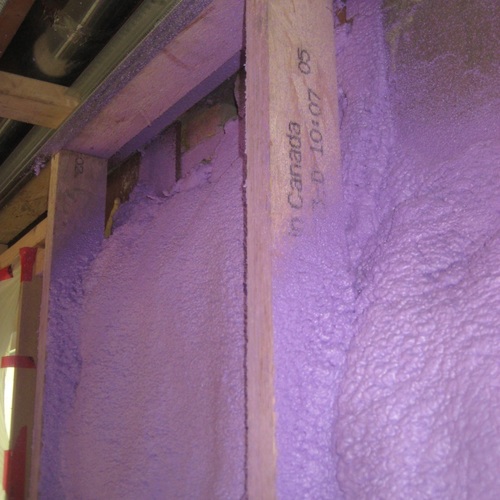

Image Credit: Fomo Products

UPDATED on December 12, 2014

Builders of a certain age — say, those older than about 55 or 60 — started their careers at a time when no one talked about air leakage or air barriers. Back in the early 1970s, even engineers were ignorant about air leakage in buildings, because the basic research hadn’t been done yet.

Times have changed, and most residential building codes now require builders to include details designed to reduce air leakage. Today’s young carpenters are working on job sites where air barriers matter.

Q. What materials make good air barriers?

A. A wide variety of materials make good air barriers, including poured concrete, glass, drywall, rigid foam insulation, plywood, and peel-and-stick rubber membrane. (Note that evidence is increasing that OSB is not an air barrier; for more information on this issue, see Is OSB Airtight?)

Although air can’t leak through these materials, it can definitely leak at the edges or seams of these materials. When these materials are used to form an air barrier for your home, additional materials such as tape, gaskets, or caulk may be required to be sure seams and edges don’t leak.

To make a good air barrier, a material not only needs to stop air flow; it also needs to be relatively rigid and durable. If you want to determine whether a material is an air barrier, hold a piece of the material up to your mouth and blow. If you can blow air through it, it’s not an air barrier.

Engineers distinguish between air barrier materials (drywall, for example), air barrier assemblies (for example, plywood with taped seams attached to wall framing), and air barrier systems (all of the materials and assemblies that make up a building’s air barrier).

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

84 Comments

air barrier

Love the article, but the picture of the outlet on the exterior wall kills me! Best thing I ever decided was to remove all wiring, venting or any other service except those very few that are absolutely necessary in the exterior walls. Brass (yes they are expensive) floor outlets work great and were easy to install. I put the minimum required by code in and then peppered the interior walls with regular outlets as required. 2nd best thing I did was to make drywall continuous on the exterior wall. Interior walls butt into the drywall. Got my house http://rosedalehouse.ca down to 1.6ACH. Not bad for an historic, therefore interior only retrofit project . I believe the historically "correct" double hung windows are my downfall. Look good, but leak like hell!

Thanks for all your posts - keep them coming

Two steps forward one step back?

Martin, does the rate of air leakage through a particular "crack" increase with the "tightness" of a home?

In other words, will crack sealing increase the rate of leakage through the cracks you don't seal (everything else being equal)?

Response to Lucas

Lucas,

The answer to your question is, "it depends." I think it's safe to say:

1. Sealing leaks will lower the air leakage rate of your house and will lower your energy bills, even if you don't track down every last crack.

2. As far as I know -- and any physicist who cares to contradict me is welcome to chime in -- there are some circumstances in which sealing one crack might increase airflow through an unsealed crack. For example, if a house has a very leaky ceiling, the basement will be under negative pressure. If a homeowner seals one crack in the basement, the airflow through unsealed cracks in the basement might increase somewhat. But the overall air leakage rate for the entire house should decrease.

Code enforced air tightness requirements?

Martin,

Much appreciated article.

Putting aside the question what the air tightness requirement(s) would be, am I safe to assume since we can all agree air tightness is a component of responsible building that we would all agree that it should be a code enforced performance requirement for new construction?

In the process of trying to determine what the requirement would be, do you think it is more of a factor for protecting the assembly from moisture damage - or - a factor for limiting conditioned air escaping through the envelope?

I was at an Building Enclosure Council meeting the other day. ASHRAE is currently testing a sample of current wall commercial buildings from different US climates for their air tightness performance. As I understand it this is the first commissioned study by ASHRAE to study the air tightness performance of commercial buildings. A good sign.

Code requirements for air tightness

J,

The code requirements for air sealing in the 2006 IRC were already fairly stringent but were almost never enforced. Here's what I wrote on the topic in an earlier blog:

"In the 2006 International Residential Code (IRC), air-sealing requirements can be found in section N1102.4. The code requires that 'The building thermal envelope shall be durably sealed to limit infiltration. …The following shall be caulked, gasketed, weatherstripped, or otherwise sealed with an air barrier material, suitable film, or solid material:

1. All joints, seams and penetrations.

2. Site-built windows, doors and skylights.

3. Openings between window and door assemblies and their respective jambs and framing.

4. Utility penetrations.

5. Dropped ceilings or chases adjacent to the thermal envelope.

6. Knee walls.

7. Walls and ceilings separating the garage from conditioned spaces.

8. Behind tubs and showers on exterior walls.

9. Common walls between dwelling units.

10. Other sources of infiltration.'

"The real zinger in this list is #10: 'Other sources of infiltration.' That just about covers it, doesn’t it?

"The IRC requires all sources of infiltration to be 'caulked, gasketed, weatherstripped, or otherwise sealed with an air barrier material, suitable film, or solid material.' The code does not include any exceptions. In other words, there is no such thing as a legal crack or air leak.

"Unfortunately, the requirements of Section N1102.4 are rarely enforced, and as a result, many new American homes — especially fiberglass-insulated homes — perform poorly."

So, that sums up the story for the 2006 IRC. The latest version of the code, the 2009 IRC, has upped the ante. It has retained the air sealing requirements found in the 2006 IRC, while adding additional requirements.

In Section N1102.4.2, the 2009 IRC gives builders two options: either have a third-party inspector verify completion of an air-barrier checklist (shown in Table N1102.4.2), or perform a blower-door test to confirm that the home's air leakage is less than 7 ach50 (a low bar, but better than no bar at all).

thanks

Thanks for outlining the current state of the residential code on air tightness.

More specifically (here's my language 'challenge' again) I'm trying to gauge whether there is enough consensus within the green building community to create a lobbying effort to require blower door confirmations of requirement(s) more stringent than 7 ach50 and do away with the visual inspection option.

Not that you alone can gauge the whether the consensus is there, but I would be curious to hear thoughts from others if they agree that this is possible route forward to raising the bar on typical residential construction; or are there obstacles to improving the codes or gaining a consensus within the green building community that I am not acknowledging?

Air leakage

Lucas and Martin,

Back in the old days when a blower door test was performed on a new house at least 2 results were noted. ACH50 and ELA (equivalent leakage area) in square inches. Reduce the ELA and lower the ACH50, I believe Martin has it right.

