Image Credit: Energy Vanguard

Image Credit: Energy Vanguard Moisture transport in assemblies, a slide from Dr. Joe Lstiburek's presentation on hygrothermal analysis at the BSC Expert's Session in November 2014.

Image Credit: Building Science Corporation Heat and moisture flow equations

Image Credit: Achilles Karagiozis Joe Lstiburek and Achilles Karagiozis share a meal at the 2013 North American Passive House Conference in Pittsburgh, PA.

Image Credit: Energy Vanguard

Dr. Joseph Lstiburek started it in 2012 when, in his keynote address at the Passive House conference, he said igloos were the first passive houses and you don’t need WUFI,1 the hygrothermal modeling tool, to design and build a good house. Dr. Achilles Karagiozis, one of the leading proponents of WUFI, struck back in a presentation at the 2013 Westford Symposium on Building Science. In it he described a scenario in which Joe was in a helicopter crash in Alaska and had to build an igloo to survive. At the Passive House conference this year, Achilles expanded on that same topic.

Last week at Building Science Corporation‘s (BSC) annual Expert’s Session, the two of them presented on the same day in a daylong seminar on hygrothermal modeling. And as a bonus, Kohta Ueno of Building Science Corporation presented on his work on the modeling and monitoring of embedded wood joists in insulated masonry walls. Here’s what you missed if you weren’t there.

A lesson in water

“The three biggest problems in buildings are water, water, and water.” Gus Handegord said this a long time ago, and it’s still true. (Now I know who to give credit to for the variation on this quote I used in Matt Risinger’s Summer Camp video.)

Lstiburek began his part of the hygrothermal modeling session with this quote and a beautiful explanation of the fundamentals of building science, the laws of thermodynamics, and the behavior of water. Although most of us are thinking about the flow of turkey and pumpkin cheesecake this week, it’s the flow of HAM — heat, air, and moisture — that’s of great concern in building science, and Joe showed how it works.

The central focus was on water, which, all by itself, is the three biggest problems in buildings. According to Joe, 80% of all construction problems are related to water.

The lesson covered the fundamentals, but Joe really shone when discussing the movement of water through porous media and through assemblies. He discussed the four — yes, four — phases of water.2 Liquid, gas, and solid are well known, of course, but adsorbed water behaves differently from any of those three.

The difference between adsorption and absorption is an important one. For water in porous materials, absorption would be liquid water filling the pores. Think of a sponge absorbing water. Adsorption would be just a few layers of water molecules lining the surfaces of the pores. Adsorbed water moves differently from water in the liquid or vapor phases, and that has significant implications for building science.

After explaining the basics, Lstiburek went into the details of the different mechanisms that get water moving through materials and assemblies, as shown in the table below (see Image #2), taken from the presentation slides (which you can download from the BSC website). He covered vapor pressure, concentration, Kelvin’s equation, contact angle, and surface energy and made it all make sense.

It was a really great presentation, and if you haven’t seen Dr. Joe do this, I certainly recommend it. A lot of what he did here was part of his two-day Building Science Fundamentals class.

The task for WUFI

When heat, air, and moisture move through materials, assemblies, and enclosures, they do so with great complexity. Moisture, for example, can move via any of the mechanisms listed in the table below (see Image #2). Also, things are always changing with time, of course, and a flow usually depends on the direction taken through an assembly as well. Properties change depending on which way you go. (The fancy physics word for this is anisotropy, and it’s where the amazingly fun del operator, ∇, comes into play.)

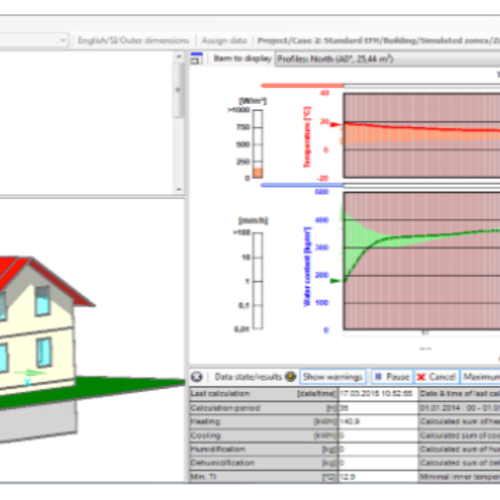

WUFI models the flow of heat and moisture through an assembly. It can do a pretty good job with isotropic (uniform in all directions) materials or assemblies… if you get the inputs right. What that means is that you can get pretty good results for one-dimensional flows in the field of an assembly, such as a wall or ceiling. Last year I wrote about WUFI 1-D and showed that it can tell you how likely a material is to grow mold based on the moisture accumulation or drying over time.

