One way of categorizing heat pumps is by how much heating and cooling they can provide. By how much, I’m not referring to, say, a 2-ton versus a 3-ton air conditioner. What I’m talking about is whether it provides a fixed capacity when it’s running (single-stage) or has the ability to change the amount of heating or cooling it puts out (multi-stage or variable capacity). Most homes have fixed-capacity systems, but minisplit heat pumps are starting to gain traction here in the United States, as are multi-stage systems. So, let’s find out about the three types of heat pumps.

Fixed-capacity heat pumps

A fixed-capacity (single-stage) heat pump has only two modes: on or off. When the thermostat says it’s time for more heating or cooling, it kicks on and ramps up to its full speed almost instantly. When the thermostat is satisfied, the power shuts off, and the system sits idly, waiting to roar up to full capacity again upon the next signal from the thermostat.

You can think of a single-stage heat pump as a car without gears or accelerator. When you turn it on, you’re going full speed. The only way to stop is to turn off the engine. That would be a terrible way to design a car, but it’s sort of okay for heating and cooling equipment.

The advantage of fixed-capacity equipment is simplicity. It’s either on or off, so the controls needed are straightforward. Because this type of system is so common in homes, finding people to work on it and getting parts for it are relatively easy, too. It’s also usually the least expensive of the three types we’re discussing here.

The biggest disadvantage of a fixed-capacity heat pump is that it’s terrible at matching the capacity to the actual load on the house. Remember the three types of heating and cooling loads: part-load, design load, and extreme load. A single-stage system is oversized for most of the year, sometimes by a huge amount, because the load is at part-load conditions close to 99 percent of the time.

That oversizing is the source of another downside of fixed-capacity systems. When the system is putting out a lot more heating or cooling than a house needs, people inside the home gets blasted every time the system comes on. That’s not a recipe for thermal comfort.

And that’s where the other two types come in.

Multi-stage heat pumps

Because the heating and cooling loads on a house go up and down throughout the course of a day as well as through the seasons, it makes sense to have heating and cooling equipment that can change their capacity. The simplest way to do that is with the second of the three types of heat pumps: a two-stage system. Such a piece of equipment has two modes of operation: a low capacity (or speed) and a high capacity.

Imagine the car from our previous example that has no gears or accelerator. The engine is either on or off, and when it’s on, it’s going full speed. A two-stage heating or cooling system is like that except it now has two engines. You can turn one engine on to go one speed, or you can turn them both on when you need to go faster.

Because the preponderance of heating hours and cooling hours occur with a house under part-load conditions, a properly sized two-stage system will operate at its lowest capacity most of the time. On the really cold or hot days, the system will shift to the high-capacity mode because the demand is higher.

A two-stage system, therefore, offers a huge improvement in efficiency and comfort over a fixed-capacity system, but it doesn’t end there. Multi-stage equipment also comes with three, four, or even five stages. Manufacturers do this by using clever compressor tricks. Because heat is moved by the refrigerant, multi-stage equipment simply needs the ability to run the refrigerant through the system at two or more different rates.

When you start looking at multi-stage equipment, an important concept to understand is turndown ratio. It’s the ratio of the highest to the lowest capacity, and it’s a good number to know when picking equipment. For example, one 4-ton, five-stage air conditioner runs at 1 ton of capacity on its lowest stage. The turndown ratio is 4 ÷ 1, or 4-to-1. That’s a good turndown ratio. The same manufacturer also offers a two-stage system with a low end that’s 83 percent of maximum. With such a small difference between low and high stages, that two-stage system doesn’t provide much advantage over a single-stage system and may not be worth the extra cost.

Variable-capacity heat pumps

As you go from two stages to several stages, the capacity difference between any two stages gets smaller and smaller. If your mind goes to calculus when you hear about gaps getting smaller, you may be thinking about that gap becoming infinitesimally small. And yes, it’s been done. That’s the variable-capacity system I will discuss now, the third of the three types of heat pumps.

In a variable-capacity system, instead of having a discrete set of stages, this type of system can vary its capacity continuously between its low end and its high end. They usually modulate with special electronic controls on the compressor, and the term “inverter-driven compressor” applies to most variable-capacity systems. Theoretically, these systems can have turndown ratios as low as 10-to-1. In the real world, getting down to 4-to-1 is good.

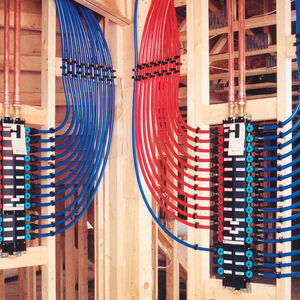

Perhaps the most common type of variable capacity heat pumps are minisplit heat pumps. In addition to being able to vary the capacity continuously, minisplits also come in smaller total capacity than do conventional fixed-capacity systems. Conventional systems generally don’t come in sizes smaller than 1-1/2 tons (18,000 BTU/hr), but you can get minisplits as small as 0.5 ton (6000 BTU/hr), and smaller ones are coming soon. And that’s good because it allows for better zoning in a house. You can use one system to heat and cool the bedrooms, one to do the common areas, and a third for a sunroom with lots of windows—and thus lots of cooling load.