Air Leakage

TEC describes the leakage area measurement far better than I did.

http://www.energyconservatory.com/support/support4.htm

High bar, low bar

The 2009 IRC requires that new home builders achieve 7 ach50.

Nine years ago, in 2002, a study of new Wisconsin homes showed a median air leakage of 3.9 ach50.

If that's what new home builders were averaging in 2002, before there were any blower-door requirements in the code, why are code officials setting the bar so low? (Or, to speak more accurately: why are they setting the leakage rate so high?)

Here's part of the answer: not everyone builds to Wisconsin standards. The code also has to work in Louisiana, Alabama, Oklahoma, and Texas, where building techniques are different from those in Wisconsin.

Response to Martin

Not all of us. And anyone who's ever lived in a drafty old house understood the importance of keeping the wind out. Below is a picture of an air/vapor barrier I installed in a double-wall fiberglass-insulated house in TN in 1982, using butyl caulk at every edge and seam. I also used the vapor barrier as an air barrier in my first Larsen Truss house, built in 1987 by placing it outside the sheathed structural frame like a housewrap with taped seams before attaching the trusses.

Until the wind blows. The 50 pascal blower door test simulates a 20 mph wind, but a 40 mph wind exerts 200 pascals of positive pressure on the windward side and almost as much negative pressure on the leeward side and the roof. Winds may not be as consistent as the stack effect, but can have much more dramatic impacts when they do blow.

The answer to Lucas' question, "does the rate of air leakage through a particular "crack" increase with the "tightness" of a home?" is not "it depends" but YES. Just as the more R-value we install in a house the more important become the voids or thermal bridges, the same is true of air leaks.

It's true that any effort at tightening a house will reduce it's overall leakage rate and save energy, but the same stack effect and wind effect pressures will drive more air faster through the remaining cracks - making those areas more vulnerable to moisture damage. It's for this reason that a 97% complete vapor barrier will be 97% effective (vapor diffusion is an area-weighted phenomenon), while a 97% complete air barrier can be 97% ineffective (because air leakage is a localized phenomenon).

Response to Robert

Robert,

Like you, I was paying attention to airtightness when building houses in the early 1980s; when I framed my own house in 1980, I used Typar as well as exterior EPS over the sheathing. When you were building in 1982, and when I was building in 1980, we were both benefiting from the pioneering research conducted by the Princeton House Doctors, who got their first federal grant in 1974, and from similar research in Canada and Sweden.

Gautam Dutt, the discoverer of the thermal bypass, had his famous "aha!" moment in a townhouse in Twin Rivers, New Jersey, in 1977. He was the first to figure out why existing energy modeling programs weren't accounting properly for significant heat loss in existing buildings.

Your point about how wind affects leaks at the so-called "neutral pressure plane" is exactly the same as mine, which is why I wrote that at "your home’s neutral pressure plane," "even if your living-room window has all kinds of cracks, not much air will leak through — as long as the wind isn’t blowing."

The answer to Lucas's question is "it depends," because leaks near the neutral pressure plane only leak when the wind is blowing or fans are operating on them -- so the leakage depends on the wind and fan operation. These cracks will not be as affected by changes in the basement cracks in the same way as unsealed cracks in the basement.

Response to Terrell Wong

In a well-designed house, there is no need to avoid or skimp on electrical outlets in exterior walls, and few owners are going to be happy with floor receptacles. Proper planning and proper air sealing is no harder to do than any other air barrier detail. And running exterior wall drywall continuously behind (and above) partitions, requires a two step drywall and rough wiring process that few builders or subcontractors would tolerate, and still requires penetrations for wiring which have to be sealed. Proper ADA techniques makes sealing at partitions just as effective and keeps the construction sequencing on track.

Code Requirements

Codes are catching up with air sealing standards. And let's not forget that code standards are MINIMUM standards - in other words, just meeting them earns you a D-. We should all be exceeding them.

While IRC may require only 7 ACH50, Energy Star has required 5 ACH50 and their new 2011 version 3.0 has a climate zone specific requirement:

Infiltration rates shall be less than or equal to the following values:

6 ACH50 in CZs 1,2

5 ACH50 in CZs 3,4

4 ACH50 in CZs 5,6,7

3 ACH50 in CZ 8

Envelope leakage shall be determined by a Rater using a RESNET-approved testing protocol.

And the Energy & Environmental Builder's Alliance (EEBA) requires less than 0.25 cfm of leakage per square foot of building surface area (including floor) @ 50 Pa.

2009 IRC Visual Inspection Checklist

Here is a link to the new thermal bypass checklist.

Eureka Moment?

I find it humorous to see such statements as "Gautam Dutt, the discoverer of the thermal bypass, had his famous "aha!" moment in a townhouse in Twin Rivers, New Jersey, in 1977."

It has the same ring to me as "Columbus discovered America".

Perhaps Dutt can take credit for giving it that name or for quantifying it, but I think most old timers knew that warm air leaks into an attic when it's cold outside.

It's funny how long it takes for scientists to "discover" or "prove" what ordinary people always knew.

On discovering the thermal bypass

Robert,

You are quite correct that builders have long known that a hole in the ceiling will leak air.

However, it took until the late 1970s for researchers to quantify residential air leakage.

Because air leakage had not be quantified before then, researchers and builders underestimated it.

Because air leakage was underestimated, remedies and good building practices were not implemented, and chases into attics were not sealed.

Response to Robert Riversong

Your claims are incorrect. The air leakage through a hole is a function of the pressure difference across the hole and the size/shape of the hole. If you seal half the holes in a house, then the "same stack effect pressure" will produce only half as much infiltration.

It's true that if you seal leaks only at the top of the building, then the remaining leaks at the top will leak a little faster because you have moved the neutral plane away from them. But if the leakage distribution doesn't change (i.e., if you seal all the leaks about equally) then the leakage rate drops in direct proportion to the reduction in hole size and the reduction in blower door reading.

sheathing effectiveness?

If sheathing is taped and penetrations sealed so it forms a proper air barrier .... then the siding guy shoots nails to attach the siding through the sheathing (and into the studs) so thousands of nails have penetrated the sheathing ... is the sheathing still considered an effective air barrier?

If so ... what if he somehow missed the studs with a half dozen or more nails ... is the sheathing still an effective air barrier?

And if so, why?

Thanks for another terrific summary, Martin.

Joe

For michael Blasnik

You stated that "The air leakage through a hole is a function of the pressure difference across the hole and the size/shape of the hole."

I agree, but, as you plug these leaks, the pressure differential will increase and cause any remaining holes to leak more. No??

Air Leaks

If you look at the Energy Conservatory link and read 3#, they explain the Canadian EqLA measured at 10 pascals and the ELA method of LBL at 4 pascals, there is no mention of a "multiplier" when air leakage is either raised or reduced. It is a straight calculation.

http://www.energyconservatory.com/support/support4.htm

Do nail holes hurt an air barrier at the sheathing?

Joe W.,

For a further discussion of the question you raise about nails in sheathing, see the comments posted at my earlier blog, Airtight Wall and Roof Sheathing -- especially Garth Sproule's comment of 6/12/10 and my response of 6/13/10.