The equations that WUFI attempts to solve are shown below (see Image #3). The software does so numerically, and it requires the user to put in a lot of information about the assemblies being modeled. The solutions show heat and moisture travel across an assembly over time.

According to Joe, when WUFI came across the Atlantic from Germany, it didn’t do a good job of incorporating air flow or rain. Now the software does a better job with them, getting closer to accurate modeling of the transport mechanisms shown in the table below. You still have to know how much wind-driven rain or air leakage to model and pick the correct weather location, but “WUFI is ready for prime time,” Lstiburek said.

The uses of WUFI

When you use WUFI and get results, you can learn a lot about how an assembly or collection of assemblies might behave. One thing you can do is to model the performance of a new type of wall assembly to see if it will dry adequately.

You can also model the performance of a whole enclosure as a collection of assemblies. This is what WUFI Passive does. PHIUS allows Certified Passive House Consultants to use either the PHPP or WUFI Passive to certify Passive House projects. This version of the software incorporates the Passive House requirements, so it gives you a dynamic look at what’s happening with the assemblies as well as the conditions inside the enclosure and whether it passes or fails.

Karagiozis said a hygrothermal analysis tool like WUFI is needed to address ASHRAE’s design methodology. We didn’t need it before, he said, because buildings were more tolerant of mistakes. Now, though, we need it because of:

- Enhanced comfort requirements

- Energy conservation

- New materials

We can use WUFI, Karagiozis said, to design for increased drying performance, better water management, and more forgiving systems.

According to Lstiburek, hygrothermal analysis is being included in more and more construction contracts these days, too. But is that a good thing?

The doctors’ advice on the limitations of WUFI

Both Dr. Lstiburek and Dr. Karagiozis cautioned the audience on the limitations of WUFI. Karagiozis used the example of him trying to give his presentation by reading notes off a regular sheet of paper held up by Lstiburek all the way in the back of the room. No matter how good your eyes are, you’re not really going to be able to read that piece of paper very well.

Karagiozis also said it’s important to use the transport properties of the actual material that’s going to be used in the assembly. You can’t use generic properties because density, permeance, and other properties vary from one product to another. Extruded polystyrene (XPS) from Owens Corning, for example, doesn’t have the same properties as XPS from Dow.

Lstiburek’s statement about hygrothermal analysis increasingly being included in contracts was followed by a big caution sign. Mechanical and structural engineers, he said, are most likely to be the ones who have to do the modeling, but if they don’t know the tricks of using WUFI, they’ll get the wrong answers.

For example, he told us about a case in Houston where an engineer ran WUFI and found that the building’s walls were getting wet from interior water vapor. So the engineer specified a vapor barrier beneath the drywall. “When you get the wrong answer, you shouldn’t be doing this,” Joe said. What he meant is you shouldn’t be doing this when you don’t recognize that you’ve gotten the wrong answer.

In addition to what Joe and Achilles said, Kohta Ueno presented what he’s learned so far in a Building America project they’ve been working on at BSC (which you can download from the BSC website). They’ve been modeling and monitoring the heat and moisture flows in embedded wood joists in insulated masonry walls, a fairly common construction. What he concluded was that using a 1-D model on a 3-D hygrothermal problem is not recommended, largely because of the great number of inputs and variables. He said you could spend a lot of time on modeling a problem like this, but it’s probably not very useful.

When should you use WUFI?

According to Joe, WUFI definitely has its uses. And those uses are in assemblies that don’t have a track record, like superinsulated, supertight Passive House projects. With R-40 truss walls or R-60 insulated rooflines, the margin for error is smaller, and WUFI can provide valuable insights into how those assemblies might work. You still have to follow up with monitoring the actual performance, but the modeling might be able to help you avoid costly mistakes.

“The tool is phenomenal,” Joe said, but he wants to help reduce the mistakes people make by using WUFI. To that end, BSC is working on materials to help users learn what kind of tolerances they’re dealing with. The BSC team is putting together lists of inputs that will produce certain results so users get a feel for the inputs and the outputs.

