Image Credit: Fine Homebuilding

UPDATED on September 18, 2013

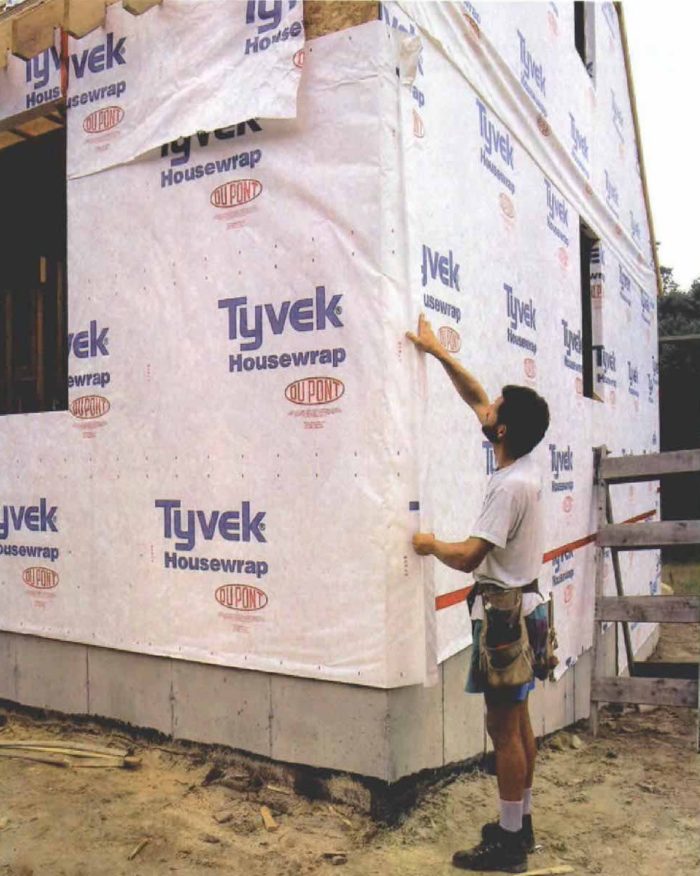

By now, almost all builders know the importance of installing a water-resistive barrier (WRB) behind siding. Most types of siding leak, so it’s a good idea (and a code requirement) to install a WRB to protect your wall sheathing from any wind-driven rain that gets past the siding.

A WRB can be vapor-permeable, like Tyvek, or vapor-impermeable, like foil-faced polyisocyanurate. As long as the wall assembly is designed to dry out when it gets wet, either vapor-permeable or vapor-impermeable WRBs work well.

In most cases, WRBs are not air barriers. (The notable exceptions are Zip System sheathing and liquid-applied WRBs.) If you want to create an air barrier on the exterior side of your wall, it usually makes more sense to create the air barrier at the sheathing layer, not at the WRB.

Although there are at least six categories of WRB — asphalt felt, Grade D building paper, plastic housewrap, liquid-applied WRBs, rigid foam, and Zip System sheathing — building codes calls for just one: asphalt felt. (One other category — three-dimensional vapor-impermeable barriers — is represented by a single product, Delta-Dry. Although it is often used as a WRB, Delta-Dry has not received code approval as a substitute for code-required WRBs.)

According to the IRC, you need asphalt felt

In section R703.2, the International Residential Code requires builders to install a layer of number 15 asphalt felt or paperbacked stucco lath over the wall sheathing or studs of every new home. The requirement includes a qualification: if you don’t want to use number 15 asphalt felt, you can use some “other approved water-resistive barrier.”

The code requirement calling for walls to be covered with asphalt felt is rather odd, because every asphalt felt manufacturer declares unequivocally that the product is intended for roofs, not walls. When builders install asphalt…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

44 Comments

What about Zip?

I can't believe you'd write an exhaustive description of all these different types of water barriers and not mention Zip sheathing. Why is that?

