This article was originally published by the HVAC School; it has been slightly edited. It is the last in a three-part series.

I am picking up where I left off in part 2 of the series, where I discussed how a pressure reading from an attached zone indicates only the ratio of the collective size of the leaks between the zone and the envelope with relation to the collective size of the leaks between the zone and outdoors (and vice versa). In other words, a zonal pressure diagnostic (ZPD) reading by itself does not tell us if a zone is very leaky or not. And it sure doesn’t mean that a given zone is “X% connected to outside.”

Here is a quick visual: First, we see a high ZPD reading (21.3 Pa) taken with a pressure pan over a recessed light. Despite this high-pressure reading—said to be “42% connected to outside”—we see that, as measured with an Acin FlowFinder–powered flow hood, it is only contributing less than 5CFM50 to the total blower-door number of the envelope.

The same day, at the same house, using the same instruments, we now see a ZPD reading taking over a supply register of a mere 1.4Pa. One would be erroneously led to believe that this is insignificant. After all, it is only “2.8% connected to outside,” right? We see, however, that this 1.4Pa is actually responsible for over 40CFM50 of the total blower-door number for the house. The blower door was running, maintaining the house at -50Pa for these tests.

That is nine times more air leakage for a pressure reading that is 15 times lower. The margin of error for this method of ZPD interpretation is just too high not to be taken seriously. To fully understand ZPD readings, we need a second piece of information in addition to the pressure. There are two ways to get to this second factor.

First approach: add a hole/flow methods

These methods are the gold standard; they are also the most complex. They consist of running the blower door to maintain a -50 Pa pressure in the house, and then take a ZPD reading of a zone before and after, adding an opening of a known dimension between it and the envelope. In cases like a crawlspace, where there might not be an opening to add between it and the house, the ventilation of the zone to outdoors can also be altered (increased or reduced) to accomplish the same purpose.

