Image Credit: Energy Vanguard

Image Credit: Energy Vanguard Poorly supported flex duct. Runs of flex should be straight and pulled tight, not sagging, as these are.

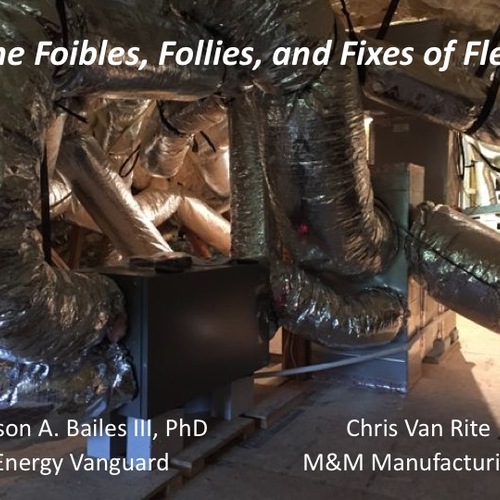

Image Credit: Energy Vanguard Behold, the Mighty Ductopus! A radial flex duct system like this one has a very poor chance of getting good air flow.

Image Credit: Energy Vanguard The duct that's too long. Sometimes installers do this to cut down on noise, but it also cuts down on air flow.

Image Credit: Energy Vanguard Torn flex duct at boot. The stress at sharp bends will cause the plastic liner to fail, as shown here. This supply duct was leaking a lot of conditioned air into the unconditioned attic.

Image Credit: Energy Vanguard

Ah, flex duct. That bane of home performance contractors and green builders everywhere. If you’ve seen only one forced-air duct system that uses flex, you’ve most likely seen a bad installation.

Good installations are certainly possible but are quite rare. Since I began blogging in March 2010, I’ve written quite a few articles about problems with flex ducts. In fact, whenever I can’t figure out what to write about, I look through my photos and often end up writing about another way that flex duct gets abused. It’s always fun to write these articles and as easy as shooting fish in a barrel (which I’ve never actually done but have always wondered why the fish were in the barrel to begin with and why someone wouldn’t just use a net to get them out).

I’ve posted plenty of photos of bad flex duct installations in the Energy Vanguard Blog and have seen much more. Remember Stumpy, the flex duct amputee? This photo (above) has become so popular that it’s showing up in other people’s presentations (with no attribution, of course. Grrrrrrr!). I found ol’ Stumpy in a crawl space here in Decatur, Georgia (hovering above a dead squirrel).

Problems with flex duct

Flex duct is almost never installed correctly. I’ve been in thousands of houses, both new construction and older homes, and I’ve seen a lot of flex duct. Mostly the installation is pretty bad. In new Energy Star homes or EarthCraft Houses, it’s usually better, but I don’t think I’ve ever seen one that made me step back and say, “Now that’s how you install flex duct.”

The most common problems I see with flex are:

So, yeah, flex duct has a lot of problems. Should it be banned completely? Should green building programs not allow it?

Energy Star (which isn’t a green building program but ducts are well within its purview) allows flex.

LEED for Homes allows flex.

The NAHB Green Building Standard allows flex.

Hmmmmm. I think Minnesota GreenStar doesn’t allow it, but I don’t know of any others. (Readers, please let me know of any programs you’re aware of that ban flex duct.)

Alternatives to flex duct

Well, if we’re not going to use flex, what’s left? There’s duct board — rigid fiberglass with a foil facing — but, in my opinion, that’s worse than flex. If any duct product should be banned, it’s duct board.

That leaves rigid sheet metal, often called hard pipe. In my opinion, hard pipe is the best duct to install. Here’s why:

- It must be designed. The installer can’t just show up and throw it in.

- The resistance to air flow is much lower.

- Most of the problems in my flex duct list above are irrelevant for hard pipe.

But hard pipe is not without its own problems. Some of the leakiest ducts I’ve tested have been made of sheet metal, not flex. The hard pipe photo you see below is one that I tested and sealed several years ago, and it turns out that it was being held together mainly by the duct insulation! When I pulled the insulation off the branch you see there, it collapsed. Of course, it had been in that attic about 30 years.

To ban or to fix?

