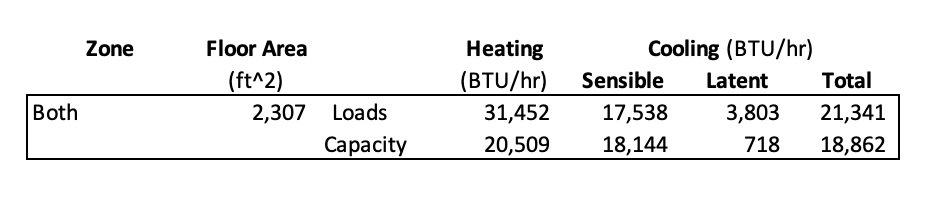

You may recall that I wrote about my undersized mini-split heat pump a couple of years ago. It’s undersized compared to both the heating and cooling loads, as you can see in the table below. I’ll discuss the heating performance in a future article. (It’s been fine for three winters). Today, though, I’d like to show you how well the heat pump did in a summer heat wave, when we had three really hot days in a string of six days at or above our design temperature.

Cooling performance in the heat wave

You can see from the numbers above that my house has a cooling load of about 21,000 BTU/hr and the heat pump has a cooling capacity of a bit less than 19,000 BTU/hr. According to those numbers, my heat pump has only 88% of the capacity it needs to keep my house cool on a design day. And our 1% design temperature is 92°F here in Atlanta, Georgia.

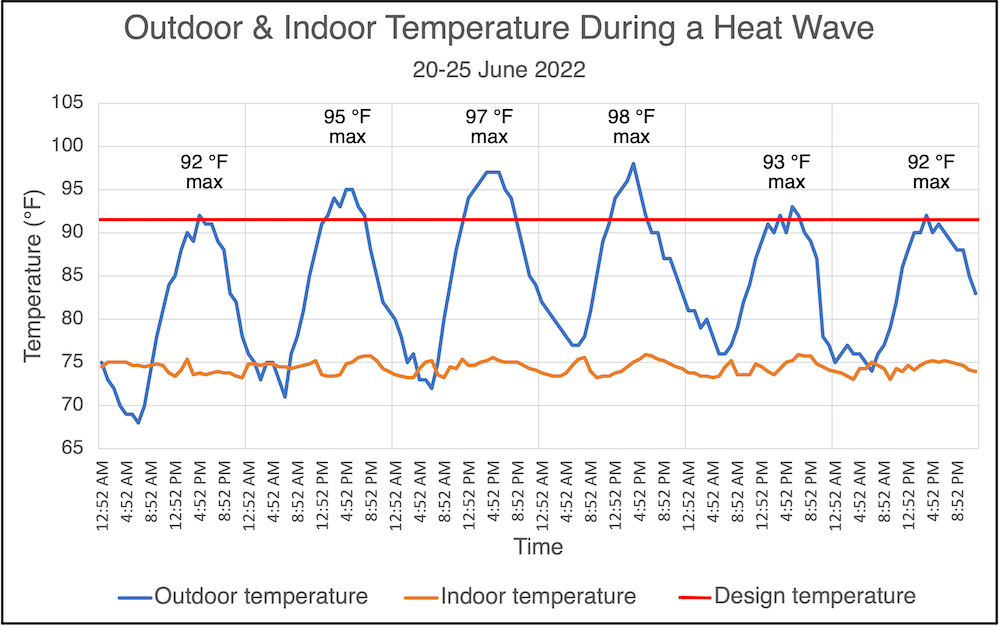

So how did we do? The graph below shows the outdoor temperature (blue) during that heat wave, the week of June 20-25, 2022. The red line is our outdoor design temperature of 92°F. And down below, the orange curve shows our indoor temperature. I leave both thermostats set to 74°F in the summer, and you can see that it stayed pretty darn close the whole time. If I showed you only the indoor temperature, I think you’d have a hard time picking out the hot days.