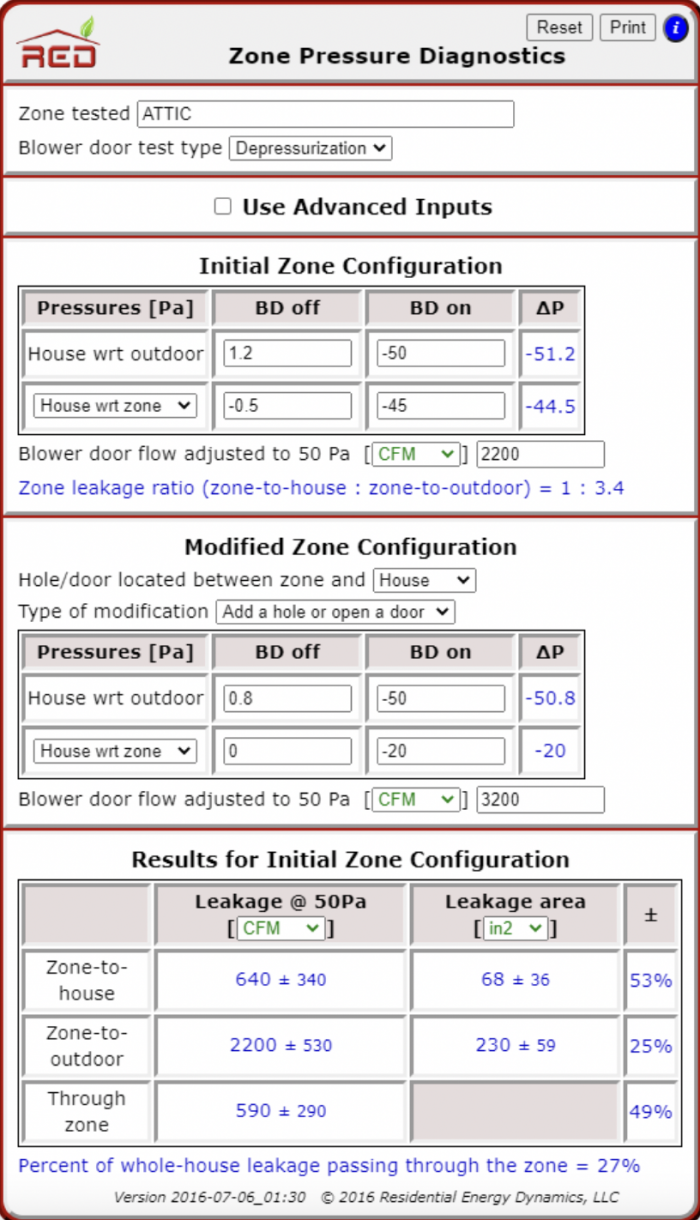

Translation: You take a ZPD reading of, say, an attic with the access door closed, as it would be taken normally. Then, you take another one after intentionally opening it to the house. Once you “add a hole” between the house and the attached zone, you create a before and after envelope pressure, CFM50; that’s a pressure relationship that can be converted into how many CFM50 each zone independently contributes to the total CFM50 value for the envelope. We do this using software or charts that have been developed for this purpose.

The two that I have used with repeatable results after enough practice are the ZPD Trainer from The Energy Conservatory (main photo) and the zone pressure diagnostics from redcalc.com (bottom photo above). The latter uses what is called the “Add a Flow Method.” To use the Add a Hole method, you’d have to know the dimensions of this added opening between the zone and the envelope.

Each of those has an accompanying user’s manual that breaks it down into steps for the user. The ZPD trainer’s manual is particularly good and detailed. There are, however, several real-life situations that are not mentioned.

At the end of this article, you’ll find job notes I made after some trial and error and peppering the experts with questions. They would only make sense once you’ve gone over the user’s manuals for the software linked above, though.

But even without going that deep, you can tell it looks like a pain in the butt, doesn’t it? That’s because it is . . . kind of. I suspect that until a more conventional software is developed, this method will remain on the back burner. Imagine a blower door manufacturer that automates the ZPD process as an integral part of their reporting software.

I can tell you, however, that it wasn’t until I started getting repeatable results using the Add a Hole/Flow methods that it all clicked for me.

Second approach: G-ZPD method

This method is the one I like best. I developed this approach after I started running into the same numbers under similar sets of circumstances. Broken down into steps, it works like this:

1. Develop an understanding of how well vented the zones are that are being tested. (This was described in Part 2 of this series.)

A side note: attic or crawlspace ventilation is straightforward:

- Are there soffit vents along the roof overhang?n

- Are there vents along the side of the house?

- Can you see light if you go into any of them?

- Can you feel air movement across these vents? This last one is largely dependent on indoor vs. outdoor temperature differential, as stack effect is its driving force.

You don’t necessarily have to calculate the total free area of the ventilation openings for an attached zone. You just need to gain an understanding of if its ventilation pattern.

2. Establish the pressure ratio relationship between the zones and the envelope

This is where you can estimate how much of a contributor a given zone is to the total envelope leakage (CFM50). By the way, avoid doing ZPD using ACH50. Calculating the volume of an envelope/zone can be an inefficient experience. Maybe avoid ACH50 altogether… unless you use 3D modeling software or something similar. But I digress.

Once you identify an attached zone as well-vented (or not), clock its ZPD reading, and understand the ratio relationship of leaks of the zone to outside vs. the zone to inside, you’ll be way ahead of the curve. It is also an invaluable tool for diagnosing comfort issues within problematic envelopes.

Here is an example:

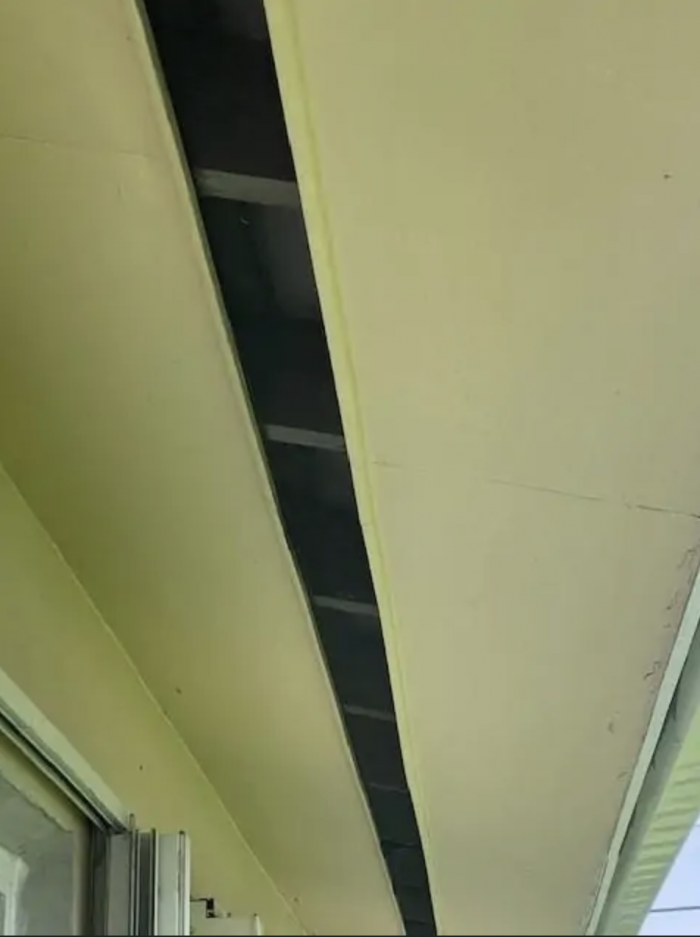

If you are testing a house with a vented attic, and when you look under the eave, you see what’s in the photo at the right.

Next, confirm the soffits offer a clear ventilation path from outside and into the attic. If so, then that ZPD reading better be 50 Pa. Otherwise, if it were 48 Pa, for example, that means that the collective size of all the infiltration paths between this attic and the house is 1/8 the size of the ventilation paths between the attic and outside.

Here’s another way of looking at it:

Let’s say you are testing a 3000-sq.-ft. house with a vented attic. It was built to some code, somewhere, requiring 1 sq. ft. of attic ventilation for every 300 sq. ft. of attic floor area. To simplify the explanation, let’s say this is a slab-on-grade house, and the windows/door assemblies, as well as the ductwork, are fairly tight. So, the main concern as far as an envelope leakage contributor is the attic, an attached intermediate zone.

That would mean that this vented attic has 10 sq. ft. worth of ventilation area (3000/300). If a blower-door test were done in the house and the ZPD reading of the attic was 49 Pa, then this would mean that the infiltration area from the attic into the house is 1/13th of those 10 sq. ft. (.76 per sq. ft.). Since each 1 sq. ft. of leakage contributes about 1400 CFM50, it would, in turn, mean that this is a fairly tight house—or one with a low Leakage Area to Infiltration Ratio (LAIR); CFM50 to conditioned floor area ratio.

If, on the other hand, the ZPD reading was 45 Pa, then the infiltration area from the attic into the house is 1/4th of the 10 sq. ft., so 2.5 sq. ft. This would surely mean that this is a fairly leaky house—one with a high LAIR.

With the exception of cases where windows/doors assemblies and duct (outside the envelope) leakage are the biggest contributors to the total blower-door number, the pattern of low ZPD readings from vented attached zones equals leaky envelopes is consistent. This is particularly true of zones that share large surface areas or boundaries with the conditioned space, as is the case with attics and crawlspaces.

Remember from part 1: Big hole = low pressure; small hole = high pressure.

3. Assess ZPD readings for interior rooms.

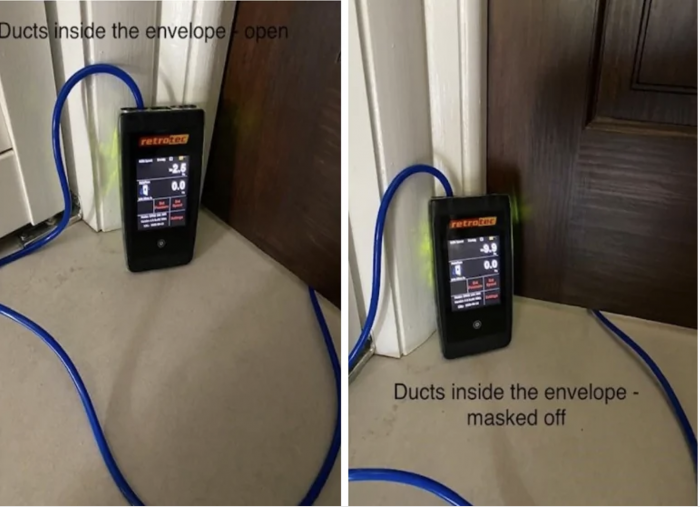

If you take anything away from this series, let it be that when you are taking ZPD readings for interior rooms that can be isolated by doors, mask off the ducts, mask off the ducts, mask off the ducts. Without at least this detail, it is like checking external static pressure but only putting one probe in the supply side, leaving the other port open. We can call that Static Pressure Theater.