Drainage Plane for Stucco

Martin:

Is there any evidence that the back side (the side against the WRB) of the first coat of 3 coat stucco (scratch coat) actually has significant holes and gaps that allow for water to drain? Someone told me that as that first coat dries and cures that it pulls away from the house a very small amount, but enough that it creates some capillary potential. I know the front side of the scratch coat that you see has a lot of roughness and uneveness to it. I will say one thing I've noticed is you never see much evidence of water draining through the weep screeds of stucco. Makes me wonder where all of that moisture is going, surely it can't all dry to the interior of the house.

Response to Larry

Larry,

Good point! I have edited the blog to include information on Zip System sheathing.

Thanks for the excellent suggestion.

30 lb felt

Why is 30lb never mentioned, and what measurable benefits does it have over 15 lb? When I do brick or stone houses I always put 30lb over Tyvek and plywood sheathing.

Response to Allan Edwards

Allan,

You're skimming instead of reading. There's a whole paragraph on 30-pound felt. Here it is again, in case you're having a hard time finding it:

"Asphalt felt is also available in a heavier version, commonly called 30-pound felt. This #30 felt is available in both unrated grades (15.7 to 19.9 lbs. per square) and ASTM-rated grades (26.4 to 27.3 lb.s per square). Since the lightest unrated #30 asphalt felt is still heavier than the heaviest ASTM-rated #15 felt, it a logical choice for builders in search of a felt that approximates the asphalt felt used by their grandparents."

On drainage planes for stucco

Allan,

For years, stucco contractors said that wet stucco caused the outer layer of Grade D paper (assuming two layers of Grade D) to get wet, and that this outer layer of Grade D paper would pucker as it dried out, allowing some drainage.

There is some evidence of this phenomenon, but there is also ample evidence that OSB sheathing under stucco with two layers of Grade D paper can rot due to insufficient drying. So whatever puckering is occurring is clearly not enough for drainage or rapid drying.

I stand by my earlier blog, in which I stated that it is risky to install stucco without a drainage gap between the stucco and the underlying sheathing -- especially if you are using OSB. And when I write about a drainage gap, I mean a real air gap created with the three-dimensional plastic matrix, not just puckered Grade D paper.

Question for Martin

Sorry about missing the 30# felt info, it was early in the morning. I've always used CDX plywood for sheathing, never cared for OSB because I felt instintively that it couldn't take water like plywood. Although I will say plywood is just a bunch of veneers glued together, so it's not like it is a total "real wood product".

I switched to Zip Wall, wondered if the OSB aspect is completely removed as a moisture/water issue if you tape the seams properly. This would be in a stucco application. Also, do multiple WRB give you eough protection (I know you recommend a drainage plane). The coating on the Zip Wall is considered some kind of WRB protection, I also apply Tyvek then one layer of grade D paper, then lath and stucco, so I am using 3 WRB layers.

I pay close attention to flashing and in fact all of my flashings are copper. I'm looking for the Martin Holliday Seal of Approval :)

Stucco without a drainage gap

Allan,

So, you use Zip System sheathing, then three layers of WRB, then stucco. Frankly, I don't have enough experience or data to know how your walls will look in 10 or 15 years. It sounds like a better job than many contractors do (ordinary OSB and 2 layers of Grade D paper). But I just don't know if your system is robust enough to keep you out of trouble.

Stucco can be scary, because it's slow to dry. It's also a siding type that makes inspection of the sheathing very difficult (unlike vinyl). If I were installing stucco, I'd want an air gap -- but that's probably because I've seen so many gruesome photos of stucco disasters and sheathing rot.

so -- local best practice?

Martin, this is another great overview ... thanks from the peanut gallery.

With 48 inches of average annual rainfall, the need for a rainscreen with a good WRB is underlined in this area. We get lots of sun, and when there isn't a drought, lots of water.

For the bungalow we're planning, I've anticipated a 3/4" 1x3 furring rainscreen over #15 felt/1" rigid foam/more felt/plywood. But I wonder if that is the best (or the most cost effective) choice. I would anticipate extra labor in detailing the 1x3, plus the breakdown of the rainscreen every 16"/24" when a new furring strip is applied.