Although I’ve been accused of wanting to take away your freedom of choice (because of my articles on can lights and McMansions), I do not think that flex duct needs to be banned. I’d just like to see it designed and installed properly. Its best use is for relatively short runs in a trunk-and-branch system, not entire air distribution systems.

Mike MacFarland, a home performance contractor in California, had some of the best advice I’ve seen for using flex. He wrote in a comment to one of my recent flex duct articles, “The trick to getting these installation right is to use rigid ductwork for all ‘deviations from straight,’ then pull the ductwork taut between the two ends which now point towards each other.” So if we’re going to ban something about flex duct, it should be banning it for changing the direction of air flow. I could almost get behind that. I do believe that long, gradual turns aren’t so bad, as long as the inner liner is pulled tight and the duct is properly supported.

The problem here is not the product; it’s the process. It’s also part of the larger issue of the HVAC industry underperforming, to put it nicely. Flex duct, I believe, can have a place in high performance homes. We just need tighter quality control.

Allison Bailes of Decatur, Georgia, is a speaker, writer, energy consultant, RESNET-certified trainer, and the author of the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

22 Comments

Question

Allison:

Does your opinion stated above also apply to small duct, high velocity systems, where they use jointless, insulated flexible ductwork?

Why not just get rid of ducts already

I don't understand why nobody does hot water rads in America like they do in Europe and used to do here. It is quieter and you don't have these problems of crappy leaky ductwork. What works for heat is lousy for AC anyways.

I have hundred year old rads under windows and a few Runtals where I have renovated, and I am comfortable.

Response to Lloyd Alter

Lloyd,

The answer is simple: air conditioning.

(I know, you're Canadian... so it's easy for you to imagine that heating is much more important than AC.)

Ductless minisplits solve the problem.

For Lloyd

I agree on heating, but what do you propose for air conditioning? Radiant cooling?

Answer for Lloyd

In a word:

Cooling

It's hard to cool a place with hydronic systems in most of the US (particularly the latent loads), and when economizing on mechanical systems the ducts tend to get used for both (and are sometimes properly sized for neither.) While panel radiators and radiant floors running at efficient condensing temperatures for the boilers are very cushy-comfortable, it's also substantially more expensive than condensing gas furnaces (or even heat pumps) even before the expense of separate heating & cooling systems get factored in.

In CA under Title 24 duct systems are required to meet Manual-D design criteria, and be pressure tested to a reasonable max-leakage number. But it's clear that not all local inspectors or installers are fully up to speed on Manual-D.

air conditioning with hydronic

you don't need ac under the windows like you do with heat, so I would agree with Martin, ductless minisplits.

Response to Lloyd Alter

Lloyd,

With a good envelope and good windows, you don't need hot radiators under the windows either. Your heat can come from the center of the room.

And if you have a ductless minisplit unit for cooling, you can also use it for heating -- so you don't need radiators anywhere.

I'm 100% with Martin on this

I'm 100% with Martin on this one. In a slightly-better-than code house with decent windows you can put the radiators or registers or mini-split heads almost anywhere. And if cooling with ductless, you may as well heat with it rather than blowing another 10-15-20 grand on condensing boilers and low temp radiation. Heating with mini-splits is remarkably comfortable- far more so than ducted fossil fired (or tepid heat pump) air, with very stable, even room temperatures. While it's not as cushy as radiant floors on the coldest days of the year, it beats fin-tube baseboard for comfort hands-down.

Since the vast majority of the heat gains through walls are from the windows, cooling that blows across the sun-swept parts of the room (not necessarily at the window) does in fact add to the comfort levels, and it's still right to consider those aspects when placing ductless heads or AC registers in rooms with south or west facing glass, even with low SGHC windows.

Should Flex Ducts Be Banned?

Probably not but I do think that those installers should be shot...

Response to Keith Groninger

Keith,

The death penalty seems a little harsh...

It's too bad

... the professional associations don't carry more clout with members. Instead, the organizations made up of pros have (always?) made the policies and positions with the organization giving a voice to the lowest common denominator.

It's not just construction. The tail wags the dog.

Going ductless

I've been trying to develop ductless and refrigerant-less personal air-conditioning for a few years now. It was intended to be an installation-free system just to make the technology more accessible. Never knew there existed so many installation problems. Thanks Allison for the article, I'd like to use some of your pictures and, being a trained researcher, will certainly acknowledge my sources!