Here's the summary: as long as the siding nails stay put, the air barrier is tight. But if you are using the roof sheathing for the air barrier, there is a potential problem: when roofers come along in 20 years to strip the asphalt shingles from the roof for a re-roofing job, they'll be pulling up the old roofing nails, leaving holes in the roof sheathing. That's definitely a problem.

If we are allowed to Guess(about crack pressure)

I agree with "depends"...

it depends on where the cracks are

what is causing the pressure

and how the cracks are "balanced"

Fireplace walls

The check list that Robert posted above includes an air barrier on fireplace walls. I'm assuming that this refers to wooden fireplace chases. Does it apply to an internal fireplace and chase? Is ADA drywall adequate or is something more required or recommended? To go above and beyond are there other practical procedures?

The fireplace has a sealed door. What is the logic behind this requirement, especially on an internal chase.

Thanks, John

Response to Garth - holes and pressures

Garth said:

The answer is generally no -- the pressure will not increase - but there are situations in which it can.

In terms of natural infiltration pressures -- wind and stack effect -- the pressure differences induced across the holes in the house will depend on the distribution of the leakage locations in walls vs. ceilings vs. floors/foundations. If you reduce the size of all holes in a home in half, the stack and wind pressures will stay the same and the natural infiltration rate will be cut in half. But if you shift the distribution of the holes in the building by mostly sealing leaks at the top or at the bottom for example, then some leaks will experience larger pressures and others will experience smaller pressures. The net effects can be roughly estimated by infiltration models such as the LBL model (which lets you specify the fraction of leaks in walls vs. top and bottom and the difference in leakage areas between top and bottom) or analyzed in even greater detail using a model such as CONTAM. In practice, reductions in air leakage as measured by a blower door are pretty much proportional to changes in infiltration rates.

When it comes to air leakage created by mechanical systems such as exhaust fans/ventilation or unbalanced duct leakage, then sealing leaks in the building will tend to increase the pressure difference across the remaining leaks (actually, just those leaks leaking inward) and lead to increased air leakage rates. The relationship is a little complicated and changes once the fan flow rate is sufficient to make all holes leak inward.

On air barriers behind zero-clearance metal fireplaces

John Reimers,

If a fireplace is located against an exterior wall, then the framed wall behind the fireplace is part of the home's thermal boundary, and therefore requires an air barrier as well as insulation.

If a fireplace is located in the center of a home, an air barrier is only required under the fireplace (this might consist of a concrete slab, for example) and at the point at which the flue chase penetrates the ceiling air barrier. Follow the chimney manufacturer's recommendations for such penetrations; if the chimney manufacturer's details are not airtight, it may be necessary to complete the air sealing with pieces of galvanized sheet metal sealed with high-temperature silicone caulk.

To Michael Blasnik

Thanks for your very helpful responses, Michael -- much appreciated.

Second image, building details, KISS is missing.

Martin, Looking at the image (image 2) showing all the details to seal and insulate a home. I would as of today anyway never build that home. Complicated labor intensive, foam intensive, tape intensive, caulk intensive, etc etc etc. To me it looks like that home if built where I live would have temperatures in the wall conducive to mold growth more than anything built to date. Even if not, it lacks the quality where I would say, wow... this follows the KISS rule beautifully. Yaa know, like E=MC^2

Is the wall moisture/mold proof? Riversong wants thick cellulose walls to be permeable to the exterior which the example is not. 1" of foam is not enough foam to meet the 1/3 rule. Showing wettable insulation against the rim joist and the concrete is not accepted, unless what you are showing is not fiberglass or cellulose.

I think the image should be pulled. More wrong to be learned than right.

And just to get Robert all up in a knot, the image to me proves more than ever that simply doing one of three types of wall is better than combining the three.

1- Exterior only insulation works. Bruce Brownell hasn't been sued out of business that I know of. Taped foil faced foam in two layers continuous around 6 sides of a home gives a high whole R value and a low ACH. Unrefutable and simple comparatively. I mean, look. your image shows no connection of your air barrier between your second floor inner foam to the first floor air barrier or whatever it is supposed to meet up with. If it does, then I need another detail posted to guide me.

2- Larson Truss/Riversong Truss with high perm exterior, double wall, cellulose only, no exterior foam to reduce perm or cause inner wall temps to near mold conditions in framing. Less complicated than the image shown here. Good wall for those that desire to use the least foam practical in a build.

3- Spray foam and Spray foam flash. Another less complicated way to build. Sealing all up for a low ACH is very easy, (I have done such quickly and inexpensively) R value is not great but there are ways to overspray framing to get some advantage of whole wall R value and the R value maintains better than fiberglass mostly. The proof is in the utility bills not in what we all think about it on websites. In my case we have seen a major reduction in energy needs for two Icynene projects.

KISS is a great rule. Keep it simple.

Where would I like to be frame wise? For my location I like the PH idea of 90% less Energy needs.

How to get there? Let's get there as simple as possible!

Robert, it's mighty cold here as I type. Fire us up. Your derogatory comments entertain as much as your knowledgeable posts inform. Living and loving all of you these days neighbor.

Thanks for all the contributions.

In the interest of exploring the "it depends" answer I'll restate my original question, then expand a bit on what I was thinking about when I asked it:

I originally asked the question because I was wondering if/how Bernoulli's principle (more specifically "venturi effect")could be applied to understanding air infiltration.

The basis for "venturi effect" is that:

"According to the laws governing fluid dynamics, a fluid's velocity must increase as it passes through a constriction to satisfy the conservation of mass, while its pressure must decrease to satisfy the conservation of energy." - Excerpt from Wikipedia.

I was imagining cracks that leak air inwards, at the mud sill say. I imagined that if the pressure gradient across the envelope remained constant, and the total cross sectional area of those cracks was decreased, the result might be somewhat like the effect of tightening the constriction within the throat of a venturi - which is to say that the rate of air infiltration would increase through the un-sealed cracks (even though the total volume of air exchange had decreased) - two steps forward one step back...

Now, after reading all the informative replys my original question generated, It is clear that pressure dynamics within a house are greatly complicated by a number of "real world" factors.

Is it even relevant to consider simple "steady state" pressure scenarios with crack sealing or does the act of crack sealing alter the "steady state"?

Regardless of changes in the pressure gradient across a particular crack, is Bernoulli's principle applicable or not?

Does the inward leaking air leak faster as the "inward cracks" become fewer and does the outward leaking air leak faster as the "outward cracks" become fewer?

Possibly the answer to my question is here: "...while its pressure must decrease to satisfy the conservation of energy".

If the rate of infiltration increases, does the cooresponding decrease in pressure mean that the two effects cancel each other out in terms of energy flux?

Thank you all for the consideration of my questions - I have an inquiring mind ;-)

Lucas, both

Any nozzle that I have used will increase velocity and decrease quantity at the same time. Via conservation of energy some side effects to balance out equations are change in temperature of such things as the nozzle getting warmer, the fluid getting warmer. As to homes, the level of pressures being discussed and the difference in pressures being so little, that in engineering we would just not work with certain aspects of all as being variable to a point of being worth the effort to figure. I have been away from class too long to do all the math for you but in the real world of nozzles, changing to smaller holes only leads to less going thru the hole at a higher velocity.