As Martin says in the blog, even the best minds aren't sure how much rainscreen is enough in a given climate.

But I believe that using HomeSlicker (equiv) (unlike 3/4" furring) might save considerable labor and would provide consistent coverage over the enclosure. Am I being too scrupulous (as I tend to be) thinking HomeSlicker may not provide enough drainage over the felt for long term effectiveness and is therefore (to me) a risk not worth the savings?

Delta Dry is more expensive than HomeSlicker but provides more room (1/2") for drainage. It too would provide consistent coverage for walls. Whaddya think?

So, making it into one question -- if you had to decide, based on the evidence available now, which choice would make the most effective rainscreen and most cost effective iinstallation?

I'll appreciate your opinions. And count on y'all to point out things I don't know to consider, lol.

Joe

Response to Joe

Joe,

I wouldn't hesitate to use Homeslicker. I'm sure it will provide adequate drainage and ventilation, as long as your other details are good.

Most builders find that vertical 1x3 or 1x4 strapping is cheaper than Homeslicker. But either option should perform very well.

I don't think you need two layers of asphalt felt, although they can't hurt. If you want to simplify your wall, choose one layer as your WRB -- make it the layer that is integrated with your window flashings -- instead of installing the felt twice.

Re: What about Zip?

Thanks Martin for the update including the Zip system. I'm guess I'm still feeling a bit squeamish about Zip since you voiced some reservations about using OSB sheathing in an earlier post. When we chose the Zip system for our house I was mainly concerned with air sealing. But as I read more, I've become concerned about Zip's longevity enough to consider adding a house wrap over the zip just to be sure. Thanks again for a great energy nerd post.

Delta

Martin -good overview of a very important subject. I have used Delta Dry in the past and like it quite a bit. I'm glad you pointed out the need for vents at top and bottom, this is a detail that is often missed.

It has been a few years, but the last I heard from the manufacturer, Delta Dry is not code approved as a WRB, only as a vented rainscreen, although it should function fine by itself without a separate WRB. Do you have more recent information that says otherwise?

Is Delta-Dry approved as a WRB?

Carl,

Thanks very much for your comment. You are right; Delta-Dry has not been approved as a WRB by the ICC-ES. I just confirmed that fact by calling the manufacturer.

That's an important point, and I'll edit my blog to reflect that fact. Thanks again.

plastic housewraps

Does anyone know if the plastic housewraps products have improved over the years? I hear rumors every once in awhile from builders that they used to have problems of one sort or another with these products but the product manufactures have addressed the problems. Rapid UV degradation, surfactant degradation, loss of permeability, loss of capacity to resist water infiltration for example. Any evidence to support these claims?

Have housewraps improved?

J,

Your question is too general for an easy, quick answer. But I know for a fact that after Tyvek was embarrassed by a series of well-documented Tyvek failures, some due to degradation by UV light exposure, and some due to problems arising from cedar extractives, Tyvek was reformulated in a way that, by most accounts, represented an improvement.

Thanks

Tyvek dominates the market here. This sounds precisely like what I have heard. Good to know that it wasn't simply an urban myth spreading around.

Fastening Tyvek to exterior side of rigid foam sheathing

Tyvek's installation instructions call for fastening the membrane into the studs and not just the sheathing. Their 1 3/4" steel stud screw makes a substantial connection back into the stud. I could not find a recommendation for fastening the Tyvek over rigid foam sheathing. would you use screws that are long enough to have the same depth in each stud?

Response to Joe Chalat

Joe,

I always thought cap nails were sufficient.

Tyvek literature includes the following information:

"DuPont Tyvek can be installed using a variety of fasteners depending on the application. To attach DuPont Tyvek to wood, insulated sheathing board or exterior gypsum board, use nails with plastic washer heads, such as DuPont Tyvek Wrap Caps. You may choose to use wide staples with a minimum 1” crown."

