A THICK SKIN THAT KEEPS A HOME WARM AND DRY

What to think about when considering exterior insulation

BY GARY BERGERON

Sheathing with foam-board insulation is a great way to get more R-value with a conventionally framed house. It can work just as well in remodeling projects as in new construction. Applying rigid foam takes some getting used to, but the basic tasks are not that much different from installing typical plywood or OSB sheathing—and the lightweight foam is easier on your back. The biggest differences are in how you detail windows and doors and how you fasten and seal the foam boards to the wall. Rigid foam can be the insulation, air barrier, and drainage plane all rolled into one. Pay attention to the details and seal every possible air leak, and you will end up with a more durable and energy-efficient home.

Some things to think about when planning to use exterior foam insulation:

For more information: Calculating the Minimum Thickness of Rigid Foam Sheathing Using Rigid Foam As a WRB

Foam panels don’t provide shear strength

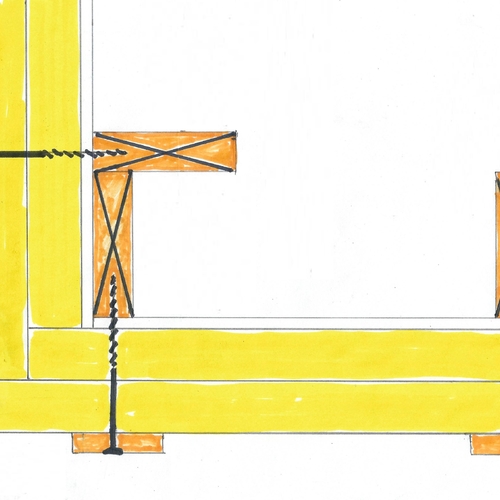

Rigid foam can replace plywood wall sheathing, but it can’t replace the strength associated with it. You still need to include some sort of bracing for this. Your engineer can specify where the shear panels or diagonal bracing needs to be. If plywood panels are used for shear strength, cover them with thinner layers of foam; this will keep the overall wall thickness consistent.

Extend the rough openings with a plywood box

Window and door rough openings get plywood boxes that extend from the inside edge of the wall to the outer edge of the foam sheathing. This allows you to mount the windows and doors flush to the outside of the wall. Be sure to compensate for the thickness of the plywood when you frame rough openings. Flash the windows to the foam with flexible flashing tape or some other window flashing system.

The right tool for the right cut

Straight, long cuts can be made easily with a tablesaw or circular saw. Long-bladed utility knives and small handsaws are great for tighter cuts and for adjusting the fit after the foam board is in place.

Effective air-sealing begins with a tight fit

Staggering the seams (two sheets of 2-inch foam, in this case) and taping the joints are important, but where foam butts windows, doors, and corners, the fit should be snug—tape shouldn’t span cracks—so it’s important to measure and cut carefully. Before installing the foam, run a bead of caulk where it will contact the top and bottom plates and the edges of walls. Be sure to tape all seams on each layer of foam, and flash to all windows and doors.

Tape sticks better on a clean surface

When cutting with a power saw, you will get a lot of dust on the boards. A paintbrush or a small dust brush works well to wipe dust off seams so that the tape adheres perfectly.

Continuous insulation is simpler and better

In the case where there’s a first-floor bump-out with a roof that intersects a second-floor wall, run the foam sheathing down to the first-floor ceiling plane. Then fasten rafters and ledgers through the foam to the adjacent wall framing, and build the roof. This way the wall maintains the full R-value right up to where it contacts the insulation in the roof or ceiling plane.

Fasteners, flashing, and furring will be covered in future videos in this series.

—Gary Bergeron is a partner at Synergy Companies Construction. The home in this video was designed by Building Science Corporation in partnership with the U.S. Department of Energy’s Building America Program.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

34 Comments

Exterior Foam Retrofit

We are putting together an estimate for one of our clients to install Hardieboard siding. My client is very interested in energy efficiency, so I mentioned adding exterior foam insulation to help insulate their home. I'm wondering if anyone has any tips on a retrofit situation like this. Existing walls are 2x4, home was just re-insulated with blown in fiberglass recently (from the exterior). There are a plethora of windows, all will need boxed out in one way or another. I appreciate any ideas. Thanks.