“I’m hoping two-thirds of the modeling that’s being done now won’t need to be done,” said Lstiburek, “and the modeling that’s needed is done correctly.”

What happened to The Igloo Chronicles, Part IV?

If you’ve been following the debate from a distance over the past two years, you might think Joe and Achilles hate each other. Nothing could be further from the truth. They’ve worked together for a long time, and Joe talks admiringly about all the hours Achilles put in to read and comment on his doctoral dissertation. I got to spend time with them at the 2013 North American Passive House conference, and it’s clear that these two men like and respect each other. (By the way, the blonde blur in Image #4 below is Betsy Pettit, Joe’s wife and business partner at BSC.)

But I just wish they’d continued the igloo theme. I don’t think either of them mentioned igloos once during the Expert Session on WUFI (although Achilles did mention candles3), so they killed my idea of calling this article, The Igloo Chronicles, Part IV.

Allison Bailes of Decatur, Georgia, is a speaker, writer, energy consultant, RESNET-certified trainer, and the author of the Energy Vanguard Blog. Check out his in-depth course, Mastering Building Science at Heatspring Learning Institute, and follow him on Twitter at @EnergyVanguard.

Footnotes

1. WUFI stands for Wärme- Und Feuchtetransport Instationärs, which translates literally (according to Google’s translator) as Heat and Moisture Transport Unsteady.

2. Since I was trained as a physicist, I thought the fourth phase would have been plasma the first time I heard someone talk about the four phases of water, but plasma doesn’t really come into play in building science, unless you’re working on a physics lab or nuclear fusion reactor.

3. In his earlier WUFI talks, Achilles described a scenario with Joe burning candles to try to stay warm enough inside his makeshift igloo to keep from dying after his Alaska helicopter crash. At the PHIUS conference this year, he also told the audience that Joe loves candles, especially scented ones, so if you want to be his friend, just give him a candle. So I gave him one last week. You should, too.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

12 Comments

CFD

“Mechanical and structural engineers, he said, are most likely to be the ones who have to do the modeling, but if they don't know the tricks of using WUFI, they'll get the wrong answers.”

“if you get the inputs right. “

In other industry Engineers do not do CFD (Computational Fluid Dynamic) modeling. There are subject matter experts, such as physic, aerodynamics, thermodynamics, etc, teams even that specialize in the development. Usually a heat flux load cell in a lab provides the inputs that are developed further by interactions, sometimes many, of prototype builds and back calibrating the model to the specific design. There are commonalities or empirical data but normally each situ has to be analyzed. Trash in trash out, including the user.

That information or load is transferred to FEM (Finite Element Modeling). There are some softwares that integrate the two but from what I understand not as effectively.

I been around of enough of this process to know, don’t waste your time unless you have the time and know what you are doing. Much can be gathered from field observations.

Besides it's much funner to watch all the "perm rating this and that" guess work that makes people LOOK like they know what they are taking about. ;)

"doesn't have the same properties"

"You can't use generic properties because density, permeance, and other properties vary from one product to another. Extruded polystyrene (XPS) from Owens Corning, for example, doesn't have the same properties as XPS from Dow."

Nicely stated, but men in the field assembling these structures do not understand these dynamics. Most do not rely on any other source but the shelf these products are stored on at HD or Lowes. That's their engineer!

This issue is going to confuse the daylights out of most builders and solution builders. Foam panels are spoken about constantly on GBA blogs as if there's no difference between product A versus B of like kind. Dr. Joe said it so it must be true! ;)

Terry I love your quote! "Besides it's much funner to watch all the "perm rating this and that" guess work that makes people LOOK like they know what they are taking about. ;)"

That is very true! Some people seem to be making a tremendous living off of complicating our building systems. It's no wonder our homes are filled with chemicals beyond belief and our homes are in constant need for repair. Buildings are science projects for the few elite to experiment on through the art of confusion!

plasma

Plasma is also used in fluorescent lamps...the best of which still have higher efficacy and better colorf than most leds.

Joe is the best thing to hit

Joe is the best thing to hit the modern building world.

Richard your post makes no sense to me and again your prosecutorial you has come forward. Good luck with that. Most builders build from architects plans and have stacks of them in their office.