Elsewhere, Tyvek lists the following possible fasteners:

"• DuPont Tyvek Wrap Cap nails

• DuPont Tyvek Wrap Cap screws

• DuPont Tyvek Wrap Cap Staples for Stinger

• 1.0 inch minimum crown staples (except when installing DuPont Tyvek over foam sheathing)."

Once your siding (or rainscreen strapping plus siding) is installed, the Tyvek isn't going anywhere, so an argument can be made that the Tyvek fasteners only need to be sufficient to keep the Tyvek secured until the siding is on. However, some builders worry that wind pressure can cause Tyvek to "pump" and "belly" back and forth when the Tyvek is installed adjacent to a rainscreen cavity, and that this back-and-forth pumping may weaken the Tyvek over time.

It's unclear whether to worry about his possibility -- we need more research.

The best tech products since the personal puter

For readers who know very little about building materials I would like to say;

Zip sheathing is a miracle product that is an order of magnitude better than plain old OSB. Use it instead of OSB if you were going to use OSB.

Also

Delta-Dry, though I have not used it, looks like it too is a miracle product for use in wet humid climates and with stucco and brick and stone siding.

The two products I mention are High Tech Green products.

Low Tech Natural alternatives are available such as rough sawn board sheathing covered with Felt. Is felt natural? Well it is made with the crap leftover from high tech processing so it is not but at least it is not high up on the evil list of products.

Martin, We need to organize this site soon. Natural Green and High Tech Green are two distinctly different topics with distinctly different solutions though someday they may collide.

WRB and Flashings

Great article. I believe there is little performance difference (subject to some special conditions, "cedar" siding, etc and some marketing) between felt and plastic housewraps, the issue of flashing is not discussed. The majority of water intrusions issues do not happen in the field but at corners, openings, penetrations, etc and that is where I see the real benefit of the plastic housewraps. Most of the plastic housewraps having a broad range of self-adhering flashings for almost any condition.

Felt also tears easily, which makes the installation even more important. With an ever decreasing intelligence in the field (as well as in the office), having a product that assists in bridging this gap has some benefits.

At stucco, I almost always see (Texas) 2 layers of Fortifiber's jumbo tex building paper. Maybe the contractors think it was designed for Texas, jumbo and tex in the same sentence:).

In the end, a great product poorly installed isn't any better than a poor product properly installed.

Response to John Linck

I recently completed a home with exterior polyiscyanurate foam (foil facers both sides) walls and roof.

The roofing is also steel snap-loc.

I still have good cel phone reception inside.

As an aside, my builder used peel & stick for all joints and window flashings.

Cement board?

I realize this is off-topic, but I'd like to know whether a WRB behind cementboard siding, without a rainscreen, leads to moisture buildup on the backside of the siding, and if this compromises the integrity of the cementboard. The only answer I've gotten so far is, "nobody puts in rainscreens around here, and there haven't been problems yet."

DC14 Drainage Mat

Excellent discussion so far.

As an option, does anybody have any experience with this Pactiv product? It is not a WRB, as it needs one behind, but it does offer a way to ventilate behind cladding. And it costs about $0.375 per per sq/ft.

I'm considering using it instead of furring strips, and I'll be interested in any opinions you might have.

Response to Chris V

Chris,

All types of siding dry faster if there is a ventilated rainscreen gap between the siding and the sheathing.

Fiber-cement siding is less susceptible to rot and peeling paint than wood siding, however, which is why fiber-cement siding is often installed without a rainscreen.

WRB's air barriers etc.

Thank You, Martin.

This is good stuff, and it does not get enough attention. As was stated, Zip does provide a good air barrier as well as a WRB. We have been involved with builders who use Zip and who have used OSB in the past. Blower door tests on both types of houses, pre drywall, confirmed.

Your comment "Plastic housewraps are rarely used under stucco. " unfortunately is not correct in the Philadelphia market and mid Atlantic, where products like Dupont Tyvek or StuccoWrap are commonly used. Sadly, we have the failures in this market too. The WRB may not always be the culprit, but it often is not up to the task it is in place to perform.