Tyvek

Mr Joyce makes no mention of housewrap. Only to say the foam is our air barrier. Does this mean there is no need for housewrap. Is this because the foam is polyisocyanurate? what about other types of ridgid foam?

Using foam as a WRB

Mike,

Either XPS or foil-faced polyiso can be used as a WRB, as long as the seams and penetrations are detailed properly. If you choose this route, you don't need housewrap. Many builders, however, use both housewrap and rigid foam.

For more information, see

Using Rigid Foam As a WRB.

Retrofitting 1979 split with 1" rigid T&G insulation

I am a furniture maker not a builder and am in need of some help. My 1979 split is a 2x4 framed house with no plywood sheathing just a layer of 1" rigid T&G blue foam on the exterior. I would like to remove the old Masonite siding and install an additional 1" foam, ventilation between the strapping and finish with Hardie plank siding. The reason for the ventilation barrier is I live in New Hampshire and the weather can be very damp at times. The north side of my house as all north sides gets no sun and is usually 5-10 degrees cooler, promoting mold and algae growth. What type of fasteners do you use to attach the strapping and does the strapping need to be pressure treated? Any help and or suggestions would be appreciated.

Re: strapping and fasteners

NHSchreiner,

Synergy Construction typically uses pan head FastenMaster Headlok screws to fasten the strapping. These fasteners are sturdier than typical deck screws, but for thin layers of foam you could just use long deck screws. I've only seen folks use pressure treated strapping where it would contact masonry or other constant sources of moisture. Otherwise, standard furring strips or rips of plywood are fine, considering that the purpose for building this way is to allow for quick drying. If you've got any other questions you could stop by our Q&A forum (look for the Q&A tab at the top of every page).

outdoor porch ceiling

is it wise to use 1.5" pink foam board insulation sheets against drywall on an old lath exterior porch ceiling with loose fill insulation and a heated floor above it? Do I need to worry about condensation on the foam board or drywall in a cold climate? What if the eaves of the porch roof allow air leakage in from the sides? The foam board forms a vapour barrier, and that's supposed to be on the warm side of any insulated wall, but there's the loose fill insulation between the floor joists above the porch. Would ordninary drywall be sufficient, or would I need to get cement board as my fire stop against the lath?

Response to Anonymous

Anonymous,

Your biggest problem isn't the rigid foam; it's the air leakage. No insulation system can work well until you've addressed air leakage. So, if the ceiling area above the porch has air leaks, you need to track them down and address them first.

Once that's done, you can install rigid foam on your porch ceiling. However, you have to be sure that your rigid foam is thick enough. The colder the climate, the thicker the foam has to be to prevent condensation or moisture accumulation. Here's more information:

Easy Ways to Avoid Condensation in Your Walls

exterior foam

closed cell styro is impermeable to water. So if you put it on the exterior of your house it acts as a vapour barior, on the cold side of your wall. A big no no. the manufacturers say to leave a half inch air space away from your wall with venting top and bottom to prevent condensation, So if you do that the styro is not insulating anything at all.

The practice of exterior clad styro should be baned where ever there is air temp. bellow freezing, before we have nothing but rotten houses left.

Response to Jason

Jason,

You need to study some building science basics. Your thinking is at least 30 years out of date.

"Closed cell styrofoam is impermeable to water. So if you put it on the exterior of your house it acts as a vapor barrier, on the cold side of your wall. A big no-no."

Says who? As long as the siding can dry out the the exterior on the exterior side of the foam, and the wall assembly can dry to the interior on the interior side of the foam, what's the problem?

"The manufacturers say to leave a half inch air space away from your wall with venting top and bottom to prevent condensation."

What manufacturers? It's true that a ventilated rainscreen gap between the siding and the sheathing (or the foam) makes sense. The gap helps your siding to dry. But you never want to put a ventilated air gap between the wall assembly and your exterior foam.

"The practice of exterior-clad styrofoam should be banned where ever there is air temperature below freezing."

I'm sure glad that you don't have the authority to establish building codes, or else your ignorance would undermine energy-efficient building practices that help us all save energy.

Exterior Wall Insulation with a Brick/Stone Veneer.

