Heat pump manufacturers publish extended performance tables that tell us how much heating or cooling a unit produces under particular indoor and outdoor conditions. But how do we know our systems are delivering their rated outputs? In this article, I’ll walk through procedures for measuring the heating and cooling a heat pump is producing. These real-world measurements of “delivered capacity” can be useful in several ways:

Start-up and commissioning. By testing at start-up, we can verify that the system is delivering the expected heating and cooling outputs. Using this initial benchmark, we can track performance over time.

Preventive maintenance. Measurements taken during routine maintenance can confirm that a system is still operating properly. A decrease in output may indicate a problem like a refrigerant leak that warrants further investigation.

Troubleshooting. Comfort complaints with ductless systems can be difficult to troubleshoot. By showing that a system is delivering its rated Btu/hr, we can rule out several equipment-related issues and focus on questions of sizing, controls, unit placement, and operator behavior.

Energy auditing. Just as we use a combustion analyzer to determine the steady-state efficiency of a fossil-fuel heating system, we can use the techniques described here to measure heat pump efficiencies.

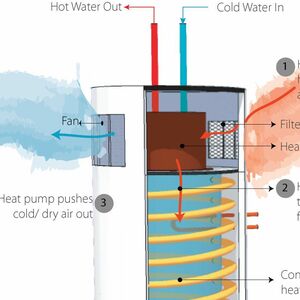

Delivered capacity is measured at the indoor unit, either a ductless head or a ducted air handler. The techniques described here do not require connecting refrigerant gauges and, therefore, do not require EPA certification or risk the release of refrigerants. The tools needed—thermo-hygrometers and, for ducted systems, a manometer with static pressure probes—are relatively affordable and are already in the toolkits of most energy auditors and HVAC technicians.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

0 Comments

Log in or become a member to post a comment.

Sign up Log in