Aside from the advantage of smaller capacities, minisplits have surprisingly quiet outdoor units. You have to get right next to them to hear anything, and even then it’s barely audible. Another advantage is efficiency. The ductless units have SEER ratings and HSPF that beat most conventional fixed-capacity or multi-stage system.

The biggest disadvantage of variable-capacity heat pumps is cost because these systems can be significantly more expensive than fixed-capacity systems. Also, even with the low-capacity units available, ductless minisplits are often still too large to put one in every room because they’ll be running at the bottom end of their capacity range. One final potential drawback is that some of the ducted minisplit air handlers have blowers that can’t produce much pressure. They can work fine, though, with proper duct design and installation.

One other issue to mention regarding both multi-stage and variable-capacity systems is airflow. When the compressor modulates the refrigerant flow, both the indoor and outdoor blowers need to be able to modulate as well. Ideally, when the system is operating at 50 percent of its full capacity, the blower also would be at 50 percent. That doesn’t always happen, though.

So now you know. Next time you need a new piece of heating and cooling equipment, remember the three types of heat pumps.

_________________________________________________________________________

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to the Energy Vanguard newsletter and follow him on LinkedIn.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

23 Comments

Question about the variable speed units. Suppose I have 2500 sq ft house served by a 2.5 ton variable speed inverter heat pump. Suppose one room in my house is very far away from the air handler. Say the variable speed unit is operating at a low capacity... say it's producing 10,000 btu and producing 350 cfm.

Is that furthest-away room going to get any cold (or hot) air? Since the whole system is operating at such a low capacity and fan speed, the static pressure in the duct system would be very low, and it just seems like not much air would be making it all the way to that furthest room. Plus, operating at a lower capacity and presumably producing a smaller delta-T, it seems that whatever small amount of air does make it to that smallest room is going to have lost a fair bit of it's heating/cooling capacity as it travels very slowly through the ductwork.

Whereas with a single stage system, the amount of air (CFM), and the delta-T of the air, should theoretically be the same all the time, so at least I can know what to expect in that furthest room in terms of heating and cooling.

Are these reasonable concerns? Is it correct to believe that for variable-speed ducted systems, the ductwork needs to very very good to avoid these sorts of concerns?

In the scenario you describe, the ducted air handler would not ramp down to 350 cfm. Typically the air handlers have ~3 speed settings (H/M/L) that are configurable by the installer and low speed might be ~70% of high speed or 700 CFM in your scenario. You still want enough air circulating to avoid the problem you described, even out the temperature of the home and accomplish filtration etc. The air handler will select the fan speed to operate at depending on the load. The dT across the coil would vary depending on the capacity the heat pump is operating at, so it is the supply air temperature that would change, not the quantity of air flow, to match the load.

If your ductwork, and equipment, are properly sized, selected, designed, installed, and insulated according to ACCA standards, your room at the farthest location should receive the proportionally correct amount of CFM/BTU's.

Just for giggles, in reality, how continuous is continuously variable?

My gut tells me it's something like 255, 1024, or 65535 steps. But I'm curious now!

Seems to me this article is incomplete because it does not cover the newer technology of vapor injection.

Each manufacture has given this technology a different trademarked name IE hyper heat.

The technology seems too good to be true in that we only read about the benefits. Other than the additional manufacturing costs are their and down sides? Do the vapor injected unit always have a higher COP or are their conditions where the non-injected unit out preform?

I think that in Alanta this moot point but the colder places want to know.

Walta

Other cold place questions is the impact of buffer tanks and Outdoor Temperature Reset for Air-to-Water Heat pumps. Once the demand for the buffer tank and DHW the heat-pump should modulate down to the heat-loss of the tank.

Bill,

I'm pretty sure "vapor injection" et al are similar to hot gas injection in a walk-in freezer used to defrost the coils. Every frost-free fridge uses some variation of the same idea. Your defrost cycle only comes on for a few minutes when the outdoor unit detects ice formation around the coils that is getting in the way of heat transfer and reducing efficiency. It's mature tech that has migrated into mini splits over the last 20 years.

My comment was more based on the process controls rather than the compressor cycle.

A buffer tank stores warm or cool water that can be used by the heat sink at a future point in time. It serves to decouple the heat source from the heat sink. For instance, you can create a cool tank of water at night when the electric rates are low and then feed that media into the heat sink/emitter when there is a call in the afternoon.