Here's a page on ductless task air-conditioning. Comments, critiques, doubts welcome:

http://about.me/zfer

I like the even distribution

I like the even distribution of hot water heat. Part of it is convection and another part is the radiation off of the warmed walls that are heated by the convection. I am not too crazy about the traditional fin tube housings though. I like the modern panel type radiators which are mostly a true radiator rather than a combination convector/radiator. It seems like there is potential for some new ideas in that area.

Sorry, looks like snake oil!

The description of the "task air conditioner" mentions a melting phase change material. I'll take that to be water, since it is the most energy dense, non-toxic, non-flammable and cost effective phase change material that I know of.

That said, it takes a heckuva lot of "melting phase change material" to duplicate the refrigerative effect of even a small windowshaker AC. For example, one would have to melt close to 40 pounds / 5 gallons of ice per hour to replicate the effect of a 6,000 Btuh air conditioner. Aside from the sheer bulk of such amounts of ice there are several design issues:

1) Creating a compact heat exchanger to melt ice at the required rate of heat transfer is difficult.

2) Creating a simple compact heat exchanger to produce ice at a reasonable rate is difficult.

3) Freezing water for later air conditioning is inherently less efficient than directly conditioning air owing to greater refrigerative lift (delta T between cold and hot sides)

While there are ice storage AC systems that take advantage of cooler nighttime temperatures and lower off-peak electric rates to reduce cooling cost, they are massive, engineered, field erected structures, not plastic boxes acting as end tables beside a couch.

Sorry, it was a nice try and a spiffy web page, though.

Curt, that was vigilant...

Hi Curt,

Thanks for the comments, love your analysis but allow me to highlight some areas you may have overlooked.

The logic behind task air-conditioning is similar to task lighting: you're not chilling the whole space, just the individual. The requirements differ by orders of magnitude. In task cooling the refrigeration is about 60W (205 BTU/h, Drake, 2010).

When used in a naturally ventilated environment the supply temperature is no longer a fixed or objective parameter but varies with mean outdoor temperature. The adaptive comfort standard in AHSRAE-55 requires indoor operative T a couple of ºC (a few ºF) below outdoor T. This is delivered by DTAC at 5-20 l/s (10-40 cfm) to the breathing zone, similar to an aeroplane's passenger blower vent.

The phase change material (PCM) in this case is a paraffin wax, we need a phase transition temperature above ambient as the tank has not been insulated, in order for it to regenerate passively. Depending on use and climate, the PCM has to be selected to be slightly higher than the hottest day's temperature. Heat is pumped and stored when the unit operates (it does not pre-charge the PCM), and released after that. The challenge, you have rightly pointed out, was to melt the PCM in a controlled way so that the solid wax continuously fed to the hot side of the thermoelectric modules. This has been achieved though I'm afraid I'm not allowed to disclose how.

In terms of efficiency the TE modules have a paltry COP ≤1. When installed in my handmade prototypes the overall system COP was 0.2 (Law, 2012). Not great but the production version will be much better with tighter tolerances.

Once again I appreciate the comments and look forward to any and all responses.

References:

Drake, Scott. 2010. The use of personal ventilation in open plan offices: a study of the TASK AIR system. In Stephen Loo, et. al. (eds), Performative Ecologies in the Built Environment: Sustainability Research Across Disciplines: 43rd Annual Conference of the Australian and New Zealand Architectural Science Association, Launceston: 2009.

Law, T., Sargison, J., Fay, R., & Banbury, S. (2012). Ductless Task Air-Conditioning. ASHRAE Transactions, 118, 367–374.

Response to Tim Law

Tim,

I'll tell you why my snake-oil defenses immediately went up: because you used a web page to announce a technological breakthrough product without answering any questions at all. The reader immediately smells a rat.

The visitor to the web page wants to know: what is the phase-change material? How many ounces or pounds are used? What is the cooling capacity of the unit? How many watts does it draw? Where does the heat go at night? If all of the heat stays in the building, how is there a net benefit?

Selling a black box without any explanations won't work. Everybody just thinks, "Another Amish heater..."