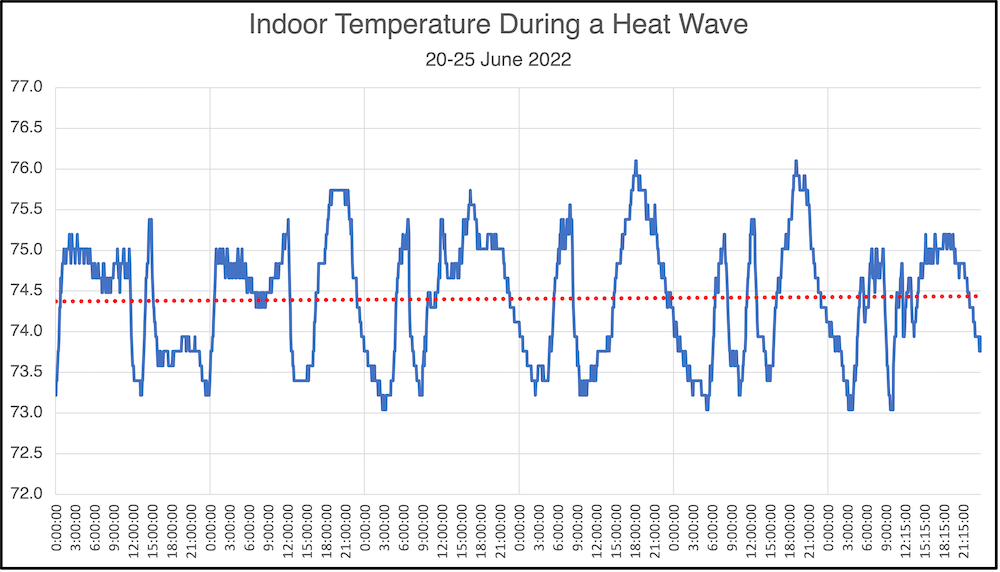

Let’s take a closer look at just the indoor temperature data. The graph below shows them along with a linear fit to the data. As you can see, the indoor temperature rose only a tiny bit over the course of these six days. The temperature varied from a low of 73.0 to a high of 76.1°F. And the average was about 74.4°F. I’d say that’s pretty impressive.

Heat pump power use

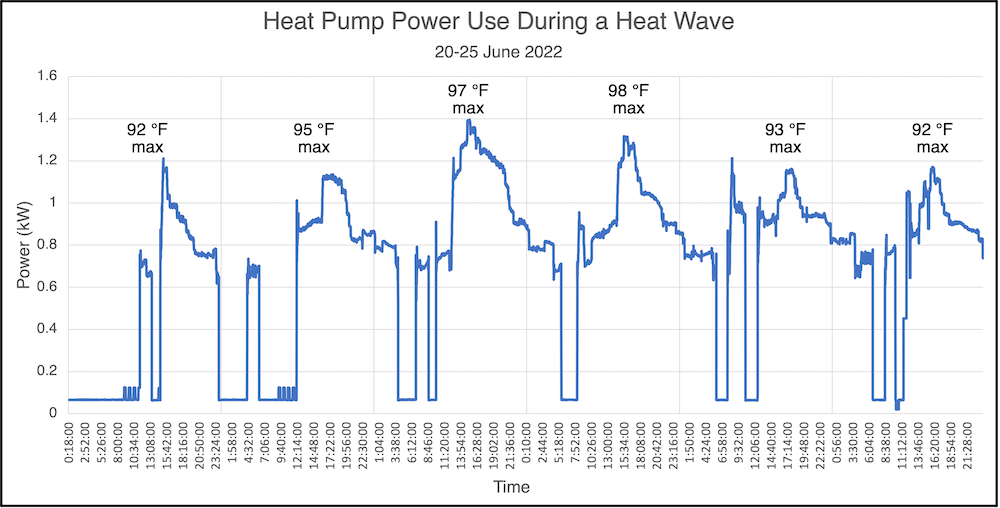

I didn’t plan it this way, but I installed my Emporia Vue electricity monitor on 19 June. Thus, the first day included in the graphs above and below was my first full day of tracking the heat pump power use. How lucky!