Hi Martin:

I plan to build a new large home next spring. It will have 2"x6" exterior framing with two floors. I am considering to have 4" exterior solid foam insulation and then 2.5" brick/stone over it with a 1.5" air space. There would be no internal 6mil poly as a vapour barrier. My concern is the extra complication of this external insulation method and extra 4" wider concrete foundation wall( more $$). Is there any cost/benefit study that compares external insulation with internal insulation when considering extra costs due to materials and labour? Are there any detailed installation specs using exterior insulation, that I can provide to my builder/architect? I live in Ontario Canada. Any help you can provide would be most appreciated.

Thank you,

Response to Ennio D'Angela

Ennio D'Angela,

1. Any good architect or designer should be able to provide cost estimates for various design options. Such estimates are a routine part of architectural practice.

2. If your designer or architect is unfamiliar with the required details for exterior rigid foam, it's time to choose a new designer.

Changing Designer??

Martin:

My designer may already be fully knowledgeable with exterior insulation and the cost benefits. I have not asked him. The reason I subscribed to Fine HomeBuilding is so that I can be as knowledgeable as possible when discussing this with the designer or the various other trades I will need to interact with in the process of constructing my new home. My reason for asking was to obtain the information. If you would assist me with obtaining this information, it would be most appreciated.

Thank you!

Second response to Ennio D'Angela

Ennio D'Angela,

Unless you are an experienced contractor, architect, or project manager, there is no easy way to develop the ability to provide cost estimates. If you want to estimate construction costs, you have two choices:

- Buy a cost estimating book (for example, one from R.S. Means) and use their cost data. This only makes sense if you have a good grounding in residential construction and a little common sense (so you can adjust the R.S. Means numbers for your geographical area).

- Contact some contractors and ask for bids.

Third response to Ennio D'Angela

Ennio D'Angela,

Q. "Are there any detailed installation specs using exterior insulation, that I can provide to my builder/architect?"

A. Yes, We have a library of such installation details here at the GBA Web site. They are available to GBA members on this Web page:

https://www.greenbuildingadvisor.com/strategies-details

Foam and brick veneer

I don't hear many discussions about thicknesses of foam board and brick veneer. Is there a sweet spot where a significant thickness of foam board can be used without incurring high costs of specialty brick ties?

I was designing a 3500 sq ft house (floor space) and coming up with $2500 in brick ties because of the distance of the brick from the OSB. I was assuming 1.5" foam and a 1" air space behind the brick.

I'm really more interested in general comments about brick over foam than addressing my situation specifically.

Thanks,

Foam and brick ties

Don,

You'll probably get more answers if you post your question on our Q&A page:

https://www.greenbuildingadvisor.com/qa

using rigid styrofoam on the interior

I would like to know if it's ok to use rigid styrofoam insulation on the interior of a house. I was thinking of using it between the drywall and the studs, providing a thermal break and added insulation value. It seems to me that putting the styrofoam on the inside would be more benificial. Do building codes say not to do this?

Thanks

Response to Wayne

Wayne,

You can install foam between your drywall and the studs if you want, although some installers don't like the fact that the foam makes the installation somewhat squishy. I have done it successfully with XPS and polyiso.

In general, exterior foam is preferred to interior foam, because exterior foam addresses thermal bridging at rim joists and partition intersections.

Understanding the vapor barrier situation

I just want to make sure I understand this: with a sealed layer of foam on the exterior, there would be NO vapor barrier (poly sheeting) on the inside under the drywall, allowing the inside of the wall to dry to the inside. Is that right? (If that's the case, then it seems to me that the extra effort in sealing up the foam exterior is easily made up for by not having to install the interior barrier, sealing it around every junction box and window opening.)

Secondly, I understand that condensation within the wall (in a cold climate) is not a problem because the exterior foam is thick enough that all the wall framing is above the dew point. If that's the case, then I suppose there's a minimum thickness required for the exterior foam, depending on the local climate? Are there published guidelines for that?

Air sealing a superinsulated house with rigid foam exterior

Martin,

Another great article.

I'll be adding two layers of 2" foil-faced polyiso shortly to a 1900 house. Staggered, taped seams, and housewrap as well, with the exterior details handled carefully. Interior stud cavities will be filled with cellulose.

Now, I completely understand why it would be dangerous to use a true vapor barrier like 6 mil poly on the inside. And I completely understand that my wall assemblies need an ability to dry in at least one direction, and in the case of exterior rigid foam, the only direction possible is to dry to the inside.