Speaking of engineering on a site with builders... I have recently picked up a digital caliper made by General Tools. I am building cabinets with it and it is helping me with going between mm and inches as I am using all Blum hardware which specs dimensions in mm. What a fine instrument for the dollars. If you need to be at 5/32 or 20mm, no problemo. Done. No finish carpenter/cabinet maker should be without one.

General makes lots of neat tools. My caliper came from HD.

http://www.generaltools.com/Products/Fraction-plus--Digital-Fractional-Caliper-(6)__147.aspx

Flow through leak nonlinear with pressure drop

One may reason that sealing some of the holes in a house's envelope reduces net flow through the house and thus lets it support a greater pressure differential at places away from the neutral plane. This would tend to increase the flow through unsealed orifices. However, pressure drop across an orfice varies with the square of velocity (IIRC). As a first approximation, I would expect inward flow through a hole to go up with the square root of the fraction increase in pressure drop.

Anyway, the increase in pressure drop across the envelope won't go up linearly with fraction of holes that are plugged. As a large number of leaks in a house are plugged one by one, I would expect the supportable pressure gradient to approach some limit asymptotically.

Imagine a limiting case, with just two small and equally sized holes in the upper floor ceiling leaking air out and another two down low leaking air in. If you plug one hole up and one hole down, you cut the number of holes in half, but the pressure gradient change is essentially nil, so the air leakage through each of the remaining holes stays the same and the total leakage essentially is cut in half.

Calking Mudsill

Martin comments that "Most builders know the importance of installing sill-seal between the top of the foundation wall and the mudsill. If the sill-seal is ineffective, this joint may need to be caulked or sealed from the inside with spray foam". Here in BC, Canada the sill plate is typically sealed with a closed cell foam gasket between the foundation wall and the sill plate (which is usually not pressure treated). This gasket is typically wider than the sill plate and serves as both an air seal and a moisture seal between the concrete and the plate. I would also like to calk the sill plate for added protection against air leaks but am uncertain how best to do this. If I trim back the sill gasket to give a clean edge where the sill plate meets the concrete to use spray foam I am concerned that I will have compromised the moisture seal at this point especially if the foam ever becomes damaged. If I do not trim the sill seal I am unlikely to get a continuous foam seal. Comments?

Wide sill seal gasket

Ross Neuman,

Do you have any evidence that air is leaking at this location? If not, don't worry.

If a blower-door test (or direct observation) shows this crack to be an air leakage location, I would trim back the gasket with a sharp utility-knife blade (back to the mudsill), and seal the crack from the interior with high quality caulk or spray foam.

reply to Lucas Durand

No, the Venturi effect is about flow through pipes, not natural infiltration in a house. They are very different situations. The pressure differences acting across leaks in homes are determined by the magnitude of the driving forces (wind speed, temperature difference, unbalanced ventilation) and the requirement that the amount of air leaking in equals the amount leaking out. The distribution of locations of the holes will affect the pressure in the home needed to maintain this mass balance.

It's a little too complicated to explain in a blog comment but if you're interested you might want read up on it -- you can find info in many places including references like ASHRAE fundamentals.

Reply to Lucas and Ross

Lucas you bring up an important point.

In some of our tightest homes (less than 2 ACH-50) we have had problems with wooden exterior doors that can warp slightly due to humidity differentials during the winter months which tend to open up small gaps at the bottom of the door near the sill. These homes have either conditioned crawls or radiant slabs so a small draft at the doorway results in a noticeably colder patch of floor and customer phone calls. They are usually pretty easy to fix and I don't see us switching to fiberglass doors or multi-point hardware but the point remains that in a tight house any small flaw is significantly more noticeable to the occupant.

Ross, the ANSI-700 National Green Building Standard is very specific about recommending that sill seal should be backed up with caulk to create a durable air barrier between the mudsill and the top of masonry. When possible we prefer to put this on the exterior to repel insects or when using a double wall system with separate bottom plates rather than the full width plywood bottom plates.

sealing mud sills

What I ,as a builder, have been doing for a dozen years of so for air and bug penetration is to put down a bead of constuction adhesive on the top of the stemwall.Then I put a 1 foot wide piece of tyvek(cut a foot off the roll with the chop saw)on top of the bead and push it over the j bolts and then put on the sill seal the mud sill and crank it all down.After that when I lift the walls(on top of another bead of caulk) with the plywood sheating hanging down past the rim joist and mud sill, I staple the tyvek that's hanging outside at the bottom up onto the plywood before I staple down the tyvek on the wall.Makes for a neat package --no air and no bugs getting behind the ply at he bottom.

House Pressure Differentials

If a butterfly's wing motion in Kansas can cause a tsunami in Asia, then yes - everything you do to change the air flow dynamics in a house will impact the internal pressure balance. And that pressure balance changes minute-by-minute with occupant behavior (doors, fans, flushing toilets) as well as environmental variables such as wind speed and direction, air temperature and relative humidity.

It's theoretically true - but trivial - that, if you seal the exact same proportion of high leaks as low leaks, then the internal pressure regime won't change. But, in the real world, nothing works that simply.

In theory, if a house has exactly the same cross-sectional area and shape of leaks bottom and top, then the neutral pressure plane will be centered in the height and the negative pressure at the bottom will be exactly the same as the negative pressure at the top.

If the only leak were an open door at the bottom, then the neutral pressure plane would be at the ground floor and the whole house would be under positive pressure. Conversely, if the only leak were an open window at the upstairs ceiling, then the entire house would be under negative pressure.

If you sealed most of the leaks at the ceiling but failed to bother with the bottom leaks (or didn't seal them adequately), then the neutral pressure plane would shift downward, increasing the positive pressure at the top and increasing the flow rate through the remaining holes. There would be less overall air exchange, but those remaining leakage areas would become highly vulnerable to moisture damage.

Those who have lived in leaky old woodstove heated houses understand this principle. Sometimes you have to crack a downstairs window to start a fire without a lot of backdrafting. If the fire gets started and you close the window, the negative pressure at the remaining "leak" (the woodstove) would increase and create backdrafting. In other words, sealing one leak (the window) increases the flow rate at the remaining leaks (the woodstove door and connector pipe).

So, in the real world, every time the leak dynamics are altered, the pressure balance is changed and flow effects may become locally problematic (drafts or moisture problems).

Bernouli Ain't Home

Bernouli's principle operates only in Italy or in venturis and on airplane wings. Diffuse air flow is directly proportional to the pressure differential, but air flow through an o-r-i-f-i-c-e (the SPAM filter thinks this is a dirty word) is proportional to the square root of the pressure differential.

The range of actual holes and cracks in a house fall somewhere on the spectrum between the two.

more on pressures

Robert wrote:

Actually, if the house only has one hole -- like an open door at the bottom -- then the neutral pressure plan will be located in the middle of that opening. The air leakage in must equal the air leakage out and so air would flow both directions through the hole. If the only hole were horizontal, then the specific location of where air starts to leak out (or in) would be essentially random but still the hole would leak in and out equally -- otherwise the house would explode/implode.