I'm glad Carl Seville clarified the proper application for Delta Dry as a ventilated rainscreen. I talked with these guys at IBS and I like their product for its intended use. Homeslicker plus Typar is an interesting product, if the budget allows, also.

So, how do we incentivize 15# felt manufacturers to improve the quality of a commodity product? Articles like this may just let the genie out of the bottle, if code officials read it.

tyvek

I just read in your comments that tyvek is susceptible to uv deterioration. Is this true and if not how long since the problem has been corrected. ? This is in reference to some building additions with no siding and just tyvek for 2-3yrs. ( i am a building inspector)

Thanks,

Response to Greg

Greg,

When installed in accordance with the manufacturer's instructions, Tyvek will not suffer any UV degradation. According to the manufacturer, "DuPont suggests that Tyvek be covered within four months (120 days) of installation." (See http://www.smithphillips.net/pdf%20files/TyvekhomewrapBeforeInstall.pdf ).

If Tyvek has been left exposed to the weather for 2 to 3 years, all bets are off. The builder has failed to follow the manufacturer's installation recommendations, and that's a code violation.

Adding to Martin's response to Chris V

I have heard by way of one of Dr. Joe's seminars that cement board siding should be considered a resevoir cladding which means it will hold moisture and that moisture can be driven into the wall due to solar exposure. Therefore a drainage space whether stapping or homeslicker or what have you should be used. My two cents to a great blog.

Response to Michael

Michael,

I agree -- a rainscreen gap goes a long way to reducing the chance of inward solar vapor drive. For more ways to limit inward solar vapor drive, see When Sunshine Drives Moisture Into Walls.

WRB

Great article on WRB's, I have read alot on this topic and your writing is clear and descriptive. On a recent remodeling job I debated using 30# felt as a lo-tech "green", non-tyvek solution, with a modest perm rating; but I recalled experiences with felt from the past; course, bulky, heavy, tears when you don't want it to, hot in the sun, stiff, sticky, lays flat until it gets wet and fish mouths all over the place, etc. On the other end there are any number of partially completed buildings in my area that have tyvek flapped to shreds after one season.

On a trip to the lumber yard I stumbled on GAF Deck Armor, a blue colored roof underlayment. I checked it out on the web and discovered it had a perm of 16 and when I made a cup out of it, it held water indefinitely. I bought a 1000 sf roll for a little under $200. I was suprised a how light the material was, the rolls are 54" wide weighing less than 40 pounds. It appears to be a thin plastic film, laminated between two layers of spun fabric. While it is intended for roofs and a proprietary GAF slate system, it worked beautifully on exterior walls, it was tough, when fastened with standard 1/2" type arrow staples it was secured very well. I was not looking for an air barrier so I just lapped it 3" horizontally and 6" vertically. It comes with a 2" grid for easy measuring and cutting. It fit inside and outside corners snuggly and multiple layers don't bulk up under strapping or siding. I have several areas on the building that have gone unfinished for 2 years and the material still looks like new. The areas I have finished I used a ship lap siding with a 1/4" plywood strapping for a capillary break. I was skeptical of the extra labor of building in the rain screen but after deciding I didn't need 3/4" of space and working out flashing details with windows, doors and Deck Armor the process went smoothly. I added a screened vent at the bottom and left a space at the top for air flow behind a barge board.

Tyvek is dead to me ... And I'll tell you why!

We have been using zip system since 2008 and won't go back. It all comes down to installation of the product vs many of the other WRBs. Tyvek is a nightmare to put on and if done incorrectly will fail. The other nice part of zip system is that we can easily apply felt paper to it and moist stop for brick etc. I haven't jumped on board with the zip system roofing product yet based on it's very high cost, but love the advantech 1 1/8" osb flooring.

As for the concerns that the tape will fail, I trust the people at huber ... having tried to remove it within a few days of installing it, I believe in it's longevity.