I don’t mean all the ducts/vents throughout the house; I mean only the duct(s) for the room you’re doing ZPD on. I also don’t mean ventilation ducts terminated directly outdoors. Only those that connect the isolated room to the rest of the house once the room door is closed.

So, now what? You’re going to have to calculate the CFM50 from each room? It can be done but that’s not my recommendation. Instead, after you’ve covered the vents/ducts from an isolated room, take the ZPD reading from the room. The accuracy of the reading will be improved between 100% and 400%. Once there, a quick way to assess a room’s leakiness is to slowly begin to crack the door open to 1 to 2 in. If the room ZPD drops to or near zero, then it’s a small leak. If it only drops a little or not at all, it is a larger leak. At that point, I’d recommend setting ZPD aside and breaking out the thermal camera or the smoke tracer—if finding these leaks is important to the client, given the testing objective.

So, since ZPD has been around for decades, I’m cautiously convinced that I can’t possibly be the first one ever to have figured this out. Therefore, there must be a reason why ZPD testing is only used by pros in the field, who tell homeowners that their room is “X% connected to outside.”

From what I have gathered, the strongest position against “advanced” ZPD testing is that its complexity will actually confuse clients and be detrimental to the sale of much-needed home-performance testing. This is a legitimate argument. If ZPD is used as part of a sales strategy, it can absolutely ruin it for you, the tester. And more importantly, it can ruin it for the homeowner, who is really the party that will benefit the most from proper testing, diagnosing, and tailored improvements to their home. It is also true that ZPD testing doesn’t have to be a must-do on every home-performance evaluation that involves a blower-door test. But does that mean that it should be neglected?

There is little chance homeowners will learn the refrigeration cycle. Therefore, they’ll never completely understand why it is that they need a new metering device, for instance. Should we, as HVAC pros, unlearn superheat and subcooling and recede into the beer-can-cold days? It is not like the average client can read a fan table. So, are we going to give up on static pressure too?

ZPD is a diagnosis tool—a very valuable one. Use it at your own discretion or not, but if you do, consider improving its practice. I’ll wrap up with this quote from Dale Sherman: “It’s important to have a good technical grasp on the various building science factors like ZPD, but only use them to support the larger mission.”

_________________________________________________________________________

Genry Garcia is president of Comfort Dynamics, Inc., a full-service heating, ventilation, and air conditioning mechanical and building control contractor based in Miami, Florida. Images courtesy of the author.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

4 Comments

A good article. For those lost in the details, properly done ZPD can tell you more about where leaks are.

> {soffit vents}: This last one is largely dependent on indoor vs. outdoor temperature differential, as stack effect is its driving force.

Research I've seen found that wind is the primary driving force for attic ventilation, although stack effect can be close.

With typical wind producing around 5 pascals and some conclusions coming from < 5 pascals of difference, it would be interesting to see more about wind induced ZPD errors.

Indeed. Dr. Collin Olson from the Energy Conservatory has helped me a lot in understanding and applying the ZPD testing techniques.

In discussing the wind induced “noise” issue with him, he explained that longer time intervals in between readings as well as logging readings through fan on/fan off cycles can help getting normalized results.

Wether or not that’s a sustainable practice due to the time that it takes to do is a different conversation.

My off-the-cuff guess is that running all tests with positive and negative pressure and averaging the results eliminates most of the wind effects. But some leaks are directional, so this can't be fully effective.

> sustainable practice due to the time

Good point. At what point is it better use of time to forget ZPD and just use the thermal camera or smoke tracer to find leaks?

Pretty early on in my opinion, time is money. This type of testing requires expensive equipment and a decent understanding of building science concepts. The compensation has to make sense for the practitioner.

Since learning and writing this series, I hardly ever bother with internal rooms. I concentrate my ZPD efforts on the adjacent zones and stay with thermal imaging for the internal rooms.

Log in or create an account to post a comment.

Sign up Log in