Image Credit: Karen Doherty/National Renewable Energy Laboratory

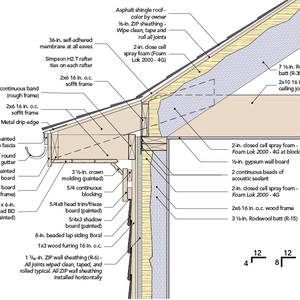

“Flash and batt” is an insulation technique that combines the air-sealing superiority of spray foam insulation with the cost benefits of fiberglass batts. An inch or two of polyurethane foam seals the cavity and the batt insulation adds R-value without costing an arm and a leg.

That’s roughly the plan Dave Frank is considering for the roof of a house — presumably his own house — in Climate Zone 5. But his plan contains a twist: He wants to spray the underside of the roof deck with foam and install the batts between the joists at ceiling level.

“My reasoning for this is to (a) get HVAC in the attic within the envelope where rafters can’t be properly vented, and (b) still have insulation on top of the flat ceiling drywall because there is some ceiling radiant heat,” he writes in a Q&A post at Green Building Advisor. “And there’s the added benefit of getting some of the R-value from a cheaper product.”

Frank wonders whether the code requirement for a total of R-38 in the roof will allow the insulation to be separated in this way, as long as the R-value totals for the different layers all add up to the right number.

Or is this a case where 2 plus 2 equals 3?

That’s the topic for this Q&A Spotlight.

The code is clear: Your idea won’t work

There’s not much wiggle room here, says GBA senior editor Martin Holladay.

He cites a provision in the International Residential Code (IRC), which says the air-permeable insulation (the fiberglass batts) must be installed “directly under” the air-impermeable layer (the spray foam).

“The air impermeable insulation shall be applied in direct contact with the underside of the structural roof sheathing as specified in Table R806.5…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

11 Comments

Blowing awfully hard to blow holes in this assembly

Peter, you straight out state exactly what the code does NOT state. You write (in direct contact) and the code states DiRECTLY UNDER.

When we meet someday I will have you stand directly under me and if you want I will drop a marshmellow instead of a hammer. Let me know about my intent, your intent the codes intent.

The code needs to be updated and have the proper words added. That is the simple end to this debate.

Code men,,,, fix your code.

Now as to convective loops and moisture transfer and gable insulation and dark closets that may scare, I think way too much blowing there to make this assembly fail.

Show me 9 out of 10 builds as such that are failing and convecting and rotting.

I can show you many a case where what GBA says works (rigid foam installed on OSB) has failed. Google image searches show quite a bit of failed OSB now that we are trying to build tight and with more continous insulation.

Most any assembly can work, so much of what we build depends on more than a list of materials.

We are building homes now that require perfection in window installs yet we have windows being shipped with directions that will guarantee failure as to moisture entry leading to wall rot.

This blog does not fully tell the tail.

For those that think codes are key, you should be screaming at the top of your lungs for the codes to catch up with mandating proper moisture/rot assemblies. Mandating the building of homes that will not have moisture/rot issues should come before the push for airtightness NOT AFTER.

The whole industry of building needs catch up with proper details that are mandated. And someone has to go thru all the details that do not work and get them out of the system.

aj blowing hard.... ;)

Uneducated/Inexperienced Point of View

Home energy efficiency and insulation have almost become an obsession of mine since my involvement in the building of my log home. My builders were conscientious and reliable but the words energy and efficiency were never spoken together. Unfortunately, I am dealing with the annual expense of that failure in my zone 7 area of the Adirondacks and have spent the past few years researching everything re insulation.

As a non-builder engineer I cannot see how the proposed install meets the code (regardless of whether the code is correct). You have one barrier of 5 and another of 13. Unless airtight AND heated, the attic will eventually reach temperature equilibrium with the outside. The ceiling then faces that temp at a rating of only 13. Heating the attic takes care of the ceiling but you have relatively rapid heat loss to the exterior due to the 5 rating of the roof. Then again, 5 may prove sufficient if the rafters are completed foamed as well. Still, why not put all the insulation in the roof/gable assembly if you are confident the attic is wholly sealed and within the envelope?

I will also add my two cents to AJ's comment about Brownell. I have toured a house of his in Lake Placid during a cold winter day with a window open. One major feature involves wrapping the entire exterior (above/below grade) in rigid foam at R-20 and, despite no interior insulation, the house was warm and comfortable. Brownell tells me has faced criticism from inside the industry for years but, as AJ stated, it somehow works. I would rather have paid more using his design during construction, and probably recouping some of that cost via tax credits, than deal with ongoing $500/mo heating bills during multiple single-digit and/or sub-zero temp days & nights.

Thanks...

I have a similar situation;

I have a similar situation; the furnace is in the unheated attic, above poorly installed R-19 insulation in the attic floor. I am exposing the rafters, and was planning to use spray foam and batt insulation between the rafters, but it does not seem there will be much room for the batts (I think the rafters are 2x6s). The plan is to bring the furnace inside the thermal envelope. Alternatively, I could use more spray foam (deeper) and then attach foam board (polyisocyanurate or XPS) to the rafters (instead of the batt insulation), which would also prevent thermal bridging.

I have a few questions; first, should I remove the R-19 in the floor, or should I leave it? Second, if I use spray foam and batts, how thick should the spray foam be (I'm assuming enough to provide airsealing qualities, but not compress the batt insulation). Third, if I install polyisocyanurate on the rafters, does it need to be covered with drywall (to protect against fire), and if so, would using XPS avoid that problem? The attic might be used for storage, but not living space (and if it were ever used for living space, I'd drywall it). Finally, there seem to be gaps in the wood on the roof; is it okay to spray foam on the underside of tar paper, or does the wood need to be continuous? If I needed to sheath each bay to avoid spraying the tar paper, I'd probably go to using foam board sealed with one-part spray foam as an air sealant; if I do that, will adhesive be enough to attach the foamboard to the underside of the roof?

