PEX tubing was introduced in Europe in the 1970s but didn’t appear in plumbing installations in the United States until more than a decade later. Since then, however, PEX has grown in popularity as builders, remodelers, and homeowners have realized its benefits over copper. Its flexibility allows it to bend, which reduces the number of connections that need to be made, thereby decreasing opportunities for leaking; it produces no water hammer; heat loss is less; it is more resistant to corrosion and scaling; it is not as susceptible to bursting when frozen; and installation is easier and faster, reducing labor costs.

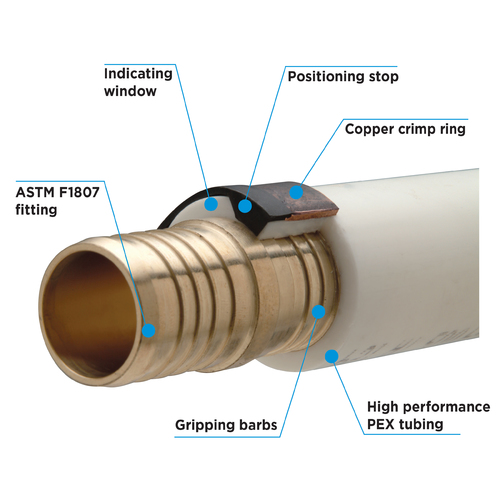

But there are differences in the way PEX is manufactured. PEX is formed when polyethylene molecules are cross-linked (PEX is an acronym for “polyethylene cross-linked”) through one of three methods. The resulting products are known as PEX-a, PEX-b, and PEX-c. Despite some claims, these designations do not correspond to a rating system on quality but only to how the tubing was manufactured. All three types exceed minimum ASTM requirements and are suitable for plumbing and heating installations. More important than the specific PEX manufacturing process is the dependability of the manufacturer. Look for good customer service and a warranty of at least 25 years.

PEX-a

This method has the highest degree of cross-linking, leading some manufacturers and suppliers to claim that it’s therefore the most uniform, most flexible, and most resistant to kinking and to damage from freezing. It is also typically the most expensive.

Sources: Rehau, Uponor

PEX-b

In a recirculating heating system that uses high- temperature chlorinated water, plastic pipes are more susceptible to weakening over time. Although tubing from all three manufacturing methods has met ASTM standards for chlorine resistance, this is the only PEX to have passed the stringent chlorine-recirculating standard of the product-testing firm NSF.

Sources: Everhot, Rifeng, Viega, Zurn

PEX-c

This is the most environmentally friendly manufacturing process because an electron beam, rather than chemicals, is used to form the cross-links. The process can result in less-than-uniform cross-linking and a more brittle composition, but this is a concern only in a poorly controlled manufacturing environment.

Sources: Nibco, Roth

Specialty offerings

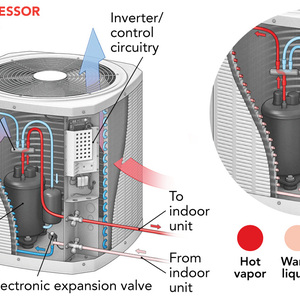

Oxygen barrier

PEX is available for both plumbing and radiant-floor heating installations, so be sure that the type you buy is approved for the project. (Some tubing can be used in both plumbing and heating; check the specs for each product.) Oxygen corrodes cast iron, so unless you are installing PEX in a heating system where you are absolutely sure there are no cast-iron parts present, choose PEX with an oxygen barrier. This is an EVOH (ethylene vinyl alcohol) coating applied during the extrusion process that limits the amount of oxygen entering the system.

UV inhibitor

All PEX is susceptible to damage from UV rays, so it should never be used in places where it could be exposed to direct or indirect sunlight. Some PEX, however, is available with a UV inhibitor that will increase the length of time before the product is compromised.

PEX-AL-PEX

Some manufacturers offer tubing that includes a layer of aluminum between two layers of PEX. The aluminum maintains the desired shape after it has been bent, which can help with controlling long stretches of tubing during installation. The aluminum also serves as an oxygen barrier. In fact, because it blocks 100% of oxygen from entering the system, it’s a more effective barrier than the EVOH coating and is a requirement when installing some brands of radiant-heat flooring. The aluminum also limits climate-related expansion and contraction, a source of occasional noise.

________________________________________________________________________

Photos: M. Chandley, courtesy of Vanguard (top); Rodney Diaz (bottom). This article originally appeared in Fine Homebuilding magazine, issue 214.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

0 Comments

Log in or create an account to post a comment.

Sign up Log in