The graph of power use shows a number of interesting features. Most nights, for example, the power use bottoms out at about 65 watts. I thought that was the absolute bottom, when only the blowers in the air handlers were running. But then I saw the data for the morning of June 25 and realized it could go even lower. It ran at a mere 20 watts for 26 minutes.

Of course, the most interesting feature is that the power ramps up and down as the cooling load goes up and down. That’s the beauty of a variable capacity inverter-driven minisplit heat pump. There’s pretty much no short-cycling of the equipment, the bane of oversized fixed-capacity air conditioners. The power level ranges from about 620 watts up to nearly 1400 watts when it’s cooling.

Also, note what happened even after three days of outdoor temperatures well above our design temperature. The power level still dropped to the (main) bottom end of 65 watts by the next morning.

Takeaways

What’s going on here? Do I really have an undersized minisplit heat pump? Judging by the data, it looks like I don’t. I think two things are happening here. First, ACCA Manual J load calculations inflate the loads 10 to 20% even when you do them correctly. And of course, I assumed a certain amount of internal load in the calculations, but we probably didn’t have that much on those days. So, the load calculation could account for all or most of the discrepancy.

Also, the ACCA Manual S standard includes a range of total cooling capacity that’s allowed. The low end in that range is 90%. With our capacity-to-load ratio of 88%, I’d say we’re in compliance with that standard.

But there’s another reason that my undersized minisplit heat pump doesn’t seem so undersized. The performance data of my Mitsubishi equipment may not be accurate. OK, I’m being generous when I say “may” there. Look at that table at the top of the article, and you’ll see that Mitsubishi says the latent capacity (for humidity removal) is a mere 718 BTU/hr. (For the HVAC geeks, that’s a sensible heat ratio of 0.96.) I don’t believe that for one second. The sensible capacity may be off, too.

Now don’t take this the wrong way. I’m not saying you never have to worry about undersizing your cooling equipment. But if you have an accurate load calculation and good cooling equipment, it may turn out better than it looks on paper. Also, I intentionally undersized my heat pump because I’m working on the house and reducing both the heating and the cooling loads (though I haven’t done much yet).

How does your air conditioning equipment do in a heat wave?

_________________________________________________________________________

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has a book on building science coming out in October 2022. You can follow him on Twitter at @EnergyVanguard. Images courtesy of author.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

12 Comments

Hi Allison, I noticed that you have one outdoor unit paired to two indoor AHUs.

I was wondering what your experience indicated about the common remark that you don't get the same variability with a multiple indoor : single outdoor unit setup as you would if you had 1:1.

Have there been any situations you've noticed where the operations might have been better with two outdoor units, one for each indoor unit?

Max

I'd love to see what your heat pump draws in the winter. I have substantial electrical constraints, so it would be good to see what the actual power usage is.

The Plate MCA is 30amps?

Hello cafferatak, I am no expert on electrical but I do see that Mitsubishi lists MCA and MOCP ratings for their outdoor units. One source of info is available at this link below.

https://hvacdirect.com/media/hvac/pdf/Mitsubishi_Electric_M_and_P_Catalog_Spring_2020.pdf

Lucky for me, MCA and MOCP were not things I had to worry about.

Allison,

Do you have any data on he indoor humidity levels over that time periods? I'm just a few hours west (Huntsville), so I'd say our weather conditions usually track well. It seems that I have to keep the house ~70F just to make it feel natural, with the RH staying in the {50,55}% range. At 74 I'm certain I'd be murdered. Am I just a wimp or was your house/system able to keep the RH down during that hot spell we just had?

Agree, the spec latent capacity was only 718 btu/hr for the equipment.

I would expect that to climb substantially if airflow as reduced though.

Unfortunately that's not a given with variable speed compressors. Systems with VS indoor fans and VS compressors can have worse latent performance at low speed, depending on their control algorithms. Based on my personal, limited experience with Mitsu minisplits (including a fair amount of time with tech support) it appears they set theirs up in a way that does not dehumidify well, and can't be changed to dehumidify well.