Reponse to Martin Holladay

Fair enough, Martin. It was a rather simplified presentation meant for a general audience, obviously over-simplified for this forum. And what was I thinking? Guys here need to be hawk-eyed to make sure ducts are properly installed, and smell a rat from a mile! I'll work out another website for the technical-minded. In the mean time I'll just answer your questions in this post.

There is about 15kg (33lbs) of PCM, capacity of 2500kJ (2400BTU) power draw of 200-300W (it boils down to the quality of TE modules we can get for the manufacturing budget). In office applications, the heat is expected to stratify in the ceiling return (plenum) at night. If adopted at a large scale some reprogramming will need to be done for AHUs to purge that in the morning. In homes, the heat is expected to be removed by natural ventilation.

Now I think I get it

You propose to use Peltier-effect solid state thermoelectric heat pumps to extract heat from a very low airflow (10-40 CFM) and direct that slightly cooled air at the head of the deskbound worker who is presumed to be largely immobile, similar to a seated airline passenger.

That heat melts 5 gallons of paraffin wax, which is somehow re-solidified after hours. Apparently the whole thing operates at a fairly miserable COP, rejecting several times as much heat as it extracts.

In round numbers a 25 CFM airflow with 205 Btuh removed from it will be cooled by about 6*F

So I guess I can validate the concept.

Off the top of my head, that might make an office worker comfortable in an ambient environment a few degrees above normal.

In the grand scheme of an office environment it is hard to imagine what good this system could do since it adds a great deal more heat to the office / home environment than it extracts from the air right around a worker's head. Furthermore, cooling air by just 6 degrees offers virtually no potential for dehumidification.

This concept seems useless for homes since home residents continually move about, unlike office workers or airline passengers.

This concept seems useless for offices in all but the most benign of climates since most office buildings are characterized by high internal heat loads (lights, computers, workers) and this system's miserably low COP would serve only to add to already high internal loads.

Evening ventilation would greatly increase humidity in most US climate zones much of the year.

What say you now?

Response to Curt Kinder

G'day Curt, thanks for validating the concept.

The genesis of the concept was for the office, where majority of thermal comfort research has been predicated. Many will already be familiar with how office air-conditioning is routinely oversized. For example, almost half of the office occupants in Singapore surveyed by WWF responded that air-conditioning was too cold (WWF, 2011). Engineers, whilst in a position to optimise M&E systems, are presented with two motivators for doing otherwise: a professional penalty for undersizing air-conditioners, and a financial incentive for oversizing them.

Your concern for adding heat is valid for personal air-conditioners like Herman Miller C2, where heat is exhausted from the back of the unit concurrently as cooling is being delivered. By using a PCM, we avoid that predicament and heat is exhausted after office hours, thus not burdening the central system. For use in offices it must be appreciated that DTAC only offers supplementary cooling, and dehumidified fresh air still has to be separately delivered by the central system. The change in approach is to operate at the upper end of the comfort envelope, instead of the low end. I.e., instead of sizing the air-conditioning units to achieve 22ºC (72ºF) and have occupants add more clothes if they are too cold, it can now be specified to 28ºC (82ºF) and users switch on personal air-conditioning when it is not cool enough. This will be particularly useful with displacement ventilation where thermal asymmetry (between ankle and face) can be minimised with task cooling.

You raise a valid point on the limitations to static application, and indeed DTAC is not suitable for high traffic areas like retail. Such locations need to still rely on space cooling. However where there is use for task lighting (a desk light, reading light, etc), be it in a residence or office, there will be a similar application for task air-conditioning. The aim is not to achieve the highest COP, that would be the equivalent of aiming for the highest lumen/watt efficiency in lighting. What one is after in task lighting is to have the lowest power consumption for sufficient illumination (lux) on the work plane. So even though a 10W halogen task light puts out far less lumens than a 40W fluorescent, it does the job for reading a book and saves energy. Transfer the same logic to task air-conditioning and I believe people will start to see the appeal of a 200W personal air-conditioner.

The primary inefficiency of DTAC is from the thermoelectric modules that average 5-10% Carnot efficiency, as opposed to vapour compressor's 40-55%. Thermotunneling solid-state cooling devices (http://www.coolchips.gi) seem to be ahead of the efficiency competition with a Carnot efficiency comparable to high-end compressors. See Dieckmann et. al. (2011) for a recent review on solid-state cooling. I think the efficiency issue will eventually be resolved, though the economics are still an unknown. Whichever heat pumping device we eventually adopt does not change the concept: that heat should still be temporarily stored until the central conditioning goes off.