Now, what I am less certain about, from a building science perspective, is whether or not it would be good to have a class 3 vapor retarder on the inside, such as vapor retarder paint, to prevent much migration of moisture into the walls in the first place. Is that an improvement or a harm in that it would slow down drying to the inside? For my climate zone, marine 4, Eugene OR, with 4500 HDD, 4" of foam is plenty to avoid condensation on the interior side of the foam.

Another reason I ask is because this related to air sealing. I'm wondering if there would be benefits to using one of the air-sealing membranes like that from SIGA -- they have a vapor control membrane called Majpel 5 which is about 0.68 US perms which is typically installed on the interior.

I'm treating my exterior rigid foam insulation as my primary air-barrier, with taped OSB sheathing, taped foam, etc. And that ought to lead to a reasonably tight house -- especially considering the roof and underfloor measures I won't mention for brevity. But I am wondering if an air-sealing membrane, like that from SIGA, would be a good addition to the exterior air sealing in order to achieve even tighter ACH50 / CFM50 results.

Thanks for your insights.

Response to CSolar

CSolar,

Q. "I just want to make sure I understand this: with a sealed layer of foam on the exterior, there would be NO vapor barrier (poly sheeting) on the inside under the drywall, allowing the inside of the wall to dry to the inside. Is that right?"

A. Yes.

Q. "Secondly, I understand that condensation within the wall (in a cold climate) is not a problem because the exterior foam is thick enough that all the wall framing is above the dew point. If that's the case, then I suppose there's a minimum thickness required for the exterior foam, depending on the local climate? Are there published guidelines for that?"

A. Yes and yes. The guidelines are laid out here: Calculating the Minimum Thickness of Rigid Foam Sheathing.

Response to Robert Dickinson

Robert,

Q. "From a building science perspective, would it be good to have a class 3 vapor retarder on the inside, such as vapor retarder paint, to prevent much migration of moisture into the walls in the first place. Is that an improvement or a harm in that it would slow down drying to the inside?"

A. Either way will work -- with vapor-retarder paint or with ordinary latex paint. Either type of paint will allow some drying to the interior.

Q. "I'm wondering if there would be benefits to using one of the air-sealing membranes like that from SIGA."

A. In general, extra air sealing efforts are always good, although it's perfectly possible to achieve a high degree of air tightness at the sheathing level. To read about the pluses and minuses of the SIGA approach, see One Air Barrier or Two?.

Foam applications

The issue of an interior vapor barrier may not me your choice to make. Be sure to check with your local building official in your area. If your stud cavity is filled with either friction fit fiberglass or cellulose and your local building code requires a "warm side in winter vapor barrier ..." your inspector may require it. He also might not consider the latex paint sufficient to meet this requirement. Of course you could try providing the official with some of the building science regarding your design, but in the end it will be up to him (or her).

Regarding internal foam applications, don't forget in addition to the deeper window jambs you also have electrical boxes to deal with, a real pain for your electrician. Also be sure everyone is on board with this design so you don't find out that your kitchen cabinets are too big by about 2" or issues with mounting due to the internal foam. Also, my experience with sheetrockers is that they will hate this job as you have created a great deal more work for them, in many ways.

fasteners

Hi GBA-

Very interested in your upcoming video on fasteners! When is it coming out? I have heard some concern by builders over fasteners for multiple layers of rigid foam. They prefer the simplicity of 1 layer of foam. Are there good options out there? I need something to convince some builders I am in discussion with. Any thoughts could help.

Response to Eric

Eric,

If you post your question on the GBA Q&A page, more readers will see you question and may offer answers:

https://www.greenbuildingadvisor.com/qa

foil facing and REMOTE walls

Two comments/questions:

1. Why do I see so much foil-faced rigid foam on the GBA website? My understanding (from Thermodynamics) is that radiation "is considered to be a surface phenomenon for solids that are opaque to thermal radiation...", so the foil will only be effective at reflecting heat (in the form of radiation) when the foil is exposed to an air space. As such, having foil-faced rigid foam sandwiched in a wall assembly is a complete waste of foil (this was all confirmed by several PhDs in Mech. Engineering that I consulted with). Furthermore, the presence of the foil (which is a highly effective vapor retarder) in the middle of a wall assembly creates the "double vapor barrier" no-no that we, in the Interior of Alaska, are trained vehemently to avoid. This traps moisture in the wall cavity and serves no purpose (in our climate, at least). In this particular case, it may not be problematic, because in between each layer of exterior rigid foam is a drainage plane and the moisture won't move back into the framing, but using foil-faced foam for header insulation (for example), when there is also a poly VR employed creates a moisture trap inside your wall cavity then I never understood the justification for. Can you please clarify why the rigid boards in this video (and elsewhere on the site) are foil-faced?