Your HD scenario had me laughing thanks for the chuckle.

You should build for a decade, get on the other side and then come back to your posts here and see what you think. It be interesting I think for you.

And Terry yes we know you're an engineer! Attend a Joe L. Seminar soon is my first and only thought. I have. Joe is the god of the gods in building world. You, no comment, interesting though... You open doors I never open which I like, though irrelevant often for me anyway.

Good blog about WUFI Allison, thanks.

AJ

I thought YOU were the GOD of building science....Is this your free-flowing polyurethane foam home?

http://www.zillow.com/blog/bethesda-mushroom-house-163230/

Did you use WUFOOL to design it? ;)

Link to paper?

Allison - is this the paper you are talking about above? http://www.buildingscience.com/documents/confpapers/cp-1301-field-monitoring-simulation-historic-mass-masonry-retrofitted-interior-insulation/view?searchterm=Kohta%20Ueno

Timely - we were just talking about this specific issue at our most recent discussion group (a confessional session about building science mistakes we have known and loved. Or at least survived).

Terry irrelevant as usual

And not even interesting.

Response to Dan Kolbert

Dan, no, here's the link to the Kohta's presentation from last week:

http://www.buildingscienceconsulting.com/presentations/documents/03_Embedded_Wood_Joists_Insulated_Masonry_Walls_Ueno.pdf

WUFI Processing

Richard, out of the entire article besides the ones I quoted, the one you quoted put a smile on my face that someone at least knows what the heck is going on here. Property input is a huge part of the design process.

AJ wrote: Richard your post makes no sense to me and again your prosecutorial you has come forward. Good luck with that. Most builders build from architects plans and have stacks of them in their office.

AJ You go around this site mocking people that actually have the design experience you very obviously do not! I'm amazed that GBA allows you to continue to personally attack professionals. We try to ignore you but, it does get old. I'm convinced most of your experience is right here on GBA, your not a builder, and have NO real design engineering experience....all you have is 'irrelevant' inaccurate comments, lets look at some of yours,

AJ wrote: Richard your post makes no sense to me and again your prosecutorial you has come forward. Good luck with that. Most builders build from architects plans and have stacks of them in their office.

Absolutely incorrect!! First off, I don't think the 'most builders' of America appointed you as a spoke person so speak for yourself. I'm sure you would never qualify to represent "most builders".

The fast majority of homes in America are not Engineered nor are they built to plans. Most jurisdictions allow building to code, called a "prescriptive path, of known's based on code that is developed by a committee (IRC) with manufactures on it, and do not do plan reviews. Code is flawed (different topic). Homes are inspected to code. If you want to design custom(rare) or not to code you need a plan, professional engineer(s), and perhaps an independent inspector that understands the design. Commercial requires plans for public safety. Besides, this has NOTHING to do with the WUFI or blog. Richard is absolutely correct in that WUFI is typically not part of the process. Contractors, builders, act as Engineers that know nothing about it and are allowed at the home level. That is the reason why homes are a mess, only last 20-25 years at best. In professional industries builders would not be allowed to be part of this blog discussion. Why? because just like you they just don't get it and bog the conversation down with "irrelevance" which is really a lack of education and experience. Most engineers stay out of building, most builders stay out of Engineering. The only time an Engineer should communicate the design with a builder is to make sure it is build able, thats all! In a mass manufacturing environment this is critical, since large budget is in building, not short term R$D. Had you ever been part of the design-build professional process you would know this, understand CFD and WUFI. The reason you can not identify is again, you have no clue what you are talking about or the subject matter, "as usual".

AJ wrote: You should build for a decade, get on the other side and then come back to your posts here and see what you think. It be interesting I think for you.

I fail to see how this applies to WUFI? Do you have Richards resume in front of you? How do you know what he has built?

AJ wrote: And Terry yes we know you're an engineer! Attend a Joe L. Seminar soon is my first and only thought. I have. Joe is the god of the gods in building world. You, no comment, interesting though... You open doors I never open which I like, though irrelevant often for me anyway.

Believe you me, I do not value your "thoughts" or what seminars you think I need to attend, completely "irrelevant to the blog" .....I've have just as much if not more experience than Joe in design, 30 + years designing and building, believe me when I say I don't need to attend one of his seminars to learn the process. I do recommend you do and stay out of topics you have no experience with. Leave members that obvious do by their post alone. We are not out here to make sure you understand basic engineering principles, this site last I checked, is not an Engineering 101 school for builders. If you want to act as engineer or designer go pay the price, get a degree, get hired in an Engineering firm, get real!