Outdoor temperature reset adjusts the heat of the heat transport media based on the outdoor temperature. For instance on design day you may need 95F media, where most times you only need 85 F water. It takes less energy to produce 85F media than 95F media.

Modulation deals with operating at different power levels. Some heat pumps modulate differently due to their discrete controls.

Vapor injection is more a function of the compressor/refrigerant to extract more energy out of the cycle.

David,

"vapor injection" is to pre-cool the refrigerant so that it can pick up usable energy from the ambiet - it HAS to be colder.

See

https://www.arcticheatpumps.com/evi-dc-inverter-for-heat-pumps.html

So with the name multi-stage being taken by discrete operations capacity; what do you call the units which use multiple refrigerants and stages to get to the desired temperature?

The two stage heat pumps in the article are running compressors in parallel to increase the capacity of the system at the same input/output temperatures. The ones you're referring to are using 2 compressors in series to increase the output temperature at the same capacity, which are the one stage heat pumps described in the article (although they might have variable capacity and EVI depending on their design).

Iainb,

"Multi stage" terminology for home HVAC probably came from the furnace manufacturers with regard to two speed heating systems.

A two stage refrigeration system is a situation one would most likely see in commercial refrigeration for a large store where some cases need to optimize for 33º F cooling and others might need to get down to -10 or -20º with different refrigerants and separate refrigerant loops (i.e. stages).

It's not likely to find it's way into homes in the short term but century-old district heating systems in Britain often used pumped seawater or river water for the first stage and then a second stage located closer to the end user would bump that heat up to the radiator and hot water temps. Either confusion will reign or more likely the use cases won't overlap much.

Here’s an example of what I mean from Arctic Heat Pumps. They use two different refrigerants to get the water temp up to old cast iron and baseboard temps. I’m slightly obsessed because it would make swapping the boiler theoretically easier, although at 0.43/kwh in the winter I’m not sure the math works.

https://www.arcticheatpumps.com/high-temperature-heat-pump.html

Are you referring to your cost of electricity ($0.43/kwh)where you live? Ours here in Wenatchee, Washington are $0.027/kwh. Or 2.7cents/kwh

Even cheaper in East Wenatchee

I wonder how that compares to vapor injection like the Mitsubishi HyperHeat units have.

The R410A side has vapor injection. Then an R134a side lifts the temperature higher. This is the manufacturer for Arctic:

https://www.macon.com.cn/product/evi-dc-inverter-two-stage-air-source-heat-pump-water-heaters-85c-hot-water.html

I'm going to try to upload a graph comparing the Arctic with the Mitsubishi M-Series. (https://ashp.neep.org/#!/product/34583/7/25000/95/7500/0///0 ). We'll see how the forum software does.

The reason I put it into a graph is that the two manufacturers provide specifications at different temperature points, putting it in a graph allows you to compare them visually. The x-axis is temperature in C. The top two lines are COP, red is Mitsubishi and blue is Arctic. The bottom two lines are output, which is expressed as percentage of rated output, which is at 7C for the Arctic and 8.3C for the Mitsubishi. Green is Arctic, dark blue is Mitsubishi.

As you can see, by both measures the Arctic falls short. Across the board the COP is about 25% higher for the Mitsubishi. Even at -25c the Mitsubishi keeps 75% of its rated output, which is more than the Arctic does at -12C. At -15C the Mitsubishi keeps 94% of its rated output.

This is not to take anything away from the technical achievement of the Arctic, for an air-to-water heat pump it's impressive. But that hot water comes at high efficiency cost.

Just for fun I did another graph which includes the Chiltrix air to water, as an example of a single stage heat pump. This is with water temp of 95F/35C.

The Chiltrix has the highest COP across the board, but also the biggest drop-off in capacity, less than half of its rated capacity at -20C.

I realize that a heat pump that is a drop-in replacement for an existing boiler has appeal, but the COP penalty for doing so is so severe I have to question whether it's worthwhile.

It would be interesting if the data at say 80-85F was published for the Arctic to see how it compares. The lower the output temperature, the greater the efficiency generally speaking.

Arctic has performance numbers for their single stage HP on their website, water temp 45C, https://www.arcticheatpumps.com/specifications.html

Here's the chart. Arctic is the blue COP line. I'm kind of suspicious of the 3.2 COP at -7C, the line isn't the shape I would expect.

Low-temp A2W has really good COP's. The Mitsubishi is a really good unit and they compare favorably to it. I'd rather see better capacity retention.

David King - not sure what you're saying exactly, but there are plenty of residential two stage heat pumps.

What is the relative reliability and longevity of the three types? Is single stage the best in both due to simplicity? Or is there very little difference between them all?

Log in or create an account to post a comment.

Sign up Log in