Thick, highly insulated walls are great for lowering energy bills and creating a more comfortable interior environment for occupants, but they present some unique challenges for builders when it comes to installing windows and doors.

I’ve designed and/or built homes with many different types of thick walls, including 2×4 walls wrapped with continuous exterior insulation, cross-strapped 2×6 walls (aka “Mooney walls”), 12-in. double-stud walls, and 18-in.-plus panelized walls—and that’s not all of the different types of thick walls out there. Here, I’ll describe some of the snags I’ve hit when installing windows in these thick-wall assemblies, and the solutions I’ve designed or used in response. The details shown here are for moderately high-performance envelopes in climate zones 3 and higher, but they can be used for warmer zones or adapted for Passive House performance levels. In a future column, I’ll address the issue of installing doors in thick walls.

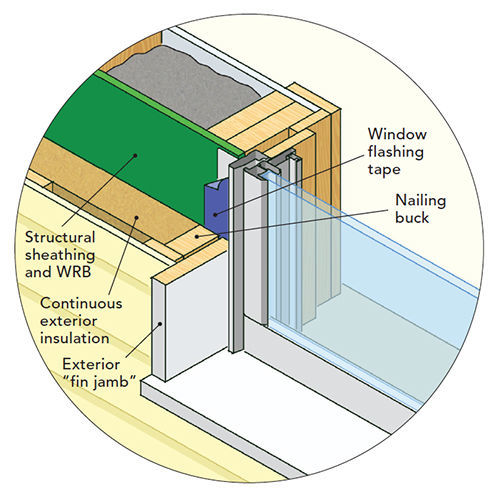

Recessed windows with “fin jambs”

Windows have to perform the functions of both the water-resistive barrier (WRB) and the air barrier. With the WRB and airtight layer at the sheathing, in some ways it’s easiest to keep the window flanges at the sheathing as well. This leaves the window recessed from the wall’s exterior plane and provides some welcome shadowlines, which are often absent from modern facades where everything is in plane. Before the continuous exterior insulation is installed, it’s business as usual. Once you add the exterior insulation, though, you have to create extension jambs toward the exterior, as well as a sill extension. This takes extra time and materials. One way to keep the added cost to a minimum is to eliminate the conventional exterior casing and allow the extension jambs to be the only exterior trim. It’s a modern look that not…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

20 Comments

Shingle returns look great!

I agree Russell. I think that's a pretty slick solution for a shingled house.

Russell,

There are a couple of good pictures of shingled-returns in this blog by Stephen Sheehy:

https://www.greenbuildingadvisor.com/article/windows-and-floors-at-a-pretty-good-house-in-maine

Always enjoy Mike Maine's contributions.

Agreed. Mike's details and recommendations are very useful.

I did a bit of travelling this month in Europe and learned an additional benefit of "innie" windows in thick walls. Add in wide eave overhangs and the windows themselves are protected from most weather. In buildings lacking A/C, the windows can generally be left open even in rainy weather for ventilation, and even when closed, the additional protection really helps with weathering. Slightly different installation details in masonry walls (attached).

Peter,

interesting observation - and aesthetically, the punched look they give is very pleasing.

Thanks for the kind words, all. Peter, good point on another advantage of "innie" windows. Flashing them properly takes a bit of extra work, but it can be worth the effort.

Im hoping we can wrap the jambs with our shingles on this project but IM afraid the sloping furring/rainscreen may make it too difficult for our price point. Carpenters blocked entire sill area of rainscreen by mistake. We may flash that now...

Tim, I don't think it would take any longer to do shingled returns with your sloping rainscreen compared to a conventional/parallel rainscreen, but it would be faster to use casing or a fin jamb.

Thank you for sharing; this is a great detail for homes with thick external insulation!

Is there any way to address the thermal bridge caused by the shingle return’s window buck? I know the shingles need a solid base for nailing, but am wondering if I could squeeze an inch or so of rigid insulation between the wood buck and the sheathing.

Also, would this detail change or is there any benefit to using flangeless windows with the shingle return? Am trying to think ahead for window replacement years down the road.

Richard

Richard, thanks for your comment. There are many different ways to install and detail a window, and this article just shows a few, relating to questions I hear often from builders and homeowners.

You asked: "Is there any way to address the thermal bridge caused by the shingle return’s window buck? I know the shingles need a solid base for nailing, but am wondering if I could squeeze an inch or so of rigid insulation between the wood buck and the sheathing."

I have used Zip-R sheathing for this situation.

You asked: "Also, would this detail change or is there any benefit to using flangeless windows with the shingle return? Am trying to think ahead for window replacement years down the road."

It would depend on the flangeless window. With many European-style windows, you may be able to eliminate the mini-casing and just land the shingles on the window frame. That wouldn't help with window replacement, though. If that's a priority, I might consider using conventional window casing at the window plane, then have shingle returns land outside the casing, on something like a backband.

Thanks Mike! BTW Has anyone ever gotten the Thermal Buck to REALLY work with one of these details? We have tried so many times but always end up with no place to attach trim (you cant attach it to Thermal Buck...you note in your detail to use really long screws but everyone of my weatherization/finish guys comes up with some reason that it wont work. ) We have tried 10 different ways to skin this cat and end up saying 'nope cant work' and then we use ZipR or a cobbled together foam board and wood buck. Which is fine. Works for us ...but I always do want to use the Thermal Buck....

Very late reply: I usually use "innie" windows; when I have used "outies" it's usually for builder-requested budgetary reasons and we end up using solid wood bucks.

@Michael Maines: I really like your fin jamb detail. Do you have any photos of this installed IRL? I’d be curious to see how folks have terminated wood siding against the “fin”, as well as the details of lapping peel and stick/WRB etc.

I was wondering if anyone has thoughts on whether the nailing buck behind the exterior “fin jamb” needs to be pressure treated or not? I wouldn’t usually worry about it for the strapping but because it is sandwiched tight to the WRB, I am wondering if this will trap water and rot.

It should not trap water, if detailed well, but it wouldn't hurt to use rot-resistant lumber if you're concerned about it. Just remember to use corrosion-resistant fasteners.

This may be a dumb question @Michael Maines, but how are you fastening the nailing buck to the wall in the first innie example? In the diagram it appears to sit directly on the nailing flange. Does it fasten through the nailing flange? Is it set wider and fastened to the sheathing? Apologies if this is obvious to others.

David, that's a good question. Attached is my drawing that Fine Homebuilding's artists used to develop the 3-D images in the article; if you look very closely, you might be able to tell that I was holding the buck just off the edge of the nailing flange, but sitting on the tape that spans from the flange to the WRB.

I don't use continuous exterior insulation often but I have used a similar detail to this several times, with a strip of foam or ripped strips of Zip-R between the buck and the extension jamb to allow more space for the nailing flange.

That makes sense to me. Thank you!

You're welcome! I have also used a similar detail to this one, combined with the one with shingled jambs, using a small piece of casing over the nailing flange but then using extension jambs instead of shingled jambs.

Log in or become a member to post a comment.

Sign up Log in