Back to the blog...

The design software does need to assign mechanical and thermal properties to each material and make no generalities. I have seen the smallest change in material properties make a huge difference. For example, the glass transition temperature of seals, or foam, or deflection and creep allowable for foam. We were just discussing this on a basement blog, many of which could not understand creep and deflection of foam. With creep and deflection as input material properties, along with many other properties the manufacture does not provide, such as, elastic modulus, tensile, shear, moisture content limit, etc, a CFD software can apply moisture, water, dynamics, etc, to determine flux loads that can be imported and used to determine the affect on mechanical or structural properties, or materials allowables (stress/strain, deflection, creep, fungi, etc)....This would be very useful in foundations where water is typically an issue as seen by a healthy foundation repair industry. Another failure mode that could be predicted is rust and chemical break down of plumbing, galvanic and pitting corrosion, life cycles, etc....

I have worked in industries that does this daily, so it is already done, nothing new and the comments in the article common general knowledge but, as I said it gets expensive. It is very useful, the model can show kinematics (motion around an axis) or worse case deflection for a basement in 3D, and there are measuring tools. The model shows the failure paths, a good designer can change that path. Yes some industry can actually design the failure paths if the input parameters are accurate. Design to fail. We can also design crack growth and propagation directions. Again, there are subject matter experts.

The other large part of the process the article did not mention is "Human Factors Engineering" . Again, there are subject matter experts. I have produced models and studies using the "80% percentile man or women" .....material properties are assigned to humans. Back in the day, in America, we would only include American people, now international, which changed the shape of size. This is controlled by international standards.

With that said, I'm not sure the building industry will ever get to a point of a comprehensive easy to use accurate program that is affordable. Not at least until as Richard pointed out Engineers are part of the home design process by law, and code has adopted CFD analysis without the manufacture, and the manufactures are required to test and disclose all material allowables for design processing by qualified Design Engineers or Architects. There are alot of variables and complexities in the accurate design process to get it right. Even those that have the expensive tools make mistakes.

Thanks for the link

We were faced with the same dilemma. In the end, we were only going to be able to insulate an insignificant % of the shell, so we decided it wasn't worth the risk and expense. But if we'd done so, I was thinking about burying a wireless HOBO meter at the beam end and monitoring conditions for a couple of years until the battery died.

Lack of good material data also a significant WUFI shortcoming

Considering how often it must be used in WUFI, the PIR insulation material entry in the WUFI Material catalogue is pretty poor - it assumes:

x Linear thermal conductivity, wet or dry (definitely wrong for un-aged pentane-blown PIR)

x Constant thermal conductivity, wet or dry (definitely wrong)

x Constant water vapour diffusion resistance (definitely wrong)

x Humidity-dependent moisture-storage is inaccurate (especially at very high humidities)

This combination of short comings makes the modelling of PIR below slabs and green roofs (for instance) highly inaccurate in some cases.

At least two or three of those shortcomings also apply to WUFI's shipping EPS and XPS material definitions.

WUFI could really do with an online user-contributed assembly and material library (much like SketchUp does for user-generated 3D models), but even with this, the PIR model is impossible for a user to fix in the current WUFI, since I don't think it supports temperature dependant vapour resistance.

Also as someone who's worked in the software industry, I have to say that the WUFI user interface is a bit sucky.

WUFI is still an excellent tool, and in many cases it's way better than nothing, but a few aspects of it handle too much like a $25 shareware tool circa 1995, rather than a $1000 piece of professional modelling software.

Add Terry

Well I hope you add lots of useable info for all of us builders to refer to. Maybe someday your picture will be up with the other four building science authors here at GBA.

Terry if we met someday I could show you all the neat projects I have done with less than an engineering team or finished degree. I think you would like many of them.

Glad you enjoy sharing your engineering acumen. I do enjoy your posts even though the Dreamliner engineering group to build a home has not been something I am convinced of. Get the teams up and running, produce some homes and I would love to see the results... Your passion seems great and endless which is super.

Log in or create an account to post a comment.

Sign up Log in