2. One of the very few things that I think Alaska is ahead of the lower 48 about is air sealing and ventilation. The thermal and vapor gradients are so enormous here that it has just simply demanded that we pay attention to these details a long time ago. I encourage everyone to check out the Alaska Building Science Network and also the Cold Climate Housing Research Center, which is becoming world-renown for their advancement of cold-climate building science and alternative technologies for extreme climates in remote locations like all of our native villages. In particular relevance to this article is their "REMOTE" wall system. I do not work their, but shamelessly plug their information for the sake of advancement of energy efficiency:

http://www.cchrc.org/remote-walls

Response to Lyle Axelarris

Lyle,

Q. "Why do I see so much foil-faced rigid foam on the GBA website?"

A. Because most of that foam is polyisocyanurate, and because polyisocyanurate is the most environmentally benign of the three major types of rigid foam (EPS, XPS, and polyiso). Polyiso does not have any blowing agents with a high global warming potential or any brominated flame retardants.

Q. "The foil will only be effective at reflecting heat (in the form of radiation) when the foil is exposed to an air space."

A. That's true. If a builder is installing foil-faced polyiso on a wall with vertical furring strips used to create a rainscreen gap, there will be some thermal benefit from the outermost later of foil.

Q. "Having foil-faced rigid foam sandwiched in a wall assembly is a complete waste of foil."

A. True, but the foil has another benefit (in addition to sometimes acting as a radiant barrier): the foil is an effective air barrier that limits migration (evaporation) of the blowing-agent gases. The longer that these bubbles of blowing agent stay within the foam, the longer the R-value of the foam will stay high.

Q. "Furthermore, the presence of the foil (which is a highly effective vapor retarder) in the middle of a wall assembly creates the 'double vapor barrier' no-no that we, in the Interior of Alaska, are trained vehemently to avoid."

A. When you have a stack of foil-faced foam, the entire stack of foam is a vapor barrier. No vapor is going through the stack. It makes no difference whether there is one layer of foil or 6 layers of foil -- the permeance is the same (very, very low). The permeance of foil-faced polyiso is 0.05 perm. So, there is no harm from stacking foam. It acts as a unit, and it is a vapor barrier.

Q. "This traps moisture in the wall cavity."

A. No it doesn't. If properly designed, a wall with rigid foam sheathing dries in both directions. Everything on the exterior side of the foam (the furring strips and the siding) dries to the exterior, while everything on the interior side of the foam (the OSB, the studs, and the drywall) dries to the interior.

Q. "Using foil-faced foam for header insulation (for example), when there is also a poly VR employed creates a moisture trap inside your wall cavity then I never understood the justification for."

A. If you choose to use rigid foam wall sheathing, then using polyethylene on the interior is a no-no. Even in Alaska.

Q. "Can you please clarify why the rigid boards in this video (and elsewhere on the site) are foil-faced?"

A. That's the way the manufacturers sell them.

Q. "In particular relevance to this article is their REMOTE wall system."

A. I have written many articles on the REMOTE and PERSIST wall systems. Here is one of them: Getting Insulation Out of Your Walls and Ceilings.

Retrofitting a home with poly

I'm considering adding rigid exterior insulation to a 1980's bungalow.

Your article suggests that if a home has rigid foam on the exterior, then there should be no 6 mil poly on the interior so that the wall assembly can dry to both the exterior and interior.

It seems that this advice is really just for new construction.

What about in the case of a retrofit where the poly is already embedded between the stud wall and the drywall?

I was expecting this type of job to not require any internal modifications. Is it possible to get away with leaving the poly vapor barrier in place?