Also, for a little more detail about flow regimes, the types of holes and cracks in homes leads to an average empirically-determined flow exponent of about 0.65 and the vast majority of homes test between 0.60 and 0.70 (square root flow = 0.5 and laminar flow = 1.0). After air sealing, the exponent tends to increase slightly, implying that the holes being sealed were more like an o-r-f-i-c-e than a smooth long passage that would be associated with laminar flow.

Fiberboard

I am looking to create an air barrier outside of board sheathing. I would like this barrier to be durable and tight, but also vapor permeable. I have been considering using fiberboard sheathing and taping the joints.

I have read some air permeability ratings for fiberboard that are a little troubling- essentially they indicate that too much air moves through fiberboard for it to be considered a true air barrier. If my memory serves me well, I don't think one could "hold a piece of the material up to your mouth and blow" through the stuff, and my intuitive sense is that it would work.

Does anyone have any experience with these products as air-barriers, or know that in fact they are too porous to suffice?

Fiberboard

Of course it depends on the brand, but in one test of air permeance ½" fiberboard passed 1.6 l/s-m2 @ 75 Pa (air barrier material can allow no more than 0.02), the same as an uncoated brick wall.

In another, 7/16" plain or asphalt-impregnated fiberboard passed 0.82 l/s-m2 @ 75 Pa, about twice as much as #15 asphalt felt.

House or Balloon?

I don't think that the typical 5 Pa (0.1 psf, 6.5 mph wind equivalent) stack effect pressure in a 2-storey house would implode or explode the envelope. Nor would the 100 pounds of buoyancy likely lift it off its foundation.

Caulk, foam, accoustical sealant, tapes?

Are there any good rules of thumb for when it is best to seal cracks, joints b/w materials, framing members, etc. with caulk vs. trigger foam vs. accoustical sealant vs. sealant tapes, etc?

I've seen more variations of what to use to seal these various intersections, but never much logic behind why one would choose one sealant materials versus another.

It would be both interesting and very valuable to hear the reasons why people use different sealing materials in different circumstances. To me, this seems worth of a whole "Musings of an Energy Nerd" column, but I would welcome any blog comments that folks are willing to post.

Caulk, foam, and tape

Robert Dickinson,

Your suggestion is a good one. Although I haven't addressed caulks in comprehensive article, I have surveyed tapes and gaskets. In case you didn't see it, here is the link: Air-Sealing Tapes and Gaskets.

Response to Robert

. I didn't say that 5pa of pressure would implode/explode the house, I said that if the flow into the house didn't equal the flow out of the house then it would explode/implode. I'm not sure you realize that a 5pa pressure difference is created by removing about 1 cubic foot of air from a house without replacing it. If you could make 200 cubic feet of air enter a home without any air leaving, that would create a 1000 pa pressure difference and the windows would blow out. My point was that the flow balance is maintained in a home and the pressure is a result of maintaining that balance. .

gba advisor status for Blasnik

Great info Michael, I would like to have you do some blogging here.

Post, post, post

Can the stack effect itself be reduced?

Before I read this definition I had assumed that in a home built to meet the PH standard of .6 ACH and that included a balanced ventilation system that the stack effect would be negated or largely diminished. Would this be the case or is the force (or potential force) of the stack effect independent of these factors in terms of the physics?

Response to J Chesnut

J,

In a Passivhaus building, the stack effect still operates. However, the cracks and holes are smaller, so the air leakage rate is less.

Remember, 0.6 ach is your air leakage rate. If you achieve the standard, you know the rate at 50 Pascals.

stack effect

Martin,

I understand that .6 ACH is the leakage rate. When the leakage rate is measured by the blower door the balanced ventilation is off and sealed.

At a low air leakage rate does the force of the balanced ventilation system negate or overcome the stack effect? In other words does the tandem of low leakage rates and balanced ventilation (air pushed @ ~30 cfm) overcome the stack effect so that you no longer have negative pressures at the bottom of the house and positive pressures at the top?

Another response to J Chesnut

J,

You wrote, "When the leakage rate is measured by the blower door the balanced ventilation is off and sealed." I'm not sure what you mean by "the balanced ventilation," but if that refers to a balanced mechanical ventilation system (like an HRV system), then I would have to disagree with you.

In most cases, ventilation system intake or exhaust vents are NOT sealed during blower door testing. (For more on blower door test protocols, see Blower Door Basics.) Of course, a homeowner, builder, or blower-door contractor can decide to have a blower-door test performed any way they want. If you want to seal the intake and exhaust vents of your mechanical ventilation system before conducting a blower-door test, you certainly can. But that's not the usual protocol.

Concerning your question about operating a balanced ventilation system: if the system has been carefully commissioned to be perfectly balanced, then it will neither pressurize nor depressurize the house with respect to the outdoors. The stack effect still applies, of course. If you have done a good job of air sealing, the stack effect won't hurt you very much, though, because the cracks and holes in your envelope will be so small.

One final point: some installers of HRVs prefer to commission their systems to be slightly unbalanced, for a variety of reasons. This will have the effect of slightly pressurizing or depressurizing the home. You can discuss whether either option makes sense with your ventilation contractor.

HRVs and blower door testing

Much as i hate to disagree with Martin, it's actually a pretty common protocol (including part of RESNET's standard test procedure) to seal off continuously operating ventilation systems when performing a blower door test.

About sealing ventilation ports

Michael,

Thanks for your post; it's fine to contradict me. It seems clear that homes are routinely tested both ways.

My source was David Keefe, who wrote in his useful JLC article ("Blower Door Testing"), "Whether or not intentional openings like ventilation ports are temporarily sealed depends on the test being performed. For a description of how an existing house normally behaves, such openings are usually left uncovered. On the other hand, if a new house is being tested for sufficiently tight construction, it may make sense to seal intentional openings, removing them from the measurement."

Here's a link to the article:

http://www.energyconservatory.com/download/blowerdoortestingjlc.pdf

Comparing air barriers.

Not being a blower-door tester I'm not sure of proper protocol... I will be having one done in the not-so-distant future...

If the goal is to test the integrity of the air barrier, shouldn't it be required to have those types of envelope penetrations sealed off?

For the purposes of determining the "tightness" of an air barrier or to compare one air barrier to another, shouldn't all penetrations be sealed as best as possible?

Response to Lucas

Lucas,

Both methods have merit. If you want to know the air leakage rate of your home under normal operating conditions, then sealing off vents that are normally open is "cheating."

However, "cheating" is sometimes useful if it helps you track down leaks.

response to Lucas

Lucas, Martin already addresses that there can be different results sought:

Do both. A blower door test does not take that long.

cheating?

Isolating factors (such as the building enclosure) and performing tests to quantify their performance results in targeted information that can be used to exploit the isolating factor to desired ends. This is science qua science Martin ; )

Oops

J, I see that now thank you.