Response to Adk Homeowner

ADK,

First of all, Dave Frank was proposing to install 3 inches of closed-cell spray foam on the underside of his roof sheathing. That insulation would have an R-value of about R-19 or R-20.

Since Dave was proposing to install fiberglass batts that would be thick enough to bring his total insulation up to R-38, we have to assume that he was planning to install R-19 fiberglass batts on his attic floor.

You wrote, "You have one barrier of 5 and another of 13." If you are talking about R-values, your numbers are too low.

Second: I disagree with your statement that "Unless airtight AND heated, the attic will eventually reach temperature equilibrium with the outside." There will be a continuous flow of heat through the ceiling, from the 72°F home below to the (presumably cooler) attic. If the outdoor temperature is (for example) 10°F, then the temperature of the attic will be somewhere between 72°F and 10°F. The exact temperature will depend on air leakage locations, the thickness of the insulation on the attic floor, and the thickness of the insulation at the roof plane. But the attic will never be at the same temperature as the outdoors.

Response to Kent James

Kent,

You propose to install insulation at your sloping roof plane in order to create a conditioned attic. The answers to many of your questions can be found in these two articles:

Creating a Conditioned Attic

How to Build an Insulated Cathedral Ceiling

Q. "If I install polyisocyanurate on the rafters, does it need to be covered with drywall (to protect against fire), and if so, would using XPS avoid that problem?"

A. You should direct that question to your local building inspector, since code interpretations vary. Most types of rigid foam, including all types of XPS, generally need to be protected with a layer of gypsum drywall. The only exception (not accepted in all jurisdications) is a brand of polyisocyanurate called Thermax, which has passed certain fire-resistance tests and can sometimes be left exposed, if your building inspector agrees.

Q. "There seem to be gaps in the wood on the roof; is it okay to spray foam on the underside of tar paper, or does the wood need to be continuous?"

A. You can install spray foam insulation against the asphalt felt that is visible between your roof sheathing boards.

agreement

Martin's posts are spot on. And a Bruce Brownell home is a PGH.

For Martin

Thanks Martin. Sloppiness on my part. I could not figure why my numbers were wrong until I realized I had been looking at the blog on defining an R-20 wall when I answered. The correct R-values certainly changes things.

Still, my limited experience with inspectors leads me to believe the large majority of them will require continuous insulation (i.e., batts in direct contact w/foam) to meet the R-38 value.

As I think on it more, would Frank's proposal in effect create a very deep cathedral ceiling -- where the structure begins w/sheetrock on interior ceiling and ends w/roof covering (such as in a hypothetical structure that uses say 48" deep rafters)? If so, then it would seem he has met the R-38 requirement. Put another way, what would happen in your discussion of defining an R-20 wall if I used 2x8 or greater studs w/R-19? Would the resulting air gap between the insulation and sheathing or drywall add, reduce, or have no impact on the R rating (understanding the thicker wood gives me a little more R)?

Thank you...

Response to Adk Homeowner

Adk,

You wrote, "My limited experience with inspectors leads me to believe the large majority of them will require continuous insulation (i.e., batts in direct contact w/foam) to meet the R-38 value."

I agree.

Q. "What would happen in your discussion of defining an R-20 wall if I used 2x8 or greater studs w/R-19? Would the resulting air gap between the insulation and sheathing or drywall add, reduce, or have no impact on the R rating (understanding the thicker wood gives me a little more R)?"

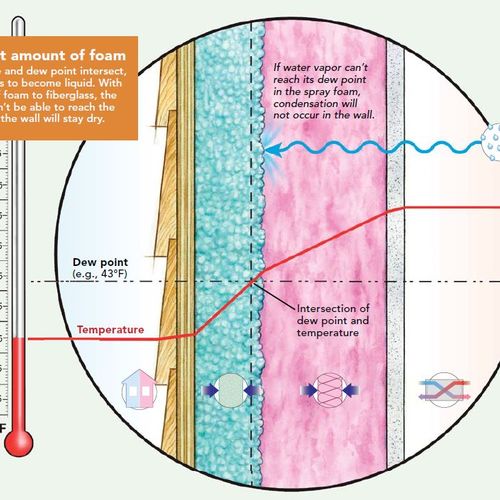

A. The air gap you describe is undesirable, for two reasons: (1) The possibility of convective looping in the air space, driven by the difference in temperature from one side of the cavity to the other, and (2) The high likelihood that there will be enough air leakage in the assembly to allow outdoor air to reach the cavity, lowering the thermal performance of the wall assembly.

Understand & last question...

So would convection airflow and other leakage in Frank's design be an issue or would having insulation against both sides reduce the temp differential enough to eliminate the problem? Thanks

Response to Adk Homeowner

Adk,

I already answered that question, and my answer was quoted in the article on this page: "If the attic were perfectly sealed — few attics are — it's probable that the proposed (illegal) assembly would work well. But if the 'sealed' attic had air leaks — infiltration and exfiltration — you wouldn't get the R-value you expect, and you would have opportunities for condensation or moisture issues."

Ignition barrier

An added benefit to keeping the batts in contact with the foam is that they fulfill the code requirement for an ignition barrier (IRC2009 R316.5.3) without the added expense of intumescent paint or another product.

Log in or become a member to post a comment.

Sign up Log in