray into this conversation as a consumer of what I believe is a product that well meets my objectives.

I think a HVAC system that can also do DHW would be a potentially great pair. But lead by HVAC, not DHW.

Martin wrote this https://www.greenbuildingadvisor.com/article/split-system-heat-pump-water-heaters in 2015. In the 9+ years since, these haven't taken off. What can we learn from this product's stagnation?

Read through the analysis in this thread:

https://www.greenbuildingadvisor.com/question/where-is-the-most-efficient-place-to-get-the-heat-for-hot-water-from

I believe in almost all climates there is no efficiency advantage to split system heat pump water heaters over having a HPWH inside the building envelope and a separate heat pump for heating and cooling.

Agreed, but I think it extends well beyond efficiency. No cooling capability, low space heating capability, exposing drinking water to outdoor temps, high expense, no-name manufacturer, etc. all probably contributed to poor sales.

Log in or create an account to post a comment.

Sign up Log in