Sorry Martin, I didn't see your comment when I posted my question.

On "cheating"

J,

That's why I put the word in quotation marks. It's "cheating," not cheating.

Yes, "cheating" is a useful way to gather data.

blower door set-up

Martin-

I think I see some misunderstanding here. My comment about sealing off ventilation systems was specifically about continuously operated ventilation systems -- not intermittent systems. Continuous operation is a key distinction because that means that the "leak" the blower door might measure from that ventilation opening is not going to be leaking like the rest of the building and so should not be included in any infiltration modeling.

I'm quite familiar with this detail having spent the past several months on a RESNET subcommittee drafting new blower door testing standards and this was an area with broad agreement. One can certainly debate some other aspects of proper house testing set-up, but this one seems fairly clear.

On continuous ventilation

Michael,

Thanks very much for the information.

So how does one define "continuous"? I know that a lot of HRVs are programmed to run for about 50% of the time. Moreover, some homeowners program their ventilation timers to turn off the ventilation systems while they are at work.

It's also common for exhaust-only ventilation systems (for example, a system using Panasonic bath fans) to operate for only 50% of the hours in a day.

It seems to me that these systems aren't continuously operating. Do you agree?

continuous ventilation

I agree -- continuous would mean continuous. Systems that cycle on and off would not be sealed during a blower door test because their leakage will act like envelope leaks whenever the system is off. I realize that many systems cycle but there are also those that run all the time and vary between lower and higher speeds.

Response to J. Edison

J. Edison,

You never described your crawl space floor, so it's hard to provide advice. I'm going to guess that the crawl space has a dirt floor.

If my guess is correct, you could consider installing a polyethylene vapor barrier under a concrete slab. Because concrete is an air barrier, the concrete will prevent any off-gassing from occurring.

If that makes you nervous -- if the idea of any polyethylene at all makes you nervous, even when it is under a layer of concrete -- you could follow the advice given in books from the 1950s. Building specialist Hubbard Cobb, writing in 1955, recommended the following materials under a concrete slab: 6 inches of crushed stone as a capillary break, topped with a 1/2-inch thick layer of cement grout, topped with a layer of asphalt felt laid in hot-mopped asphalt. Then you pour your slab on top of the asphalt.

If you don't want asphalt, you can always use deep crushed stone as a capillary break -- the deeper, the better -- topped with 2 or 3 inches of concrete. This isn't a perfect moisture barrier, but it contains neither polyethylene nor asphalt.

Alternatives to poly?

First off let me say, I have chemical sensitivities; so, everything I plan to do to my house in the next year has to be addressed with this in mind. Since I'm very sensitive to the off-gassing of so many products, I can't even walk into places such as Target anymore without gagging, and often find I have anaphylactic responses from many other products... people's body products, air fresheners, candles, the laundry and body products aisles at all stores. I've known for 30 years now that I've got this problem. I've done the best I could without turning myself into a bubble woman. I have to hold my breath a lot and open windows and doors sometimes to air out my house or car from things that cause me reactions. It's gotten worse in the past 10 years.

I live in Boulder, CO where the weather varies, sometimes erratically, year round. In January, we can get highs as much as 70F one day and 10 the following. The wind can gust here up to 100mph as it screams over the Continental Divide then slams down into the Front Range communities. This happened just 2 nights ago. Funny thing was, it was the first time I ever noticed how drafty my bedroom is, outside of the annoying whistling sound as the air enters through the wood double hung windows, of which there are too many in this house. It was late at night, around midnight when I noticed it. I was reading in bed (about 10 ft from the nearest window) at the time and could feel a definite slight cooling breeze around me. My house thermostat is set to bedtime as 11, so I'm not surprised when at midnight it's cooler, but this was wafting cooler air. Good thing I'm about to do more work on the house.

I'd replace all the windows, but can't afford to do this now; the payback is outrageously long when there are 5 large windows in my bedroom alone. There are 18 windows on the second floor total, 16 windows and 4 doors on the 1st floor and 4 large slider windows in the basement. We're talking a huge layout I don't have to replace them all. I'm not planning on living here long enough anyway to make it worth taking a loan out for this. So, moving on...

My reason for posting today is to ask about air and vapor sealing my crawl space under the basement floor, that doesn't involve spray foams or encapsulating it with some sort of poly sheeting.

I've been reading a lot here, and various other places, on the different methods, but have yet to find any alternative to air and vapor sealing without using some sort of foam and/or plastic sheeting. Even if I wasn't chemically sensitive, I'd never use the foams, now that I know how nasty they all are from cradle to grave.

Seems every insulation company, and my contractor, have said if I don't use foam, then there is only plastic sheeting of some sort. I like the Basement Systems product, but it's made of seven layers of high-density polyethylene, lot-density polyethylene, and polyester cord, and it has some trademark antimicrobial additive on the underside layer, which is either applied on or infused in it. When I asked their rep about this, they said because it's on the bottom side, it won't off-gass into my home. So, how safe is the whole product? I told him I'd want them to air out the poly for at least a couple of days before they bring it here, but they said due to the amount I need, it might not be possible as warehouse space is limited. Guess I'll have to insist on this though. I don't want to be sick every time I go down in my basement to do something fun, mess around in my store room, or for whatever other reason I have to down there.

Any suggestions for alternatives?

Response to Martin's response

Martin, thanks for the alternate suggestion, but I don’t think your way is doable. I’m pretty sure that method would cost way more money than using the polyethylene products, in both labor and material, but I'll discuss it with my contractor.

When I build or remodel my homes (I'm on my 7th) I try to do everything in a healthy, environmentally sound way, not just for energy efficiency and beauty (which is subjective anyway).

This 1994 house is about 3800 sq. ft. finished. It was built in a neighborhood that was once wetlands. Some people have concrete slab basements while others, including me, have crawl spaces with dirt floors and floating plywood subfloors.

I moved here in 1997 and did little in the way of decorating, outside of painting some bedrooms and twice repainting the exterior, which will be done again this summer. I just needed something ready to move into, in a neighborhood with kids, and school bus service. I had young children then, school had begun already, and I had a very busy life then too, and honestly, it hasn't slowed down since.

My basement was finished off in 1998, using fiberglass batts in the walls, recycled PET carpet (which I never liked after it was done), recycled carpet pad, and low VOC paints. It was totally unfinished before that. I didn't know about air and vapor sealing back then. I’ve sure learned a lot since then on how it SHOULD be done, in terms of energy efficiency AND environmental aspects. Some good new stuff on the market, but some not so good (ex: foam insulation). Now that I’ve got some money saved up, I can do it right this time!