As building managers become more energy-conscious we can also expect the internal loads to go down. The one internal load that cannot be reduced is the metabolic load, which for an office fluctuates with occupancy. I suggest that the benefit of task-ambient systems is that it allows a shift from oversizing air-conditioning, to right-sizing them for the the upper limit of comfort and allowing occupants that require more cooling to have personal systems. DTAC simply allows this benefit without installation.

References:

Dieckmann, John, Alissa Cooperman, and James Brodrick. (2011). Solid-State Cooling, Part 2. ASHRAE Journal 53(4): 66-68.

WWF. (2011). WWF - Earth Hour Poll: Nearly Half of Singaporeans Give Thumbs Down to Strong Air-Conditioning. Retrieved February 24, 2012, from http://wwf.panda.org/who_we_are/wwf_offices/singapore/?199561/Earth-Hour-Poll-Nearly-Half-of-Singaporeans-Give-Thumbs-Down-to-Strong-Air-Conditioning

I'm on board with much of

I'm on board with much of that. I routinely design for the upper end of the comfort cloud (25-26*C) and am thus able to significantly downsize AC tonnage. Since in America I absolutely cannot sell any sort of discomfort or deprivation, I downsize by exercising particular care with latent load. I trade somewhat higher drybulb temps for reduced RH, striving for 45%.

That said, while I stand by my earlier validation of your concept, it still strikes me as simply not worth the expense and hassle compared with better managing the entire interior environment. In other words, we go to great pains to seal and secure the pressure and temperature envelopes of the built environment; having done so, let's reasonably reward ourselves by conditioning ALL the air within the envelopes to comfortable temperature and humidity.

Wrapping up…

It's good to know that you are not one to oversize air-conditioning. I know I'm speaking to the converted, but many who do not read these discussions are prone to do otherwise.

I absolutely concur that we 'cannot sell any sort of discomfort or deprivation' and the development of DTAC was based on offering better economy with a commercialiseable angle: personal comfort. In an isothermal environment, the percentage dissatisfied is at least 5% under laboratory conditions (ISO7730, 2005), and at least 20% in real-life (Schiller, 1990).

Right-sizing is a valuable step but even that does not alter the fact that there is no one right temperature for all. Lee Kuan Yew, the founding prime minister of Singapore and the one who promoted air-conditioning for national productivity, works at 22ºC and sleeps at 19ºC (McCarthy, 1999). I expect the future trend in climate control to be increasingly personalised, especially as occupants become more demanding about personal ergonomics.

A brief thought and I will wrap up.

Whilst it is true that you can reduce humidity to compensate for increased temperature, the tradeoff in enthalpy is counterproductive. 'Typically a 10% higher relative humidity is felt to be as warm as a 0.3°C rise in the operative temperature' (ISO7730 p.44). Fountain (1999) has also reviewed over a dozen thermal comfort studies in moderate and high RH to find little impact with increased RH.

I would be absolutely thrilled to further this discussion and welcome anymore comments privately, or in the right forum if someone can direct me to one. I feel apologetic to Allison that we have digressed from his topic, and thanks to the GBA moderators for allowing me to go on for so long.

Email (remove numerics):

[email protected]

References:

Fountain, M., Arens, E. A., Xu, T., Bauman, F., & Oguru, M. (1999). An Investigation of Thermal Comfort at High Humidities. ASHRAE Transactions, 105(2), 94–103.

ISO. (2005). ISO 7730 Ergonomics of the thermal environment -- Analytical determination and interpretation of thermal comfort using calculation of the PMV and PPD indices and local thermal comfort criteria.

McCarthy, T. (1999). Lee Kuan Yew. Time. Retrieved from http://www.time.com/time/world/article/0,8599,2054444,00.html

flex duct advantages

One advantage of flex ducts is that they significantly reduce noise transfer . If you oversize them and put a few gentle serpentine esse's in them, they absorb sound very effectively.

Log in or create an account to post a comment.

Sign up Log in