Garage Rehab Problem(s)

To Martin Holladay: Are you available for consulation?

Response to Marvin Oosterbaan

Marvin,

In general, I have a full-time job that doesn't leave time for moonlighting. But I'll do my best to provide advice if you have a question, which can either be posted here or sent to me: martin [at] greenbuildingadvisor [dot] com.

Liquid-WRB + paint for OSB shed

Hi Martin,

I have built an OSB-sheathed storage shed, whilch I plan to finish in something weather-proof, but don't need insulation etc. The barn-style doors allow lots of ventilation. My plan is to use a liquid-applied WRB (likely StoGuard EmeraldCoat or GoldCoat), and paint over that directly with exterior house paint. I understand this is not conventional, but I think this should work to protect the OSB & frame. What are your thoughts? I'm keen to save on the time & expense of using stucco over mesh etc. Any comments are welcome. Thanks very much

Response to Phil Burman

Phil,

I can't recommend your suggested approach. Paint is not siding. No manufacturer of liquid-applied WRB would approve of your plan.

Liquid-applied WRBs need to be protected by siding after no more than 4 months of weather exposure. What's going to happen to your WRB when your paint starts to peel?

Twist on the "How long can Tyvek be exposed" question

All questions about "How long can Tyvek be exposed" that I have seen have been from the perspective of someone who intended to use it as-is whenever they got around to covering it.

I have a couple of walls covered with Tyvek, and I fully plan to take it off and put on new when I get there. It has been up for ten months, and I am wondering if it will remain an adequate water / rain barrier for another year or two until I can get the job done, then put on new Tyvek and side. Or do I need to replace it every year I delay?

It is very well fastened (Cleats mostly, some cap nails) and is not going anywhere unless it disintegrates. I just don't want that to happen between November and March!

It is in upstate NY. Thanks.

Response to Ray Clark

Ray,

This is a question that is best answered with common sense. If winter is approaching, inspect the Tyvek before the weather gets too brutal. Is it fraying? Coming loose around the fasteners? Showing signs of transparency? If so, replace it.

If it looks good, leave it.

I was thinking that as the

I was thinking that as the sunlight broke it down that it would get weaker, and at some point under stress it would suddenly rip. Of course there is alot of stress when there are high winds in the winter, and if it went then it would be difficult to repair, so sometime around September/October I need to make a judgement as to whether or not it is going to make it. Although there are no guarantees, I was hoping that there were some anecdotal experiences, like "Mine was fine for X years" or "Mine failed after X years" or "After X years it looses its strength and easily rips". Yes, I certainly will look at it, but I would think that it would be weakened too much long before it was apparent, so I was hoping that I could get some experiences to weigh with my observation.

Combining Housewrap and Asphalt felt?

My company is a manufacturer of synthetic faux stone panels and we are evaulating our installation instructions for 2013. We would like to know if it makes any sense to recommend a combination of a waterproofing felt and a house wrap for more confidence in keeping water out in case water gets through the interlocking panel seams.. We understand that another option might be a drainage system, but drainage systems are more expensive than asphalt sheets (and yes the drainage system provides a different function).

Response to Rod Jarboe

Rod,

First of all, I hope that your company has good insurance. Right now, I believe that there are more construction-defect lawsuits arising from faux-stone veneer than any other cladding. (To see some photos of the types of problems that end up in court, see All About Wall Rot.)

Here's my prediction: any manufacturer of faux-stone panels that does not recommend the use of a ventilated air gap between their cladding and the wall sheathing will be bankrupt within a few years.

Frankly, it's a little scary that a manufacturer would seek advice on this website. I strongly urge you to spend a few thousand dollars hiring a consultant from the Building Science Corporation to develop your installation manual. It will be an excellent investment that, over the next few years, will save you thousands of dollars in settlement fees.