However, there is way more to do around the house in terms of air sealing and redecorating in healthy ways, so I can't blow my whole budget in the basement. My money should be able to cover it all, but one never knows. I do what I can as I can afford it. But, I don't want to go overboard. I don't plan to live here more than another year, but then again, I've been saying this for 5 years now :)). Life is funny that way. My kids are grown and gone, for the most part, and I'm ready for a smaller house in a different location. I've never lived anywhere as long as I've lived here, and I really want to build my own home from the ground up. Likely it's going to be a one story, large eat-in kitchen (my kitchen has always been the heart of my homes), 3 bd/3bath, straw bale house, with a separate guest house, and separate art studio, all surrounding an outdoor partially covered patio and garden, as off-the-grid as reasonably as I can be, and NOT in suburbia. I'm an artist, I love company, but I also like my personal space and nature is a must for my happiness. View of the mountains and maybe the ocean somewhere -- Hawaii or Belize? Oh yeah, but I'm allergic to mold too, which is why I live in dryish Colorado; guess I'll have to think more about where to go.

Leaving that tangent... the entire basement floor footprint is ~1315 sq. ft.. (see attached drawing below). The basement rooms are from subfloor to ceiling: 7' 9" in the bedroom and closet, 6' 11" in the bathroom, and 7' 8" in the hallway and large rec. room. The storage and utility rooms (the little room between the bathroom and storage room) are unfinished, so floor to ceiling height is closer to 8’. There are a few soffits in some rooms that lower the ceiling height to 6' 9" or less; so, I think raising the floor up higher is out of the question as I have friends and family members who are over 6' 6" tall.

The crawl space is pretty shallow, averaging 3 ft deep at the most, depending on where you are in it, and the grading of the dirt floor isn't level. There are currently 3 accesses to it. One in the basement bedroom floor very close to the window, a much smaller one in the bedroom closet floor, and the last is in the storage room floor, not far from the sump pump.

I haven't been under the plywood floors myself. I have seen only what can easily be seen when the access hatches up and I'm laying on the floor looking underneath. So, this is what my contractor and the insulation guys have told me. There is a very thin layer of dirt and rock on top of poorly laid 3 or maybe 6 mil plastic sheeting on the dirt floor of the crawl space. It is torn in many places and disintegrating in others. I have no idea what is under the plastic sheeting other than more rocks and dirt. The exterior foundation concrete walls sit on top of pylons. The floating subfloor is plywood, on top of wooden joists, on top of some steel beams. You can't crawl under the steel beams unless you are a rodent, a cat (mine have found their way in there once or twice when a hatch was left open) or a small child, maybe. According to the 5 adults who have been down there, none of them have been able to shimmy under the steel beams, where it's closer to under a foot between the dirt and the bottom of the beams.

To do this air and vapor sealing, several areas of the plywood will have to come up, if not all of it. Some of these need replacing anyway, thanks to my cats soiling them.

I guess, I’ll probably go with the thick polyethylene that can be wrapped up the walls. If only it wasn’t winter! I may have to air out the basement for a while after this is done, if there is an off-gassing odor issue. I’ll also have the basement door that comes up to the 1st floor sealed up tight too. This should also help reduce the stack effect. There are air vents in the crawl space to that need sealing up, I think.

After the proper air and vapor sealing happens in the crawl space, I plan to put R-30 recycled cotton batts under the floating floor. Air and vapor sealing will continue in the walls too. Will have recycled carpet tiles or maybe cork tile laid on top of the plywood. R-19 bats or R-21 will go in the walls. I’m not sure what insulation is in the ceiling, but likely it's more fiberglass batts. Will put cotton batts in there too as the ceiling will have to come down due to all the holes from pool cue sticks and air sealing that will be done around the recessed light cans and the heating ducts. I also find them to be great sound proofing. I have cork tile flooring on the 2nd floor and love it, tho the cats hate it. Nothing to shred and they slide across it when they go tearing around the house... what a hoot! But, they aren’t allowed in the basement anymore anyway, so more likely it'll be the carpet tiles, which are so much fun to mix and match, as well as easy to clean or dry out, if need be. Also the pool table and other heavy furniture won't ruin them like cork or lino tiles. Dents from heavy objects can spring back easier or if need be I'll switch out carpet tiles, also easier to do than anything else.

Dripping Recessed Lighting

Great article Martin. Just wanted to add from my experience. We had a new house under construction and were seeing drops of water on the plywood deck below a few recessed lights in a two story space. What we discovered was that warm interior air was entering the conduit feeding the can lights. This conduit went up into the attic space, above our insulation (poor choice by the contractor, that wasn't initially seen). The warm air would condense in the cold part of the conduit, causing the water dripping. Stopping air from entering the conduit was the solution at the time, but since then, I won't be installing any recessed lighting in ceiling/roof planes again. Not worth the worry. Sconces that illuminate the ceiling are a better solution on many levels. Food for thought.

Response to Mark Miller

Mark,

Good detective work!

And I couldn't agree with you more: sconces that illuminate the ceiling are much better than recessed cans that light up the floor and cast strange shadows on people's faces.

concrete as air barrier

I was glad to see the mention of the stack effect's effect on concrete's performance as an air barrier in the basement section (I think the grammar on that sentence is actually correct, believe it or not :) ). This is critically important in radon-mitigation strategies. A slab IS NOT ENOUGH to keep Radon out of your home. Poly and perf-pipe under the slab (connected to a fan and exhausted outside of the home) is critical for keeping Radon out. I'm surprised at how many green builders aren't aware of this fact (I've even seen NZE home builders ignore Radon mitigation - to save energy, I guess).

I take some exception to the unapologetic promotion of spray foam on this (and other) green building sites. There is an incredibly high amount of embodied energy in petroleum-based spray foam, the off-gassing is a legitimate concern, and perhaps most relevant to this column, spray foam can get leaky through time, because it separates from wood framing members (which expand and contract with temperature and humidity fluctuations). That may seem impossible, but in the interior of Alaska, where indoor RH's drop below 30% and temperature gradients (between inside and outside) are over 100 degrees, this absolutely happens and studies at the Cold Climate Housing Research Center confirm remodelers' experience. Outsulation techniques such as the REMOTE wall or Thorsten Chlupp's hybrid walls (on two NZE and PassivHause homes in Alaska) accomplish ACH50 below 0.4 without poly or spray foam in the wall cavity.

Thanks, Martin, for another great read.

Building airtight w/o (spray)-foam

An example how to get away from depending on spray foam is to take the rim-board out of the air-sealing equation by making the plywood sub-floor airtight - this can be done by taping the boards together. Of course services entering the airtight floor of the house (electric and plumbing) need to be sealed as well, with a durable connections. As mentioned most spray-foam and caulks will shrink/dry-out or lose adhesion to the substrate over time, which is a reason age tested tapes and rubber gaskets are a better way make long lasting seals. Disclosure, I sell imported air-sealing tapes, intelligent membranes and accessories that are available at http://www.foursevenfive.com

Regarding the walls and ceilings - a good rule of thumb is to have >66% of the insulation outboard of the most vapor retarding layer- to prevent condensation on cold surfaces in the winter. But if in addition to that, you want the wall to be more vapor open on the exterior than on the interior so any moisture that 'leaks' into the insulation can dry outwards in winter - a reason why Joe loves vented roofs.

However a OSB sheathed buildings with exterior foam could have condensation problems in summer in an airconditioned house, since the vapor drive now is reversed and the hot humid summer air could condense on this (interior) sheathing. The same goes for a interior PE-vapor retarder.