I grew up in a very large home with Zoned Ductwork -- this was done back in the 50's before I was born and clearly done by someone who knew what they were doing. Especially since the initial systems were oil. Every later HVAC company wanted larger equipment (both heating and cooling). Getting a really good heat and cooling load is so important and often close to impossible. Even when you get a good one done the installers want to go bigger. Pre-variable speed equipment forced accurate heat and cool loads if you wanted the zoned systems to work correctly .. can't be oversized.

The success with heat pumps has much to do with the climate and building. I know many here don't like spray foam but I have done many old homes in the mid-atlantic and spray foam gets you air sealing and enough R value in a retrofit situation to get a very efficient house. Few people get the chance to experience the same building over time with different equipment and different building envelope. My last project was a converted church with over 4k of floor space ... HVAC companies had a low of 5T cooling for the space and a high of 7T. The detailed load for cooling was 35k .... in went a 37k Carrier system and it's had no trouble keeping the place very comfortable at 74 and low humidity -- even with this summers heat wave at 100. We never tried to lower it -- it was running all out at 2pm on the hot days. The VS saves you with the humidity ... it's running all the time taking the humidity out of the air.

Minisplits are no different -- I have them at my beach house, guest house on my main property and my studio. The VS of the mini eliminates the humidity if you leave them on. I think too many HVAC companies size based on partial use and want a bigger system to bring down the temp --- but in a humid area this is not as comfortable.

Another important thing to remember is the head outputs are not the same on the single systems and the multi-head systems that all tie back to the condenser. The range on the multi is much tighter and will not get you the output posted on the single charts ...... every Mitsubishi installer I have run across misses this ..... including systems to be done with a diamond dealer this past summer. The multi head are great in some situations (when they will all typically be on 24/7) but in other they are not --- only one running on a three head say. You really have to do your homework in the multi-head setups

We just built a "pretty good house" style 1700 sq foot addition that is relatively isolcated from the main house in terms of air flow. We had a tough time sizing the HVAC equipment because of the wide difference in temperature between winter and summer and very low cooling/heating loads. The HVAC engineers are great at producing a set of figures on paper, but these professionals are so busy that they don't have much time for long discussions about equipment sizing - at least in my experience.

For the new 1700 square footage, the engineering firm calculated the design loads to be 9,800 BTU cooling at +30C, In terms of heating load it was 12,800 btu load at -25C. We have R40 walls, R90 roof and air exchange of a respectable 0.13 ACH50 thanks to A---barrier product applied after reaching 0.44 ACH50 with the original design of the envelope. We chose the Mitsubishi SVZKP18NAHZ* outdoor unit and a SVZKP18NAHZ* air handler with ducts inside the house. (Z = Cold Climate version)

The Mitsubishi specs indicate: A) a rated cooling capacity of (9360~18000) with max ext. temp of +46C and B) a rated heating capacity of (8800~28000) with min temp outside of -25C.

This results in excess cooling capacity at almost all times in cooling season, and undersize heating capacity at the extremes of the heating season. It was a tough decision because the average temparature in January is -5C daytime and -15C nighttime. We added a 5KW heating coil in the airhandler to make up for any shortfall on the heating capacity.

In my experience, right sizing a heat pump for cooling and heating is rather difficult when you live in an area that has large temperature swings between seasons.

IMO you nailed the problem w/ heat pumps. The capacity mismatch -- my heating load was almost 60k. No way to do that with a cooling load of 35k --- my ac ductwork was sized and properly zoned for the 3T system ... doing that for 5t would have been a problem. Even with VS equipment ... too big of a mismatch.

The Mitsubishi head with duel vanes and the eye is a great unit .... the problem is none of the other systems they sell have the same adaptability .. they don't have the smarts of that head. The newest ceiling cassettes has the eye and seem to work more like the wall unit ... but, not quite. The wall units get you true VS with inside and outside working together. The other systems work more like fixed on/off systems with simple fan speed differences.