I notice from Linked In that your company is Replications Unlimited. A few of the statements in your brochures raise red flags:

"Designed for interior or exterior applications"

"Unlike real stone (or cultured stone) which requires several stages and specialized stone mason's labor to install, URESTONE panels installs easily and quickly with screws and/or adhesives . The only tools required are a drill (used as a screw-driver) and any wood type saw for trimming to exact fit. Anyone that knows how to use these simple tools can easily install several hundred square feet in a day!"

Faux Stone question

Thanks for your response and appreciate your thoughts. - Regarding exterior applications - our company focuses on Metal building and Modualr building applications that are over exisitng exterior systems. Regarding projects outside this area - i am not totally in the loop but management is aware of the issues with the EFIS system and has addressed surface preparation systems prior to adding the faux stone system. After coming accross your article - just was curious if there were any other options - got the message.

Moisture damage

I'm a General Contractor in the Pacific Northwest and I specialize in rot repairs. I have contended for the past 6 years that if you have a home built with OSB, a WRB and vinyl windows and it faces south you have a problem. If you are frustrated with the lack of information, the conflicts and inconsistencies in manufacturer installation instructions and the lack of solutions or the high cost of screen systems you are not alone. Close scrutiny of expert advise from engineers with little or no bloody hands experience in the forensics of rot damage reveals there is a lack of cohesive advise on solving moisture rot problems. My situation is unique in that I take care of 111 homes in a condo association and I see a tremendous amount of product failures, installation errors and maintenance issues. The use of primed white wood trim, Masonite, Hardie siding and vinyl windows exacerbates the problem of moisture rot as well. The solution is early detection and correction and ideally a meticulously installed screen and siding system. Bring your money. I have attempted to illustrate what I see with my website. I have also tried to get as many manufacturer representatives on site as I can but they are in the sales volume business not bloody hands on constructive advise business.

felt paper with strips for ventilation

When all is said and done I remain intrigued by felt paper as an inexpensive, effective, time-tested WRB.

One thing I would like to see felt paper improve on is the rainscreen issue. Let's say I feel that furring strips are overkill as far as a rainscreen for my climate and specific project location. But as a nod to rainscreens I'm looking at a textured housewrap like Hydrogap.

I was just reviewing some step by step instructions on This Old House on installing clapboards and there is a recommendation to install 2" strips of felt paper over studs to provide a bit of ventilation behind the clapboards. This seems like a low-cost, low-fuss way to get the best of both worlds. I am not familiar with this practice but I get the impression that it's been around.

What do you think—Martin or others? Thanks.

Response to Tristan Roberts

Tristan,

A variety of materials can be used to create an air gap between the back of the siding and the WRB or sheathing. Many builders use the trick you are talking about -- installing vertical strips of folded-over asphalt felt to create a small air gap. The vertical strips are usually installed over a continuous layer of asphalt felt, although there is no reason why the strips couldn't be installed over plastic housewrap.

I wrote about this approach in an article called "Another Rainscreen Tip." The article was published in the March 2007 issue of Energy Design Update. In that article, I wrote:

"The latest tip for creating an airspace between siding and the water-resistive barrier (WRB) is simple and inexpensive: install vertical strips of folded-over asphalt felt every 16 or 24 inches on center. Depending on the choice of asphalt felt (#15 or #30) and the number of folds, a variety of thicknesses can be created; in fact, by varying the strip thickness, the strips can be used as shims to correct minor framing irregularities.

"According to Troy Sprout of Hendersonville, Tennessee, the method has many advantages. It’s ‘a simple, fast and efficient means to mark the studs over the housewrap,’ he notes. ‘The system prevents the siding from bowing over random button-caps [housewrap nails], and maintains an air gap/drainage plane to prevent the paint from being forced off the siding.’

"Sprout is a fan of asphalt felt. ‘I prefer felt as a sheathing wrap to any of the newer woven products,’ he says. ‘I’ve witnessed it still doing its job after 50 years behind brick. I even use it under modern housewraps when a building inspector will only accept the modern plastic wraps. It is inexpensive, durable, easy for one person to install and, most importantly, very effective at preventing water damage to the framing.’ "

Log in or become a member to post a comment.

Sign up Log in