Solution to these condensation issues, mold and potential for structural decay is an intelligent vapor retarding membrane (INTELLO or the paper based DB+). These membranes are vapor closed in winter, vapor open in summer. This allows you to use insulation with low environmental footprints (cellulose or cotton) - and if combined with a service cavity (http://foursevenfive.wordpress.com/2011/11/22/the-service-cavity-making-airtight-construction-easy-2/) puts the airtight and vapor control layer in the right locaiton and protects it from the homeowner (which ADA doesn't). It can be used in new construction or renovations without having to resort to floor-outlets, sealing each and every outlets (ADA).

Stack effect and heated basements

Martin, I have a finished walk out basement. Should I keep heat turned up a bit higher than the main floor to try to minimize the stack effect? Will this approach save any energy?

Response to Katherine Slufik

Katherine,

You should adjust your heat to provide comfort. If you feel cold, and you can afford the cost of your fuel, then turn up the heat.

Turning up the heat will not reduce the stack effect; if anything, it will increase it. Nor will it save energy. If you turn up the heat, you will burn more fuel.

The only way to reduce the stack effect is to perform air-sealing work. If you know that your house has air leaks, start sealing them. Begin at the attic and the basement. If you aren't sure where the leaks are, you can hire a blower-door contractor to help you find them.

Air barriers in vented roofs

In a standard vented roof assembly, with an air barrier at the ceiling, and the attic insulated with fiberglass, cellulose or other air-permeable stuff, why is there no additional air barrier on top of this insulation? It would seem the air in the vented attic could bypass the insulation. I've read that any fluffy insulation needs a 6 sided air barrier like enclosed in a stud bay to be effective, but I've never seen an air barrier above attic insulation. I can appreciate why more effort is given to ensuring the ceiling air barrier is tight so conditioned air doesn't escape. But I would also want to avoid unconditioned air bypassing the insulation. Vented roofs are common and they supposedly work well, so what am I missing here?

Response to Mark Fredericks

Mark,

Q. "In a standard vented roof assembly, with an air barrier at the ceiling, and the attic insulated with fiberglass, cellulose or other air-permeable stuff, why is there no additional air barrier on top of this insulation?"

A. There are two kinds of people who ask this question: those who care about thermal performance, and those who don't. The answer for those who don't (old-fashioned builders) is simple: "Because that's the way we've always done it, and because we'll fight tooth and nail if anyone tries to change the code and tell us to do it differently."

The answer for the second group -- those who do care about thermal performance -- is more subtle. Yes, there is a thermal penalty to not having a topside air barrier -- epecially for fiberglass batts or blown-in fiberglass -- but it's not a huge penalty. It turns out that it is cheaper to simply install deeper insulation (enough to make up for the thermal penalty) than it is to try to correct the problem with a layer of housewrap.

So, here's the moral of the story: if you care about this minor thermal penalty:

- Choose cellulose, not fiberglass, and

- Just make the cellulose a little bit deeper if you want to make up for the (slight) thermal penalty associated with the lack of a topside air barrier.

Thanks

Thanks Martin for your quick and clear response. Your answer is not unexpected, I can imagine the headache of trying to seal an air barrier around all the roof framing for only a minor performance gain. However it's comforting to know that just because it's not common, doesn't mean it's not valuable. Thanks again.

non-drywall ceiling?

Thanks for all the fantastic information. Can you tell me if an air barrier is used at the ceiling with insulation between the joists above, is it still possible to use wood for the ceiling or does it have to be drywall in order to keep the integrity of the airseal? Would using an adhesive or silicone where screw/nail penetrations would occur have any use?

Response to Enga Lokey

Enga,

You say that you plan to install "wood for the ceiling." By "wood," I'm assuming that you mean boards -- either square-edged boards or tongue-and-groove boards.

A board ceiling leaks air like a sieve. This is the most common type of ceiling involved with cathedral ceiling disasters, because this type of ceiling allows lots of warm, humid interior air to enter the cold rafter bays and condense.

The nail penetrations aren't really the problem. The problem is the cracks between the boards. There is no way that caulk or adhesive can be used to stop air leaks through these cracks, because normal changes in temperature and humidity cause the boards to swell and shrink, stressing any caulk to the breaking point.

The best (and easiest) solution is to install a drywall ceiling first (with taped joints) before installing the boards. Another option is to install foil-faced polyisocyanurate with taped seams first; in these case, the polyiso is the air barrier. (If you use polyiso, make sure to seal any leaks at the perimeter of the ceiling with caulk or tape.) After installing the polyiso, you can install 1x4 strapping and boards.

non-drywall ceiling?

OK, so one of the fancy Intello air barriers between the boards and underside of rafters will not make wood cracking and gaps a non-issue? I wasn't thinking the wood was the barrier, but the air-barrier membrane was, although this would have holes in it where nails penetrated to attach the wood. Thanks!

air barrier wrap

Still wondering about the extent to which the Intello and similar materials are sufficient as an air barrier on the ceiling, regardless of what ceiling lining is used. It would seem that they are an expensive waste of time if airtight drywall or foam sheeting is also needed.

Resonse to Enga Lokey

Enga,

I agree. Either gypsum drywall or carefully taped and sealed foil-faced polyisocyanurate makes a good ceiling air barrier. If you are using drywall or polyiso as your air barrier, you don't need an additional sheet membrane.

Rim joist insulation: open cell?

Would you discourage the use of open cell foam to insulate the rim joist? (I see the note about a preference for CC in the rim joist)

Found the answer... I believe

On https://www.finehomebuilding.com/2013/09/12/insulating-rim-joists I read:

"One advantage of using spray foam to insulate rim joists—an approach sometimes called the critical-seal method—is that a single product performs two tasks: sealing air leaks and insulating. In mild climate zones, either open-cell spray foam or closed-cell spray foam will work; however, in climate zone 6 and colder zones, it’s safer to use closed-cell spray foam."

I'm in Climate zone 4.

Response to Adam W (Comments #78 and #79)

Adam,

Yes, you found the answer. Open-cell spray foam is fine in your climate zone. Good luck.

"The solution is to install a sump with an airtight lid; these are available from Jackel, Inc." They have many products on their website. Which one are you referring to? I've been wondering how a sump can let water out without letting air in.

Qofmiwok,

Jackel has many models to choose from. Here is a link to one product: http://jackel.com/sf1850e.html. Call up the company for more information.

Water enters the sump through a below-slab pipe (usually a 4" diameter perforated plastic pipe) laid in crushed stone. The purpose of the airtight lid is to limit the entry of air into the basement -- air that might otherwise enter through the soil and crushed stone -- when the basement is depressurized due to the stack effect or the operation of an exhaust fan in the house above.

Thanks Martin. So do typical sumps adversely affect air tightness as measured with a blower door test?

Qofmiwok,

Yes. Sumps without airtight lids are entry points for air.

When a house is depressurized by the stack effect or an exhaust fan, outdoor air is drawn through the soil into the house -- and a sump lacking an airtight lid can be a major entry point.

Log in or become a member to post a comment.

Sign up Log in