Don't get me wrong ... mini splits are greta problem solvers ... my latest project has three. All singles

Yeldogt, I am writing and responding because I felt totally isolated when I was going through this research and decision making process. Now I find people here who understand the issues well.

It was quite the puzzle for a lay person to fit all these pieces together and right-size the system, especially that we were trying to right-size by slightly "undersizing" (topic of this article).

We actually wanted to use those technologies you mention (heads/ceiling cassettes) placed in a central/strategic locations in the living space - but we encountered a problem at the last minute. We found out that our minicipality requires a heating source in each room (or is this the ON building code?). I still don't know why our builder did not alert us about this requirement earlier in the process.

None of the manufacturers had a wall mounted head with a small enough BTU rating for our bathrooms, or our bedrooms so they would all have been significantly oversized if we chose this option - which I refused to do. The option of using low static pressure ducted system with the ceiling cassettes might have worked; however, my research indicated that many engineers shy away from designing those low static pressure systems and the technology is too new to find an installer who is confident performing the install (not sure if this is really true).

When I would speak to the certified heat pump intallers, they all told me that they did install heatpumps but they ALL recommended that we stick to a gas furnace. Of course, other than D---son in Quebec, I found zero gas furnaces that modulated below 20,000 BTU of heat. The online reviews for D---son, warranted or not, were not good. Online comments are often not reliable but D---son did not appear to be responding to those online comments from what I recall. I have since heard from a local installer that D---son systems are amazing and the issues are actually related to install and not the actual product. Apparently D---son has a large well established commercial product series so they are not new to the HVAC world.

On top of all of this, I could not find an online calculator that would help me calculate the anticipated heating cost for the different options available: gas/electric heating element/heat pumps. There are various online tools, but I found nothing specifically designed to help with high efficiency homes and/or the heat pump technology (heat pumps required me to consider the varying COP ratings based on varying outside temperature).

The last HVAC person I spoke with (a few weeks ago) asked me how I knew so much about HVAC. I told him that it was because I could not find professionals around me (likely my own fault) who had a depth of knowledge and understanding of heat pump products and their implementation in Eastern Ontario climate. Of course he quickly showed me that even my own knowledge of HVAC is quite limited.

One HVAC company did prepare a manual J calculation, but looking at he calculations very closely, it became clear that manual J does not work for high efficiency homes (not the way it was prepared for me anyway). All HVAC installers (except for one) that I spoke with had never heard of PassiveHouse desing or even "pretty good house". That is not a knock against them, it is just that it made my task harder.

In the end, all HVAC people I hired were excellent but my recolletion is that they were relieved when I told them that I wanted a backup 5KW heating element in the air handler. What an adventure.

Mr. Hugh, I wanted to say thanks for all your inputs on various questions that others have asked on this site - you obviously care about the topic and have done a lot of research. I just wanted to add to your knowledge base about the requirement for heating:

You said:

We found out that our municipality requires a heating source in each room (or is this the ON building code?)

Comment:

This is actually in the International Residential Code (IRC), section 303.10 (link is to the 2018 code since that is the one we are currently under here)

https://codes.iccsafe.org/content/IRC2018P4/chapter-3-building-planning#IRC2018P4_Ch03_SecR303.10

I am building a very tight ICF house in Colorado and came across this in my research, someone else here doing a similar project was required by their building department to install baseboard heaters in upstairs rooms that did not really need them - he put them in for the inspection then promptly removed them and sold them to someone who did need them.

Our house was renovated to what I would say is close to "Pretty Good House" standards. It's bigger than it needs to be at 3,000 s.f. for a family of four and has a lot of operable windows (that rarely get used) plus a 16' x 8' leaky bifold patio door. I'm a little below Manual J design with a 1.5 ton ducted Fujitsu system for the whole house. We just had some extreme heat with three days over design temps and the house was comfortable throughout. I don't have the data you have to support it but I'm impressed with how well it works.

Log in or create an account to post a comment.

Sign up Log in