Regards,

DC

Response to Dave Corning

Dave,

Here is my standard answer to this often-asked question:

Many energy experts worry that it may not be a good idea to install exterior foam on a house with interior polyethylene. Although it would be better if the poly weren't there, the fact is that tens of thousands of Canadian homes with interior poly have been retrofitted with exterior rigid foam, and there haven't been any reports of widespread problems. According to building scientist John Straube, all indications show that these retrofits are "not so risky as most people think. These homes will probably be fine."

That said, the installation of exterior foam is not advised on any home that has suffered wet-wall problems like leaking windows, condensation in stud cavities, or mold. If you plan to install exterior foam during a siding replacement job, keep an eye out for any signs of moisture problems when stripping the old siding from the walls. Investigate any water stains on housewrap or sheathing to determine whether the existing flashing was adequate.

If there is any sheathing rot, determine the cause -- the most common cause is a flashing problem, but condensation of interior moisture is not impossible -- and correct the problem if possible. If you are unsure of the source of the moisture, hire a home performance contractor to help you solve the mystery.

If your sheathing is dry and sound, I don't think you need to worry about adding exterior foam. Adding a rainscreen gap will certainly go a long way toward avoiding future moisture problems. Of course, it's important to be meticulous with your details when you are installing your new WRB and window flashing. It's also important to keep your interior relative humidity within reasonable levels during the winter. Never use a humidifier.

To summarize, here are four caveats:

1. Be sure that your foam is thick enough to keep the wall sheathing above the dew point in winter. Read more on this topic here: Calculating the Minimum Thickness of Rigid Foam Sheathing.

2. When the siding is being removed, inspect the existing sheathing carefully for any signs of water intrusion, and correct any flashing or housewrap problems.

3. Install rainscreen strapping so that there is a ventilated gap between the new exterior foam and the siding.

4. Keep your interior humidity under control during the winter; if the interior humidity gets too high, operate your ventilation fan more frequently.

Interior Retrofit

I am planning a remodel of a bedroom that will require removal of the drywall. Years ago I saw a report from the Agway Farm Research Center about the benefits of a construction method where polyiso rigid board was used on the interior between the drywall and the studs. Has the adviseability of this method been disproven?

The method tapes the interior surface of the rigid board to reduce infiltration. Razor cuts are made on the exterior side of the rigid board to create a migration path for condensation.

Other than longer screws to secure the drywall and having to box out fixtures, are there downsides to this method?

Thanks for any input or references you may have.

Response to Aviv Goldsmith

Aviv,

If you want to install rigid foam on a wall, the best location for the rigid foam is on the exterior. That way, the wall sheathing stays warm, and the chance of condensation is reduced or eliminated.

If you absolutely can't find a way to install exterior rigid foam, it's possible to install rigid foam on the interior side of the wall, between the studs and the drywall, as you propose. There are several disadvantages to this approach, but they are not insurmountable: (a) you need to come up with a good method for insulate the rim joist areas; (b) you need to come up with a good way to insulate partition intersections (where partitions intersect the exterior wall); (c) you have to extend the electrical boxes, which usually irritates your electrician; and (d) you need to install the drywall with long screws, which usually irritates the drywall contractor. (This last problem can be addressed by installing horizontal 1x4 furring strips between the rigid foam and the drywall.)

One last point: There is no justification whatsoever for the idea of making razor cuts in the exterior side of the rigid foam. Those razor just won't change the vapor permeance or the air permeance of the rigid foam layer in any way whatsoever. And in any case, there won't be any water vapor flowing through the foil-faced foam.

Response to Martin re: Interior Retrofit

Thank you!

Boxing out Doors

The plywood box out of the windows I get. Can someone explain how to do this with more detail for doors. The door sill would need to be supported and the plywood extension doesn't seem strong enough for a door. I was thinking of using 2x extensions but then there would be a thermal bridge. Thanks for the help.

Response to Michael Prisco

Michael,

Your question has been discussed several times on our Q&A pages. Here are links to four Q&A threads on the topic:

Exterior door thresholds for thick walls

Exterior door details with 4" thick foam walls

PERSIST / REMOTE door installation quandry

Window and Door Installations in “Thick” Walls

After reviewing these threads, you can post a new question if you want on our Q&A page (not here, since few people will see your question if you post it here). To create a new Q&A thread, start at this GBA page:

https://www.greenbuildingadvisor.com/qa

Log in or create an account to post a comment.

Sign up Log in